Wankel Engine Customization for Niche Markets

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Customization Objectives

The Wankel rotary engine, first conceptualized by Felix Wankel in the 1920s and developed into a working prototype by 1957, represents a significant departure from conventional reciprocating piston engines. Its evolution has been marked by periods of both enthusiasm and skepticism within the automotive industry. Initially celebrated for its compact design, smooth operation, and high power-to-weight ratio, the Wankel engine gained prominence when NSU and later Mazda adopted it for production vehicles in the 1960s and 1970s.

The technology reached its commercial zenith with Mazda's RX series, particularly the RX-7 and RX-8 sports cars, which demonstrated the engine's capability to deliver exceptional performance in specialized applications. However, widespread adoption has been hindered by persistent challenges including apex seal durability, higher fuel consumption, and emissions concerns that became increasingly problematic as environmental regulations tightened globally.

Recent technological advancements have revitalized interest in Wankel engines for niche applications. Improvements in materials science, particularly in ceramic composites and advanced metallurgy, have addressed some historical durability issues. Computational fluid dynamics and precision manufacturing techniques have enabled more efficient combustion chamber designs, reducing the traditional fuel efficiency gap compared to conventional engines.

The primary objective of Wankel engine customization for niche markets is to leverage its inherent advantages while mitigating known limitations through application-specific engineering. For aviation applications, the focus is on maximizing the power-to-weight ratio and operational reliability at constant speeds. In marine environments, customization aims at corrosion resistance and adaptability to variable load conditions. For specialized automotive applications such as range extenders in hybrid electric vehicles, the emphasis shifts to optimizing fuel efficiency at specific operating points.

Another critical customization objective involves addressing emissions challenges through innovative approaches such as hydrogen adaptation, which eliminates hydrocarbon emissions while maintaining the rotary engine's core benefits. For motorsport applications, customization targets include maximizing power output and thermal efficiency while ensuring durability under extreme operating conditions.

The technological roadmap for Wankel customization encompasses several parallel development paths: advanced materials research for improved seal durability, combustion optimization through direct injection and variable geometry intake systems, and integration with hybrid powertrains to complement electric propulsion systems. Each path requires tailored solutions based on the specific requirements of target niche markets rather than pursuing a one-size-fits-all approach that has historically limited the engine's broader adoption.

The technology reached its commercial zenith with Mazda's RX series, particularly the RX-7 and RX-8 sports cars, which demonstrated the engine's capability to deliver exceptional performance in specialized applications. However, widespread adoption has been hindered by persistent challenges including apex seal durability, higher fuel consumption, and emissions concerns that became increasingly problematic as environmental regulations tightened globally.

Recent technological advancements have revitalized interest in Wankel engines for niche applications. Improvements in materials science, particularly in ceramic composites and advanced metallurgy, have addressed some historical durability issues. Computational fluid dynamics and precision manufacturing techniques have enabled more efficient combustion chamber designs, reducing the traditional fuel efficiency gap compared to conventional engines.

The primary objective of Wankel engine customization for niche markets is to leverage its inherent advantages while mitigating known limitations through application-specific engineering. For aviation applications, the focus is on maximizing the power-to-weight ratio and operational reliability at constant speeds. In marine environments, customization aims at corrosion resistance and adaptability to variable load conditions. For specialized automotive applications such as range extenders in hybrid electric vehicles, the emphasis shifts to optimizing fuel efficiency at specific operating points.

Another critical customization objective involves addressing emissions challenges through innovative approaches such as hydrogen adaptation, which eliminates hydrocarbon emissions while maintaining the rotary engine's core benefits. For motorsport applications, customization targets include maximizing power output and thermal efficiency while ensuring durability under extreme operating conditions.

The technological roadmap for Wankel customization encompasses several parallel development paths: advanced materials research for improved seal durability, combustion optimization through direct injection and variable geometry intake systems, and integration with hybrid powertrains to complement electric propulsion systems. Each path requires tailored solutions based on the specific requirements of target niche markets rather than pursuing a one-size-fits-all approach that has historically limited the engine's broader adoption.

Niche Market Demand Analysis for Rotary Engines

The rotary engine market has experienced significant shifts over the past decade, transitioning from mainstream automotive applications to specialized niche markets. Current market analysis indicates growing demand in several key sectors where the Wankel engine's unique characteristics provide competitive advantages over conventional piston engines.

