Vacuum Pump Optimization for High-Resolution Electron Microscopy

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution and Objectives

Vacuum pump technology has undergone significant evolution since its inception in the 17th century. The development of vacuum pumps has been closely tied to advancements in scientific research and industrial applications, particularly in the field of electron microscopy. The journey from early mechanical pumps to modern high-performance vacuum systems reflects the increasing demand for precise control over vacuum environments.

In the context of high-resolution electron microscopy, vacuum pump technology has faced continuous challenges to meet the stringent requirements of ultra-high vacuum conditions. The primary objective in this field is to achieve and maintain extremely low pressures, typically in the range of 10^-8 to 10^-11 mbar, to ensure optimal imaging conditions and prevent sample contamination.

The evolution of vacuum pumps for electron microscopy has been marked by several key milestones. Early systems relied on oil-sealed rotary vane pumps, which, while effective, introduced the risk of oil contamination. This led to the development of oil-free technologies such as scroll pumps and diaphragm pumps for the initial vacuum stages. For high and ultra-high vacuum levels, the introduction of turbomolecular pumps in the 1950s represented a significant leap forward, offering oil-free operation and high pumping speeds.

Recent advancements have focused on improving pump efficiency, reducing vibration, and enhancing reliability. The integration of multiple pump technologies in staged systems has become common practice, allowing for optimized performance across different pressure ranges. Additionally, the development of hybrid pumps, combining the advantages of various technologies, has emerged as a promising direction for future innovations.

The objectives of vacuum pump optimization for high-resolution electron microscopy are multifaceted. Firstly, there is a continuous drive to achieve lower ultimate pressures, pushing the boundaries of ultra-high vacuum capabilities. Secondly, improving pumping speed and efficiency is crucial to reduce sample preparation time and enhance microscope throughput. Thirdly, minimizing vibration and electromagnetic interference from pump operation is essential to preserve image quality and resolution.

Another key objective is to develop more compact and energy-efficient pump systems, addressing the growing need for sustainable laboratory practices. This includes exploring novel materials and designs that can withstand the demanding conditions of continuous operation while reducing power consumption and maintenance requirements.

Looking ahead, the field of vacuum pump technology for electron microscopy aims to integrate smart control systems and predictive maintenance capabilities. These advancements will enable real-time optimization of pump performance based on specific imaging requirements and environmental conditions, further enhancing the reliability and efficiency of high-resolution electron microscopy systems.

In the context of high-resolution electron microscopy, vacuum pump technology has faced continuous challenges to meet the stringent requirements of ultra-high vacuum conditions. The primary objective in this field is to achieve and maintain extremely low pressures, typically in the range of 10^-8 to 10^-11 mbar, to ensure optimal imaging conditions and prevent sample contamination.

The evolution of vacuum pumps for electron microscopy has been marked by several key milestones. Early systems relied on oil-sealed rotary vane pumps, which, while effective, introduced the risk of oil contamination. This led to the development of oil-free technologies such as scroll pumps and diaphragm pumps for the initial vacuum stages. For high and ultra-high vacuum levels, the introduction of turbomolecular pumps in the 1950s represented a significant leap forward, offering oil-free operation and high pumping speeds.

Recent advancements have focused on improving pump efficiency, reducing vibration, and enhancing reliability. The integration of multiple pump technologies in staged systems has become common practice, allowing for optimized performance across different pressure ranges. Additionally, the development of hybrid pumps, combining the advantages of various technologies, has emerged as a promising direction for future innovations.

The objectives of vacuum pump optimization for high-resolution electron microscopy are multifaceted. Firstly, there is a continuous drive to achieve lower ultimate pressures, pushing the boundaries of ultra-high vacuum capabilities. Secondly, improving pumping speed and efficiency is crucial to reduce sample preparation time and enhance microscope throughput. Thirdly, minimizing vibration and electromagnetic interference from pump operation is essential to preserve image quality and resolution.

Another key objective is to develop more compact and energy-efficient pump systems, addressing the growing need for sustainable laboratory practices. This includes exploring novel materials and designs that can withstand the demanding conditions of continuous operation while reducing power consumption and maintenance requirements.

