Vacuum Pump Optimization in Electric Vehicle Component Manufacturing

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Vacuum Pump Tech Evolution and Objectives

Vacuum pump technology has played a crucial role in the manufacturing of electric vehicle components, evolving significantly over the past decades. The primary objective of this technology in the EV industry is to create a controlled environment for precise component fabrication, ensuring high-quality production and optimal performance of electric vehicles.

The evolution of vacuum pump technology in EV component manufacturing can be traced back to the early 2000s when the first mass-produced electric vehicles entered the market. Initially, vacuum pumps were primarily used for basic air extraction in battery production and motor assembly processes. As EV technology advanced, so did the demands on vacuum pump systems, leading to more sophisticated and efficient designs.

By the mid-2010s, vacuum pump technology had become an integral part of EV component manufacturing, particularly in the production of lithium-ion batteries. The focus shifted towards creating ultra-clean environments to prevent contamination during cell assembly and electrolyte filling processes. This period saw the introduction of multi-stage vacuum pumps capable of achieving higher vacuum levels and maintaining them for extended periods.

The current technological landscape is characterized by the integration of smart features and Industry 4.0 principles. Modern vacuum pumps in EV manufacturing are equipped with sensors and connectivity options, allowing for real-time monitoring and predictive maintenance. This has significantly improved production efficiency and reduced downtime in EV component manufacturing facilities.

Looking ahead, the objectives for vacuum pump technology in EV component manufacturing are multifaceted. One primary goal is to further enhance energy efficiency, as vacuum pumps are significant energy consumers in the production process. Manufacturers are exploring novel pump designs and materials to reduce power consumption without compromising performance.

Another critical objective is to develop vacuum pumps capable of handling the increasing complexity of EV components. As battery technologies evolve and new materials are introduced, vacuum systems must adapt to more diverse and challenging manufacturing environments. This includes the ability to maintain precise vacuum levels across a wider range of pressures and temperatures.

Sustainability is also becoming a key focus in vacuum pump development for EV manufacturing. Objectives include reducing the environmental impact of pump operation through the use of eco-friendly lubricants and materials, as well as designing pumps with longer lifespans and easier recyclability.

In conclusion, the evolution of vacuum pump technology in EV component manufacturing has been driven by the need for higher precision, cleaner environments, and increased efficiency. Future objectives center around energy optimization, adaptability to new manufacturing processes, and environmental sustainability, all of which are crucial for supporting the continued growth and innovation in the electric vehicle industry.

The evolution of vacuum pump technology in EV component manufacturing can be traced back to the early 2000s when the first mass-produced electric vehicles entered the market. Initially, vacuum pumps were primarily used for basic air extraction in battery production and motor assembly processes. As EV technology advanced, so did the demands on vacuum pump systems, leading to more sophisticated and efficient designs.

By the mid-2010s, vacuum pump technology had become an integral part of EV component manufacturing, particularly in the production of lithium-ion batteries. The focus shifted towards creating ultra-clean environments to prevent contamination during cell assembly and electrolyte filling processes. This period saw the introduction of multi-stage vacuum pumps capable of achieving higher vacuum levels and maintaining them for extended periods.

The current technological landscape is characterized by the integration of smart features and Industry 4.0 principles. Modern vacuum pumps in EV manufacturing are equipped with sensors and connectivity options, allowing for real-time monitoring and predictive maintenance. This has significantly improved production efficiency and reduced downtime in EV component manufacturing facilities.

Looking ahead, the objectives for vacuum pump technology in EV component manufacturing are multifaceted. One primary goal is to further enhance energy efficiency, as vacuum pumps are significant energy consumers in the production process. Manufacturers are exploring novel pump designs and materials to reduce power consumption without compromising performance.

Another critical objective is to develop vacuum pumps capable of handling the increasing complexity of EV components. As battery technologies evolve and new materials are introduced, vacuum systems must adapt to more diverse and challenging manufacturing environments. This includes the ability to maintain precise vacuum levels across a wider range of pressures and temperatures.

