Vacuum Pumps in Advanced Biomedical Imaging Systems

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vacuum Pump Evolution in Biomedical Imaging

The evolution of vacuum pumps in biomedical imaging systems has been a critical factor in advancing the capabilities and applications of medical imaging technologies. This progression can be traced through several key stages, each marked by significant technological improvements and expanding clinical applications.

In the early days of medical imaging, basic mechanical pumps were used primarily in X-ray systems to create the necessary vacuum conditions. These pumps were often noisy, inefficient, and required frequent maintenance. As imaging technologies advanced, particularly with the advent of computed tomography (CT) and magnetic resonance imaging (MRI) in the 1970s and 1980s, the demands on vacuum systems increased significantly.

The introduction of rotary vane pumps in the 1990s marked a significant leap forward. These pumps offered improved reliability, reduced noise levels, and enhanced vacuum performance, making them well-suited for the growing needs of advanced imaging modalities. This period also saw the integration of turbomolecular pumps in high-end imaging systems, providing ultra-high vacuum conditions necessary for certain specialized applications.

The early 2000s witnessed the emergence of dry pumps, which eliminated the need for oil in the pumping mechanism. This innovation addressed concerns about oil contamination and reduced maintenance requirements, making them particularly valuable in clean room environments and sensitive medical settings. Scroll pumps, a type of dry pump, gained popularity due to their compact size and low vibration characteristics.

In recent years, the focus has shifted towards developing more energy-efficient and environmentally friendly vacuum solutions. Multi-stage pumps combining different technologies have become increasingly common, offering optimized performance across various pressure ranges. Additionally, the integration of smart controls and IoT capabilities has enabled remote monitoring and predictive maintenance, enhancing the overall reliability and uptime of imaging systems.

The latest advancements in vacuum pump technology for biomedical imaging include the development of cryogenic pumps for ultra-low temperature applications, such as in superconducting magnets used in high-field MRI systems. These specialized pumps play a crucial role in maintaining the extreme cooling conditions necessary for these advanced imaging technologies.

Looking ahead, the evolution of vacuum pumps in biomedical imaging is likely to continue focusing on miniaturization, increased energy efficiency, and enhanced integration with imaging systems. As new imaging modalities emerge and existing ones become more sophisticated, vacuum pump technology will need to adapt to meet these evolving requirements, ensuring its continued importance in the field of medical diagnostics and research.

In the early days of medical imaging, basic mechanical pumps were used primarily in X-ray systems to create the necessary vacuum conditions. These pumps were often noisy, inefficient, and required frequent maintenance. As imaging technologies advanced, particularly with the advent of computed tomography (CT) and magnetic resonance imaging (MRI) in the 1970s and 1980s, the demands on vacuum systems increased significantly.

The introduction of rotary vane pumps in the 1990s marked a significant leap forward. These pumps offered improved reliability, reduced noise levels, and enhanced vacuum performance, making them well-suited for the growing needs of advanced imaging modalities. This period also saw the integration of turbomolecular pumps in high-end imaging systems, providing ultra-high vacuum conditions necessary for certain specialized applications.

The early 2000s witnessed the emergence of dry pumps, which eliminated the need for oil in the pumping mechanism. This innovation addressed concerns about oil contamination and reduced maintenance requirements, making them particularly valuable in clean room environments and sensitive medical settings. Scroll pumps, a type of dry pump, gained popularity due to their compact size and low vibration characteristics.

In recent years, the focus has shifted towards developing more energy-efficient and environmentally friendly vacuum solutions. Multi-stage pumps combining different technologies have become increasingly common, offering optimized performance across various pressure ranges. Additionally, the integration of smart controls and IoT capabilities has enabled remote monitoring and predictive maintenance, enhancing the overall reliability and uptime of imaging systems.

The latest advancements in vacuum pump technology for biomedical imaging include the development of cryogenic pumps for ultra-low temperature applications, such as in superconducting magnets used in high-field MRI systems. These specialized pumps play a crucial role in maintaining the extreme cooling conditions necessary for these advanced imaging technologies.

Looking ahead, the evolution of vacuum pumps in biomedical imaging is likely to continue focusing on miniaturization, increased energy efficiency, and enhanced integration with imaging systems. As new imaging modalities emerge and existing ones become more sophisticated, vacuum pump technology will need to adapt to meet these evolving requirements, ensuring its continued importance in the field of medical diagnostics and research.

