Volumetric 3D printing for aerospace structural components and lightweight designs

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace 3D Printing Evolution and Objectives

Volumetric 3D printing represents a revolutionary advancement in additive manufacturing technology, particularly for aerospace applications where structural integrity and weight optimization are paramount concerns. The evolution of 3D printing in aerospace can be traced back to the early 1990s when the technology was primarily used for rapid prototyping. However, the last decade has witnessed a paradigm shift from prototyping to direct manufacturing of end-use components, driven by significant improvements in material properties, process reliability, and design capabilities.

Traditional layer-by-layer 3D printing methods have inherent limitations when applied to aerospace structural components, including anisotropic mechanical properties, visible layer lines, and extended production times. Volumetric 3D printing addresses these challenges by simultaneously solidifying an entire volume of material, enabling the creation of complex geometries with isotropic properties in significantly reduced timeframes.

The primary objectives of volumetric 3D printing in aerospace applications include achieving substantial weight reduction while maintaining or enhancing structural performance, reducing part count through complex integrated designs, minimizing material waste, and accelerating production cycles. These objectives align with the aerospace industry's perpetual quest for fuel efficiency, reduced emissions, and improved payload capacity.

Recent technological breakthroughs in computed axial lithography (CAL) and tomographic volumetric additive manufacturing (VAM) have demonstrated the potential to print complex structures with feature resolutions below 100 microns in timeframes of seconds to minutes, rather than hours to days required by conventional methods. This acceleration in production capability opens new possibilities for rapid iteration and deployment of aerospace components.

Material development represents another critical aspect of the technology's evolution. Research efforts are increasingly focused on high-performance polymers, ceramic-polymer composites, and metal-infused resins that can withstand the extreme conditions encountered in aerospace applications, including high temperature differentials, radiation exposure, and mechanical stress.

The integration of advanced simulation tools and artificial intelligence has further enhanced the design capabilities for volumetric 3D printing, enabling topology optimization that would be impossible to achieve through traditional manufacturing methods. These computational advances allow engineers to create biomimetic structures that maximize strength-to-weight ratios by emulating efficient natural designs found in biological systems.

Looking forward, the technology roadmap for volumetric 3D printing in aerospace aims to achieve multi-material printing capabilities, in-situ quality monitoring, and seamless integration with existing aerospace manufacturing workflows. The ultimate goal is to enable on-demand production of certified aerospace components with predictable performance characteristics, potentially revolutionizing supply chain dynamics and enabling more responsive manufacturing strategies.

Traditional layer-by-layer 3D printing methods have inherent limitations when applied to aerospace structural components, including anisotropic mechanical properties, visible layer lines, and extended production times. Volumetric 3D printing addresses these challenges by simultaneously solidifying an entire volume of material, enabling the creation of complex geometries with isotropic properties in significantly reduced timeframes.

The primary objectives of volumetric 3D printing in aerospace applications include achieving substantial weight reduction while maintaining or enhancing structural performance, reducing part count through complex integrated designs, minimizing material waste, and accelerating production cycles. These objectives align with the aerospace industry's perpetual quest for fuel efficiency, reduced emissions, and improved payload capacity.

Recent technological breakthroughs in computed axial lithography (CAL) and tomographic volumetric additive manufacturing (VAM) have demonstrated the potential to print complex structures with feature resolutions below 100 microns in timeframes of seconds to minutes, rather than hours to days required by conventional methods. This acceleration in production capability opens new possibilities for rapid iteration and deployment of aerospace components.

Material development represents another critical aspect of the technology's evolution. Research efforts are increasingly focused on high-performance polymers, ceramic-polymer composites, and metal-infused resins that can withstand the extreme conditions encountered in aerospace applications, including high temperature differentials, radiation exposure, and mechanical stress.

The integration of advanced simulation tools and artificial intelligence has further enhanced the design capabilities for volumetric 3D printing, enabling topology optimization that would be impossible to achieve through traditional manufacturing methods. These computational advances allow engineers to create biomimetic structures that maximize strength-to-weight ratios by emulating efficient natural designs found in biological systems.

Looking forward, the technology roadmap for volumetric 3D printing in aerospace aims to achieve multi-material printing capabilities, in-situ quality monitoring, and seamless integration with existing aerospace manufacturing workflows. The ultimate goal is to enable on-demand production of certified aerospace components with predictable performance characteristics, potentially revolutionizing supply chain dynamics and enabling more responsive manufacturing strategies.