Looking ahead, the field of vacuum pump technology for electron microscopy aims to integrate smart control systems and predictive maintenance capabilities. These advancements will enable real-time optimization of pump performance based on specific imaging requirements and environmental conditions, further enhancing the reliability and efficiency of high-resolution electron microscopy systems.

Market Analysis for Advanced Microscopy

The advanced microscopy market has experienced significant growth in recent years, driven by increasing demand for high-resolution imaging across various scientific and industrial applications. This market segment encompasses a range of sophisticated microscopy technologies, including electron microscopes, scanning probe microscopes, and super-resolution optical microscopes.

The global advanced microscopy market was valued at approximately $6.2 billion in 2020 and is projected to reach $9.8 billion by 2026, growing at a CAGR of 7.9% during the forecast period. This growth is primarily fueled by advancements in nanotechnology, materials science, and life sciences research, which require increasingly powerful and precise imaging tools.

Within the advanced microscopy market, electron microscopy holds a substantial share, accounting for roughly 40% of the total market value. High-resolution electron microscopy, in particular, has seen a surge in demand due to its ability to provide atomic-level imaging crucial for cutting-edge research in fields such as semiconductor development, battery technology, and structural biology.

The market for vacuum pumps specifically designed for high-resolution electron microscopy is closely tied to the overall electron microscopy market. These specialized pumps are essential components in maintaining the ultra-high vacuum environments required for optimal electron microscope performance. The vacuum pump segment for electron microscopy is estimated to be worth around $500 million annually, with a growth rate slightly outpacing the overall microscopy market at 8.5% CAGR.

Key drivers for the vacuum pump market in advanced microscopy include the increasing adoption of cryo-electron microscopy in life sciences, the push for higher resolution in semiconductor inspection, and the growing demand for in-situ electron microscopy in materials research. Additionally, there is a rising need for more energy-efficient and quieter vacuum pumps to improve overall system performance and reduce operating costs.

Geographically, North America and Europe dominate the advanced microscopy market, collectively accounting for over 60% of the global market share. However, the Asia-Pacific region is experiencing the fastest growth, driven by increasing R&D investments in countries like China, Japan, and South Korea. This regional growth is particularly relevant for vacuum pump manufacturers, as many Asian countries are rapidly expanding their semiconductor and nanotechnology industries, which heavily rely on high-resolution electron microscopy.

The global advanced microscopy market was valued at approximately $6.2 billion in 2020 and is projected to reach $9.8 billion by 2026, growing at a CAGR of 7.9% during the forecast period. This growth is primarily fueled by advancements in nanotechnology, materials science, and life sciences research, which require increasingly powerful and precise imaging tools.

Within the advanced microscopy market, electron microscopy holds a substantial share, accounting for roughly 40% of the total market value. High-resolution electron microscopy, in particular, has seen a surge in demand due to its ability to provide atomic-level imaging crucial for cutting-edge research in fields such as semiconductor development, battery technology, and structural biology.

The market for vacuum pumps specifically designed for high-resolution electron microscopy is closely tied to the overall electron microscopy market. These specialized pumps are essential components in maintaining the ultra-high vacuum environments required for optimal electron microscope performance. The vacuum pump segment for electron microscopy is estimated to be worth around $500 million annually, with a growth rate slightly outpacing the overall microscopy market at 8.5% CAGR.

Key drivers for the vacuum pump market in advanced microscopy include the increasing adoption of cryo-electron microscopy in life sciences, the push for higher resolution in semiconductor inspection, and the growing demand for in-situ electron microscopy in materials research. Additionally, there is a rising need for more energy-efficient and quieter vacuum pumps to improve overall system performance and reduce operating costs.

Geographically, North America and Europe dominate the advanced microscopy market, collectively accounting for over 60% of the global market share. However, the Asia-Pacific region is experiencing the fastest growth, driven by increasing R&D investments in countries like China, Japan, and South Korea. This regional growth is particularly relevant for vacuum pump manufacturers, as many Asian countries are rapidly expanding their semiconductor and nanotechnology industries, which heavily rely on high-resolution electron microscopy.