Market Demand Analysis

The market demand for vacuum pumps in advanced biomedical imaging systems has been experiencing significant growth in recent years. This surge is primarily driven by the increasing adoption of sophisticated imaging technologies in healthcare facilities worldwide. As medical diagnostics become more advanced, the need for high-performance vacuum pumps to support these systems has become crucial.

The global biomedical imaging market, which heavily relies on vacuum pump technology, is projected to expand at a steady rate. This growth is fueled by factors such as the rising prevalence of chronic diseases, an aging population, and the continuous advancements in imaging technologies. Vacuum pumps play a critical role in maintaining the precise environmental conditions required for optimal performance of imaging equipment such as MRI machines, CT scanners, and electron microscopes.

In the field of magnetic resonance imaging (MRI), vacuum pumps are essential for maintaining the superconducting magnets at extremely low temperatures. The increasing number of MRI installations in hospitals and diagnostic centers worldwide is directly contributing to the demand for specialized vacuum pumps. Similarly, in electron microscopy, which is gaining prominence in both medical research and clinical diagnostics, high-performance vacuum pumps are indispensable for creating the ultra-high vacuum environment necessary for electron beam propagation.

The market demand is further bolstered by the trend towards miniaturization and portability in medical imaging devices. This shift requires vacuum pumps that are not only powerful but also compact and energy-efficient. Manufacturers are responding to this demand by developing innovative pump designs that offer improved performance in smaller form factors.

Another significant factor driving market growth is the increasing focus on preventive healthcare and early disease detection. Advanced imaging techniques enabled by high-quality vacuum pumps are playing a crucial role in early diagnosis and treatment planning. This trend is particularly evident in oncology, neurology, and cardiology, where precise imaging is paramount for accurate diagnosis and treatment.

Geographically, North America and Europe continue to be major markets for vacuum pumps in biomedical imaging systems, owing to their well-established healthcare infrastructure and high adoption rates of advanced medical technologies. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential, driven by increasing healthcare expenditure and improving access to advanced medical facilities.

The market demand is also influenced by regulatory standards and quality requirements in the healthcare sector. Vacuum pump manufacturers are increasingly focusing on developing products that meet stringent medical-grade specifications, ensuring reliability and safety in critical healthcare applications. This emphasis on quality and compliance is expected to further drive innovation and market growth in the coming years.

The global biomedical imaging market, which heavily relies on vacuum pump technology, is projected to expand at a steady rate. This growth is fueled by factors such as the rising prevalence of chronic diseases, an aging population, and the continuous advancements in imaging technologies. Vacuum pumps play a critical role in maintaining the precise environmental conditions required for optimal performance of imaging equipment such as MRI machines, CT scanners, and electron microscopes.

In the field of magnetic resonance imaging (MRI), vacuum pumps are essential for maintaining the superconducting magnets at extremely low temperatures. The increasing number of MRI installations in hospitals and diagnostic centers worldwide is directly contributing to the demand for specialized vacuum pumps. Similarly, in electron microscopy, which is gaining prominence in both medical research and clinical diagnostics, high-performance vacuum pumps are indispensable for creating the ultra-high vacuum environment necessary for electron beam propagation.

The market demand is further bolstered by the trend towards miniaturization and portability in medical imaging devices. This shift requires vacuum pumps that are not only powerful but also compact and energy-efficient. Manufacturers are responding to this demand by developing innovative pump designs that offer improved performance in smaller form factors.

Another significant factor driving market growth is the increasing focus on preventive healthcare and early disease detection. Advanced imaging techniques enabled by high-quality vacuum pumps are playing a crucial role in early diagnosis and treatment planning. This trend is particularly evident in oncology, neurology, and cardiology, where precise imaging is paramount for accurate diagnosis and treatment.

Geographically, North America and Europe continue to be major markets for vacuum pumps in biomedical imaging systems, owing to their well-established healthcare infrastructure and high adoption rates of advanced medical technologies. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential, driven by increasing healthcare expenditure and improving access to advanced medical facilities.