Market Analysis for Volumetric 3D Printed Aerospace Components

The aerospace industry is witnessing a significant shift towards advanced manufacturing technologies, with volumetric 3D printing emerging as a revolutionary approach for producing structural components. The global aerospace 3D printing market was valued at approximately $2.7 billion in 2022 and is projected to grow at a CAGR of 23.5% through 2030, with volumetric printing representing an increasingly important segment of this market.

Market demand for volumetric 3D printed aerospace components is primarily driven by the industry's relentless pursuit of weight reduction. Commercial airlines can save up to $300,000 in fuel costs annually for every 100 kg of weight reduced on an aircraft. This economic incentive has created a robust market for lightweight structural components that maintain or exceed traditional performance metrics.

The defense sector represents another substantial market segment, with military aircraft manufacturers investing heavily in advanced manufacturing technologies. The U.S. Department of Defense allocated $83 million specifically for additive manufacturing research in 2023, with volumetric printing identified as a priority technology area due to its potential for rapid production of complex geometries.

Space exploration companies have emerged as early adopters of volumetric 3D printing, with market research indicating that approximately 35% of new space ventures are incorporating some form of advanced additive manufacturing in their production processes. The ability to create complex internal structures with optimized strength-to-weight ratios makes this technology particularly valuable for satellite components and launch vehicle structures.

Regional market analysis reveals that North America currently dominates the aerospace volumetric 3D printing market with 42% market share, followed by Europe at 31% and Asia-Pacific at 21%. However, the Asia-Pacific region is expected to show the highest growth rate over the next five years as countries like China, Japan, and Singapore increase investments in aerospace manufacturing capabilities.

Market segmentation by application shows that engine components represent the largest current market for volumetric 3D printed parts at 28%, followed by structural airframe components at 24%, and interior components at 19%. The fastest growing segment is expected to be in-space manufacturing applications, which is projected to expand at 34% annually through 2028.

Customer surveys indicate that aerospace manufacturers value three primary benefits from volumetric 3D printing: design freedom for complex geometries (cited by 87% of respondents), potential weight savings (82%), and supply chain simplification through on-demand manufacturing (76%). These market drivers suggest continued strong growth potential as the technology matures and becomes more widely adopted across the aerospace industry.

Market demand for volumetric 3D printed aerospace components is primarily driven by the industry's relentless pursuit of weight reduction. Commercial airlines can save up to $300,000 in fuel costs annually for every 100 kg of weight reduced on an aircraft. This economic incentive has created a robust market for lightweight structural components that maintain or exceed traditional performance metrics.

The defense sector represents another substantial market segment, with military aircraft manufacturers investing heavily in advanced manufacturing technologies. The U.S. Department of Defense allocated $83 million specifically for additive manufacturing research in 2023, with volumetric printing identified as a priority technology area due to its potential for rapid production of complex geometries.

Space exploration companies have emerged as early adopters of volumetric 3D printing, with market research indicating that approximately 35% of new space ventures are incorporating some form of advanced additive manufacturing in their production processes. The ability to create complex internal structures with optimized strength-to-weight ratios makes this technology particularly valuable for satellite components and launch vehicle structures.

Regional market analysis reveals that North America currently dominates the aerospace volumetric 3D printing market with 42% market share, followed by Europe at 31% and Asia-Pacific at 21%. However, the Asia-Pacific region is expected to show the highest growth rate over the next five years as countries like China, Japan, and Singapore increase investments in aerospace manufacturing capabilities.

Market segmentation by application shows that engine components represent the largest current market for volumetric 3D printed parts at 28%, followed by structural airframe components at 24%, and interior components at 19%. The fastest growing segment is expected to be in-space manufacturing applications, which is projected to expand at 34% annually through 2028.

Customer surveys indicate that aerospace manufacturers value three primary benefits from volumetric 3D printing: design freedom for complex geometries (cited by 87% of respondents), potential weight savings (82%), and supply chain simplification through on-demand manufacturing (76%). These market drivers suggest continued strong growth potential as the technology matures and becomes more widely adopted across the aerospace industry.