Sustainability is also becoming a key focus in vacuum pump development for EV manufacturing. Objectives include reducing the environmental impact of pump operation through the use of eco-friendly lubricants and materials, as well as designing pumps with longer lifespans and easier recyclability.

In conclusion, the evolution of vacuum pump technology in EV component manufacturing has been driven by the need for higher precision, cleaner environments, and increased efficiency. Future objectives center around energy optimization, adaptability to new manufacturing processes, and environmental sustainability, all of which are crucial for supporting the continued growth and innovation in the electric vehicle industry.

EV Component Market Demand Analysis

The electric vehicle (EV) component market is experiencing rapid growth, driven by the increasing global demand for electric vehicles. This surge in demand is primarily fueled by environmental concerns, government regulations promoting clean energy, and advancements in battery technology. The market for EV components, including those manufactured using vacuum pump technology, is expected to expand significantly in the coming years.

Vacuum pumps play a crucial role in the production of various EV components, such as batteries, electric motors, and power electronics. These components require precise manufacturing processes in clean, controlled environments, which vacuum technology helps to achieve. As the EV market grows, the demand for high-quality, efficient vacuum pumps in component manufacturing is also rising.

The global EV component market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the next five years. This growth is particularly strong in regions with supportive government policies and infrastructure development for electric vehicles, such as China, Europe, and North America. The increasing adoption of EVs in these markets is driving the demand for components and, consequently, the manufacturing equipment used to produce them.

In the context of vacuum pump optimization for EV component manufacturing, there is a growing need for more energy-efficient and cost-effective solutions. Manufacturers are seeking vacuum pumps that can maintain high performance while reducing energy consumption and operational costs. This demand is driven by the need to improve overall production efficiency and reduce the environmental impact of manufacturing processes.

The market is also seeing a trend towards more compact and versatile vacuum pump systems that can be easily integrated into existing production lines. As EV manufacturers strive to increase production capacity and streamline their operations, there is a growing demand for vacuum pumps that offer flexibility and scalability.

Another significant market trend is the increasing focus on smart manufacturing and Industry 4.0 concepts. This is creating a demand for vacuum pumps with advanced monitoring and control capabilities, allowing for predictive maintenance and real-time optimization of manufacturing processes. Such features are becoming increasingly important as EV component manufacturers seek to improve quality control and reduce downtime.

The demand for vacuum pumps in EV component manufacturing is also influenced by the evolving design of electric vehicles. As automakers strive to improve the range and performance of EVs, there is a constant push for innovation in component design and materials. This, in turn, creates new challenges and opportunities for vacuum pump technology in the manufacturing process.

In conclusion, the market demand for optimized vacuum pumps in EV component manufacturing is robust and multifaceted. It is driven by the overall growth of the EV market, the need for more efficient and flexible manufacturing processes, and the ongoing technological advancements in both electric vehicles and manufacturing technologies. This presents significant opportunities for innovation and market growth in the vacuum pump sector, particularly for solutions that can meet the evolving needs of EV component manufacturers.

Vacuum pumps play a crucial role in the production of various EV components, such as batteries, electric motors, and power electronics. These components require precise manufacturing processes in clean, controlled environments, which vacuum technology helps to achieve. As the EV market grows, the demand for high-quality, efficient vacuum pumps in component manufacturing is also rising.

The global EV component market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the next five years. This growth is particularly strong in regions with supportive government policies and infrastructure development for electric vehicles, such as China, Europe, and North America. The increasing adoption of EVs in these markets is driving the demand for components and, consequently, the manufacturing equipment used to produce them.

In the context of vacuum pump optimization for EV component manufacturing, there is a growing need for more energy-efficient and cost-effective solutions. Manufacturers are seeking vacuum pumps that can maintain high performance while reducing energy consumption and operational costs. This demand is driven by the need to improve overall production efficiency and reduce the environmental impact of manufacturing processes.