The market demand is also influenced by regulatory standards and quality requirements in the healthcare sector. Vacuum pump manufacturers are increasingly focusing on developing products that meet stringent medical-grade specifications, ensuring reliability and safety in critical healthcare applications. This emphasis on quality and compliance is expected to further drive innovation and market growth in the coming years.

Current Challenges

The integration of vacuum pumps in advanced biomedical imaging systems faces several significant challenges that hinder their optimal performance and widespread adoption. One of the primary issues is the need for ultra-high vacuum levels in certain imaging modalities, such as electron microscopy and mass spectrometry. Achieving and maintaining these extreme vacuum conditions consistently over extended periods remains a formidable task, often requiring complex multi-stage pumping systems.

Noise and vibration generated by vacuum pumps pose another critical challenge, particularly in sensitive imaging applications. These disturbances can significantly impact image quality and resolution, necessitating advanced isolation and damping techniques. The development of quieter, low-vibration pump technologies is an ongoing area of research and development in the field.

Size and portability constraints present additional hurdles for vacuum pump integration in biomedical imaging systems. As the trend towards more compact and mobile imaging devices continues, there is a growing demand for smaller, lighter vacuum pumps that can deliver comparable performance to their larger counterparts. This miniaturization effort often involves trade-offs between pump efficiency, vacuum levels, and power consumption.

Energy efficiency and heat management are also key concerns in vacuum pump design for biomedical imaging. High-performance pumps often consume substantial amounts of energy and generate significant heat, which can affect both the imaging system's overall efficiency and the sensitive biological samples being analyzed. Developing more energy-efficient pump technologies and improved cooling systems is crucial for addressing these issues.

Contamination control represents another major challenge, particularly in applications involving biological samples or clean room environments. Vacuum pumps must be designed to minimize the risk of sample contamination and maintain the cleanliness of the imaging environment. This often requires the use of specialized materials, filtration systems, and pump designs that prevent backstreaming of pump fluids or particulates.

The reliability and maintenance requirements of vacuum pumps in biomedical imaging systems also present ongoing challenges. Given the critical nature of many imaging applications in healthcare and research settings, pump failures or frequent maintenance needs can lead to significant downtime and disruption. Developing more robust, low-maintenance pump technologies and implementing predictive maintenance strategies are key areas of focus for addressing these reliability concerns.

Lastly, the integration of vacuum pumps with advanced control systems and software platforms poses both challenges and opportunities. There is a growing need for smart, networked pump systems that can provide real-time monitoring, diagnostics, and performance optimization. However, developing these integrated solutions requires overcoming issues related to data security, interoperability, and user interface design.

Noise and vibration generated by vacuum pumps pose another critical challenge, particularly in sensitive imaging applications. These disturbances can significantly impact image quality and resolution, necessitating advanced isolation and damping techniques. The development of quieter, low-vibration pump technologies is an ongoing area of research and development in the field.

Size and portability constraints present additional hurdles for vacuum pump integration in biomedical imaging systems. As the trend towards more compact and mobile imaging devices continues, there is a growing demand for smaller, lighter vacuum pumps that can deliver comparable performance to their larger counterparts. This miniaturization effort often involves trade-offs between pump efficiency, vacuum levels, and power consumption.

Energy efficiency and heat management are also key concerns in vacuum pump design for biomedical imaging. High-performance pumps often consume substantial amounts of energy and generate significant heat, which can affect both the imaging system's overall efficiency and the sensitive biological samples being analyzed. Developing more energy-efficient pump technologies and improved cooling systems is crucial for addressing these issues.

Contamination control represents another major challenge, particularly in applications involving biological samples or clean room environments. Vacuum pumps must be designed to minimize the risk of sample contamination and maintain the cleanliness of the imaging environment. This often requires the use of specialized materials, filtration systems, and pump designs that prevent backstreaming of pump fluids or particulates.

The reliability and maintenance requirements of vacuum pumps in biomedical imaging systems also present ongoing challenges. Given the critical nature of many imaging applications in healthcare and research settings, pump failures or frequent maintenance needs can lead to significant downtime and disruption. Developing more robust, low-maintenance pump technologies and implementing predictive maintenance strategies are key areas of focus for addressing these reliability concerns.