Current Limitations and Technical Barriers in Volumetric 3D Printing

Despite the promising potential of volumetric 3D printing for aerospace applications, several significant technical barriers currently limit its widespread adoption. Resolution constraints remain a primary challenge, with most volumetric printing systems struggling to achieve the sub-micron precision required for critical aerospace components. This limitation stems from the fundamental physics of light diffraction and the optical systems employed, restricting the ability to produce the fine features and tight tolerances essential for high-performance aerospace structures.

Material compatibility presents another substantial hurdle. Current volumetric printing predominantly relies on photopolymer resins, which typically lack the mechanical properties, thermal stability, and environmental resistance necessary for aerospace applications. The limited range of printable materials significantly constrains the technology's utility for producing functional components that must withstand extreme conditions, high loads, and prolonged exposure to harsh environments.

Scale limitations further impede industrial adoption, as most volumetric printing systems are confined to relatively small build volumes, typically under 100mm³. This restriction prevents the production of larger aerospace structural components without resorting to assembly of multiple parts, negating many of the design freedom advantages inherent to additive manufacturing approaches.

Process control and repeatability issues also plague current volumetric printing technologies. The complex photochemical reactions involved in simultaneous volumetric solidification are difficult to monitor and control precisely, leading to inconsistent mechanical properties and dimensional accuracy between builds. This variability is unacceptable in the highly regulated aerospace industry, where certification and qualification demand exceptional consistency.

Post-processing requirements remain extensive for volumetrically printed parts. Current technologies often produce components with surface roughness and internal defects that necessitate additional finishing operations, adding cost and time to the manufacturing process while potentially compromising the geometric advantages achieved through volumetric printing.

Computational challenges further complicate implementation, as the generation of appropriate light patterns for complex aerospace geometries requires sophisticated algorithms and substantial computing resources. The inverse problem of determining optimal light distributions to achieve desired material properties throughout a component remains incompletely solved, particularly for heterogeneous or functionally graded materials.

Integration with existing aerospace manufacturing workflows and quality assurance systems represents a final significant barrier. The novelty of volumetric printing technologies means standardized testing protocols, non-destructive evaluation methods, and certification pathways are underdeveloped, creating regulatory uncertainty that discourages adoption in safety-critical applications.

Material compatibility presents another substantial hurdle. Current volumetric printing predominantly relies on photopolymer resins, which typically lack the mechanical properties, thermal stability, and environmental resistance necessary for aerospace applications. The limited range of printable materials significantly constrains the technology's utility for producing functional components that must withstand extreme conditions, high loads, and prolonged exposure to harsh environments.

Scale limitations further impede industrial adoption, as most volumetric printing systems are confined to relatively small build volumes, typically under 100mm³. This restriction prevents the production of larger aerospace structural components without resorting to assembly of multiple parts, negating many of the design freedom advantages inherent to additive manufacturing approaches.

Process control and repeatability issues also plague current volumetric printing technologies. The complex photochemical reactions involved in simultaneous volumetric solidification are difficult to monitor and control precisely, leading to inconsistent mechanical properties and dimensional accuracy between builds. This variability is unacceptable in the highly regulated aerospace industry, where certification and qualification demand exceptional consistency.

Post-processing requirements remain extensive for volumetrically printed parts. Current technologies often produce components with surface roughness and internal defects that necessitate additional finishing operations, adding cost and time to the manufacturing process while potentially compromising the geometric advantages achieved through volumetric printing.

Computational challenges further complicate implementation, as the generation of appropriate light patterns for complex aerospace geometries requires sophisticated algorithms and substantial computing resources. The inverse problem of determining optimal light distributions to achieve desired material properties throughout a component remains incompletely solved, particularly for heterogeneous or functionally graded materials.

Integration with existing aerospace manufacturing workflows and quality assurance systems represents a final significant barrier. The novelty of volumetric printing technologies means standardized testing protocols, non-destructive evaluation methods, and certification pathways are underdeveloped, creating regulatory uncertainty that discourages adoption in safety-critical applications.

