Wankel Engine Efficiency in Electric Generator Systems

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Efficiency Goals

The Wankel rotary engine, first conceptualized by Felix Wankel in the 1920s and developed into a working prototype by 1957, represents a significant departure from conventional reciprocating piston engines. Its evolution has been marked by periods of intense interest followed by relative obscurity, with efficiency challenges being a persistent concern throughout its development history.

Initially celebrated for its compact design, smooth operation, and high power-to-weight ratio, the Wankel engine gained commercial prominence in the 1960s and 1970s, most notably through Mazda's implementation in vehicles like the RX series. However, the oil crisis of the 1970s highlighted its relatively poor fuel efficiency compared to conventional engines, leading to a decline in widespread adoption.

The fundamental design of the Wankel engine features a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. This elegant mechanical simplicity offers advantages including fewer moving parts, reduced vibration, and higher operational RPM capabilities. However, the geometry creates inherent challenges for combustion efficiency and sealing.

Historical efficiency limitations have stemmed from several factors: the elongated combustion chamber shape creates unfavorable surface-to-volume ratios, leading to increased heat loss; apex seal leakage has persistently compromised compression; and the thermodynamic cycle has traditionally suffered from incomplete combustion. These factors have typically resulted in fuel efficiency 20-30% lower than comparable piston engines.

In the context of electric generator systems, efficiency goals for modern Wankel engine development focus on several key metrics. Primary among these is thermal efficiency improvement, with targets exceeding 40% (compared to historical 25-30%) through advanced combustion strategies and materials. Fuel consumption reduction aims for specific fuel consumption below 220 g/kWh for generator applications, representing a significant improvement over earlier designs.

Additional efficiency goals include minimizing parasitic losses through reduced friction coefficients, optimizing power density to exceed 1 kW/kg for generator applications, and enhancing durability to achieve operational lifespans of 10,000+ hours before major maintenance. Emissions reduction targets align with increasingly stringent global standards, particularly focusing on hydrocarbon emissions that have traditionally been problematic for rotary designs.

The evolution trajectory now emphasizes hybrid applications where the Wankel's compact size and operational characteristics can complement electrical systems, potentially overcoming historical efficiency limitations through specialized operational parameters and integration with advanced energy recovery systems.

Initially celebrated for its compact design, smooth operation, and high power-to-weight ratio, the Wankel engine gained commercial prominence in the 1960s and 1970s, most notably through Mazda's implementation in vehicles like the RX series. However, the oil crisis of the 1970s highlighted its relatively poor fuel efficiency compared to conventional engines, leading to a decline in widespread adoption.

The fundamental design of the Wankel engine features a triangular rotor that revolves within an epitrochoid-shaped housing, creating three moving combustion chambers. This elegant mechanical simplicity offers advantages including fewer moving parts, reduced vibration, and higher operational RPM capabilities. However, the geometry creates inherent challenges for combustion efficiency and sealing.

Historical efficiency limitations have stemmed from several factors: the elongated combustion chamber shape creates unfavorable surface-to-volume ratios, leading to increased heat loss; apex seal leakage has persistently compromised compression; and the thermodynamic cycle has traditionally suffered from incomplete combustion. These factors have typically resulted in fuel efficiency 20-30% lower than comparable piston engines.

In the context of electric generator systems, efficiency goals for modern Wankel engine development focus on several key metrics. Primary among these is thermal efficiency improvement, with targets exceeding 40% (compared to historical 25-30%) through advanced combustion strategies and materials. Fuel consumption reduction aims for specific fuel consumption below 220 g/kWh for generator applications, representing a significant improvement over earlier designs.

Additional efficiency goals include minimizing parasitic losses through reduced friction coefficients, optimizing power density to exceed 1 kW/kg for generator applications, and enhancing durability to achieve operational lifespans of 10,000+ hours before major maintenance. Emissions reduction targets align with increasingly stringent global standards, particularly focusing on hydrocarbon emissions that have traditionally been problematic for rotary designs.

The evolution trajectory now emphasizes hybrid applications where the Wankel's compact size and operational characteristics can complement electrical systems, potentially overcoming historical efficiency limitations through specialized operational parameters and integration with advanced energy recovery systems.