Lastly, the integration of vacuum pumps with advanced control systems and software platforms poses both challenges and opportunities. There is a growing need for smart, networked pump systems that can provide real-time monitoring, diagnostics, and performance optimization. However, developing these integrated solutions requires overcoming issues related to data security, interoperability, and user interface design.

Existing Vacuum Solutions

01 Improvements in vacuum pump design

Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.- Improvements in vacuum pump design: Various advancements in vacuum pump design have been made to enhance efficiency and performance. These improvements include modifications to pump components, optimized fluid flow paths, and innovative sealing mechanisms. Such enhancements contribute to increased pumping speed, better vacuum levels, and improved overall reliability.

- Specialized vacuum pumps for specific applications: Vacuum pumps have been developed for specific industrial and scientific applications. These specialized pumps are designed to meet unique requirements such as high vacuum levels, corrosive gas handling, or clean room compatibility. Custom features and materials are incorporated to ensure optimal performance in diverse operating conditions.

- Integration of vacuum pumps in semiconductor manufacturing: Vacuum pumps play a crucial role in semiconductor manufacturing processes. Innovations in this area focus on integrating pumps into complex fabrication systems, ensuring contamination-free environments, and maintaining precise vacuum levels. These advancements contribute to improved yield and quality in semiconductor production.

- Energy-efficient vacuum pump technologies: Efforts have been made to develop energy-efficient vacuum pump technologies. These innovations include improved motor designs, advanced control systems, and optimized pumping mechanisms. The focus is on reducing power consumption while maintaining or enhancing pump performance, contributing to overall energy savings in industrial processes.

- Vacuum pump maintenance and monitoring systems: Advancements in vacuum pump maintenance and monitoring systems have been developed to ensure optimal pump performance and longevity. These innovations include real-time condition monitoring, predictive maintenance algorithms, and automated diagnostic tools. Such systems help prevent unexpected failures, reduce downtime, and optimize maintenance schedules.

02 Specialized vacuum pumps for semiconductor manufacturing

Vacuum pumps tailored for semiconductor manufacturing processes have been developed. These pumps are designed to handle specific gases and maintain ultra-high vacuum levels required in semiconductor fabrication. Features may include corrosion-resistant materials, contamination control mechanisms, and integration with process control systems.Expand Specific Solutions03 Energy-efficient vacuum pump systems

Energy efficiency in vacuum pump systems has been a focus of recent innovations. These developments include variable speed drives, intelligent control systems, and heat recovery mechanisms. Such features help reduce power consumption, optimize pump performance based on demand, and improve overall system sustainability.Expand Specific Solutions04 Vacuum pump noise reduction techniques

Various methods have been implemented to reduce noise levels in vacuum pumps. These include acoustic enclosures, vibration isolation systems, and redesigned pump components to minimize noise generation. Such improvements contribute to a better working environment and compliance with noise regulations in industrial settings.Expand Specific Solutions05 Multi-stage and combination vacuum pump systems

Advanced vacuum systems incorporating multiple pump stages or combining different pump types have been developed. These systems can achieve higher vacuum levels, handle a wider range of pressure conditions, and offer improved pumping efficiency across various applications. Such configurations allow for optimized performance in complex vacuum processes.Expand Specific Solutions

Key Industry Players

The vacuum pump market in advanced biomedical imaging systems is in a growth phase, driven by increasing demand for high-resolution imaging technologies. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, the field is moderately mature but continues to evolve. Key players like Edwards Ltd., Pfeiffer Vacuum GmbH, and Leybold AG are leading innovation in this space, focusing on developing more efficient, compact, and noise-reduced vacuum pumps. These companies are investing in R&D to enhance pump performance and reliability, crucial for sensitive biomedical imaging applications. Emerging players such as MKS, Inc. and Agilent Technologies, Inc. are also making significant strides, introducing advanced vacuum solutions tailored for the biomedical sector.

Edwards Ltd.

Technical Solution: Edwards Ltd. has developed advanced vacuum pumps specifically designed for biomedical imaging systems. Their GXS dry screw vacuum pump series offers high pumping speeds and ultimate pressures suitable for MRI and CT scanners [1]. The pumps feature a unique screw mechanism that provides oil-free operation, crucial for maintaining clean environments in medical settings. Edwards has also introduced intelligent pump control systems that optimize performance and energy efficiency in imaging applications [2]. Their vacuum pumps incorporate advanced materials and coatings to resist corrosion from aggressive gases used in some imaging processes, ensuring long-term reliability and reduced maintenance needs [3].

