Wankel Engine Innovations for Future Mobility

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Evolution and Innovation Objectives

The Wankel rotary engine, first patented by Felix Wankel in 1929, represents a significant departure from conventional reciprocating piston engines. Its evolution spans nearly a century, characterized by periods of intense development, commercial application, and technological challenges. Initially conceived as a solution to the inherent vibration and complexity issues of piston engines, the Wankel design offers compelling advantages including fewer moving parts, smoother operation, and higher power-to-weight ratios.

The historical trajectory of Wankel engine development shows distinct phases. The 1950s-1960s marked the initial commercialization period, with NSU and later Mazda pioneering its automotive applications. The 1970s-1980s saw both expansion and contraction, as oil crises highlighted efficiency concerns while simultaneously demonstrating the engine's versatility in various applications beyond automobiles. The 1990s-2000s witnessed Mazda's continued refinement with the RX series, culminating in the RX-8's advanced RENESIS engine.

Recent technological advancements have created new opportunities for Wankel engine innovation. Modern materials science offers solutions to historical challenges such as apex seal wear and housing distortion. Computational fluid dynamics and advanced simulation techniques enable more precise optimization of combustion chamber geometry and thermal management. Additionally, emerging manufacturing techniques like 3D printing allow for previously impossible complex geometries and cooling passages.

The primary innovation objectives for future Wankel engine development center around four key areas. First, efficiency enhancement through advanced combustion strategies, including direct injection, variable compression, and potentially HCCI (Homogeneous Charge Compression Ignition) adaptation. Second, emissions reduction via improved sealing technologies, catalytic systems specifically designed for rotary thermal characteristics, and potentially hybrid integration.

Third, durability improvement through advanced materials for apex seals (including ceramic composites and carbon-based materials), optimized lubrication systems, and enhanced cooling strategies. Fourth, versatility expansion by exploring multi-fuel capabilities (including hydrogen and sustainable synthetic fuels), modular designs for various applications, and integration with electrification technologies.

The convergence of these innovation pathways aims to position the Wankel engine as a viable power solution for future mobility applications, particularly in range-extended electric vehicles, aviation applications, and specialized automotive niches where its unique characteristics provide competitive advantages. The technical evolution trajectory suggests that with focused development, the Wankel engine could overcome its historical limitations while leveraging its inherent advantages in the increasingly diverse powertrain landscape.

The historical trajectory of Wankel engine development shows distinct phases. The 1950s-1960s marked the initial commercialization period, with NSU and later Mazda pioneering its automotive applications. The 1970s-1980s saw both expansion and contraction, as oil crises highlighted efficiency concerns while simultaneously demonstrating the engine's versatility in various applications beyond automobiles. The 1990s-2000s witnessed Mazda's continued refinement with the RX series, culminating in the RX-8's advanced RENESIS engine.

Recent technological advancements have created new opportunities for Wankel engine innovation. Modern materials science offers solutions to historical challenges such as apex seal wear and housing distortion. Computational fluid dynamics and advanced simulation techniques enable more precise optimization of combustion chamber geometry and thermal management. Additionally, emerging manufacturing techniques like 3D printing allow for previously impossible complex geometries and cooling passages.

The primary innovation objectives for future Wankel engine development center around four key areas. First, efficiency enhancement through advanced combustion strategies, including direct injection, variable compression, and potentially HCCI (Homogeneous Charge Compression Ignition) adaptation. Second, emissions reduction via improved sealing technologies, catalytic systems specifically designed for rotary thermal characteristics, and potentially hybrid integration.

Third, durability improvement through advanced materials for apex seals (including ceramic composites and carbon-based materials), optimized lubrication systems, and enhanced cooling strategies. Fourth, versatility expansion by exploring multi-fuel capabilities (including hydrogen and sustainable synthetic fuels), modular designs for various applications, and integration with electrification technologies.