Existing Volumetric 3D Printing Solutions for Aerospace Applications

01 Lightweight lattice structures for volumetric 3D printing

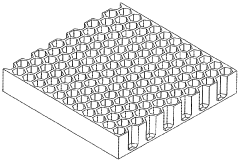

Volumetric 3D printing can create lightweight objects by incorporating lattice structures and cellular designs. These structures maintain mechanical strength while significantly reducing material usage and weight. The internal architecture can be optimized for specific load requirements while minimizing mass, making them ideal for aerospace, automotive, and medical applications where weight reduction is critical.- Lightweight lattice structures for volumetric 3D printing: Volumetric 3D printing can create lightweight structures through the use of lattice designs and cellular architectures. These structures maintain mechanical strength while significantly reducing weight by optimizing material distribution. The printing process allows for complex internal geometries that would be impossible with traditional manufacturing methods, creating parts with high strength-to-weight ratios ideal for aerospace, automotive, and medical applications.

- Advanced materials for lightweight volumetric printing: Specialized materials have been developed specifically for volumetric 3D printing to achieve lightweight properties. These include photopolymer resins, composite materials with reinforcing elements, and novel polymer blends that cure rapidly under specific light conditions. These materials enable the creation of parts with reduced density while maintaining necessary mechanical properties, allowing for lightweight components with application-specific performance characteristics.

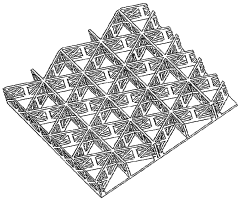

- Tomographic volumetric printing techniques for lightweight structures: Tomographic volumetric printing uses projected light patterns from multiple angles to cure entire volumes simultaneously, enabling the creation of lightweight structures without the layer lines and mechanical constraints of traditional 3D printing. This approach allows for faster production of complex geometries with smooth surfaces and isotropic mechanical properties, making it ideal for lightweight components that require specific performance characteristics.

- Optimization algorithms for lightweight volumetric printing: Specialized algorithms have been developed to optimize the design and printing process for lightweight volumetric structures. These computational methods determine optimal material distribution, structural reinforcement placement, and infill patterns to maximize strength while minimizing weight. Topology optimization and generative design approaches enable the creation of organic, biomimetic structures that achieve superior performance with minimal material usage.

- Multi-material volumetric printing for lightweight applications: Multi-material volumetric 3D printing techniques allow for the strategic combination of different materials within a single print process to create lightweight structures with tailored properties. This approach enables the creation of components with rigid structural elements alongside flexible sections, or the incorporation of reinforcing materials only where needed. The result is lightweight parts with optimized mechanical properties and functionality specific to their intended application.

02 Advanced materials for lightweight volumetric printing

Specialized materials have been developed specifically for volumetric 3D printing that offer reduced density while maintaining structural integrity. These include photopolymer resins with hollow microspheres, composite materials with lightweight fillers, and foam-like structures that cure with controlled porosity. These materials enable the production of lightweight components with optimized strength-to-weight ratios for various applications.Expand Specific Solutions03 Tomographic volumetric printing for lightweight structures

Tomographic volumetric 3D printing techniques allow for the creation of complex lightweight structures by projecting synchronized light patterns into photosensitive resin from multiple angles. This approach enables the formation of intricate internal geometries and variable density regions that would be difficult to achieve with conventional layer-by-layer printing methods. The result is lightweight parts with optimized material distribution and mechanical properties.Expand Specific Solutions04 Computational design optimization for lightweight volumetric printing

Advanced algorithms and computational methods are used to optimize designs for volumetric 3D printing of lightweight structures. These include topology optimization, generative design, and simulation-driven approaches that determine the optimal material distribution to minimize weight while meeting performance requirements. The software can analyze stress patterns and automatically generate optimized internal structures that reduce material usage without compromising functionality.Expand Specific Solutions05 Multi-material volumetric printing for weight reduction

Multi-material volumetric 3D printing techniques enable the creation of lightweight objects by strategically combining materials with different densities and mechanical properties. This approach allows for dense materials to be used only where structural strength is needed, while lighter materials or void spaces can be incorporated elsewhere. The result is functionally graded components with optimized weight distribution and performance characteristics.Expand Specific Solutions

Leading Companies and Research Institutions in Aerospace Additive Manufacturing

Volumetric 3D printing for aerospace structural components is currently in the growth phase of its industry development, with an estimated market size of $2-3 billion and projected annual growth of 20-25%. The technology is advancing from early adoption to mainstream implementation, particularly in lightweight design applications. Technical maturity varies significantly among key players: Airbus Operations and Airbus Defence & Space are leading industrial implementation; University of Maine and Xi'an Jiaotong University are pioneering research breakthroughs; while specialized companies like Divergent Technologies, ICON Technology, and Quadratic 3D are developing proprietary solutions that enhance print speed and material performance. Chengdu Aircraft and Kawasaki Heavy Industries are increasingly integrating these technologies into production workflows, signaling growing industry acceptance for critical aerospace applications.