Strengths: Oil-free operation, high pumping speeds, and intelligent control systems. Weaknesses: May be more expensive than traditional oil-sealed pumps, and require specialized maintenance.

Pfeiffer Vacuum GmbH

Technical Solution: Pfeiffer Vacuum has developed the HiPace turbomolecular pump series, which is particularly well-suited for advanced biomedical imaging systems. These pumps offer high compression ratios and pumping speeds, essential for maintaining the ultra-high vacuum conditions required in electron microscopy and mass spectrometry imaging [4]. Pfeiffer's pumps feature advanced rotor designs that minimize vibration, crucial for high-resolution imaging. They have also implemented hybrid bearing technology, combining ceramic ball bearings with magnetic levitation, to extend pump lifespan and reduce maintenance intervals [5]. Additionally, Pfeiffer has developed smart interfaces that allow seamless integration with imaging system controls, enabling real-time vacuum monitoring and adjustment [6].

Strengths: High compression ratios, low vibration, and smart integration capabilities. Weaknesses: Higher initial cost compared to conventional pumps, and may require specialized training for operation and maintenance.

Core Vacuum Technologies

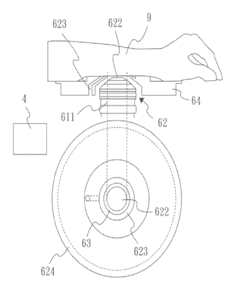

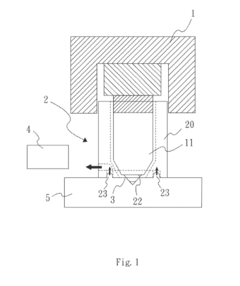

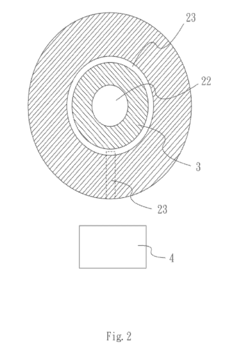

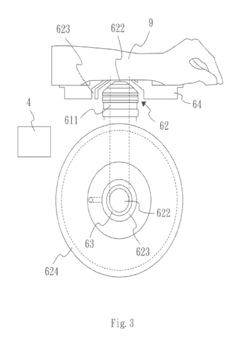

Vacuum-pump sucker

PatentActiveUS20120150042A1

Innovation

- The vacuum-pump sucker design stabilizes tissue for high-resolution microscopy, improving image stability and resolution in clinical optical virtual biopsy systems.

- The sucker body can removably receive or retrieve the focusing lens, allowing for flexibility in lens selection and maintenance.

- The vacuum-pump sucker enables accurate control of image depth, facilitating 3D imaging of living tissue.

Vacuum pump, vacuum pump set for evacuating a semiconductor processing chamber and method of evacuating a semiconductor processing chamber

PatentWO2021140329A1

Innovation

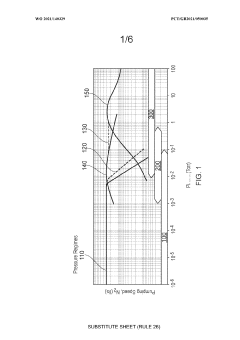

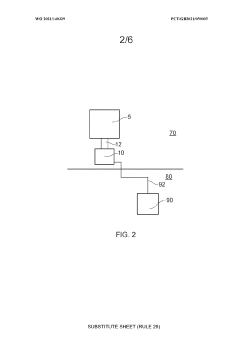

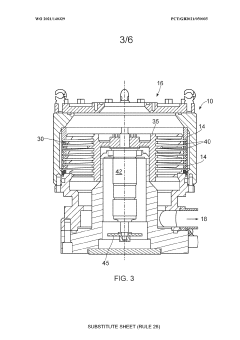

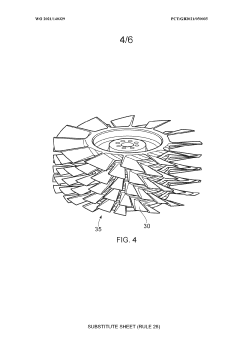

- A vacuum pump with a rotor and stator design featuring angled blades on a helical path, magnetically levitated bearings, and high transparency perforated elements, allowing effective pumping between 1 mbar and 5 × 10^2 mbar, backed by a roots blower for enhanced performance across the transitional flow regime.