Aviation represents one of the most promising growth segments, particularly in the ultralight and light sport aircraft categories. The rotary engine's exceptional power-to-weight ratio (typically 20-30% better than comparable piston engines) addresses the critical need for lightweight propulsion systems. Market research shows the global ultralight aircraft segment growing at approximately 7% annually, with rotary engines capturing an increasing share due to their compact design and reduced vibration characteristics.

The unmanned aerial vehicle (UAV) sector presents another substantial opportunity. Commercial and military drone applications require reliable, lightweight power sources with minimal vibration signatures. The rotary engine's smooth operation provides significant advantages for sensor platforms and surveillance equipment. This market segment is projected to expand rapidly as regulatory frameworks for commercial drone operations mature across global markets.

Marine applications constitute a third significant niche, particularly in personal watercraft and small recreational boats. The compact form factor of Wankel engines allows for innovative hull designs and improved weight distribution. Additionally, the rotary engine's inherent resistance to water ingestion compared to traditional marine engines provides a compelling selling point for manufacturers targeting premium recreational markets.

Racing and motorsport applications continue to demonstrate steady demand for customized rotary engines. Despite their retreat from mainstream production vehicles, rotary engines maintain a dedicated following in competitive motorsports due to their high-revving capability and power density. Specialized racing series and drift competitions showcase the continued relevance of rotary technology in performance applications.

Generator sets and auxiliary power units represent an emerging application area with substantial growth potential. The rotary engine's compact size, low vibration, and ability to run on multiple fuel types make it ideal for portable power generation in remote locations, emergency services, and military applications. This versatility addresses growing market demand for flexible power solutions in increasingly unpredictable operational environments.

Market research indicates that customers in these niche segments are willing to pay premium prices for the specific advantages rotary engines offer, with price sensitivity significantly lower than in mainstream automotive markets. This premium positioning creates opportunities for specialized manufacturing approaches and customization services that would be economically unfeasible in mass-market applications.

Aviation represents one of the most promising growth segments, particularly in the ultralight and light sport aircraft categories. The rotary engine's exceptional power-to-weight ratio (typically 20-30% better than comparable piston engines) addresses the critical need for lightweight propulsion systems. Market research shows the global ultralight aircraft segment growing at approximately 7% annually, with rotary engines capturing an increasing share due to their compact design and reduced vibration characteristics.

The unmanned aerial vehicle (UAV) sector presents another substantial opportunity. Commercial and military drone applications require reliable, lightweight power sources with minimal vibration signatures. The rotary engine's smooth operation provides significant advantages for sensor platforms and surveillance equipment. This market segment is projected to expand rapidly as regulatory frameworks for commercial drone operations mature across global markets.

Marine applications constitute a third significant niche, particularly in personal watercraft and small recreational boats. The compact form factor of Wankel engines allows for innovative hull designs and improved weight distribution. Additionally, the rotary engine's inherent resistance to water ingestion compared to traditional marine engines provides a compelling selling point for manufacturers targeting premium recreational markets.

Racing and motorsport applications continue to demonstrate steady demand for customized rotary engines. Despite their retreat from mainstream production vehicles, rotary engines maintain a dedicated following in competitive motorsports due to their high-revving capability and power density. Specialized racing series and drift competitions showcase the continued relevance of rotary technology in performance applications.

Generator sets and auxiliary power units represent an emerging application area with substantial growth potential. The rotary engine's compact size, low vibration, and ability to run on multiple fuel types make it ideal for portable power generation in remote locations, emergency services, and military applications. This versatility addresses growing market demand for flexible power solutions in increasingly unpredictable operational environments.

Market research indicates that customers in these niche segments are willing to pay premium prices for the specific advantages rotary engines offer, with price sensitivity significantly lower than in mainstream automotive markets. This premium positioning creates opportunities for specialized manufacturing approaches and customization services that would be economically unfeasible in mass-market applications.

Technical Challenges and Global Development Status

The Wankel rotary engine, despite its innovative design and theoretical advantages, faces significant technical challenges that have limited its widespread adoption. The primary obstacle remains the sealing system at the apexes of the rotor, where the combination of high temperatures and mechanical stress leads to accelerated wear and reduced longevity. This fundamental issue has persisted since Felix Wankel's original design, with incremental improvements failing to fully resolve the problem. Additionally, the engine's inherently high fuel consumption and emissions profile have become increasingly problematic in an era of stringent environmental regulations.

