Vacuum Pump Roles in Development of Fluoropolymer Coatings

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluoropolymer Coating Evolution and Vacuum Pump Integration

The evolution of fluoropolymer coatings has been closely intertwined with advancements in vacuum pump technology. In the early stages of fluoropolymer coating development, basic vacuum systems were employed primarily for removing air and moisture from coating chambers. These rudimentary setups allowed for the initial application of fluoropolymer coatings but were limited in their ability to create high-quality, uniform layers.

As the demand for more sophisticated fluoropolymer coatings grew, particularly in industries requiring high-performance materials, the role of vacuum pumps became increasingly critical. The introduction of more advanced vacuum pump systems in the 1970s and 1980s marked a significant turning point. These improved pumps could achieve higher vacuum levels, enabling better control over the coating environment and resulting in enhanced coating properties.

The 1990s saw a surge in research and development focused on optimizing vacuum pump technology specifically for fluoropolymer coating processes. This period witnessed the integration of specialized vacuum pumps designed to handle the unique challenges posed by fluoropolymer materials, such as their tendency to outgas during the coating process. These purpose-built pumps incorporated features like corrosion-resistant components and improved vapor handling capabilities.

The turn of the millennium brought about a new era of precision in fluoropolymer coating applications, largely due to the integration of computer-controlled vacuum systems. These systems allowed for real-time monitoring and adjustment of vacuum levels, leading to unprecedented control over coating thickness, uniformity, and adhesion. The ability to maintain stable, ultra-low pressures throughout the coating process became instrumental in developing advanced fluoropolymer coatings with enhanced durability and performance characteristics.

Recent years have seen a focus on energy efficiency and environmental considerations in vacuum pump design for fluoropolymer coating applications. The development of dry vacuum pumps and the implementation of intelligent pump control systems have not only improved the overall efficiency of the coating process but also reduced the environmental impact of fluoropolymer coating production.

Today, state-of-the-art vacuum pump technology plays a pivotal role in pushing the boundaries of fluoropolymer coating capabilities. Advanced pumps enable the creation of multi-layer coatings with precisely controlled properties, opening up new possibilities for applications in electronics, aerospace, and medical industries. The symbiotic relationship between vacuum pump technology and fluoropolymer coating development continues to drive innovation, with each advancement in pump design enabling new breakthroughs in coating performance and application methods.

As the demand for more sophisticated fluoropolymer coatings grew, particularly in industries requiring high-performance materials, the role of vacuum pumps became increasingly critical. The introduction of more advanced vacuum pump systems in the 1970s and 1980s marked a significant turning point. These improved pumps could achieve higher vacuum levels, enabling better control over the coating environment and resulting in enhanced coating properties.

The 1990s saw a surge in research and development focused on optimizing vacuum pump technology specifically for fluoropolymer coating processes. This period witnessed the integration of specialized vacuum pumps designed to handle the unique challenges posed by fluoropolymer materials, such as their tendency to outgas during the coating process. These purpose-built pumps incorporated features like corrosion-resistant components and improved vapor handling capabilities.

The turn of the millennium brought about a new era of precision in fluoropolymer coating applications, largely due to the integration of computer-controlled vacuum systems. These systems allowed for real-time monitoring and adjustment of vacuum levels, leading to unprecedented control over coating thickness, uniformity, and adhesion. The ability to maintain stable, ultra-low pressures throughout the coating process became instrumental in developing advanced fluoropolymer coatings with enhanced durability and performance characteristics.

Recent years have seen a focus on energy efficiency and environmental considerations in vacuum pump design for fluoropolymer coating applications. The development of dry vacuum pumps and the implementation of intelligent pump control systems have not only improved the overall efficiency of the coating process but also reduced the environmental impact of fluoropolymer coating production.

Today, state-of-the-art vacuum pump technology plays a pivotal role in pushing the boundaries of fluoropolymer coating capabilities. Advanced pumps enable the creation of multi-layer coatings with precisely controlled properties, opening up new possibilities for applications in electronics, aerospace, and medical industries. The symbiotic relationship between vacuum pump technology and fluoropolymer coating development continues to drive innovation, with each advancement in pump design enabling new breakthroughs in coating performance and application methods.

Market Analysis for Vacuum-Assisted Fluoropolymer Coatings

The market for vacuum-assisted fluoropolymer coatings has experienced significant growth in recent years, driven by increasing demand across various industries. This technology offers superior performance characteristics, including enhanced durability, chemical resistance, and low friction properties, making it highly desirable in sectors such as automotive, aerospace, electronics, and industrial manufacturing.