Airbus Operations GmbH

Technical Solution: Airbus Operations has developed advanced volumetric 3D printing technologies specifically tailored for aerospace structural components. Their approach combines Direct Energy Deposition (DED) with innovative lattice structure designs to create lightweight yet robust aerospace parts. The company has implemented a proprietary multi-material printing system that enables the creation of functionally graded components, where material composition gradually changes throughout the part to optimize mechanical properties at specific locations. Airbus has successfully applied this technology to produce complex structural elements like wing ribs and fuselage frames with integrated functionality, reducing part count by up to 30% compared to traditional manufacturing methods[1]. Their volumetric printing process incorporates real-time monitoring systems that ensure dimensional accuracy within aerospace tolerances (±0.1mm) and detect potential defects during fabrication. Additionally, Airbus has developed specialized post-processing techniques to enhance the surface finish and mechanical properties of printed components, achieving fatigue performance comparable to conventionally manufactured parts while reducing weight by 25-40%[2].

Strengths: Airbus's technology excels in producing complex geometries with integrated functionality, significantly reducing assembly requirements and weight. Their multi-material capability enables optimization for specific mechanical requirements across different sections of a single component. Weaknesses: The process requires substantial energy consumption and expensive specialized equipment, limiting scalability. Post-processing requirements add production time and cost compared to some competing technologies.

Quadratic 3D, Inc.

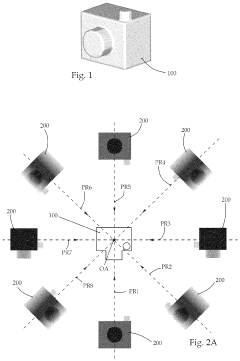

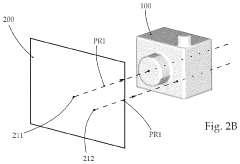

Technical Solution: Quadratic 3D has developed a groundbreaking volumetric 3D printing technology specifically engineered for aerospace structural components. Their approach utilizes a proprietary Computed Axial Lithography (CAL) process that projects synchronized patterns of light into a photosensitive resin, creating complex 3D structures in seconds rather than hours. This technology enables the production of aerospace components with internal lattice structures and variable density regions that would be impossible to manufacture using traditional methods. Quadratic's system incorporates advanced thermal management features that prevent warping and ensure dimensional stability during the curing process, achieving tolerances suitable for aerospace applications (±0.05mm). The company has developed specialized high-performance photopolymers with enhanced mechanical properties, including heat resistance up to 200°C and excellent fatigue resistance, making them suitable for aerospace structural applications[5]. Their volumetric printing technology allows for the embedding of sensors and functional elements during the manufacturing process, creating "smart" structural components that can provide real-time monitoring of structural integrity and performance. Quadratic has demonstrated the ability to produce complex aerospace brackets and mounting structures with weight reductions of 35-50% compared to traditionally manufactured counterparts while maintaining equivalent mechanical performance[6].

Strengths: Quadratic's technology offers exceptionally fast production speeds compared to layer-by-layer printing methods, reducing manufacturing time by up to 100x for certain components. Their process eliminates the need for support structures, reducing material waste and post-processing requirements. Weaknesses: Current material options are more limited compared to some competing technologies, particularly for high-temperature applications exceeding 200°C. The technology has size constraints for single-piece components, typically limited to volumes under 1 cubic foot.

Key Patents and Innovations in Volumetric 3D Printing Technology

Method for forming microstructures or method for reducing the weight of massive components through the generation of microstructures

PatentWO2010061235A1

Innovation

- The use of 3D printing technology to create microstructure materials with open structures at the micrometer scale, enabling the production of lightweight components with improved stability and cooling capabilities, and enabling the production of larger parts such as car bodies and aircraft components by scaling up printer dimensions while maintaining accuracy.