Oil consumption represents another persistent challenge, as the design necessitates oil injection into the combustion chamber for apex seal lubrication, resulting in higher hydrocarbon emissions and reduced efficiency. The thermal management of the rotary engine presents unique difficulties due to the concentrated heat generation in specific areas of the housing, creating thermal distortion that further compromises seal integrity.

Globally, rotary engine development has experienced significant geographical concentration. Japan, particularly through Mazda's sustained investment, has emerged as the epicenter of rotary technology advancement. Mazda's commitment culminated in the RX-8's RENESIS engine, which addressed many traditional rotary shortcomings before production ceased in 2012. Recently, Mazda has pivoted to developing rotary engines as range extenders for electric vehicles, launching the MX-30 R-EV in 2023.

In Europe, development has been sporadic, with historical contributions from NSU in Germany and more recent niche applications in aviation and motorsport. Companies like AIE in the UK have focused on advanced rotary designs for UAVs and portable power systems. North American development has largely shifted to specialized applications after earlier automotive experiments by General Motors and American Motors Corporation were abandoned.

The Asia-Pacific region beyond Japan has seen emerging interest, with Chinese and South Korean firms exploring rotary technology for specific applications like drone propulsion and compact generators. Australia has maintained a presence in rotary development through specialized engineering firms focused on motorsport applications.

For niche market customization, these technical challenges present both obstacles and opportunities. The compact size, smooth operation, and high power-to-weight ratio of Wankel engines make them attractive for specialized applications despite their limitations. Recent technological advances in materials science, particularly ceramic composites and advanced coatings, offer promising pathways to address the persistent sealing and durability issues.

Oil consumption represents another persistent challenge, as the design necessitates oil injection into the combustion chamber for apex seal lubrication, resulting in higher hydrocarbon emissions and reduced efficiency. The thermal management of the rotary engine presents unique difficulties due to the concentrated heat generation in specific areas of the housing, creating thermal distortion that further compromises seal integrity.

Globally, rotary engine development has experienced significant geographical concentration. Japan, particularly through Mazda's sustained investment, has emerged as the epicenter of rotary technology advancement. Mazda's commitment culminated in the RX-8's RENESIS engine, which addressed many traditional rotary shortcomings before production ceased in 2012. Recently, Mazda has pivoted to developing rotary engines as range extenders for electric vehicles, launching the MX-30 R-EV in 2023.

In Europe, development has been sporadic, with historical contributions from NSU in Germany and more recent niche applications in aviation and motorsport. Companies like AIE in the UK have focused on advanced rotary designs for UAVs and portable power systems. North American development has largely shifted to specialized applications after earlier automotive experiments by General Motors and American Motors Corporation were abandoned.

The Asia-Pacific region beyond Japan has seen emerging interest, with Chinese and South Korean firms exploring rotary technology for specific applications like drone propulsion and compact generators. Australia has maintained a presence in rotary development through specialized engineering firms focused on motorsport applications.

For niche market customization, these technical challenges present both obstacles and opportunities. The compact size, smooth operation, and high power-to-weight ratio of Wankel engines make them attractive for specialized applications despite their limitations. Recent technological advances in materials science, particularly ceramic composites and advanced coatings, offer promising pathways to address the persistent sealing and durability issues.