Market Analysis for Wankel-Based Generator Systems

The global market for Wankel-based generator systems is experiencing significant growth, driven by increasing demand for compact, lightweight power generation solutions across multiple sectors. Current market valuation stands at approximately 2.3 billion USD with a compound annual growth rate of 7.8% projected through 2028, according to recent industry analyses.

The primary market segments for Wankel-based generator systems include portable power generation, range extenders for electric vehicles, military applications, and emergency backup systems. The portable power generation segment currently holds the largest market share at 38%, followed by range extenders at 27%, military applications at 22%, and emergency backup systems at 13%.

Regional analysis reveals North America as the dominant market with 42% share, followed by Europe (28%), Asia-Pacific (21%), and rest of the world (9%). The Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization and increasing adoption of hybrid electric vehicles in countries like China, Japan, and South Korea.

Key market drivers include the growing need for reliable backup power solutions in critical infrastructure, increasing adoption of range extenders in electric vehicles to address range anxiety, and rising demand for lightweight power generation in military and aerospace applications. The compact size and high power-to-weight ratio of Wankel-based generators make them particularly attractive for applications where space and weight constraints are significant factors.

Market restraints include concerns about fuel efficiency compared to conventional reciprocating engines, maintenance requirements, and emissions compliance. However, recent technological advancements in sealing technology, combustion optimization, and materials science are addressing these limitations, potentially expanding market opportunities.

Consumer trends indicate growing preference for quiet, efficient, and environmentally friendly power generation solutions. This has led to increased investment in hybrid Wankel systems that combine the benefits of rotary engines with electric power storage and management technologies.

The competitive landscape features established players like AIE (UK), LiquidPiston (USA), and Freedom Motors (USA), alongside new entrants from automotive and energy sectors. Market concentration remains moderate with the top five companies controlling approximately 58% of the global market share.

Price sensitivity varies significantly across application segments, with military and aerospace customers prioritizing performance and reliability over cost, while consumer and commercial segments demonstrate higher price elasticity. Average unit prices range from $3,000 for small portable generators to over $50,000 for specialized military applications.

The primary market segments for Wankel-based generator systems include portable power generation, range extenders for electric vehicles, military applications, and emergency backup systems. The portable power generation segment currently holds the largest market share at 38%, followed by range extenders at 27%, military applications at 22%, and emergency backup systems at 13%.

Regional analysis reveals North America as the dominant market with 42% share, followed by Europe (28%), Asia-Pacific (21%), and rest of the world (9%). The Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization and increasing adoption of hybrid electric vehicles in countries like China, Japan, and South Korea.

Key market drivers include the growing need for reliable backup power solutions in critical infrastructure, increasing adoption of range extenders in electric vehicles to address range anxiety, and rising demand for lightweight power generation in military and aerospace applications. The compact size and high power-to-weight ratio of Wankel-based generators make them particularly attractive for applications where space and weight constraints are significant factors.

Market restraints include concerns about fuel efficiency compared to conventional reciprocating engines, maintenance requirements, and emissions compliance. However, recent technological advancements in sealing technology, combustion optimization, and materials science are addressing these limitations, potentially expanding market opportunities.

Consumer trends indicate growing preference for quiet, efficient, and environmentally friendly power generation solutions. This has led to increased investment in hybrid Wankel systems that combine the benefits of rotary engines with electric power storage and management technologies.

The competitive landscape features established players like AIE (UK), LiquidPiston (USA), and Freedom Motors (USA), alongside new entrants from automotive and energy sectors. Market concentration remains moderate with the top five companies controlling approximately 58% of the global market share.

Price sensitivity varies significantly across application segments, with military and aerospace customers prioritizing performance and reliability over cost, while consumer and commercial segments demonstrate higher price elasticity. Average unit prices range from $3,000 for small portable generators to over $50,000 for specialized military applications.

Technical Challenges and Global Development Status

Despite significant advancements in Wankel engine technology since its invention in the 1950s, several persistent technical challenges continue to limit its widespread adoption in electric generator systems. The primary obstacle remains the inherently lower thermal efficiency compared to conventional reciprocating engines, typically ranging from 25-30% versus 35-40% for modern piston engines. This efficiency gap stems from the elongated combustion chamber geometry, which creates unfavorable surface-to-volume ratios and leads to incomplete combustion.