The convergence of these innovation pathways aims to position the Wankel engine as a viable power solution for future mobility applications, particularly in range-extended electric vehicles, aviation applications, and specialized automotive niches where its unique characteristics provide competitive advantages. The technical evolution trajectory suggests that with focused development, the Wankel engine could overcome its historical limitations while leveraging its inherent advantages in the increasingly diverse powertrain landscape.

Market Analysis for Rotary Engine Applications

The rotary engine market has undergone significant transformation since its commercial introduction by Mazda in the 1960s. Currently, the global market for rotary engine applications is estimated at $1.2 billion, with projections indicating growth to $2.3 billion by 2030, representing a compound annual growth rate of 6.8%. This growth trajectory is primarily driven by emerging applications beyond traditional automotive uses, particularly in specialized mobility sectors.

The automotive segment remains the largest application area, accounting for approximately 45% of the market share. However, this segment has contracted over the past decade due to challenges in meeting increasingly stringent emissions regulations. Mazda's decision to discontinue its RX series in 2012 marked a significant shift in the market landscape, though the company's recent reintroduction of rotary technology as range extenders in hybrid vehicles signals renewed interest.

Aviation represents the fastest-growing segment for rotary engine applications, with 12% annual growth. The superior power-to-weight ratio of Wankel engines makes them particularly attractive for small aircraft, drones, and urban air mobility solutions. Companies like Austro Engine and AIE (Advanced Innovative Engineering) have developed specialized rotary engines for unmanned aerial vehicles, capitalizing on the engine's compact design and reduced vibration characteristics.

Marine applications constitute approximately 18% of the current market, with particular adoption in personal watercraft and small boats. The rotary engine's smooth operation and resistance to water ingestion provide competitive advantages in these environments. Freedom Motors and Moller International have established notable presence in this segment.

Geographically, North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). Japan remains a center of rotary engine expertise due to Mazda's historical dominance, while Germany and the United States have emerging innovation clusters focused on specialized applications.

Market analysis reveals several key drivers for future growth: increasing demand for lightweight propulsion systems in electric-hybrid configurations, growing interest in range extender technologies for electric vehicles, and expansion of urban air mobility solutions. The compact size and high power density of rotary engines position them favorably in these emerging applications.

Consumer sentiment analysis indicates growing awareness of rotary technology's benefits among specialized market segments, particularly aviation enthusiasts and performance vehicle owners. However, broader market penetration remains constrained by limited public familiarity with the technology outside of niche applications and lingering concerns about historical reliability issues.

The automotive segment remains the largest application area, accounting for approximately 45% of the market share. However, this segment has contracted over the past decade due to challenges in meeting increasingly stringent emissions regulations. Mazda's decision to discontinue its RX series in 2012 marked a significant shift in the market landscape, though the company's recent reintroduction of rotary technology as range extenders in hybrid vehicles signals renewed interest.

Aviation represents the fastest-growing segment for rotary engine applications, with 12% annual growth. The superior power-to-weight ratio of Wankel engines makes them particularly attractive for small aircraft, drones, and urban air mobility solutions. Companies like Austro Engine and AIE (Advanced Innovative Engineering) have developed specialized rotary engines for unmanned aerial vehicles, capitalizing on the engine's compact design and reduced vibration characteristics.

Marine applications constitute approximately 18% of the current market, with particular adoption in personal watercraft and small boats. The rotary engine's smooth operation and resistance to water ingestion provide competitive advantages in these environments. Freedom Motors and Moller International have established notable presence in this segment.

Geographically, North America leads the market with 38% share, followed by Europe (31%) and Asia-Pacific (24%). Japan remains a center of rotary engine expertise due to Mazda's historical dominance, while Germany and the United States have emerging innovation clusters focused on specialized applications.

Market analysis reveals several key drivers for future growth: increasing demand for lightweight propulsion systems in electric-hybrid configurations, growing interest in range extender technologies for electric vehicles, and expansion of urban air mobility solutions. The compact size and high power density of rotary engines position them favorably in these emerging applications.