The global fluoropolymer coatings market, which includes vacuum-assisted applications, was valued at approximately $1.6 billion in 2020 and is projected to reach $2.4 billion by 2027, growing at a CAGR of around 6.5% during the forecast period. This growth is primarily attributed to the expanding automotive and aerospace industries, as well as the increasing adoption of advanced coating technologies in emerging economies.

Vacuum-assisted fluoropolymer coatings have gained particular traction in the automotive sector, where they are used to enhance the performance and longevity of various components, including engine parts, fuel systems, and exterior surfaces. The automotive industry's shift towards electric vehicles has further boosted demand for these coatings, as they play a crucial role in improving battery efficiency and thermal management.

In the aerospace industry, vacuum-assisted fluoropolymer coatings have become essential for protecting aircraft components from harsh environmental conditions and reducing fuel consumption through improved aerodynamics. The market in this sector is expected to grow steadily as air travel rebounds post-pandemic and as manufacturers focus on developing more fuel-efficient aircraft.

The electronics industry represents another significant market for vacuum-assisted fluoropolymer coatings, particularly in the production of semiconductors and printed circuit boards. As the demand for smaller, more powerful electronic devices continues to rise, the need for high-performance coatings that can withstand extreme conditions and provide excellent insulation properties is expected to increase.

Geographically, North America and Europe currently dominate the market for vacuum-assisted fluoropolymer coatings, owing to the presence of major automotive and aerospace manufacturers in these regions. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and growing investments in infrastructure development.

Despite the positive market outlook, challenges such as high production costs and environmental concerns related to the use of certain fluoropolymers may impact market growth. However, ongoing research and development efforts aimed at developing more sustainable and cost-effective fluoropolymer coatings are expected to address these challenges and further drive market expansion in the long term.

The global fluoropolymer coatings market, which includes vacuum-assisted applications, was valued at approximately $1.6 billion in 2020 and is projected to reach $2.4 billion by 2027, growing at a CAGR of around 6.5% during the forecast period. This growth is primarily attributed to the expanding automotive and aerospace industries, as well as the increasing adoption of advanced coating technologies in emerging economies.

Vacuum-assisted fluoropolymer coatings have gained particular traction in the automotive sector, where they are used to enhance the performance and longevity of various components, including engine parts, fuel systems, and exterior surfaces. The automotive industry's shift towards electric vehicles has further boosted demand for these coatings, as they play a crucial role in improving battery efficiency and thermal management.

In the aerospace industry, vacuum-assisted fluoropolymer coatings have become essential for protecting aircraft components from harsh environmental conditions and reducing fuel consumption through improved aerodynamics. The market in this sector is expected to grow steadily as air travel rebounds post-pandemic and as manufacturers focus on developing more fuel-efficient aircraft.

The electronics industry represents another significant market for vacuum-assisted fluoropolymer coatings, particularly in the production of semiconductors and printed circuit boards. As the demand for smaller, more powerful electronic devices continues to rise, the need for high-performance coatings that can withstand extreme conditions and provide excellent insulation properties is expected to increase.

Geographically, North America and Europe currently dominate the market for vacuum-assisted fluoropolymer coatings, owing to the presence of major automotive and aerospace manufacturers in these regions. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and growing investments in infrastructure development.

Despite the positive market outlook, challenges such as high production costs and environmental concerns related to the use of certain fluoropolymers may impact market growth. However, ongoing research and development efforts aimed at developing more sustainable and cost-effective fluoropolymer coatings are expected to address these challenges and further drive market expansion in the long term.

Vacuum Pump Technology in Fluoropolymer Application

Vacuum pump technology plays a crucial role in the development and application of fluoropolymer coatings. These pumps are essential for creating the controlled environment necessary for the deposition and curing of fluoropolymer materials. The primary function of vacuum pumps in this context is to remove air and other gases from the coating chamber, ensuring a clean and contaminant-free environment for the coating process.

In the fluoropolymer coating industry, various types of vacuum pumps are utilized, each serving specific purposes. Rotary vane pumps are commonly employed for their ability to achieve medium vacuum levels, which is often sufficient for many coating applications. For more demanding processes requiring higher vacuum levels, turbomolecular pumps are frequently used in conjunction with backing pumps to achieve ultra-high vacuum conditions.