The market is also seeing a trend towards more compact and versatile vacuum pump systems that can be easily integrated into existing production lines. As EV manufacturers strive to increase production capacity and streamline their operations, there is a growing demand for vacuum pumps that offer flexibility and scalability.

Another significant market trend is the increasing focus on smart manufacturing and Industry 4.0 concepts. This is creating a demand for vacuum pumps with advanced monitoring and control capabilities, allowing for predictive maintenance and real-time optimization of manufacturing processes. Such features are becoming increasingly important as EV component manufacturers seek to improve quality control and reduce downtime.

The demand for vacuum pumps in EV component manufacturing is also influenced by the evolving design of electric vehicles. As automakers strive to improve the range and performance of EVs, there is a constant push for innovation in component design and materials. This, in turn, creates new challenges and opportunities for vacuum pump technology in the manufacturing process.

In conclusion, the market demand for optimized vacuum pumps in EV component manufacturing is robust and multifaceted. It is driven by the overall growth of the EV market, the need for more efficient and flexible manufacturing processes, and the ongoing technological advancements in both electric vehicles and manufacturing technologies. This presents significant opportunities for innovation and market growth in the vacuum pump sector, particularly for solutions that can meet the evolving needs of EV component manufacturers.

Vacuum Pump Challenges in EV Manufacturing

The optimization of vacuum pumps in electric vehicle (EV) component manufacturing faces several significant challenges. These challenges stem from the unique requirements of EV production processes and the increasing demand for high-performance, energy-efficient components.

One of the primary challenges is achieving and maintaining the required vacuum levels for various EV manufacturing processes. Different components, such as battery cells, electric motors, and power electronics, often require specific vacuum conditions for optimal production. Ensuring consistent vacuum levels across diverse manufacturing stages poses a considerable technical hurdle.

Energy efficiency is another critical challenge in vacuum pump optimization for EV manufacturing. As the automotive industry strives to reduce its carbon footprint, there is a growing need for vacuum pumps that consume less energy while maintaining high performance. This necessitates innovative designs and advanced control systems to minimize power consumption without compromising vacuum quality.

The demand for increased production speed in EV manufacturing also presents challenges for vacuum pump systems. Faster cycle times require vacuum pumps to achieve and release vacuum more quickly, putting additional stress on the equipment and potentially affecting the quality of the vacuum produced. Balancing speed with precision and reliability is a complex engineering task.

Contamination control is a crucial aspect of EV component manufacturing, particularly in battery production. Vacuum pumps must be designed to prevent oil or particulate contamination, which can significantly impact the performance and lifespan of EV components. This challenge requires the development of oil-free or dry vacuum pump technologies that can meet the stringent cleanliness standards of EV production.

Scalability and flexibility pose additional challenges in vacuum pump optimization. As EV manufacturers ramp up production and introduce new models, vacuum pump systems need to be easily scalable and adaptable to changing production requirements. This demands modular designs and intelligent control systems that can be quickly reconfigured to meet evolving manufacturing needs.

Maintenance and reliability are ongoing concerns in vacuum pump optimization. The continuous operation in high-volume EV production environments puts significant stress on vacuum pumps, necessitating robust designs and predictive maintenance strategies to minimize downtime and ensure consistent performance.

Lastly, the integration of vacuum pump systems with Industry 4.0 technologies presents both opportunities and challenges. Implementing IoT sensors, data analytics, and AI-driven control systems can enhance pump performance and efficiency but requires overcoming complexities in data management, cybersecurity, and system interoperability.

One of the primary challenges is achieving and maintaining the required vacuum levels for various EV manufacturing processes. Different components, such as battery cells, electric motors, and power electronics, often require specific vacuum conditions for optimal production. Ensuring consistent vacuum levels across diverse manufacturing stages poses a considerable technical hurdle.

Energy efficiency is another critical challenge in vacuum pump optimization for EV manufacturing. As the automotive industry strives to reduce its carbon footprint, there is a growing need for vacuum pumps that consume less energy while maintaining high performance. This necessitates innovative designs and advanced control systems to minimize power consumption without compromising vacuum quality.