Current Customization Approaches and Solutions

01 Wankel Engine Design and Structure

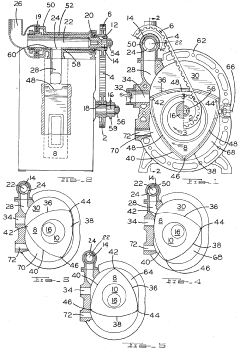

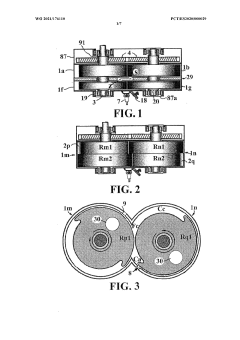

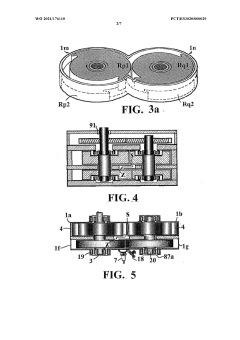

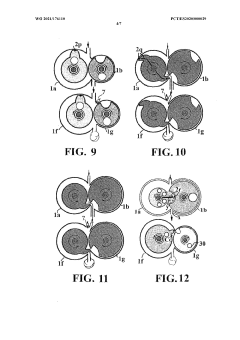

The Wankel engine features a unique rotary design with a triangular rotor that revolves within an epitrochoidal housing. This design eliminates the need for conventional reciprocating pistons, resulting in fewer moving parts and smoother operation. The engine's structure includes specific components such as eccentric shafts, rotor housings, and sealing systems that are critical to its functionality and performance.- Wankel Engine Design and Structure: The Wankel engine features a unique rotary design with a triangular rotor that revolves inside an epitrochoid-shaped housing. This design eliminates the need for conventional pistons, connecting rods, and crankshafts found in reciprocating engines. The rotor's movement creates expanding and contracting chambers that perform the four-stroke cycle (intake, compression, combustion, and exhaust) in a continuous motion, resulting in smoother operation and higher power-to-weight ratio compared to traditional piston engines.

- Sealing Systems for Wankel Engines: Effective sealing is critical in Wankel engines to maintain compression and prevent gas leakage between the chambers. Advanced sealing systems include apex seals at the rotor corners, side seals along the rotor faces, and oil seals to manage lubrication. These sealing components are typically made from specialized materials such as carbon compounds, ceramic composites, or high-temperature alloys to withstand the extreme conditions of temperature and pressure while minimizing friction and wear.

- Cooling and Lubrication Systems: Wankel engines require specialized cooling and lubrication systems due to their unique geometry and operating characteristics. Cooling systems often incorporate liquid cooling channels within the housing to manage the uneven heat distribution characteristic of rotary engines. Lubrication systems typically use oil injection methods to deliver lubricant directly to critical components such as apex seals and bearings. These systems are crucial for preventing overheating and ensuring longevity of the engine components under high-speed operation.

- Emissions Control and Efficiency Improvements: Modern Wankel engine designs incorporate various technologies to address traditional challenges with emissions and fuel efficiency. These include advanced fuel injection systems, improved combustion chamber designs, and integration with hybrid or electric systems. Some innovations focus on optimizing the rotor geometry and housing shape to enhance thermal efficiency and reduce unburned hydrocarbon emissions. Other approaches include variable compression ratio mechanisms and stratified charge combustion systems to improve overall environmental performance.

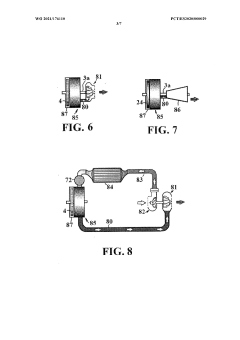

- Applications and Specialized Implementations: Wankel engines find applications across various industries due to their compact size, high power density, and smooth operation. They are used in automotive applications, aircraft engines, marine propulsion, and portable power generators. Specialized implementations include multi-rotor configurations for increased power output, miniaturized versions for unmanned aerial vehicles, and adaptations for alternative fuels such as hydrogen. Recent developments also explore integration with electric systems in hybrid powertrains to leverage the rotary engine's advantages while mitigating its traditional limitations.

02 Sealing Systems for Wankel Engines

Effective sealing is crucial for Wankel engine performance. Various sealing technologies have been developed to address the challenges of maintaining compression between the rotor and housing. These include apex seals at the rotor corners, side seals along the rotor faces, and oil seals to prevent lubricant leakage. Advanced materials and designs for these sealing components help improve engine efficiency, reduce emissions, and extend operational life.Expand Specific Solutions03 Cooling and Lubrication Systems

Wankel engines require specialized cooling and lubrication systems due to their unique geometry and operating characteristics. Innovative cooling methods address the uneven heat distribution across the housing, while specialized lubrication systems ensure proper oil delivery to critical components like apex seals and bearings. These systems are essential for preventing overheating, reducing wear, and maintaining optimal performance under various operating conditions.Expand Specific Solutions04 Emissions Control and Efficiency Improvements