Consumer sentiment analysis indicates growing awareness of rotary technology's benefits among specialized market segments, particularly aviation enthusiasts and performance vehicle owners. However, broader market penetration remains constrained by limited public familiarity with the technology outside of niche applications and lingering concerns about historical reliability issues.

Technical Challenges and Global Development Status

Despite its innovative rotary design and inherent advantages, the Wankel engine faces significant technical challenges that have limited its widespread adoption in the automotive industry. The primary obstacle remains the apex seal durability issue, where the triangular rotor's seals experience accelerated wear due to high friction and thermal stress. This results in reduced engine longevity and increased maintenance requirements compared to conventional piston engines. Additionally, the Wankel design suffers from inherent thermal efficiency limitations, with combustion chamber geometry creating unfavorable surface-to-volume ratios that contribute to incomplete combustion and higher emissions.

Fuel efficiency represents another major challenge, as Wankel engines typically consume 15-20% more fuel than equivalent piston engines. This inefficiency stems from combustion chamber shape, seal leakage, and thermodynamic constraints inherent to the rotary design. Emissions compliance has become increasingly problematic as global regulations tighten, with the Wankel's higher hydrocarbon emissions and oil consumption creating significant hurdles for meeting Euro 7, China 7, and US Tier 3 standards.

Globally, Wankel engine development has experienced a notable geographic shift. Japan, particularly through Mazda's decades-long commitment, has historically led rotary engine innovation, culminating in the RX-8's RENESIS engine before production ceased in 2012. Recently, Mazda has pivoted to developing rotary engines as range extenders for electric vehicles, launching the MX-30 e-Skyactiv R-EV in 2023 - representing the first commercial application of a rotary range extender.

European development has been sporadic, with companies like NSU pioneering early applications before abandoning the technology. Currently, German aerospace firms like Wankel SuperTec focus on specialized applications for UAVs and portable generators. In North America, development has largely shifted to niche applications, with companies like LiquidPiston and Freedom Motors refining rotary designs for specific use cases rather than mainstream automotive applications.

China has emerged as a new development hub, with companies like Changan Automobile and Wankel Engine Technology Co. investing in rotary technology research, particularly for range extenders in electric vehicles. This aligns with China's strategic focus on new energy vehicles and represents a potential growth area for Wankel technology.

The current global development landscape shows a clear trend toward repurposing Wankel engines for specialized applications rather than mainstream propulsion. Range extenders, aviation applications, and compact power generation represent the most promising development paths, leveraging the rotary engine's high power-to-weight ratio and compact design while mitigating its efficiency and emissions challenges through limited operational profiles.

Fuel efficiency represents another major challenge, as Wankel engines typically consume 15-20% more fuel than equivalent piston engines. This inefficiency stems from combustion chamber shape, seal leakage, and thermodynamic constraints inherent to the rotary design. Emissions compliance has become increasingly problematic as global regulations tighten, with the Wankel's higher hydrocarbon emissions and oil consumption creating significant hurdles for meeting Euro 7, China 7, and US Tier 3 standards.

Globally, Wankel engine development has experienced a notable geographic shift. Japan, particularly through Mazda's decades-long commitment, has historically led rotary engine innovation, culminating in the RX-8's RENESIS engine before production ceased in 2012. Recently, Mazda has pivoted to developing rotary engines as range extenders for electric vehicles, launching the MX-30 e-Skyactiv R-EV in 2023 - representing the first commercial application of a rotary range extender.

European development has been sporadic, with companies like NSU pioneering early applications before abandoning the technology. Currently, German aerospace firms like Wankel SuperTec focus on specialized applications for UAVs and portable generators. In North America, development has largely shifted to niche applications, with companies like LiquidPiston and Freedom Motors refining rotary designs for specific use cases rather than mainstream automotive applications.