The demand for increased production speed in EV manufacturing also presents challenges for vacuum pump systems. Faster cycle times require vacuum pumps to achieve and release vacuum more quickly, putting additional stress on the equipment and potentially affecting the quality of the vacuum produced. Balancing speed with precision and reliability is a complex engineering task.

Contamination control is a crucial aspect of EV component manufacturing, particularly in battery production. Vacuum pumps must be designed to prevent oil or particulate contamination, which can significantly impact the performance and lifespan of EV components. This challenge requires the development of oil-free or dry vacuum pump technologies that can meet the stringent cleanliness standards of EV production.

Scalability and flexibility pose additional challenges in vacuum pump optimization. As EV manufacturers ramp up production and introduce new models, vacuum pump systems need to be easily scalable and adaptable to changing production requirements. This demands modular designs and intelligent control systems that can be quickly reconfigured to meet evolving manufacturing needs.

Maintenance and reliability are ongoing concerns in vacuum pump optimization. The continuous operation in high-volume EV production environments puts significant stress on vacuum pumps, necessitating robust designs and predictive maintenance strategies to minimize downtime and ensure consistent performance.

Lastly, the integration of vacuum pump systems with Industry 4.0 technologies presents both opportunities and challenges. Implementing IoT sensors, data analytics, and AI-driven control systems can enhance pump performance and efficiency but requires overcoming complexities in data management, cybersecurity, and system interoperability.

Current Vacuum Pump Optimization Solutions

01 Improved pump design and configuration

Optimization of vacuum pump design involves enhancing the structural configuration and components to improve efficiency and performance. This includes modifications to impeller design, housing geometry, and sealing mechanisms to reduce internal leakage and increase pumping capacity.- Improved pump design and configuration: Optimization of vacuum pump design involves enhancing the overall configuration and structure of the pump. This includes improvements in rotor design, housing geometry, and the arrangement of internal components to increase efficiency and performance. Advanced materials and manufacturing techniques may be employed to reduce weight and improve durability.

- Enhanced sealing and lubrication systems: Developing better sealing mechanisms and lubrication systems is crucial for vacuum pump optimization. This involves implementing advanced sealing technologies to minimize leakage and improve vacuum quality. Improved lubrication systems ensure smooth operation, reduce wear, and extend the pump's lifespan while maintaining optimal performance.

- Intelligent control and monitoring systems: Incorporating smart control systems and sensors for real-time monitoring and adjustment of vacuum pump operations. These systems can optimize performance based on varying load conditions, detect potential issues before they become critical, and provide data for predictive maintenance, ultimately improving efficiency and reducing downtime.

- Energy efficiency and heat management: Focusing on improving the energy efficiency of vacuum pumps through advanced motor designs, power management systems, and heat recovery mechanisms. This includes developing methods to reduce power consumption, minimize heat generation, and effectively dissipate or utilize waste heat, leading to more sustainable and cost-effective pump operation.

- Multi-stage and hybrid pump systems: Developing innovative multi-stage and hybrid vacuum pump systems that combine different pumping technologies or stages to achieve higher performance and efficiency. These systems can be tailored to specific applications, offering improved vacuum levels, faster pumping speeds, and better adaptability to varying process requirements.

02 Advanced control systems and algorithms

Implementation of sophisticated control systems and algorithms for vacuum pump operation. This includes adaptive control strategies, predictive maintenance algorithms, and real-time performance optimization techniques to enhance pump efficiency and reliability across various operating conditions.Expand Specific Solutions03 Energy efficiency and heat management

Focus on improving energy efficiency and heat management in vacuum pumps. This involves developing innovative cooling systems, utilizing energy-efficient motors, and implementing heat recovery mechanisms to reduce power consumption and improve overall system performance.Expand Specific Solutions04 Multi-stage and hybrid pump systems