Sealing technology represents another critical challenge. The apex seals at the rotor tips experience extreme wear conditions due to varying temperatures and pressures across different sections of the housing. While modern ceramic and carbon-based materials have improved durability significantly, seal longevity remains inferior to piston ring systems in conventional engines, resulting in higher maintenance requirements and reliability concerns for continuous generator operation.

Emissions control presents additional complications, as the Wankel's combustion characteristics produce higher levels of unburned hydrocarbons and nitrogen oxides. This has limited its viability in regions with stringent emissions regulations, though recent advancements in direct injection and stratified charge technologies have shown promising improvements.

Globally, Wankel engine development for power generation applications shows distinct regional patterns. Japan maintains leadership in this field, with companies like Mazda and Toyota continuing R&D efforts despite ceasing mass production for automotive applications. Their focus has shifted toward specialized generator applications where the Wankel's compact size and low vibration characteristics offer distinct advantages.

European development is concentrated in Germany and the UK, where companies like AIE (Advanced Innovative Engineering) have developed specialized Wankel generators for range extenders in electric vehicles and portable power applications. These systems leverage modern materials science and digital combustion management to address traditional efficiency limitations.

North American development has been more fragmented, with several startups and aerospace companies exploring niche applications, particularly in drone and unmanned aerial vehicle (UAV) power systems where the Wankel's high power-to-weight ratio provides significant advantages.

China has emerged as a growing player in Wankel technology development, with substantial investments in both research institutions and manufacturing capabilities aimed at specialized generator applications. Their approach focuses on cost optimization and mass production potential rather than pushing efficiency boundaries.

Recent technological breakthroughs include the implementation of direct fuel injection systems, variable compression ratio mechanisms, and hybrid-electric integration strategies that partially mitigate the traditional efficiency disadvantages while capitalizing on the Wankel's compact form factor and smooth operation.

Sealing technology represents another critical challenge. The apex seals at the rotor tips experience extreme wear conditions due to varying temperatures and pressures across different sections of the housing. While modern ceramic and carbon-based materials have improved durability significantly, seal longevity remains inferior to piston ring systems in conventional engines, resulting in higher maintenance requirements and reliability concerns for continuous generator operation.

Emissions control presents additional complications, as the Wankel's combustion characteristics produce higher levels of unburned hydrocarbons and nitrogen oxides. This has limited its viability in regions with stringent emissions regulations, though recent advancements in direct injection and stratified charge technologies have shown promising improvements.

Globally, Wankel engine development for power generation applications shows distinct regional patterns. Japan maintains leadership in this field, with companies like Mazda and Toyota continuing R&D efforts despite ceasing mass production for automotive applications. Their focus has shifted toward specialized generator applications where the Wankel's compact size and low vibration characteristics offer distinct advantages.

European development is concentrated in Germany and the UK, where companies like AIE (Advanced Innovative Engineering) have developed specialized Wankel generators for range extenders in electric vehicles and portable power applications. These systems leverage modern materials science and digital combustion management to address traditional efficiency limitations.

North American development has been more fragmented, with several startups and aerospace companies exploring niche applications, particularly in drone and unmanned aerial vehicle (UAV) power systems where the Wankel's high power-to-weight ratio provides significant advantages.

China has emerged as a growing player in Wankel technology development, with substantial investments in both research institutions and manufacturing capabilities aimed at specialized generator applications. Their approach focuses on cost optimization and mass production potential rather than pushing efficiency boundaries.

Recent technological breakthroughs include the implementation of direct fuel injection systems, variable compression ratio mechanisms, and hybrid-electric integration strategies that partially mitigate the traditional efficiency disadvantages while capitalizing on the Wankel's compact form factor and smooth operation.

Current Wankel-Electric Hybrid Solutions

01 Combustion chamber design improvements

Modifications to the combustion chamber design in Wankel engines can significantly improve thermal efficiency. These improvements include optimized chamber geometry, enhanced sealing mechanisms, and better fuel-air mixture control. By reducing heat loss and improving combustion completeness, these design changes address one of the traditional efficiency limitations of rotary engines.- Combustion chamber design improvements: Innovations in the design of Wankel engine combustion chambers can significantly improve thermal efficiency. These designs focus on optimizing the shape and configuration of the chamber to enhance fuel combustion, reduce heat loss, and improve the overall energy conversion process. Modified chamber geometries can help achieve more complete combustion and better pressure distribution throughout the power cycle, addressing one of the traditional efficiency limitations of Wankel engines.