The vacuum environment created by these pumps serves multiple purposes in fluoropolymer coating applications. Firstly, it helps in removing moisture and air bubbles from the coating material, resulting in a more uniform and defect-free coating. Secondly, it allows for better control over the coating thickness and uniformity by manipulating the pressure inside the chamber. This precise control is particularly important for applications requiring thin, even layers of fluoropolymer coatings.

Moreover, vacuum technology enables the use of advanced deposition techniques such as plasma-enhanced chemical vapor deposition (PECVD) for fluoropolymer coatings. In PECVD processes, vacuum pumps are essential for maintaining the low-pressure plasma environment necessary for the decomposition and deposition of fluoropolymer precursors onto the substrate surface.

The selection of appropriate vacuum pump technology is critical for optimizing the coating process. Factors such as the required vacuum level, pumping speed, and compatibility with fluoropolymer materials must be carefully considered. For instance, oil-sealed pumps may not be suitable for certain fluoropolymer applications due to the risk of contamination, making dry pumps a preferred choice in many cases.

Advancements in vacuum pump technology have led to improvements in fluoropolymer coating processes. Modern pumps offer enhanced reliability, reduced maintenance requirements, and improved energy efficiency. These developments have contributed to the overall quality and cost-effectiveness of fluoropolymer coating applications across various industries, including electronics, automotive, and aerospace sectors.

In the fluoropolymer coating industry, various types of vacuum pumps are utilized, each serving specific purposes. Rotary vane pumps are commonly employed for their ability to achieve medium vacuum levels, which is often sufficient for many coating applications. For more demanding processes requiring higher vacuum levels, turbomolecular pumps are frequently used in conjunction with backing pumps to achieve ultra-high vacuum conditions.

The vacuum environment created by these pumps serves multiple purposes in fluoropolymer coating applications. Firstly, it helps in removing moisture and air bubbles from the coating material, resulting in a more uniform and defect-free coating. Secondly, it allows for better control over the coating thickness and uniformity by manipulating the pressure inside the chamber. This precise control is particularly important for applications requiring thin, even layers of fluoropolymer coatings.

Moreover, vacuum technology enables the use of advanced deposition techniques such as plasma-enhanced chemical vapor deposition (PECVD) for fluoropolymer coatings. In PECVD processes, vacuum pumps are essential for maintaining the low-pressure plasma environment necessary for the decomposition and deposition of fluoropolymer precursors onto the substrate surface.

The selection of appropriate vacuum pump technology is critical for optimizing the coating process. Factors such as the required vacuum level, pumping speed, and compatibility with fluoropolymer materials must be carefully considered. For instance, oil-sealed pumps may not be suitable for certain fluoropolymer applications due to the risk of contamination, making dry pumps a preferred choice in many cases.

Advancements in vacuum pump technology have led to improvements in fluoropolymer coating processes. Modern pumps offer enhanced reliability, reduced maintenance requirements, and improved energy efficiency. These developments have contributed to the overall quality and cost-effectiveness of fluoropolymer coating applications across various industries, including electronics, automotive, and aerospace sectors.

Current Vacuum-Assisted Fluoropolymer Coating Techniques

01 Improved vacuum pump designs

Various innovations in vacuum pump designs aim to enhance efficiency, reduce noise, and improve overall performance. These designs may include modifications to rotor configurations, sealing mechanisms, or the integration of advanced materials to optimize pump operation.- Improved pump design for enhanced efficiency: Vacuum pumps with innovative designs to improve efficiency and performance. These designs may include optimized rotor configurations, advanced sealing mechanisms, or novel compression techniques to enhance suction power and reduce energy consumption.

- Multi-stage vacuum pump systems: Development of multi-stage vacuum pump systems that combine different pump types or stages to achieve higher vacuum levels or improved performance across a wider pressure range. These systems may integrate various pump technologies to optimize overall efficiency and functionality.

- Vacuum pump control and monitoring systems: Integration of advanced control and monitoring systems in vacuum pumps to optimize operation, detect faults, and improve maintenance scheduling. These systems may include sensors, data analytics, and smart control algorithms to enhance pump performance and reliability.

- Specialized vacuum pumps for specific applications: Development of vacuum pumps tailored for specific industrial or scientific applications, such as semiconductor manufacturing, food processing, or medical equipment. These pumps may have unique features or materials to meet the requirements of their intended use.

- Environmentally friendly vacuum pump technologies: Innovation in vacuum pump technologies focused on reducing environmental impact, such as oil-free designs, lower energy consumption, or the use of eco-friendly materials. These pumps aim to minimize pollution and improve sustainability in various industries.