Current Vacuum Pump Challenges

Vacuum pump optimization for high-resolution electron microscopy faces several significant challenges in the current technological landscape. These challenges stem from the increasing demands for ultra-high vacuum (UHV) conditions necessary for advanced imaging and analysis techniques.

One of the primary challenges is achieving and maintaining the required vacuum levels. High-resolution electron microscopy often requires pressures as low as 10^-10 mbar or even lower. Conventional vacuum pumps struggle to reach these extreme levels consistently, especially when considering the need for long-term stability during extended imaging sessions.

Contamination control presents another major hurdle. Even minute amounts of hydrocarbons or other contaminants can severely impact image quality and resolution. Current vacuum pump systems often introduce trace amounts of oil or other substances, necessitating complex filtering and trapping mechanisms that can reduce overall system efficiency.

The issue of vibration is particularly critical in electron microscopy applications. Mechanical pumps, while effective at initial vacuum creation, can introduce significant vibrations that interfere with high-resolution imaging. This necessitates the use of vibration isolation systems or alternative pumping technologies, each with its own set of limitations.

Energy efficiency and heat generation are growing concerns in vacuum pump optimization. As microscopy systems become more sophisticated, the power requirements for maintaining UHV conditions increase. This not only impacts operational costs but also introduces thermal management challenges that can affect instrument stability and performance.

Size and integration constraints pose significant design challenges. Modern electron microscopes often have limited space for vacuum systems, requiring compact yet powerful pumping solutions. Balancing size reduction with performance maintenance is a complex engineering task that current technologies struggle to address effectively.

Reliability and maintenance requirements are also key considerations. High-resolution electron microscopy often involves continuous operation over extended periods. Current vacuum pump technologies may require frequent maintenance or replacement, leading to system downtime and increased operational costs.

The need for rapid pump-down times conflicts with the requirement for stable, ultra-low pressures. Achieving a balance between quick initial evacuation and long-term pressure stability remains a significant challenge for existing pump designs.

Lastly, the increasing complexity of multi-stage pumping systems introduces control and synchronization challenges. Optimizing the interplay between different types of pumps (e.g., turbomolecular, ion, and cryogenic pumps) to achieve the best overall performance is a complex task that current control systems struggle to manage effectively.

One of the primary challenges is achieving and maintaining the required vacuum levels. High-resolution electron microscopy often requires pressures as low as 10^-10 mbar or even lower. Conventional vacuum pumps struggle to reach these extreme levels consistently, especially when considering the need for long-term stability during extended imaging sessions.

Contamination control presents another major hurdle. Even minute amounts of hydrocarbons or other contaminants can severely impact image quality and resolution. Current vacuum pump systems often introduce trace amounts of oil or other substances, necessitating complex filtering and trapping mechanisms that can reduce overall system efficiency.

The issue of vibration is particularly critical in electron microscopy applications. Mechanical pumps, while effective at initial vacuum creation, can introduce significant vibrations that interfere with high-resolution imaging. This necessitates the use of vibration isolation systems or alternative pumping technologies, each with its own set of limitations.

Energy efficiency and heat generation are growing concerns in vacuum pump optimization. As microscopy systems become more sophisticated, the power requirements for maintaining UHV conditions increase. This not only impacts operational costs but also introduces thermal management challenges that can affect instrument stability and performance.

Size and integration constraints pose significant design challenges. Modern electron microscopes often have limited space for vacuum systems, requiring compact yet powerful pumping solutions. Balancing size reduction with performance maintenance is a complex engineering task that current technologies struggle to address effectively.

Reliability and maintenance requirements are also key considerations. High-resolution electron microscopy often involves continuous operation over extended periods. Current vacuum pump technologies may require frequent maintenance or replacement, leading to system downtime and increased operational costs.

The need for rapid pump-down times conflicts with the requirement for stable, ultra-low pressures. Achieving a balance between quick initial evacuation and long-term pressure stability remains a significant challenge for existing pump designs.