China has emerged as a new development hub, with companies like Changan Automobile and Wankel Engine Technology Co. investing in rotary technology research, particularly for range extenders in electric vehicles. This aligns with China's strategic focus on new energy vehicles and represents a potential growth area for Wankel technology.

The current global development landscape shows a clear trend toward repurposing Wankel engines for specialized applications rather than mainstream propulsion. Range extenders, aviation applications, and compact power generation represent the most promising development paths, leveraging the rotary engine's high power-to-weight ratio and compact design while mitigating its efficiency and emissions challenges through limited operational profiles.

Current Wankel Engine Design Solutions

01 Wankel Engine Design and Structure

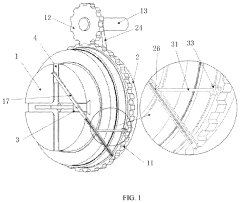

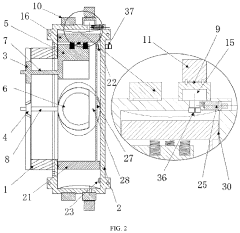

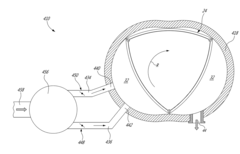

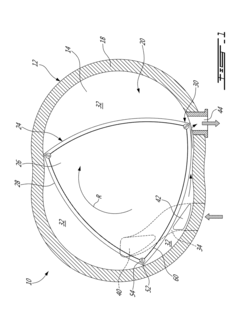

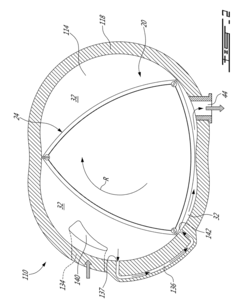

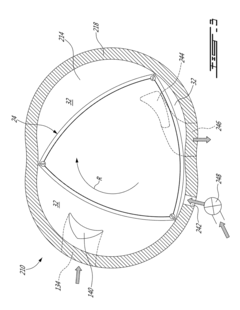

The Wankel engine features a unique rotary design with a triangular rotor that revolves inside an epitrochoid-shaped housing. This design eliminates the need for conventional pistons, connecting rods, and crankshafts found in reciprocating engines. The rotor creates three moving combustion chambers, allowing for a smoother operation with fewer moving parts and reduced vibration compared to traditional piston engines.- Wankel Engine Design and Structure: The Wankel engine features a unique rotary design with a triangular rotor that revolves inside an epitrochoid-shaped housing. This design eliminates the need for conventional pistons, connecting rods, and crankshafts found in reciprocating engines. The rotor creates three separate chambers that continuously change volume as it rotates, completing the four-stroke cycle (intake, compression, combustion, and exhaust) in one revolution. This design offers advantages such as smoother operation, fewer moving parts, and a higher power-to-weight ratio compared to traditional piston engines.

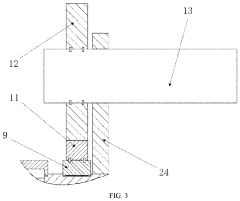

- Sealing Systems for Wankel Engines: Effective sealing is critical in Wankel engines to maintain compression and prevent leakage between the chambers. Various sealing systems have been developed, including apex seals at the corners of the rotor, side seals along the rotor faces, and oil seals. These sealing components must withstand high temperatures, pressures, and continuous friction while maintaining a tight seal between the rotor and housing. Innovations in sealing materials and designs have focused on improving durability, reducing friction, and enhancing overall engine efficiency.

- Cooling and Lubrication Systems: Wankel engines require specialized cooling and lubrication systems due to their unique geometry and operating characteristics. The eccentric shaft and rotor bearings need consistent lubrication, while the combustion chamber areas require effective cooling to prevent overheating. Various approaches include oil injection systems for apex seals, water cooling jackets for the housing, and air cooling systems for smaller applications. Advanced cooling designs help address the thermal management challenges inherent to the Wankel configuration, particularly the temperature gradient across the housing.