Modern Wankel engine developments focus on addressing traditional challenges related to emissions and fuel efficiency. Innovations include modified combustion chamber designs, advanced fuel injection systems, and integration with hybrid powertrains. These improvements aim to reduce hydrocarbon emissions, improve thermal efficiency, and meet increasingly stringent environmental regulations while maintaining the inherent advantages of rotary engine design.Expand Specific Solutions05 Applications and Specialized Implementations

Wankel engines find applications across various industries due to their compact size, high power-to-weight ratio, and smooth operation. They are utilized in automotive applications, aircraft engines, marine propulsion, and as range extenders in electric vehicles. Specialized implementations include multi-rotor configurations, variable compression designs, and integration with alternative fuels to address specific operational requirements in different sectors.Expand Specific Solutions

Key Manufacturers and Competitive Landscape

The Wankel engine customization market for niche applications is in a growth phase, characterized by specialized development rather than mass adoption. The market size remains relatively modest but shows potential in sectors requiring compact, high-power-to-weight ratio engines. Technologically, the field demonstrates varying maturity levels across players. Research institutions like Chongqing University and Beihang University are advancing theoretical foundations, while automotive manufacturers including Zhejiang Geely, SAIC GM Wuling, and Chery Automobile focus on practical applications. Specialized companies such as Warn Industries and MTU Detroit Diesel bring expertise in adapting Wankel technology for specific use cases. The competitive landscape reveals a blend of academic research, automotive industry adaptation, and specialized engineering firms working to overcome traditional Wankel limitations for targeted niche applications.

Guangxi Yuchai Machinery Co., Ltd.

Technical Solution: Yuchai has developed an innovative Wankel engine platform specifically for distributed power generation and specialized industrial applications. Their approach focuses on fuel flexibility and durability in continuous operation scenarios. The company has engineered a multi-fuel capable Wankel design that can efficiently operate on natural gas, propane, biogas, and liquid fuels without significant modifications. Their rotor housing design incorporates advanced thermal management with strategic cooling channels and heat-resistant alloys to maintain dimensional stability during extended operation. Yuchai's apex seal technology utilizes a self-adjusting mechanism that compensates for wear over time, significantly extending service intervals. The combustion control system features real-time monitoring with adaptive algorithms that optimize performance based on fuel quality and load demands. Their modular design approach allows for easy scaling and customization for different power requirements, making it adaptable to various niche applications from backup power generation to specialized industrial equipment.

Strengths: Exceptional fuel flexibility making it ideal for applications where fuel availability varies; compact footprint allows installation in space-constrained environments. Weaknesses: Higher manufacturing complexity compared to conventional generators; requires specialized technical expertise for optimal maintenance and operation.

Ford Global Technologies LLC

Technical Solution: Ford has developed a hybrid Wankel engine system specifically for niche markets that combines the compact rotary design with electric propulsion. Their approach focuses on using the Wankel engine as a range extender in hybrid vehicles, leveraging its high power-to-weight ratio and compact size. The system incorporates advanced materials for apex seals, including silicon nitride and carbon-based composites, to address traditional wear issues. Ford's customization includes variable rotor geometry that can be adjusted based on performance requirements, allowing for optimization across different niche applications from marine to specialized utility vehicles. Their proprietary cooling system addresses the thermal management challenges inherent to Wankel designs, using targeted oil jets and advanced thermal barrier coatings to maintain optimal operating temperatures.

Strengths: Exceptional power-to-weight ratio making it ideal for applications where space and weight are critical; highly scalable design allowing customization across multiple niche markets. Weaknesses: Still faces challenges with fuel efficiency compared to conventional piston engines; requires specialized maintenance expertise which can limit adoption in some markets.

Critical Patents and Engineering Innovations

Rotary internal combustion engine

PatentInactiveUS4082065A

Innovation

- Introducing a stratified air charge into the combustion chamber at idling speeds, allowing the engine to operate with a leaner fuel-air mixture and reducing operating temperature, which enhances fuel efficiency and extends seal life.

Rotary internal combustion engine

PatentWO2021176110A2

Innovation

- A rotary engine design featuring interconnected cylindrical chambers with cylindrical-elliptical rotors and a single-piece shaft, eliminating the need for valves, cams, and eccentric elements, utilizing a small separation between rotors and casings to reduce vibrations and oil consumption, and incorporating advanced materials like ceramics and aluminum alloys for improved performance and durability.