Lastly, the increasing complexity of multi-stage pumping systems introduces control and synchronization challenges. Optimizing the interplay between different types of pumps (e.g., turbomolecular, ion, and cryogenic pumps) to achieve the best overall performance is a complex task that current control systems struggle to manage effectively.

Existing Vacuum Pump Solutions

01 Improved pump design and configuration

Optimization of vacuum pump design involves enhancing the overall configuration and structure of the pump. This includes modifications to the rotor, stator, and other internal components to improve efficiency and performance. Advanced materials and manufacturing techniques may be employed to reduce friction, increase durability, and optimize fluid flow within the pump.- Improved pump design and configuration: Optimization of vacuum pump design involves enhancing the overall configuration and structure of the pump. This includes modifications to the rotor, stator, and other internal components to improve efficiency and performance. Advanced materials and manufacturing techniques may be employed to reduce friction, increase durability, and optimize fluid dynamics within the pump.

- Control system and algorithm optimization: Implementing advanced control systems and algorithms can significantly enhance vacuum pump performance. This includes the use of smart sensors, adaptive control mechanisms, and predictive maintenance algorithms. These systems can optimize pump operation in real-time, adjusting parameters based on load conditions and environmental factors to maximize efficiency and reduce energy consumption.

- Energy efficiency improvements: Focusing on energy efficiency is crucial for vacuum pump optimization. This involves developing more efficient motors, implementing variable speed drives, and utilizing energy recovery systems. Advanced insulation techniques and heat management strategies can also be employed to reduce energy losses and improve overall pump efficiency.

- Noise and vibration reduction: Minimizing noise and vibration is an important aspect of vacuum pump optimization. This can be achieved through improved balancing techniques, advanced damping systems, and innovative acoustic designs. Implementing these features not only enhances the pump's performance but also improves the working environment and extends the pump's lifespan.

- Multi-stage and hybrid pump systems: Developing multi-stage and hybrid pump systems can lead to significant improvements in vacuum pump performance. These systems combine different pumping technologies or stages to achieve higher vacuum levels, increased pumping speeds, and better overall efficiency. By optimizing the interaction between different stages or technologies, these systems can offer superior performance across a wide range of operating conditions.

02 Enhanced control systems and monitoring

Implementation of sophisticated control systems and monitoring technologies can significantly optimize vacuum pump operation. This includes the use of sensors, data analytics, and intelligent algorithms to adjust pump parameters in real-time, ensuring optimal performance under varying conditions. Advanced monitoring systems can predict maintenance needs and prevent unexpected failures.Expand Specific Solutions03 Energy efficiency improvements

Focusing on energy efficiency is crucial for vacuum pump optimization. This involves developing pumps with higher energy conversion rates, implementing variable speed drives, and utilizing energy recovery systems. Optimizing the pump's power consumption while maintaining or improving its performance is a key aspect of this approach.Expand Specific Solutions04 Specialized pump designs for specific applications

Tailoring vacuum pump designs for specific industrial applications can lead to significant optimization. This includes developing pumps with unique features or operating principles suited for particular processes or environments, such as high-temperature operations, corrosive materials handling, or ultra-high vacuum applications.Expand Specific Solutions05 Maintenance and reliability enhancements

Improving the maintenance aspects and overall reliability of vacuum pumps is essential for optimization. This involves designing pumps with easier access for maintenance, developing self-diagnostic capabilities, and using materials and coatings that reduce wear and extend operational life. Predictive maintenance strategies and modular designs for quick part replacement are also key considerations.Expand Specific Solutions

Key Vacuum Pump Manufacturers

The vacuum pump optimization for high-resolution electron microscopy market is in a mature growth stage, with a steady global market size driven by ongoing demand in research and industrial applications. The technology has reached a high level of maturity, with established players like Edwards Ltd., Pfeiffer Vacuum GmbH, and SAES Getters SpA offering advanced solutions. These companies, along with others such as Hitachi High-Tech America, Inc. and Shimazu KK, are continuously innovating to improve pump efficiency, reduce vibration, and enhance vacuum quality. The competitive landscape is characterized by a mix of specialized vacuum technology firms and diversified scientific equipment manufacturers, with ongoing research collaborations between industry leaders and academic institutions like MIT and Tokyo Institute of Technology driving further advancements in the field.