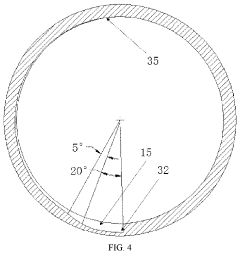

- Fuel Delivery and Combustion Optimization: Optimizing fuel delivery and combustion in Wankel engines presents unique challenges due to the elongated combustion chamber and moving flame front. Various innovations focus on improving fuel injection positioning, timing, and spray patterns to enhance combustion efficiency. Direct injection systems, stratified charge configurations, and multiple spark plug arrangements have been developed to address the combustion challenges. These improvements aim to increase fuel efficiency, reduce emissions, and enhance power output while maintaining the inherent advantages of the rotary design.

- Hybrid and Alternative Fuel Applications: Recent developments in Wankel engine technology include adaptations for hybrid powertrains and alternative fuels. The compact size and smooth operation of Wankel engines make them suitable as range extenders in hybrid electric vehicles. Modifications to accommodate hydrogen, natural gas, and other alternative fuels have been explored to address emissions concerns. These applications leverage the Wankel engine's favorable power-to-weight ratio and packaging advantages while working to overcome traditional efficiency limitations through integration with electric motors or optimization for specific fuel types.

02 Sealing Systems for Wankel Engines

Effective sealing is critical in Wankel engines to maintain compression and prevent gas leakage between the combustion chambers. Various sealing technologies have been developed, including apex seals at the rotor corners, side seals along the rotor faces, and oil seals. These sealing systems are designed to withstand high temperatures and pressures while minimizing friction and wear to ensure engine efficiency and longevity.Expand Specific Solutions03 Cooling and Lubrication Systems

Wankel engines require specialized cooling and lubrication systems due to their unique geometry and operating characteristics. The cooling system must address the uneven temperature distribution across the housing, particularly at the exhaust area. Lubrication systems are designed to provide oil to the rotor bearings, seals, and internal surfaces while preventing excessive oil consumption. Advanced cooling and lubrication solutions help improve engine efficiency and durability.Expand Specific Solutions04 Fuel Delivery and Combustion Optimization

Innovations in fuel delivery and combustion processes aim to improve the efficiency and reduce emissions of Wankel engines. These include direct injection systems, stratified charge configurations, and advanced ignition timing control. Modified combustion chamber designs and optimized port configurations enhance the mixing of fuel and air, resulting in more complete combustion and improved thermal efficiency while reducing hydrocarbon emissions.Expand Specific Solutions05 Applications and Hybrid Systems

Wankel engines find applications in various fields due to their compact size, high power-to-weight ratio, and smooth operation. They are used in automobiles, motorcycles, aircraft, and power generation systems. Recent developments include hybrid systems that combine Wankel engines with electric motors to serve as range extenders in electric vehicles. These hybrid configurations leverage the Wankel engine's compact size and consistent power output while addressing efficiency concerns through electric assistance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine innovation landscape for future mobility is currently in a transitional phase, with the market expected to reach significant growth as automotive and aerospace industries seek more efficient propulsion systems. While the technology has been historically limited by sealing issues and emissions concerns, recent advancements show promising maturity. Key players driving innovation include established aerospace companies like Pratt & Whitney Canada and United Technologies, automotive manufacturers such as LG Electronics and Great Wall Motor, and research institutions including Beijing Institute of Technology and University of Tokyo. Specialized entities like Shaanxi New Year Power Technology Group have made breakthrough improvements addressing traditional Wankel engine limitations through structural innovations, positioning this technology for potential disruption in multiple mobility sectors.