Development of multi-stage and hybrid vacuum pump systems that combine different pumping technologies to achieve higher vacuum levels and improved efficiency. This approach allows for optimized performance across a wide range of pressure regimes and applications.Expand Specific Solutions05 Smart monitoring and diagnostics

Integration of smart monitoring and diagnostic capabilities in vacuum pumps. This includes the use of sensors, IoT technologies, and data analytics to enable real-time performance monitoring, predictive maintenance, and remote diagnostics, leading to improved reliability and reduced downtime.Expand Specific Solutions

Key Players in EV Vacuum Pump Industry

The vacuum pump optimization market in electric vehicle component manufacturing is in a growth phase, driven by increasing demand for EVs and the need for more efficient production processes. The market size is expanding rapidly, with major automotive players like Ford, Continental, and BYD investing heavily in this technology. The technical maturity varies, with established companies like Edwards Japan and Pfeiffer Vacuum offering advanced solutions, while newer entrants like Ola Electric are still developing their capabilities. Traditional automotive giants such as Honda, Hyundai, and Mercedes-Benz are also adapting their manufacturing processes to incorporate optimized vacuum pump technologies, indicating a shift towards widespread adoption in the industry.

Ford Global Technologies LLC

Technical Solution: Ford has developed an innovative vacuum pump optimization system for electric vehicle component manufacturing. Their approach focuses on enhancing energy efficiency and reducing noise levels in the production process. The system utilizes advanced sensor technology to monitor vacuum levels in real-time, allowing for precise control and adjustment of pump operation[1]. Ford's solution incorporates a variable speed drive that modulates pump speed based on demand, significantly reducing energy consumption[2]. Additionally, they have implemented a smart scheduling algorithm that optimizes the operation of multiple pumps in a production line, further improving overall efficiency[3]. The system also features predictive maintenance capabilities, using machine learning algorithms to analyze pump performance data and predict potential failures before they occur[4].

Strengths: Improved energy efficiency, reduced noise levels, and predictive maintenance capabilities. Weaknesses: May require significant initial investment and potential complexity in implementation across diverse manufacturing environments.

Edwards Japan Ltd.

Technical Solution: Edwards Japan has developed a cutting-edge vacuum pump solution specifically tailored for electric vehicle component manufacturing. Their system employs a combination of dry and oil-sealed pumps to achieve optimal performance across various manufacturing processes[1]. The company's innovative design incorporates advanced materials that enhance pump durability and reduce maintenance requirements[2]. Edwards' solution features a modular architecture, allowing for easy integration and scalability in different production environments[3]. The pumps are equipped with intelligent control systems that optimize performance based on specific process requirements, resulting in improved energy efficiency and reduced operating costs[4]. Additionally, Edwards has implemented a unique heat recovery system that captures and repurposes waste heat from the pumps, further enhancing overall energy efficiency in the manufacturing process[5].

Strengths: Versatile pump combination, modular design for easy integration, and innovative heat recovery system. Weaknesses: Potentially higher initial costs and may require specialized training for maintenance personnel.

Core Innovations in EV Vacuum Pump Tech

Method and assembly for controlling a vacuum pump

PatentWO2012104168A1

Innovation

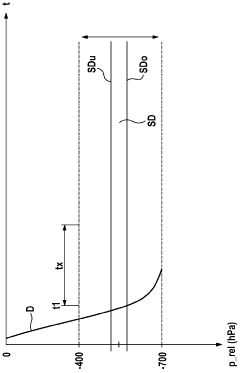

- A method that allows for a selectable saturation range with adjustable mean and width values, where the vacuum pump is switched off if the pressure remains within this range for a predetermined time, and the range is dynamically adjusted based on external pressure conditions, using a sliding threshold band and variable detection time to improve reliability.