Emissions Compliance Strategies for Rotary Engines

Emissions compliance represents one of the most significant challenges for Wankel rotary engine applications in niche markets. Traditional rotary engines have historically struggled with meeting increasingly stringent emissions standards due to their inherent combustion chamber geometry and sealing characteristics. The elongated combustion chamber creates uneven temperature distribution, leading to incomplete combustion and higher hydrocarbon emissions compared to conventional piston engines.

Recent advancements in emissions control technologies have opened new pathways for rotary engine compliance. Direct injection systems specifically calibrated for the rotary's unique combustion dynamics have demonstrated significant reductions in unburned hydrocarbon emissions by optimizing fuel delivery timing and spray patterns. These systems can be further enhanced through variable injection pressure mechanisms that adapt to different operating conditions.

Thermal management represents another critical compliance strategy. Advanced ceramic apex seals with improved temperature resistance properties allow for higher combustion temperatures while maintaining seal integrity. This enables more complete combustion while reducing oil consumption—a traditional weakness of rotary designs that contributes substantially to particulate emissions.

Exhaust aftertreatment systems tailored specifically for rotary applications have shown promising results. Multi-stage catalytic converters with specialized catalyst formulations address the unique exhaust gas composition of rotary engines. Some manufacturers have implemented rotary-specific particulate filters with regeneration cycles calibrated to the distinctive exhaust temperature profiles of these engines.

Hybrid integration offers perhaps the most promising compliance pathway for niche market applications. Using the rotary engine as a range extender or generator in a hybrid powertrain allows operation at optimal fixed RPM points where emissions can be more effectively controlled. This approach has been successfully implemented in several concept vehicles targeting specialty markets where the rotary's compact size and smooth operation provide distinct advantages.

Software-based solutions have emerged as cost-effective compliance tools. Advanced engine control units with rotary-specific combustion modeling capabilities enable real-time combustion optimization across varying operating conditions. These systems can incorporate machine learning algorithms that continuously refine combustion parameters based on operational data, progressively reducing emissions over the engine's service life.

For ultra-niche applications where regulatory exemptions may apply, alternative fuel adaptation presents a viable strategy. Hydrogen conversion kits for rotary engines have demonstrated near-zero emissions operation while preserving the core mechanical advantages of the Wankel design. Similarly, synthetic fuel formulations optimized for rotary combustion characteristics offer pathways to carbon-neutral operation in specialized applications.

Recent advancements in emissions control technologies have opened new pathways for rotary engine compliance. Direct injection systems specifically calibrated for the rotary's unique combustion dynamics have demonstrated significant reductions in unburned hydrocarbon emissions by optimizing fuel delivery timing and spray patterns. These systems can be further enhanced through variable injection pressure mechanisms that adapt to different operating conditions.

Thermal management represents another critical compliance strategy. Advanced ceramic apex seals with improved temperature resistance properties allow for higher combustion temperatures while maintaining seal integrity. This enables more complete combustion while reducing oil consumption—a traditional weakness of rotary designs that contributes substantially to particulate emissions.

Exhaust aftertreatment systems tailored specifically for rotary applications have shown promising results. Multi-stage catalytic converters with specialized catalyst formulations address the unique exhaust gas composition of rotary engines. Some manufacturers have implemented rotary-specific particulate filters with regeneration cycles calibrated to the distinctive exhaust temperature profiles of these engines.

Hybrid integration offers perhaps the most promising compliance pathway for niche market applications. Using the rotary engine as a range extender or generator in a hybrid powertrain allows operation at optimal fixed RPM points where emissions can be more effectively controlled. This approach has been successfully implemented in several concept vehicles targeting specialty markets where the rotary's compact size and smooth operation provide distinct advantages.

Software-based solutions have emerged as cost-effective compliance tools. Advanced engine control units with rotary-specific combustion modeling capabilities enable real-time combustion optimization across varying operating conditions. These systems can incorporate machine learning algorithms that continuously refine combustion parameters based on operational data, progressively reducing emissions over the engine's service life.

For ultra-niche applications where regulatory exemptions may apply, alternative fuel adaptation presents a viable strategy. Hydrogen conversion kits for rotary engines have demonstrated near-zero emissions operation while preserving the core mechanical advantages of the Wankel design. Similarly, synthetic fuel formulations optimized for rotary combustion characteristics offer pathways to carbon-neutral operation in specialized applications.