Hitachi High-Tech America, Inc.

Technical Solution: Hitachi High-Tech has developed a comprehensive vacuum system optimization approach for their electron microscopes. They utilize a combination of ion pumps and non-evaporable getter (NEG) pumps to achieve ultra-high vacuum (UHV) conditions[5]. Their proprietary NEG materials have high sorption capacity for active gases and can be easily regenerated in-situ[6]. Hitachi's electron microscopes incorporate differential pumping systems, allowing for higher pressure at the electron source while maintaining UHV at the specimen chamber[7]. They've also implemented advanced vacuum control algorithms that dynamically adjust pumping parameters based on real-time pressure measurements and microscope operating conditions, ensuring optimal vacuum stability during imaging sessions[8].

Strengths: Integrated vacuum solutions specifically designed for electron microscopy, with advanced control systems. Weaknesses: Reliance on proprietary technologies may limit compatibility with third-party components.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum has developed advanced turbomolecular pumps specifically designed for high-resolution electron microscopy applications. Their HiPace series utilizes a hybrid bearing system combining ceramic ball bearings and permanent magnetic radial bearings, allowing for vibration-free operation[1]. The pumps achieve ultimate pressures below 1×10^-10 mbar and have pumping speeds up to 2700 l/s for N2[2]. They've also implemented advanced rotor designs with optimized blade geometries to enhance compression ratios and pumping efficiency across a wide range of gas types[3]. Additionally, Pfeiffer has integrated intelligent drive technology that enables precise speed control and monitoring, crucial for maintaining stable vacuum conditions during sensitive microscopy operations[4].

Strengths: High pumping speeds, ultra-low ultimate pressures, and vibration-free operation ideal for electron microscopy. Weaknesses: Higher cost compared to conventional vacuum pumps, may require specialized maintenance.

Innovative Vacuum Pump Designs

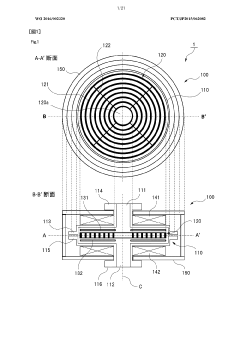

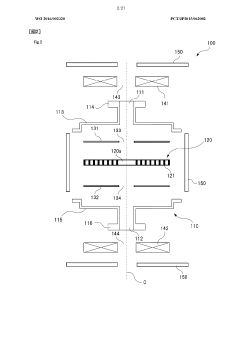

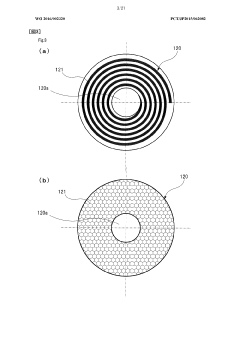

Laminated ultra-high vacuum forming device

PatentWO2016002320A1

Innovation

- A compact, lightweight ion pump design with a uniaxially symmetrical electrode arrangement, incorporating board-shaped electrodes and magnets, allowing for reduced size in the central axis direction while maintaining pumping performance, and the ability to stack pumps for enhanced performance and flexibility.

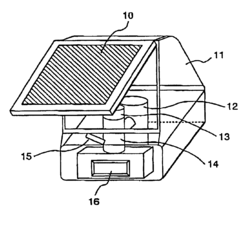

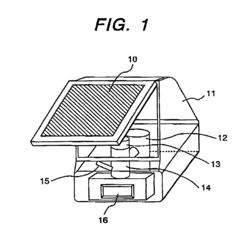

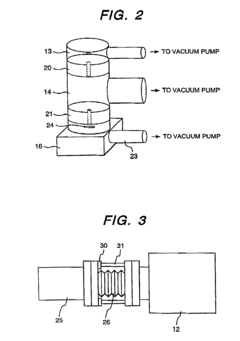

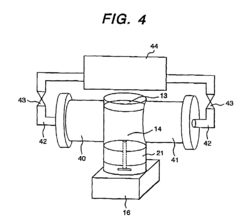

Electron microscope

PatentInactiveUS6833550B2

Innovation

- A compact, lightweight electron microscope design with a casing housing a vacuum container, turbo molecule pump, nano-electrode emitter, and display, featuring a shock absorber to reduce vibration, multiple evacuation ports, and user-friendly features like a transparent outer frame and vacuum degree display to alleviate psychological stress during operation.