Regulatory Compliance

Regulatory compliance is a critical aspect of developing and implementing vacuum pumps in advanced biomedical imaging systems. The use of these pumps in medical devices necessitates adherence to stringent regulations to ensure patient safety, device efficacy, and overall quality standards. In the United States, the Food and Drug Administration (FDA) oversees the regulation of medical devices, including those incorporating vacuum pump technology. Manufacturers must comply with the FDA's Quality System Regulation (QSR) and obtain premarket approval or clearance before introducing their products to the market.

The European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) also play significant roles in shaping the regulatory landscape for vacuum pumps in biomedical imaging systems. These regulations emphasize the importance of risk management, clinical evaluation, and post-market surveillance throughout the product lifecycle. Manufacturers must obtain CE marking to demonstrate compliance with these regulations before selling their products in the European market.

International standards such as ISO 13485 for medical device quality management systems and IEC 60601 for medical electrical equipment safety are essential for ensuring global regulatory compliance. These standards provide guidelines for design, manufacturing, and risk management processes, which are crucial for vacuum pump integration in biomedical imaging systems.

Specific to vacuum pumps, regulations often focus on noise levels, electromagnetic compatibility, and contamination control. The pumps must meet specified performance criteria while minimizing potential risks to patients and operators. This includes ensuring that the pumps do not introduce contaminants into the imaging environment or interfere with the operation of other medical equipment.

Regulatory bodies also require manufacturers to implement robust documentation and traceability systems. This includes maintaining detailed records of design processes, risk assessments, testing procedures, and any changes made to the device throughout its lifecycle. Such documentation is essential for demonstrating compliance during regulatory audits and inspections.

As technology advances, regulatory frameworks continue to evolve. Manufacturers must stay informed about changes in regulations and adapt their processes accordingly. This may involve ongoing training for staff, regular audits of quality management systems, and proactive engagement with regulatory bodies to ensure continued compliance.

In conclusion, regulatory compliance for vacuum pumps in advanced biomedical imaging systems is a complex and dynamic field. It requires a comprehensive approach that encompasses design, manufacturing, testing, and post-market surveillance. By adhering to these regulations, manufacturers can ensure the safety and efficacy of their products while maintaining market access in various global regions.

The European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) also play significant roles in shaping the regulatory landscape for vacuum pumps in biomedical imaging systems. These regulations emphasize the importance of risk management, clinical evaluation, and post-market surveillance throughout the product lifecycle. Manufacturers must obtain CE marking to demonstrate compliance with these regulations before selling their products in the European market.

International standards such as ISO 13485 for medical device quality management systems and IEC 60601 for medical electrical equipment safety are essential for ensuring global regulatory compliance. These standards provide guidelines for design, manufacturing, and risk management processes, which are crucial for vacuum pump integration in biomedical imaging systems.

Specific to vacuum pumps, regulations often focus on noise levels, electromagnetic compatibility, and contamination control. The pumps must meet specified performance criteria while minimizing potential risks to patients and operators. This includes ensuring that the pumps do not introduce contaminants into the imaging environment or interfere with the operation of other medical equipment.

Regulatory bodies also require manufacturers to implement robust documentation and traceability systems. This includes maintaining detailed records of design processes, risk assessments, testing procedures, and any changes made to the device throughout its lifecycle. Such documentation is essential for demonstrating compliance during regulatory audits and inspections.

As technology advances, regulatory frameworks continue to evolve. Manufacturers must stay informed about changes in regulations and adapt their processes accordingly. This may involve ongoing training for staff, regular audits of quality management systems, and proactive engagement with regulatory bodies to ensure continued compliance.

In conclusion, regulatory compliance for vacuum pumps in advanced biomedical imaging systems is a complex and dynamic field. It requires a comprehensive approach that encompasses design, manufacturing, testing, and post-market surveillance. By adhering to these regulations, manufacturers can ensure the safety and efficacy of their products while maintaining market access in various global regions.