02 Energy-efficient vacuum pump systems

Development of energy-efficient vacuum pump systems focuses on reducing power consumption while maintaining high performance. These systems may incorporate advanced control algorithms, variable speed drives, or heat recovery mechanisms to optimize energy usage.Expand Specific Solutions03 Vacuum pump cooling and lubrication

Innovations in cooling and lubrication systems for vacuum pumps aim to improve reliability and extend operational life. These may include advanced cooling circuits, novel lubricant formulations, or self-lubricating components to enhance pump performance and durability.Expand Specific Solutions04 Multi-stage vacuum pump configurations

Multi-stage vacuum pump designs combine different pump types or stages to achieve higher vacuum levels or improved pumping speeds. These configurations may integrate various pump technologies to optimize performance across a wide range of pressure conditions.Expand Specific Solutions05 Smart vacuum pump control systems

Integration of smart control systems in vacuum pumps enables advanced monitoring, diagnostics, and optimization of pump operation. These systems may incorporate sensors, IoT connectivity, and predictive maintenance algorithms to enhance pump efficiency and reliability.Expand Specific Solutions

Key Manufacturers in Vacuum Pump and Fluoropolymer Industries

The development of fluoropolymer coatings is in a mature stage, with a growing market driven by increasing demand in various industries. The global fluoropolymer coatings market size is expected to reach significant value in the coming years, indicating substantial growth potential. Technologically, the field is well-established but continues to evolve, with companies like PPG Industries, DAIKIN INDUSTRIES, and The Chemours Co. leading innovation. These industry leaders, along with others such as DuPont de Nemours and Arkema, are investing in research and development to improve coating performance, durability, and environmental sustainability. Vacuum pump technology plays a crucial role in the manufacturing process, with companies like Edwards Ltd. providing specialized equipment to enhance production efficiency and quality control in fluoropolymer coating applications.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has developed advanced vacuum pump technologies for fluoropolymer coating applications. Their approach involves using multi-stage dry vacuum pumps with specialized coatings to handle corrosive fluoropolymer precursors. These pumps maintain high vacuum levels (10^-3 to 10^-6 Torr) required for uniform coating deposition[1]. DAIKIN's pumps incorporate oil-free designs to prevent contamination, and feature temperature-controlled chambers to optimize precursor vaporization. They have also implemented intelligent control systems that adjust pumping speeds based on process parameters, enhancing coating quality and energy efficiency[3].

Strengths: Expertise in fluoropolymer chemistry, advanced pump designs for corrosive environments, and intelligent control systems. Weaknesses: High initial equipment costs and potential complexity in operation and maintenance.

The Chemours Co.

Technical Solution: Chemours has developed a comprehensive vacuum pump strategy for fluoropolymer coating processes. Their approach utilizes specialized corrosion-resistant vacuum pumps designed to handle aggressive fluoropolymer precursors. These pumps incorporate advanced materials such as perfluoroalkoxy (PFA) coatings on internal components to resist chemical attack[2]. Chemours' vacuum systems are optimized for precise pressure control in the range of 1-100 mTorr, crucial for achieving uniform coating thickness. They have also implemented energy-efficient pump designs with variable frequency drives, reducing power consumption by up to 30% compared to conventional systems[4]. Additionally, Chemours has developed integrated abatement systems to capture and neutralize fluoropolymer byproducts, ensuring environmental compliance.

Strengths: Extensive experience with fluoropolymer chemistry, corrosion-resistant pump designs, and integrated abatement solutions. Weaknesses: Potentially higher costs due to specialized materials and limited applicability outside fluoropolymer processes.

Innovative Vacuum Technologies for Fluoropolymer Coatings

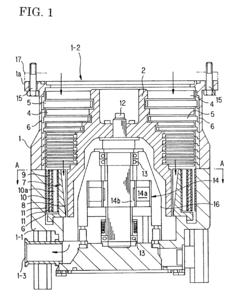

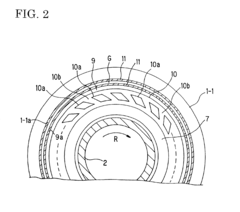

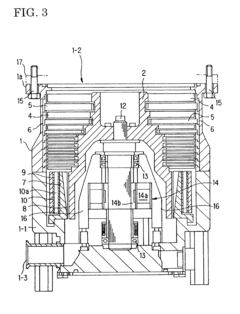

Vacuum pump

PatentInactiveUS6814536B2

Innovation

- A vacuum pump design featuring a rigid ring positioned outside the screw stator to absorb and dissipate the shock load, combined with a buffer member and low-frictional surfaces to reduce frictional forces, preventing the transfer of damaging torque to the process chamber.