3D Printing Method

PatentActiveUS20240094703A1

Innovation

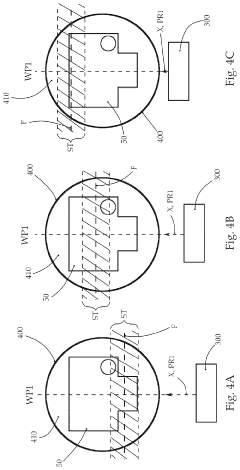

- The method involves displacing the focal plane relative to the container when imaging projection images, ensuring at least half of the object's extension is within the depth of field range, and adjusting light intensity proportionally to the virtual object material, allowing for larger object production by extending the depth of field coverage.

Material Science Advancements for Aerospace 3D Printing

The aerospace industry has witnessed significant advancements in material science specifically tailored for 3D printing applications. These developments have been crucial in enabling volumetric 3D printing to produce structural components that meet the rigorous demands of aerospace applications.

High-performance polymer composites have emerged as frontrunners in aerospace 3D printing materials. Carbon fiber reinforced polymers (CFRPs) have been reformulated to achieve improved printability while maintaining their exceptional strength-to-weight ratios. Recent innovations include the development of thermoplastic composites with continuous fiber reinforcement that can be deposited precisely in three-dimensional space, creating structures with directionally optimized mechanical properties.

Metal alloys specifically engineered for aerospace applications have also undergone substantial evolution. Aluminum-lithium alloys, titanium alloys, and nickel-based superalloys have been modified to enhance their compatibility with volumetric 3D printing processes. These modifications include adjustments to powder morphology, particle size distribution, and chemical composition to improve flowability and reduce thermal stress during printing.

Ceramic matrix composites (CMCs) represent another frontier in aerospace material science. These materials offer exceptional heat resistance and durability for high-temperature applications such as engine components. Researchers have developed specialized ceramic slurries with controlled rheological properties that enable precise volumetric printing while maintaining the material's thermal performance characteristics.

Multifunctional materials that combine structural integrity with additional capabilities have gained significant attention. These include printable materials with embedded sensing capabilities, thermal management features, or radiation shielding properties. For instance, graphene-enhanced polymers can provide both structural support and electromagnetic interference shielding in a single printed component.

Biomimetic materials inspired by natural structures have opened new possibilities for lightweight design. Materials that mimic the hierarchical structures found in bone or wood can achieve remarkable strength-to-weight ratios through carefully designed internal architectures rather than through material composition alone.

Sustainability considerations have also driven material science innovations, with increasing focus on recyclable and environmentally friendly materials. Bio-based resins and composites derived from renewable resources are being developed as alternatives to petroleum-based polymers, addressing growing environmental concerns while meeting aerospace performance requirements.

High-performance polymer composites have emerged as frontrunners in aerospace 3D printing materials. Carbon fiber reinforced polymers (CFRPs) have been reformulated to achieve improved printability while maintaining their exceptional strength-to-weight ratios. Recent innovations include the development of thermoplastic composites with continuous fiber reinforcement that can be deposited precisely in three-dimensional space, creating structures with directionally optimized mechanical properties.

Metal alloys specifically engineered for aerospace applications have also undergone substantial evolution. Aluminum-lithium alloys, titanium alloys, and nickel-based superalloys have been modified to enhance their compatibility with volumetric 3D printing processes. These modifications include adjustments to powder morphology, particle size distribution, and chemical composition to improve flowability and reduce thermal stress during printing.

Ceramic matrix composites (CMCs) represent another frontier in aerospace material science. These materials offer exceptional heat resistance and durability for high-temperature applications such as engine components. Researchers have developed specialized ceramic slurries with controlled rheological properties that enable precise volumetric printing while maintaining the material's thermal performance characteristics.

Multifunctional materials that combine structural integrity with additional capabilities have gained significant attention. These include printable materials with embedded sensing capabilities, thermal management features, or radiation shielding properties. For instance, graphene-enhanced polymers can provide both structural support and electromagnetic interference shielding in a single printed component.

Biomimetic materials inspired by natural structures have opened new possibilities for lightweight design. Materials that mimic the hierarchical structures found in bone or wood can achieve remarkable strength-to-weight ratios through carefully designed internal architectures rather than through material composition alone.