Environmental Impact Assessment

The optimization of vacuum pumps for high-resolution electron microscopy has significant environmental implications that warrant careful consideration. The primary environmental impact stems from energy consumption, as these pumps require substantial power to maintain the ultra-high vacuum conditions necessary for electron microscopy. Improved pump efficiency can lead to reduced energy usage, thereby lowering the carbon footprint associated with microscopy operations.

Another crucial environmental aspect is the potential release of harmful gases and particulates. Vacuum pumps used in electron microscopy often handle various gases, including inert gases and potentially hazardous substances. Optimized pumps with enhanced sealing and filtration systems can minimize the risk of accidental releases, protecting both the immediate laboratory environment and the broader ecosystem.

The manufacturing process of advanced vacuum pumps also carries environmental considerations. The production of specialized materials and components may involve resource-intensive processes and the use of rare or toxic materials. As pump designs evolve, there is an opportunity to incorporate more sustainable manufacturing practices and materials, reducing the overall environmental impact of pump production.

Noise pollution is another environmental factor to consider. High-performance vacuum pumps can generate significant noise levels, potentially affecting the work environment and surrounding areas. Optimization efforts that focus on noise reduction can contribute to a healthier work environment and minimize disturbances to nearby ecosystems, particularly in research facilities located near sensitive habitats.

The disposal and recycling of vacuum pump components at the end of their lifecycle present additional environmental challenges. Many pumps contain lubricants, seals, and electronic components that require proper handling to prevent contamination of soil and water sources. Developing pumps with more easily recyclable materials and implementing effective recycling programs can significantly reduce the environmental footprint of these devices.

Water usage is an often-overlooked environmental aspect of vacuum pump operation. Some pump designs require water for cooling, and optimizing this process can lead to substantial water conservation. Implementing closed-loop cooling systems or air-cooled alternatives can dramatically reduce water consumption, particularly in regions facing water scarcity.

Lastly, the optimization of vacuum pumps can indirectly benefit the environment by enabling more efficient and precise electron microscopy research. This can lead to advancements in materials science, nanotechnology, and other fields that may contribute to the development of more environmentally friendly technologies and processes across various industries.

Another crucial environmental aspect is the potential release of harmful gases and particulates. Vacuum pumps used in electron microscopy often handle various gases, including inert gases and potentially hazardous substances. Optimized pumps with enhanced sealing and filtration systems can minimize the risk of accidental releases, protecting both the immediate laboratory environment and the broader ecosystem.

The manufacturing process of advanced vacuum pumps also carries environmental considerations. The production of specialized materials and components may involve resource-intensive processes and the use of rare or toxic materials. As pump designs evolve, there is an opportunity to incorporate more sustainable manufacturing practices and materials, reducing the overall environmental impact of pump production.

Noise pollution is another environmental factor to consider. High-performance vacuum pumps can generate significant noise levels, potentially affecting the work environment and surrounding areas. Optimization efforts that focus on noise reduction can contribute to a healthier work environment and minimize disturbances to nearby ecosystems, particularly in research facilities located near sensitive habitats.

The disposal and recycling of vacuum pump components at the end of their lifecycle present additional environmental challenges. Many pumps contain lubricants, seals, and electronic components that require proper handling to prevent contamination of soil and water sources. Developing pumps with more easily recyclable materials and implementing effective recycling programs can significantly reduce the environmental footprint of these devices.