University of Tokyo

Technical Solution: The University of Tokyo has developed a groundbreaking "Ceramic Matrix Composite Rotary Engine" (CMCRE) that addresses the fundamental thermal and sealing challenges of traditional Wankel designs. Their research team has created a comprehensive solution using silicon carbide ceramic matrix composites for critical engine components, including the rotor housing and apex seals. This material innovation allows operating temperatures up to 200°C higher than conventional metal designs while maintaining dimensional stability. The CMCRE incorporates a novel cooling system that uses microchannels embedded within the ceramic structure to provide targeted temperature management across the epitrochoidal housing. Their apex seal design features a multi-layer composite structure with a self-lubricating ceramic outer layer and a flexible carbon fiber reinforced core that maintains sealing integrity while reducing friction by approximately 60% compared to conventional designs. The University team has also developed an advanced surface treatment process that creates microscopic texturing on the trochoid surface, improving oil retention and reducing wear rates by up to 70%. Additionally, their combustion system incorporates multiple laser ignition points that can be precisely timed to optimize the combustion process across different engine speeds and loads, significantly improving thermal efficiency and reducing emissions of NOx by approximately 45% and unburned hydrocarbons by 35% compared to conventional rotary engines.

Strengths: Revolutionary materials science approach solves fundamental rotary engine limitations; significantly higher operating temperature capability enables better thermal efficiency; dramatically improved durability and service life potential. Weaknesses: Advanced ceramic materials significantly increase manufacturing costs; requires specialized production facilities; technology remains primarily in research phase with limited real-world validation.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed a revolutionary aviation-focused Wankel engine platform called the "Advanced Rotary Propulsion System" (ARPS). This technology leverages P&WC's extensive aerospace engineering expertise to overcome traditional rotary engine limitations for aircraft applications. The ARPS features a multi-rotor configuration with sequential combustion chambers that optimize the thermodynamic cycle, achieving approximately 25% better specific fuel consumption than conventional rotary designs. Their proprietary apex seal technology utilizes advanced carbon-ceramic composites with specialized coating treatments that can withstand over 2,000 hours of operation before inspection—a critical improvement for aviation reliability requirements. P&WC has implemented a variable geometry intake system that optimizes airflow across different altitude and speed conditions, maintaining efficiency throughout the flight envelope. The engine incorporates an advanced electronic control system that precisely manages fuel delivery, ignition timing, and emissions control, meeting stringent aviation environmental standards. Additionally, their design includes an integrated oil cooling system that addresses the thermal management challenges inherent to Wankel engines while reducing overall weight by approximately 30% compared to equivalent power piston aircraft engines.

Strengths: Exceptional power-to-weight ratio critical for aviation applications; significantly reduced vibration compared to reciprocating engines; compact design allows for flexible aircraft integration options. Weaknesses: Higher manufacturing complexity increases production costs; requires specialized maintenance procedures and training; still faces challenges with thermal efficiency at certain operating points.

Critical Patents and Engineering Breakthroughs

Rotary engine

PatentActiveUS20230151762A1

Innovation

- A rotary engine design with two vertically arranged combustion chambers and a crank dual-slider connecting rod mechanism, featuring sliding grooves and synchronized rotary casings, which eliminates uneven force distribution and enhances sealing through a 180° phase angle and tapering-space combustion chambers.

Rotary internal combustion engine

PatentActiveUS20180045110A1

Innovation

- The implementation of a rotary engine design with a primary inlet port, a secondary inlet port (purge port) positioned rearwardly of the primary inlet port and forwardly of the exhaust port, and independently closable communications between air sources and these ports, allowing simultaneous air intake and exhaust gas purging through the secondary inlet port.

Emissions Compliance and Sustainability Factors

The Wankel engine faces significant challenges in meeting increasingly stringent global emissions standards, which has been a primary factor limiting its widespread adoption in modern vehicles. Traditional rotary engines produce higher levels of unburned hydrocarbons (UHC) and nitrogen oxides (NOx) compared to conventional piston engines due to their elongated combustion chamber geometry and inherent sealing challenges. These emissions characteristics have made compliance with Euro 6, China 6, and US Tier 3 standards particularly difficult without substantial modifications.