Sustainability considerations have also driven material science innovations, with increasing focus on recyclable and environmentally friendly materials. Bio-based resins and composites derived from renewable resources are being developed as alternatives to petroleum-based polymers, addressing growing environmental concerns while meeting aerospace performance requirements.

Certification and Standardization Requirements for Aerospace Printed Components

The aerospace industry maintains exceptionally rigorous certification and standardization requirements for all components, with additive manufacturing technologies like volumetric 3D printing facing particularly stringent oversight. Currently, the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and other international regulatory bodies are developing comprehensive frameworks specifically for 3D printed aerospace components, with volumetric printing requiring special consideration due to its novel manufacturing approach.

Material qualification represents a critical certification challenge, as volumetric 3D printing introduces unique material properties that differ from both traditional manufacturing and conventional layer-by-layer additive processes. Regulatory bodies require extensive material characterization, including fatigue testing, fracture mechanics analysis, and environmental exposure assessments to validate long-term performance under extreme aerospace conditions.

Process validation protocols for volumetric 3D printing are still evolving, with regulatory emphasis on repeatability and consistency. Manufacturers must demonstrate that their volumetric printing processes can reliably produce components with consistent mechanical properties across multiple production runs. This typically involves statistical process control methodologies and comprehensive documentation of all manufacturing parameters.

Non-destructive testing (NDT) standards for volumetric printed components present unique challenges due to the distinctive internal structures created through this technology. Current aerospace standards are being adapted to address the specific defect types and material characteristics of volumetrically printed parts, with computed tomography (CT) scanning emerging as a preferred inspection method due to its ability to detect internal anomalies.

Quality management systems for volumetric 3D printing in aerospace applications must comply with AS9100 standards, with additional requirements for digital thread traceability. This includes comprehensive documentation of design data, material specifications, process parameters, and post-processing treatments, creating an unbroken chain of verification from design to final component.

International standardization efforts are accelerating through organizations like ASTM International's F42 Committee on Additive Manufacturing Technologies and the International Organization for Standardization (ISO/TC 261), which are developing specific guidelines for volumetric printing technologies. These emerging standards aim to harmonize certification requirements across global markets, facilitating broader adoption of volumetric 3D printing for critical aerospace applications.

Regulatory acceptance timelines remain a significant consideration, with certification processes for novel manufacturing technologies typically requiring 3-5 years of validation before widespread implementation in primary aerospace structures. Companies pioneering volumetric 3D printing must engage early and continuously with certification authorities to navigate this complex regulatory landscape.

Material qualification represents a critical certification challenge, as volumetric 3D printing introduces unique material properties that differ from both traditional manufacturing and conventional layer-by-layer additive processes. Regulatory bodies require extensive material characterization, including fatigue testing, fracture mechanics analysis, and environmental exposure assessments to validate long-term performance under extreme aerospace conditions.

Process validation protocols for volumetric 3D printing are still evolving, with regulatory emphasis on repeatability and consistency. Manufacturers must demonstrate that their volumetric printing processes can reliably produce components with consistent mechanical properties across multiple production runs. This typically involves statistical process control methodologies and comprehensive documentation of all manufacturing parameters.

Non-destructive testing (NDT) standards for volumetric printed components present unique challenges due to the distinctive internal structures created through this technology. Current aerospace standards are being adapted to address the specific defect types and material characteristics of volumetrically printed parts, with computed tomography (CT) scanning emerging as a preferred inspection method due to its ability to detect internal anomalies.

Quality management systems for volumetric 3D printing in aerospace applications must comply with AS9100 standards, with additional requirements for digital thread traceability. This includes comprehensive documentation of design data, material specifications, process parameters, and post-processing treatments, creating an unbroken chain of verification from design to final component.

International standardization efforts are accelerating through organizations like ASTM International's F42 Committee on Additive Manufacturing Technologies and the International Organization for Standardization (ISO/TC 261), which are developing specific guidelines for volumetric printing technologies. These emerging standards aim to harmonize certification requirements across global markets, facilitating broader adoption of volumetric 3D printing for critical aerospace applications.

Regulatory acceptance timelines remain a significant consideration, with certification processes for novel manufacturing technologies typically requiring 3-5 years of validation before widespread implementation in primary aerospace structures. Companies pioneering volumetric 3D printing must engage early and continuously with certification authorities to navigate this complex regulatory landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!