Water usage is an often-overlooked environmental aspect of vacuum pump operation. Some pump designs require water for cooling, and optimizing this process can lead to substantial water conservation. Implementing closed-loop cooling systems or air-cooled alternatives can dramatically reduce water consumption, particularly in regions facing water scarcity.

Lastly, the optimization of vacuum pumps can indirectly benefit the environment by enabling more efficient and precise electron microscopy research. This can lead to advancements in materials science, nanotechnology, and other fields that may contribute to the development of more environmentally friendly technologies and processes across various industries.

Microscopy Integration Strategies

The integration of vacuum pump systems into high-resolution electron microscopy setups requires careful consideration of various factors to ensure optimal performance. One key strategy involves the strategic placement of pumps to maximize efficiency and minimize vibration. This often entails positioning turbo-molecular pumps close to the microscope column while keeping roughing pumps at a distance to reduce mechanical interference.

Another crucial aspect is the implementation of differential pumping systems. This approach allows for the creation of pressure gradients within the microscope, enabling the maintenance of ultra-high vacuum conditions in critical areas while permitting slightly higher pressures in less sensitive regions. Such a strategy not only enhances overall system performance but also reduces the load on individual pumps.

The selection of appropriate pump types for different microscope sections is equally important. For instance, ion pumps are often preferred for maintaining ultra-high vacuum in the electron gun area due to their vibration-free operation. Meanwhile, cryogenic pumps may be employed in the specimen chamber to efficiently handle water vapor and other condensable gases.

Intelligent pump control systems play a vital role in microscopy integration. These systems can automatically adjust pumping speeds and sequences based on pressure readings from various parts of the microscope. This dynamic approach ensures optimal vacuum conditions are maintained throughout the imaging process while minimizing energy consumption and wear on pump components.

Consideration must also be given to the integration of vacuum measurement and monitoring systems. Strategically placed gauges, coupled with advanced data logging and analysis software, allow for real-time tracking of vacuum conditions. This enables prompt detection of potential issues and facilitates predictive maintenance schedules.

The physical integration of vacuum components must account for the limited space often available in microscopy facilities. Compact pump designs and innovative mounting solutions can help overcome space constraints while maintaining necessary performance levels. Additionally, the use of modular vacuum systems can provide flexibility for future upgrades or reconfigurations of the microscope setup.

Lastly, the integration strategy should include provisions for effective vibration isolation. This may involve the use of specialized mounting platforms, damping materials, or even active vibration cancellation systems to minimize the transmission of pump-induced vibrations to sensitive microscope components.

Another crucial aspect is the implementation of differential pumping systems. This approach allows for the creation of pressure gradients within the microscope, enabling the maintenance of ultra-high vacuum conditions in critical areas while permitting slightly higher pressures in less sensitive regions. Such a strategy not only enhances overall system performance but also reduces the load on individual pumps.

The selection of appropriate pump types for different microscope sections is equally important. For instance, ion pumps are often preferred for maintaining ultra-high vacuum in the electron gun area due to their vibration-free operation. Meanwhile, cryogenic pumps may be employed in the specimen chamber to efficiently handle water vapor and other condensable gases.

Intelligent pump control systems play a vital role in microscopy integration. These systems can automatically adjust pumping speeds and sequences based on pressure readings from various parts of the microscope. This dynamic approach ensures optimal vacuum conditions are maintained throughout the imaging process while minimizing energy consumption and wear on pump components.

Consideration must also be given to the integration of vacuum measurement and monitoring systems. Strategically placed gauges, coupled with advanced data logging and analysis software, allow for real-time tracking of vacuum conditions. This enables prompt detection of potential issues and facilitates predictive maintenance schedules.

The physical integration of vacuum components must account for the limited space often available in microscopy facilities. Compact pump designs and innovative mounting solutions can help overcome space constraints while maintaining necessary performance levels. Additionally, the use of modular vacuum systems can provide flexibility for future upgrades or reconfigurations of the microscope setup.

Lastly, the integration strategy should include provisions for effective vibration isolation. This may involve the use of specialized mounting platforms, damping materials, or even active vibration cancellation systems to minimize the transmission of pump-induced vibrations to sensitive microscope components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!