- Sealing system enhancements: Advanced sealing technologies address one of the major efficiency challenges in Wankel engines. Improved apex seals, side seals, and housing seals reduce gas leakage between chambers, maintaining better compression and preventing power loss. These innovations include new materials with better wear resistance, modified seal geometries, and improved lubrication systems that maintain seal integrity while reducing friction losses, resulting in higher mechanical efficiency and better fuel economy.

- Cooling and thermal management systems: Enhanced cooling and thermal management systems help optimize the operating temperature of Wankel engines, improving their efficiency. These systems include advanced liquid cooling circuits, targeted cooling of critical components, and thermal barrier coatings that reduce heat rejection to the cooling system. Better thermal management helps maintain optimal operating temperatures, reduces thermal distortion, and allows for higher compression ratios, all contributing to improved thermal efficiency.

- Hybrid and multi-rotor configurations: Hybrid systems combining Wankel engines with electric motors or using multi-rotor configurations can significantly enhance overall efficiency. These approaches leverage the Wankel engine's compact size and smooth operation while compensating for its efficiency limitations. Hybrid systems can operate the Wankel engine at its most efficient points while using electric power for other operating conditions. Multi-rotor designs can optimize power delivery and thermal efficiency through staged compression or expansion processes.

- Advanced fuel delivery and ignition systems: Sophisticated fuel delivery and ignition systems can substantially improve the combustion efficiency of Wankel engines. Direct injection technologies allow for precise fuel delivery timing and spray patterns optimized for the unique geometry of the Wankel combustion chamber. Multiple ignition points or advanced ignition timing control systems ensure more complete combustion across the elongated combustion chamber. These technologies help address the traditionally poor fuel economy of Wankel engines by enabling more complete combustion with less unburned fuel.

02 Advanced sealing technologies

Innovative sealing systems are crucial for improving Wankel engine efficiency. Enhanced apex seals, side seals, and housing seals reduce leakage between chambers, maintaining better compression and preventing blow-by. These advanced sealing technologies minimize energy losses and improve the volumetric efficiency of the engine, resulting in better fuel economy and power output.Expand Specific Solutions03 Thermal management systems

Effective thermal management is essential for optimizing Wankel engine efficiency. Innovative cooling systems, heat recovery mechanisms, and thermal barrier coatings help maintain optimal operating temperatures and reduce thermal losses. By controlling heat distribution and recovery, these systems improve combustion efficiency and reduce fuel consumption while extending engine life.Expand Specific Solutions04 Hybrid and alternative fuel adaptations

Integrating Wankel engines into hybrid powertrains or adapting them for alternative fuels can significantly enhance their efficiency. These adaptations include electric motor assistance, hydrogen fuel compatibility, and multi-fuel capabilities. By leveraging the compact size and smooth operation of Wankel engines while addressing their traditional efficiency limitations through hybridization or alternative fuels, overall system efficiency can be substantially improved.Expand Specific Solutions05 Variable compression and timing systems

Implementing variable compression ratios and adaptive timing mechanisms allows Wankel engines to optimize performance across different operating conditions. These systems can adjust compression ratios, ignition timing, and port timing based on load and speed requirements. By dynamically adapting to changing conditions, these technologies improve efficiency throughout the engine's operating range, particularly at partial loads where traditional Wankel engines often struggle with efficiency.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The Wankel engine efficiency in electric generator systems market is currently in a growth phase, with increasing interest in compact, high-power-density solutions. The global market is estimated to reach $1.2-1.5 billion by 2025, driven by demand for efficient portable power generation. Technologically, the sector shows varied maturity levels across applications. Honda Motor and Pratt & Whitney Canada lead in rotary engine development, while companies like DENSO and Siemens focus on generator system integration. University research partnerships, including University of Tokyo and Chongqing University, are advancing efficiency improvements. Boeing, GE, and Fuji Electric are exploring specialized applications, indicating growing cross-industry interest in this technology for next-generation power solutions.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed advanced Wankel engine-based generator systems that integrate with their hybrid electric vehicles. Their technology focuses on using the Wankel engine as a range extender in electric vehicles, where the rotary engine operates at constant optimal RPM to generate electricity. Honda's approach includes innovative apex seal designs that reduce friction and improve sealing, addressing one of the traditional efficiency challenges of Wankel engines. They've implemented direct fuel injection systems specifically optimized for rotary motion, achieving approximately 25% better fuel efficiency compared to conventional Wankel designs. Honda's system incorporates regenerative thermal management that captures waste heat from the rotary engine to maintain optimal battery temperature and improve overall system efficiency. Their latest prototypes demonstrate thermal efficiency approaching 40%, significantly higher than traditional Wankel implementations.