Electric vacuum pump control apparatus and electric vacuum pump control method

PatentWO2018123336A1

Innovation

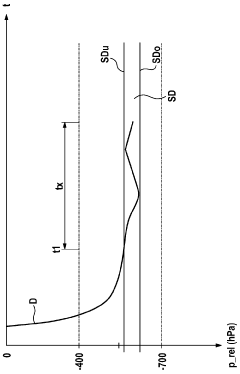

- An electric vacuum pump control device and method that dynamically determines the OFF point based on pump filling performance standard data and current performance data, allowing for adaptive control to optimize both performance and lifespan by adjusting the OFF threshold and operation time.

Environmental Impact of Vacuum Pump Use

The environmental impact of vacuum pump use in electric vehicle component manufacturing is a critical consideration as the industry strives for sustainability. Vacuum pumps, while essential for various processes, contribute significantly to energy consumption and associated carbon emissions. The primary environmental concerns stem from the high electricity usage of these pumps, which often operate continuously during production cycles.

Energy efficiency is a key factor in mitigating the environmental impact of vacuum pumps. Traditional pumps may consume excessive energy, particularly when running at full capacity during low-demand periods. This inefficiency not only increases operational costs but also leads to unnecessary carbon emissions. Implementing variable speed drives and intelligent control systems can optimize pump performance, reducing energy consumption by up to 50% in some cases.

Another environmental consideration is the use of working fluids in certain vacuum pump types. Oil-sealed pumps, for instance, require regular oil changes and disposal, potentially leading to soil and water contamination if not managed properly. Dry pumps, which operate without oil, offer a more environmentally friendly alternative but may have higher initial costs and different maintenance requirements.

Noise pollution is an often-overlooked environmental impact of vacuum pump operation. Excessive noise can affect worker health and local ecosystems. Modern pump designs incorporating sound-dampening technologies and proper installation techniques can significantly reduce noise levels, improving the working environment and minimizing disturbance to surrounding areas.

The manufacturing and disposal of vacuum pumps also contribute to their environmental footprint. The production of pump components involves resource extraction and energy-intensive processes. At the end of their lifecycle, improper disposal can lead to electronic waste and potential release of harmful materials. Implementing circular economy principles, such as designing for recyclability and establishing take-back programs, can help mitigate these impacts.

Water consumption is another environmental aspect to consider, particularly in vacuum systems that use water for sealing or cooling. While water-sealed pumps can be efficient, they may contribute to water scarcity issues in regions where water resources are limited. Dry pumps or those with closed-loop cooling systems offer more water-efficient alternatives.

As the electric vehicle industry expands, the cumulative environmental impact of vacuum pump use across multiple manufacturing facilities becomes increasingly significant. Addressing these environmental concerns through technological innovations, operational optimizations, and sustainable practices is crucial for aligning electric vehicle production with broader environmental goals and regulations.

Energy efficiency is a key factor in mitigating the environmental impact of vacuum pumps. Traditional pumps may consume excessive energy, particularly when running at full capacity during low-demand periods. This inefficiency not only increases operational costs but also leads to unnecessary carbon emissions. Implementing variable speed drives and intelligent control systems can optimize pump performance, reducing energy consumption by up to 50% in some cases.

Another environmental consideration is the use of working fluids in certain vacuum pump types. Oil-sealed pumps, for instance, require regular oil changes and disposal, potentially leading to soil and water contamination if not managed properly. Dry pumps, which operate without oil, offer a more environmentally friendly alternative but may have higher initial costs and different maintenance requirements.

Noise pollution is an often-overlooked environmental impact of vacuum pump operation. Excessive noise can affect worker health and local ecosystems. Modern pump designs incorporating sound-dampening technologies and proper installation techniques can significantly reduce noise levels, improving the working environment and minimizing disturbance to surrounding areas.

The manufacturing and disposal of vacuum pumps also contribute to their environmental footprint. The production of pump components involves resource extraction and energy-intensive processes. At the end of their lifecycle, improper disposal can lead to electronic waste and potential release of harmful materials. Implementing circular economy principles, such as designing for recyclability and establishing take-back programs, can help mitigate these impacts.