Method for producing fluoropolymer composition

PatentPendingUS20230348636A1

Innovation

- A method involving polymerizing fluoronomers in the presence of a fluorine-containing surfactant and initiator, followed by removing unreacted monomers and adding a radical generator for heat treatment, which decomposes the surfactants and compounds, reducing their content in the final fluoropolymer composition.

Environmental Impact of Vacuum-Assisted Coating Methods

The environmental impact of vacuum-assisted coating methods in the development of fluoropolymer coatings is a critical consideration for both manufacturers and environmental regulators. These methods, which utilize vacuum pumps to create controlled environments for coating application, offer significant advantages in terms of coating quality and efficiency. However, they also present unique environmental challenges that must be addressed.

One of the primary environmental concerns associated with vacuum-assisted coating methods is the potential release of volatile organic compounds (VOCs) and other hazardous air pollutants. During the coating process, these substances can be emitted into the atmosphere, contributing to air pollution and potentially harming human health and ecosystems. To mitigate this issue, many facilities have implemented advanced air filtration systems and VOC capture technologies, significantly reducing emissions and improving air quality in and around coating facilities.

Water consumption and wastewater management are also important environmental factors to consider. Vacuum-assisted coating processes often require water for cooling and cleaning purposes. The resulting wastewater may contain trace amounts of fluoropolymers, solvents, and other chemicals used in the coating process. Proper treatment and disposal of this wastewater are essential to prevent contamination of local water sources and ecosystems. Many companies have invested in on-site water treatment facilities and implemented water recycling programs to minimize their environmental footprint.

Energy consumption is another significant aspect of the environmental impact of vacuum-assisted coating methods. The operation of vacuum pumps and associated equipment requires substantial amounts of electricity, contributing to greenhouse gas emissions if sourced from non-renewable energy. To address this, some manufacturers have turned to renewable energy sources or implemented energy-efficient technologies to reduce their carbon footprint.

The production and disposal of fluoropolymer coatings themselves also pose environmental challenges. While these coatings are highly durable and resistant to degradation, this very quality makes them persistent in the environment when improperly disposed of. Efforts are being made to develop more environmentally friendly fluoropolymer formulations and improve end-of-life recycling and disposal methods for coated products.

Despite these challenges, vacuum-assisted coating methods offer several environmental benefits compared to traditional coating techniques. The precision and efficiency of these methods often result in reduced material waste and improved coating performance, potentially extending the lifespan of coated products and reducing the need for frequent replacements. Additionally, the controlled environment provided by vacuum systems can allow for the use of more environmentally friendly coating formulations that might not be feasible with conventional application methods.

As environmental regulations become increasingly stringent, manufacturers are investing in research and development to further improve the sustainability of vacuum-assisted coating processes. This includes exploring alternative coating materials, developing more efficient vacuum pump technologies, and implementing closed-loop systems that minimize waste and emissions throughout the coating process.

One of the primary environmental concerns associated with vacuum-assisted coating methods is the potential release of volatile organic compounds (VOCs) and other hazardous air pollutants. During the coating process, these substances can be emitted into the atmosphere, contributing to air pollution and potentially harming human health and ecosystems. To mitigate this issue, many facilities have implemented advanced air filtration systems and VOC capture technologies, significantly reducing emissions and improving air quality in and around coating facilities.

Water consumption and wastewater management are also important environmental factors to consider. Vacuum-assisted coating processes often require water for cooling and cleaning purposes. The resulting wastewater may contain trace amounts of fluoropolymers, solvents, and other chemicals used in the coating process. Proper treatment and disposal of this wastewater are essential to prevent contamination of local water sources and ecosystems. Many companies have invested in on-site water treatment facilities and implemented water recycling programs to minimize their environmental footprint.

Energy consumption is another significant aspect of the environmental impact of vacuum-assisted coating methods. The operation of vacuum pumps and associated equipment requires substantial amounts of electricity, contributing to greenhouse gas emissions if sourced from non-renewable energy. To address this, some manufacturers have turned to renewable energy sources or implemented energy-efficient technologies to reduce their carbon footprint.

The production and disposal of fluoropolymer coatings themselves also pose environmental challenges. While these coatings are highly durable and resistant to degradation, this very quality makes them persistent in the environment when improperly disposed of. Efforts are being made to develop more environmentally friendly fluoropolymer formulations and improve end-of-life recycling and disposal methods for coated products.