Recent innovations have focused on addressing these emissions concerns through advanced combustion control systems. Direct injection technology, when applied to the Wankel architecture, has demonstrated potential to reduce UHC emissions by up to 30% by enabling more precise fuel delivery and improved atomization. Additionally, the integration of variable rotor timing mechanisms allows for optimized combustion across different operating conditions, further reducing emissions output.

Exhaust aftertreatment systems specifically designed for rotary engines represent another critical development area. Modified three-way catalytic converters with enhanced thermal management capabilities have shown promise in addressing the higher exhaust temperatures characteristic of Wankel engines. Some research teams have developed specialized catalyst formulations that activate at lower temperatures to address cold-start emissions, which have historically been problematic for rotary engines.

From a sustainability perspective, the Wankel engine offers certain advantages that align with future mobility requirements. Its compact size and favorable power-to-weight ratio enable more efficient packaging solutions, potentially reducing overall vehicle mass and associated lifecycle emissions. Furthermore, the rotary's mechanical simplicity—featuring fewer moving parts than conventional piston engines—translates to reduced material requirements and potentially extended service life.

Hydrogen combustion represents a particularly promising pathway for sustainable Wankel engine applications. The rotary architecture's tolerance for hydrogen fuel—which can cause pre-ignition issues in conventional engines—positions it as an attractive option for zero-carbon applications. Mazda's HCCI (Homogeneous Charge Compression Ignition) rotary prototype has demonstrated near-zero NOx emissions when operating on hydrogen, suggesting a potential pathway to emissions compliance without requiring complex aftertreatment systems.

Hybrid integration strategies offer another avenue for emissions compliance. Using the Wankel as a range extender in series hybrid configurations allows the engine to operate exclusively within its optimal efficiency range, significantly reducing emissions output. This approach has been commercialized in vehicles like the Mazda MX-30 e-Skyactiv R-EV, where the rotary engine operates under carefully controlled conditions to meet emissions requirements while providing extended vehicle range.

Recent innovations have focused on addressing these emissions concerns through advanced combustion control systems. Direct injection technology, when applied to the Wankel architecture, has demonstrated potential to reduce UHC emissions by up to 30% by enabling more precise fuel delivery and improved atomization. Additionally, the integration of variable rotor timing mechanisms allows for optimized combustion across different operating conditions, further reducing emissions output.

Exhaust aftertreatment systems specifically designed for rotary engines represent another critical development area. Modified three-way catalytic converters with enhanced thermal management capabilities have shown promise in addressing the higher exhaust temperatures characteristic of Wankel engines. Some research teams have developed specialized catalyst formulations that activate at lower temperatures to address cold-start emissions, which have historically been problematic for rotary engines.

From a sustainability perspective, the Wankel engine offers certain advantages that align with future mobility requirements. Its compact size and favorable power-to-weight ratio enable more efficient packaging solutions, potentially reducing overall vehicle mass and associated lifecycle emissions. Furthermore, the rotary's mechanical simplicity—featuring fewer moving parts than conventional piston engines—translates to reduced material requirements and potentially extended service life.

Hydrogen combustion represents a particularly promising pathway for sustainable Wankel engine applications. The rotary architecture's tolerance for hydrogen fuel—which can cause pre-ignition issues in conventional engines—positions it as an attractive option for zero-carbon applications. Mazda's HCCI (Homogeneous Charge Compression Ignition) rotary prototype has demonstrated near-zero NOx emissions when operating on hydrogen, suggesting a potential pathway to emissions compliance without requiring complex aftertreatment systems.

Hybrid integration strategies offer another avenue for emissions compliance. Using the Wankel as a range extender in series hybrid configurations allows the engine to operate exclusively within its optimal efficiency range, significantly reducing emissions output. This approach has been commercialized in vehicles like the Mazda MX-30 e-Skyactiv R-EV, where the rotary engine operates under carefully controlled conditions to meet emissions requirements while providing extended vehicle range.