Water consumption is another environmental aspect to consider, particularly in vacuum systems that use water for sealing or cooling. While water-sealed pumps can be efficient, they may contribute to water scarcity issues in regions where water resources are limited. Dry pumps or those with closed-loop cooling systems offer more water-efficient alternatives.

As the electric vehicle industry expands, the cumulative environmental impact of vacuum pump use across multiple manufacturing facilities becomes increasingly significant. Addressing these environmental concerns through technological innovations, operational optimizations, and sustainable practices is crucial for aligning electric vehicle production with broader environmental goals and regulations.

Cost-Benefit Analysis of Pump Optimization

The cost-benefit analysis of vacuum pump optimization in electric vehicle component manufacturing reveals significant potential for operational efficiency and financial savings. Initial investment in advanced pump technology and optimization strategies may present a substantial upfront cost, ranging from $50,000 to $200,000 depending on the scale of operations. However, the long-term benefits far outweigh these initial expenditures.

Energy consumption reduction stands out as a primary benefit, with optimized vacuum pumps potentially decreasing energy usage by 30-50%. This translates to annual energy cost savings of $10,000 to $50,000 for medium-sized manufacturing facilities. The reduced energy demand also contributes to lowering the carbon footprint, aligning with sustainability goals and potentially qualifying for green energy incentives.

Maintenance costs see a notable decrease with optimized pumps. Traditional pumps often require frequent maintenance, costing up to $15,000 annually. Optimized systems can reduce these expenses by 40-60%, resulting in yearly savings of $6,000 to $9,000. The extended lifespan of optimized pumps, typically 20-30% longer than standard models, further enhances the cost-benefit ratio.

Production efficiency improvements represent another significant advantage. Optimized vacuum pumps can reduce cycle times by 10-20%, potentially increasing production output by a similar margin. For a facility producing 100,000 units annually, this could translate to an additional 10,000-20,000 units without significant additional overhead costs.

Quality improvements resulting from more consistent vacuum levels can lead to a reduction in defect rates by 5-10%. This not only saves on material costs but also enhances customer satisfaction and reduces warranty claims. For components with an average value of $100, a 5% reduction in defects in a production run of 100,000 units could save $500,000 annually.

The return on investment (ROI) for vacuum pump optimization projects typically ranges from 18 to 36 months, depending on the scale of implementation and specific manufacturing processes. After this period, the ongoing savings contribute directly to improved profitability and competitiveness in the electric vehicle component manufacturing sector.

Energy consumption reduction stands out as a primary benefit, with optimized vacuum pumps potentially decreasing energy usage by 30-50%. This translates to annual energy cost savings of $10,000 to $50,000 for medium-sized manufacturing facilities. The reduced energy demand also contributes to lowering the carbon footprint, aligning with sustainability goals and potentially qualifying for green energy incentives.

Maintenance costs see a notable decrease with optimized pumps. Traditional pumps often require frequent maintenance, costing up to $15,000 annually. Optimized systems can reduce these expenses by 40-60%, resulting in yearly savings of $6,000 to $9,000. The extended lifespan of optimized pumps, typically 20-30% longer than standard models, further enhances the cost-benefit ratio.

Production efficiency improvements represent another significant advantage. Optimized vacuum pumps can reduce cycle times by 10-20%, potentially increasing production output by a similar margin. For a facility producing 100,000 units annually, this could translate to an additional 10,000-20,000 units without significant additional overhead costs.

Quality improvements resulting from more consistent vacuum levels can lead to a reduction in defect rates by 5-10%. This not only saves on material costs but also enhances customer satisfaction and reduces warranty claims. For components with an average value of $100, a 5% reduction in defects in a production run of 100,000 units could save $500,000 annually.

The return on investment (ROI) for vacuum pump optimization projects typically ranges from 18 to 36 months, depending on the scale of implementation and specific manufacturing processes. After this period, the ongoing savings contribute directly to improved profitability and competitiveness in the electric vehicle component manufacturing sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!