Environmental Impact

The environmental impact of vacuum pumps in advanced biomedical imaging systems is a critical consideration in the development and deployment of these technologies. These pumps play a crucial role in maintaining the necessary vacuum conditions for various imaging modalities, such as electron microscopy and mass spectrometry. However, their operation can have significant environmental implications that need to be carefully addressed.

One of the primary environmental concerns associated with vacuum pumps is their energy consumption. These devices often require substantial power to operate continuously, contributing to the overall energy footprint of biomedical imaging facilities. The increased energy demand not only raises operational costs but also indirectly impacts carbon emissions if the energy source is not renewable. As a result, there is a growing emphasis on developing more energy-efficient vacuum pump technologies to mitigate these environmental effects.

Another important aspect is the use of working fluids in certain types of vacuum pumps, particularly oil-sealed rotary vane pumps. These fluids can potentially lead to environmental contamination if not properly managed. Leaks or improper disposal of used pump oil can result in soil and water pollution, posing risks to local ecosystems. Consequently, there is a trend towards the adoption of dry vacuum pumps that eliminate the need for working fluids, thereby reducing the potential for environmental contamination.

Noise pollution is an often-overlooked environmental impact of vacuum pumps in biomedical imaging systems. The continuous operation of these pumps can generate significant noise levels, affecting both the immediate working environment and potentially the surrounding areas. This issue is particularly relevant in urban settings where imaging facilities may be located near residential or other noise-sensitive areas. Efforts to develop quieter pump technologies and implement effective noise insulation measures are ongoing to address this concern.

The manufacturing and disposal of vacuum pumps also have environmental implications. The production process involves the use of various materials, some of which may be rare or environmentally sensitive. Additionally, the disposal of old or malfunctioning pumps at the end of their lifecycle can contribute to electronic waste if not properly managed. This has led to increased focus on designing pumps with more sustainable materials and implementing effective recycling programs for end-of-life equipment.

As the biomedical imaging field continues to advance, there is a growing emphasis on developing more environmentally friendly vacuum pump technologies. This includes research into novel pump designs that offer improved efficiency, reduced energy consumption, and minimized environmental impact. Additionally, the integration of smart control systems and predictive maintenance algorithms is being explored to optimize pump operation and extend equipment lifespan, further reducing the overall environmental footprint of these critical components in advanced biomedical imaging systems.

One of the primary environmental concerns associated with vacuum pumps is their energy consumption. These devices often require substantial power to operate continuously, contributing to the overall energy footprint of biomedical imaging facilities. The increased energy demand not only raises operational costs but also indirectly impacts carbon emissions if the energy source is not renewable. As a result, there is a growing emphasis on developing more energy-efficient vacuum pump technologies to mitigate these environmental effects.

Another important aspect is the use of working fluids in certain types of vacuum pumps, particularly oil-sealed rotary vane pumps. These fluids can potentially lead to environmental contamination if not properly managed. Leaks or improper disposal of used pump oil can result in soil and water pollution, posing risks to local ecosystems. Consequently, there is a trend towards the adoption of dry vacuum pumps that eliminate the need for working fluids, thereby reducing the potential for environmental contamination.

Noise pollution is an often-overlooked environmental impact of vacuum pumps in biomedical imaging systems. The continuous operation of these pumps can generate significant noise levels, affecting both the immediate working environment and potentially the surrounding areas. This issue is particularly relevant in urban settings where imaging facilities may be located near residential or other noise-sensitive areas. Efforts to develop quieter pump technologies and implement effective noise insulation measures are ongoing to address this concern.

The manufacturing and disposal of vacuum pumps also have environmental implications. The production process involves the use of various materials, some of which may be rare or environmentally sensitive. Additionally, the disposal of old or malfunctioning pumps at the end of their lifecycle can contribute to electronic waste if not properly managed. This has led to increased focus on designing pumps with more sustainable materials and implementing effective recycling programs for end-of-life equipment.

As the biomedical imaging field continues to advance, there is a growing emphasis on developing more environmentally friendly vacuum pump technologies. This includes research into novel pump designs that offer improved efficiency, reduced energy consumption, and minimized environmental impact. Additionally, the integration of smart control systems and predictive maintenance algorithms is being explored to optimize pump operation and extend equipment lifespan, further reducing the overall environmental footprint of these critical components in advanced biomedical imaging systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!