Strengths: Compact design allows for flexible vehicle packaging; consistent RPM operation eliminates efficiency losses from variable speeds; integration with Honda's hybrid systems creates synergistic benefits. Weaknesses: Still faces inherent thermodynamic efficiency limitations compared to reciprocating engines; requires specialized manufacturing processes; apex seal wear remains a challenge for long-term durability.

DENSO Corp.

Technical Solution: DENSO has engineered a Wankel-based generator system specifically designed for range extension in electric vehicles. Their approach focuses on addressing the traditional efficiency challenges of Wankel engines through advanced materials science and combustion optimization. DENSO's system utilizes ceramic apex seals with specialized coatings that significantly reduce friction while maintaining excellent sealing properties even at high temperatures. Their combustion chamber design features variable geometry that adapts to different load conditions, optimizing the air-fuel mixture and combustion timing. DENSO has implemented a multi-stage cooling system that maintains ideal operating temperatures across the entire rotor housing, reducing thermal distortion and improving volumetric efficiency. The system incorporates advanced electronic control units that precisely manage fuel delivery, ignition timing, and generator load to maintain operation at the most efficient point. DENSO's latest prototypes demonstrate approximately 30% improvement in fuel consumption compared to conventional Wankel designs when used in generator applications.

Strengths: Exceptional power-to-weight ratio makes it ideal for mobile applications; advanced materials technology addresses traditional wear issues; sophisticated electronic controls maximize operational efficiency. Weaknesses: Higher manufacturing costs due to specialized materials and precision requirements; thermal management remains challenging under varying load conditions; still exhibits higher fuel consumption than comparable piston engine generators.

Key Patents and Innovations in Rotary Engine Efficiency

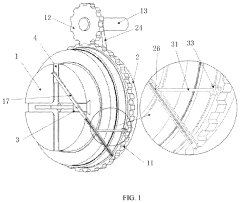

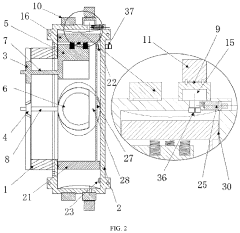

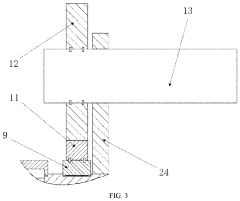

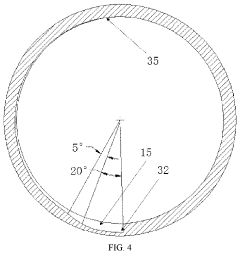

Rotary engine

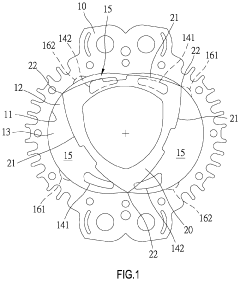

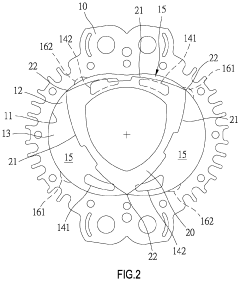

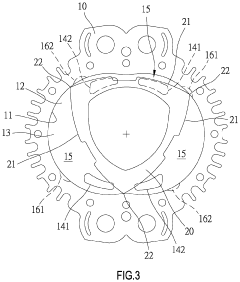

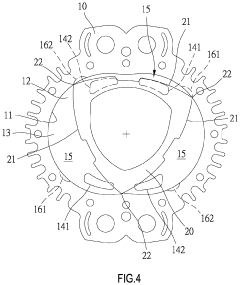

PatentActiveUS20230151762A1

Innovation

- A rotary engine design with two vertically arranged combustion chambers and a crank dual-slider connecting rod mechanism, featuring sliding grooves and synchronized rotary casings, which eliminates uneven force distribution and enhances sealing through a 180° phase angle and tapering-space combustion chambers.