Integration Potential with Hybrid and EV Systems

The integration of Wankel rotary engines with hybrid and electric vehicle systems represents a promising frontier in automotive powertrain development. The inherent characteristics of rotary engines—compact size, high power-to-weight ratio, and smooth operation—make them particularly suitable candidates for integration with electrification technologies. This synergy could potentially address the traditional limitations of Wankel engines while leveraging their unique advantages.

Recent developments have demonstrated several viable integration architectures. The series-hybrid configuration, where the Wankel engine serves exclusively as a generator to charge batteries and power electric motors, has gained significant traction. This arrangement allows the rotary engine to operate at its optimal efficiency point, mitigating issues related to fuel consumption and emissions that have historically plagued these engines.

Range-extended electric vehicles (REEVs) represent another promising application. In this configuration, the Wankel engine functions as an auxiliary power unit that activates only when battery charge depletes beyond a certain threshold. Mazda's experiments with rotary range extenders in their MX-30 model illustrate the commercial viability of this approach, offering extended driving range without compromising the primary electric drivetrain benefits.

The multi-fuel capability of Wankel engines adds another dimension to their integration potential. These engines can operate on various fuels including hydrogen, natural gas, and synthetic fuels with minimal modifications. This flexibility aligns well with the transitional energy landscape of the automotive industry, potentially serving as a bridge technology during the gradual shift toward full electrification.

Thermal management synergies present additional integration opportunities. The waste heat from rotary engines can be harnessed for battery temperature regulation in cold conditions, improving overall system efficiency. Conversely, the electric systems can provide precise control over rotary engine parameters, optimizing combustion processes and reducing emissions.

Challenges remain in perfecting these integrations, particularly in controlling emissions during cold starts and optimizing the control algorithms that determine when and how the rotary engine engages. However, advancements in materials science and digital control systems are progressively addressing these hurdles.

The weight and packaging advantages of rotary-hybrid integrations make them especially suitable for specific vehicle categories such as sports cars, where the compact powertrain allows for optimal weight distribution, and urban delivery vehicles, where space efficiency translates to increased cargo capacity without expanding the vehicle footprint.

Recent developments have demonstrated several viable integration architectures. The series-hybrid configuration, where the Wankel engine serves exclusively as a generator to charge batteries and power electric motors, has gained significant traction. This arrangement allows the rotary engine to operate at its optimal efficiency point, mitigating issues related to fuel consumption and emissions that have historically plagued these engines.

Range-extended electric vehicles (REEVs) represent another promising application. In this configuration, the Wankel engine functions as an auxiliary power unit that activates only when battery charge depletes beyond a certain threshold. Mazda's experiments with rotary range extenders in their MX-30 model illustrate the commercial viability of this approach, offering extended driving range without compromising the primary electric drivetrain benefits.

The multi-fuel capability of Wankel engines adds another dimension to their integration potential. These engines can operate on various fuels including hydrogen, natural gas, and synthetic fuels with minimal modifications. This flexibility aligns well with the transitional energy landscape of the automotive industry, potentially serving as a bridge technology during the gradual shift toward full electrification.

Thermal management synergies present additional integration opportunities. The waste heat from rotary engines can be harnessed for battery temperature regulation in cold conditions, improving overall system efficiency. Conversely, the electric systems can provide precise control over rotary engine parameters, optimizing combustion processes and reducing emissions.

Challenges remain in perfecting these integrations, particularly in controlling emissions during cold starts and optimizing the control algorithms that determine when and how the rotary engine engages. However, advancements in materials science and digital control systems are progressively addressing these hurdles.

The weight and packaging advantages of rotary-hybrid integrations make them especially suitable for specific vehicle categories such as sports cars, where the compact powertrain allows for optimal weight distribution, and urban delivery vehicles, where space efficiency translates to increased cargo capacity without expanding the vehicle footprint.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!