Materials Science Advancements for Rotor Sealing

Recent advancements in materials science have revolutionized the approach to one of the Wankel engine's most persistent challenges: rotor sealing. Traditional apex seals, typically made from carbon-based materials, have historically limited the engine's efficiency and durability, particularly under high-temperature and high-pressure conditions encountered in specialized applications.

The development of ceramic-metal composite (cermet) materials represents a significant breakthrough for rotor sealing technology. These materials combine the heat resistance of ceramics with the flexibility and durability of metals, creating seals that can withstand temperatures exceeding 1000°C while maintaining structural integrity. Silicon nitride-based cermets have demonstrated particularly promising results in laboratory testing, showing wear rates approximately 60% lower than conventional carbon seals when operating in niche applications such as small aircraft engines.

Nano-engineered surface coatings have emerged as another critical advancement in this field. Diamond-like carbon (DLC) coatings applied through plasma-enhanced chemical vapor deposition provide exceptional hardness and low friction coefficients, addressing the traditional wear issues at the apex seal-housing interface. When combined with molybdenum disulfide secondary layers, these coatings have demonstrated a 40% reduction in friction and a corresponding increase in seal longevity under variable load conditions typical in marine applications.

Self-healing polymer composites represent the cutting edge of sealing technology research. These materials incorporate microcapsules containing healing agents that are released when microscopic cracks form, effectively repairing damage during operation. Early prototypes tested in modified Wankel engines have shown the potential to extend seal life by up to 30% in intermittent high-stress applications, making them particularly suitable for emergency service vehicles and other specialized equipment that experiences irregular usage patterns.

Temperature-adaptive materials that change their physical properties in response to operating conditions are showing particular promise for niche market applications. Shape memory alloys incorporated into seal designs can adjust their tension and contact pressure based on thermal conditions, optimizing sealing performance across a wider range of operating parameters than conventional fixed-geometry seals. This adaptability is especially valuable in environments with extreme temperature variations, such as high-altitude drones or arctic exploration vehicles.

The integration of sensor technology with advanced materials has enabled real-time monitoring of seal condition and performance. Piezoelectric elements embedded within composite seals can provide continuous feedback on wear patterns and contact pressure, allowing for predictive maintenance protocols that significantly reduce unexpected failures in critical applications. This capability is particularly valuable in remote operation scenarios where maintenance access is limited or costly.

The development of ceramic-metal composite (cermet) materials represents a significant breakthrough for rotor sealing technology. These materials combine the heat resistance of ceramics with the flexibility and durability of metals, creating seals that can withstand temperatures exceeding 1000°C while maintaining structural integrity. Silicon nitride-based cermets have demonstrated particularly promising results in laboratory testing, showing wear rates approximately 60% lower than conventional carbon seals when operating in niche applications such as small aircraft engines.

Nano-engineered surface coatings have emerged as another critical advancement in this field. Diamond-like carbon (DLC) coatings applied through plasma-enhanced chemical vapor deposition provide exceptional hardness and low friction coefficients, addressing the traditional wear issues at the apex seal-housing interface. When combined with molybdenum disulfide secondary layers, these coatings have demonstrated a 40% reduction in friction and a corresponding increase in seal longevity under variable load conditions typical in marine applications.

Self-healing polymer composites represent the cutting edge of sealing technology research. These materials incorporate microcapsules containing healing agents that are released when microscopic cracks form, effectively repairing damage during operation. Early prototypes tested in modified Wankel engines have shown the potential to extend seal life by up to 30% in intermittent high-stress applications, making them particularly suitable for emergency service vehicles and other specialized equipment that experiences irregular usage patterns.

Temperature-adaptive materials that change their physical properties in response to operating conditions are showing particular promise for niche market applications. Shape memory alloys incorporated into seal designs can adjust their tension and contact pressure based on thermal conditions, optimizing sealing performance across a wider range of operating parameters than conventional fixed-geometry seals. This adaptability is especially valuable in environments with extreme temperature variations, such as high-altitude drones or arctic exploration vehicles.

The integration of sensor technology with advanced materials has enabled real-time monitoring of seal condition and performance. Piezoelectric elements embedded within composite seals can provide continuous feedback on wear patterns and contact pressure, allowing for predictive maintenance protocols that significantly reduce unexpected failures in critical applications. This capability is particularly valuable in remote operation scenarios where maintenance access is limited or costly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!