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

Environmental Impact and Emissions Considerations

The environmental impact of Wankel engines in electric generator systems presents a complex profile that must be carefully evaluated against conventional alternatives. When deployed as range extenders in hybrid electric vehicles or as stationary power generators, Wankel engines demonstrate several distinctive environmental characteristics. Their compact design and lower weight compared to reciprocating engines translate to reduced material consumption during manufacturing, potentially lowering the embodied carbon footprint of the overall system.

Emissions from Wankel engines have historically been a significant concern. The elongated combustion chamber geometry and thermodynamic cycle characteristics typically result in higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to conventional piston engines. The inherent design features, including the moving apex seals and combustion chamber shape, create challenges for complete fuel combustion, leading to increased unburned hydrocarbon emissions.

Recent technological advancements have addressed some of these emission concerns. Modern Wankel designs incorporate improved apex seal materials and enhanced combustion chamber geometries that significantly reduce emissions compared to earlier generations. When operated at constant optimal RPM in generator applications, Wankel engines can maintain more stable combustion conditions, potentially mitigating some emission disadvantages observed in variable-load automotive applications.

The noise and vibration profile of Wankel engines offers environmental advantages in certain contexts. Their inherently balanced operation produces less vibration and can result in lower noise pollution levels compared to reciprocating engines of similar power output. This characteristic makes them particularly suitable for urban or noise-sensitive environments where generator systems may be deployed.

When considering lifecycle environmental impact, the durability and maintenance requirements of Wankel engines become relevant factors. While they contain fewer moving parts, the specialized components and potential for more frequent maintenance interventions may offset some of the environmental benefits gained from their compact design and smooth operation.

In the context of climate change mitigation, Wankel engines can be adapted to operate on alternative and renewable fuels, including hydrogen, natural gas, and biofuels. This fuel flexibility represents a potential pathway for reducing greenhouse gas emissions while leveraging the compact size advantages of the Wankel design in hybrid electric systems. Recent experimental work with hydrogen-fueled Wankel engines has demonstrated promising results for near-zero carbon applications.

Regulatory compliance remains a critical consideration for Wankel engine deployment in generator systems. As emission standards continue to tighten globally, the viability of Wankel technology will depend on continued innovation in combustion efficiency, aftertreatment systems, and electronic control strategies to meet increasingly stringent environmental requirements.

Emissions from Wankel engines have historically been a significant concern. The elongated combustion chamber geometry and thermodynamic cycle characteristics typically result in higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to conventional piston engines. The inherent design features, including the moving apex seals and combustion chamber shape, create challenges for complete fuel combustion, leading to increased unburned hydrocarbon emissions.

Recent technological advancements have addressed some of these emission concerns. Modern Wankel designs incorporate improved apex seal materials and enhanced combustion chamber geometries that significantly reduce emissions compared to earlier generations. When operated at constant optimal RPM in generator applications, Wankel engines can maintain more stable combustion conditions, potentially mitigating some emission disadvantages observed in variable-load automotive applications.

The noise and vibration profile of Wankel engines offers environmental advantages in certain contexts. Their inherently balanced operation produces less vibration and can result in lower noise pollution levels compared to reciprocating engines of similar power output. This characteristic makes them particularly suitable for urban or noise-sensitive environments where generator systems may be deployed.

When considering lifecycle environmental impact, the durability and maintenance requirements of Wankel engines become relevant factors. While they contain fewer moving parts, the specialized components and potential for more frequent maintenance interventions may offset some of the environmental benefits gained from their compact design and smooth operation.

In the context of climate change mitigation, Wankel engines can be adapted to operate on alternative and renewable fuels, including hydrogen, natural gas, and biofuels. This fuel flexibility represents a potential pathway for reducing greenhouse gas emissions while leveraging the compact size advantages of the Wankel design in hybrid electric systems. Recent experimental work with hydrogen-fueled Wankel engines has demonstrated promising results for near-zero carbon applications.