Despite these challenges, vacuum-assisted coating methods offer several environmental benefits compared to traditional coating techniques. The precision and efficiency of these methods often result in reduced material waste and improved coating performance, potentially extending the lifespan of coated products and reducing the need for frequent replacements. Additionally, the controlled environment provided by vacuum systems can allow for the use of more environmentally friendly coating formulations that might not be feasible with conventional application methods.

As environmental regulations become increasingly stringent, manufacturers are investing in research and development to further improve the sustainability of vacuum-assisted coating processes. This includes exploring alternative coating materials, developing more efficient vacuum pump technologies, and implementing closed-loop systems that minimize waste and emissions throughout the coating process.

Cost-Benefit Analysis of Vacuum Pump Integration

The integration of vacuum pumps in the development of fluoropolymer coatings presents a complex cost-benefit scenario that requires careful analysis. On the cost side, the initial investment in high-quality vacuum pumps can be substantial, often representing a significant portion of the overall equipment budget for coating facilities. These pumps require specialized maintenance and occasional replacement of components, adding to the ongoing operational expenses. Additionally, the energy consumption of vacuum pumps contributes to utility costs, which can be considerable in large-scale production environments.

However, the benefits of incorporating vacuum pumps in fluoropolymer coating processes often outweigh these costs. Vacuum technology significantly enhances the quality and performance of the coatings by removing air and moisture from the application environment. This results in improved adhesion, reduced defects, and increased uniformity of the coating layer. The superior finish achieved through vacuum-assisted processes can command premium prices in the market, potentially offsetting the initial investment and ongoing costs.

From a production efficiency standpoint, vacuum pumps can accelerate the coating process by facilitating faster drying and curing times. This increased throughput allows manufacturers to handle larger volumes or more complex orders without expanding their physical footprint. The precision control offered by vacuum systems also reduces material waste, as less overspray and fewer rejected pieces are produced. Over time, these efficiency gains can translate into substantial cost savings and improved profitability.

In terms of product differentiation, the use of advanced vacuum technology in fluoropolymer coating applications can be a key selling point. It enables manufacturers to offer coatings with enhanced properties such as improved chemical resistance, better weatherability, and longer service life. These superior characteristics can justify higher prices and open up new market segments, particularly in industries with demanding performance requirements like aerospace, automotive, and high-end consumer goods.

When considering the long-term perspective, the investment in vacuum pump technology for fluoropolymer coatings can lead to reduced warranty claims and improved customer satisfaction. The enhanced durability and performance of vacuum-assisted coatings mean fewer product failures and returns, which not only saves on replacement costs but also strengthens brand reputation and customer loyalty. This positive feedback loop can result in increased market share and sustained business growth, further justifying the initial capital outlay and ongoing operational costs associated with vacuum pump integration.

However, the benefits of incorporating vacuum pumps in fluoropolymer coating processes often outweigh these costs. Vacuum technology significantly enhances the quality and performance of the coatings by removing air and moisture from the application environment. This results in improved adhesion, reduced defects, and increased uniformity of the coating layer. The superior finish achieved through vacuum-assisted processes can command premium prices in the market, potentially offsetting the initial investment and ongoing costs.

From a production efficiency standpoint, vacuum pumps can accelerate the coating process by facilitating faster drying and curing times. This increased throughput allows manufacturers to handle larger volumes or more complex orders without expanding their physical footprint. The precision control offered by vacuum systems also reduces material waste, as less overspray and fewer rejected pieces are produced. Over time, these efficiency gains can translate into substantial cost savings and improved profitability.

In terms of product differentiation, the use of advanced vacuum technology in fluoropolymer coating applications can be a key selling point. It enables manufacturers to offer coatings with enhanced properties such as improved chemical resistance, better weatherability, and longer service life. These superior characteristics can justify higher prices and open up new market segments, particularly in industries with demanding performance requirements like aerospace, automotive, and high-end consumer goods.

When considering the long-term perspective, the investment in vacuum pump technology for fluoropolymer coatings can lead to reduced warranty claims and improved customer satisfaction. The enhanced durability and performance of vacuum-assisted coatings mean fewer product failures and returns, which not only saves on replacement costs but also strengthens brand reputation and customer loyalty. This positive feedback loop can result in increased market share and sustained business growth, further justifying the initial capital outlay and ongoing operational costs associated with vacuum pump integration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!