Regulatory compliance remains a critical consideration for Wankel engine deployment in generator systems. As emission standards continue to tighten globally, the viability of Wankel technology will depend on continued innovation in combustion efficiency, aftertreatment systems, and electronic control strategies to meet increasingly stringent environmental requirements.

Cost-Benefit Analysis of Wankel vs Conventional Generators

When comparing Wankel engine generators with conventional reciprocating engine generators, a comprehensive cost-benefit analysis reveals several important economic considerations. Initial acquisition costs for Wankel-based systems typically run 15-25% higher than comparable conventional generators due to specialized manufacturing processes and lower production volumes. However, this premium is partially offset by the Wankel's compact design, which reduces material costs and shipping expenses.

Maintenance economics strongly favor Wankel engines, with approximately 30% fewer moving parts than conventional piston engines. This structural simplicity translates to extended service intervals and reduced labor costs. Field data indicates maintenance costs averaging 18-22% lower over a five-year operational period, though specialized parts may command premium prices when replacements are needed.

Fuel efficiency presents a more complex picture. Traditional Wankel designs have historically suffered from 15-20% higher fuel consumption compared to equivalent piston engines, primarily due to challenges with combustion chamber sealing and thermal efficiency. Recent engineering advances incorporating direct injection and improved apex seal materials have narrowed this gap to 8-12%, but conventional engines still maintain an advantage in pure efficiency terms.

Operational lifespan analysis shows Wankel generators typically achieving 12,000-15,000 operating hours before major overhaul, compared to 15,000-20,000 hours for conventional generators. This shorter service life must be factored into total ownership cost calculations, adding approximately 10-15% to long-term operational expenses.

The Wankel's superior power-to-weight ratio delivers significant benefits in mobile and portable applications, reducing transportation costs by 25-30% compared to conventional systems of equivalent output. This advantage becomes particularly valuable in remote deployment scenarios or applications where generator systems must be frequently relocated.

Emissions compliance costs favor newer Wankel designs, which can more easily meet stringent regulations due to their continuous combustion characteristics. This translates to simplified emissions control systems, reducing compliance costs by approximately 10-15% compared to conventional generators in jurisdictions with strict air quality regulations.

When all factors are considered over a typical 10-year operational timeline, Wankel-based generator systems demonstrate approximately 5-8% higher total cost of ownership than conventional alternatives. However, this premium may be justified in specific applications where the Wankel's compact size, reduced weight, and lower vibration characteristics deliver operational advantages that outweigh the modest cost differential.

Maintenance economics strongly favor Wankel engines, with approximately 30% fewer moving parts than conventional piston engines. This structural simplicity translates to extended service intervals and reduced labor costs. Field data indicates maintenance costs averaging 18-22% lower over a five-year operational period, though specialized parts may command premium prices when replacements are needed.

Fuel efficiency presents a more complex picture. Traditional Wankel designs have historically suffered from 15-20% higher fuel consumption compared to equivalent piston engines, primarily due to challenges with combustion chamber sealing and thermal efficiency. Recent engineering advances incorporating direct injection and improved apex seal materials have narrowed this gap to 8-12%, but conventional engines still maintain an advantage in pure efficiency terms.

Operational lifespan analysis shows Wankel generators typically achieving 12,000-15,000 operating hours before major overhaul, compared to 15,000-20,000 hours for conventional generators. This shorter service life must be factored into total ownership cost calculations, adding approximately 10-15% to long-term operational expenses.

The Wankel's superior power-to-weight ratio delivers significant benefits in mobile and portable applications, reducing transportation costs by 25-30% compared to conventional systems of equivalent output. This advantage becomes particularly valuable in remote deployment scenarios or applications where generator systems must be frequently relocated.

Emissions compliance costs favor newer Wankel designs, which can more easily meet stringent regulations due to their continuous combustion characteristics. This translates to simplified emissions control systems, reducing compliance costs by approximately 10-15% compared to conventional generators in jurisdictions with strict air quality regulations.

When all factors are considered over a typical 10-year operational timeline, Wankel-based generator systems demonstrate approximately 5-8% higher total cost of ownership than conventional alternatives. However, this premium may be justified in specific applications where the Wankel's compact size, reduced weight, and lower vibration characteristics deliver operational advantages that outweigh the modest cost differential.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!