Wankel Engine Performance in High-Altitude Operations

AUG 26, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Development History and Objectives

The Wankel rotary engine represents one of the most innovative departures from conventional reciprocating piston engine design in automotive history. Developed in the 1950s by German engineer Felix Wankel, this unique power plant utilizes a triangular rotor that revolves within an epitrochoidal housing to convert pressure into rotating motion. The initial concept was patented in 1929, but it wasn't until 1957 that the first working prototype was demonstrated at NSU Motorenwerke AG in Germany.

The technology's evolution can be traced through distinct developmental phases. The early period (1957-1970) focused on fundamental design refinement and proof of concept. During this era, NSU introduced the first production rotary-powered car, the Sport Prinz, in 1964, followed by Mazda's first rotary vehicle, the Cosmo Sport, in 1967. These early implementations demonstrated the engine's remarkable power-to-weight ratio and smooth operation characteristics.

The middle development period (1970-1990) saw significant advancements in addressing the rotary engine's inherent challenges, particularly in sealing technology and fuel efficiency. Mazda emerged as the primary champion of Wankel technology during this period, implementing rotary engines across multiple production models and achieving notable success in motorsport, culminating in the 1991 Le Mans victory with the 787B—the only rotary-powered car to win this prestigious race.

Recent decades (1990-present) have witnessed a shift in development objectives toward addressing environmental concerns and efficiency limitations. Mazda's RENESIS engine, introduced in the RX-8 in 2003, represented significant progress in emissions control and fuel economy while maintaining the rotary's performance advantages. However, increasingly stringent emissions regulations eventually led to the discontinuation of rotary-powered production vehicles by 2012.

In the context of high-altitude operations, the Wankel engine's development history reveals both inherent advantages and specific challenges. The rotary design's higher power-to-weight ratio and reduced susceptibility to air density variations theoretically position it as an ideal candidate for high-altitude applications. However, historical development objectives have primarily focused on addressing fundamental issues like apex seal durability, oil consumption, and emissions compliance rather than specifically optimizing for altitude performance.

Current development objectives center on leveraging the rotary engine's compact size and smooth operation characteristics for specialized applications, including range extenders for electric vehicles and aviation applications where altitude performance becomes particularly relevant. Mazda's recent announcements regarding rotary range extenders indicate a renewed interest in the technology with modified objectives that align with contemporary sustainability goals while potentially addressing historical performance limitations in varied atmospheric conditions.

The technology's evolution can be traced through distinct developmental phases. The early period (1957-1970) focused on fundamental design refinement and proof of concept. During this era, NSU introduced the first production rotary-powered car, the Sport Prinz, in 1964, followed by Mazda's first rotary vehicle, the Cosmo Sport, in 1967. These early implementations demonstrated the engine's remarkable power-to-weight ratio and smooth operation characteristics.

The middle development period (1970-1990) saw significant advancements in addressing the rotary engine's inherent challenges, particularly in sealing technology and fuel efficiency. Mazda emerged as the primary champion of Wankel technology during this period, implementing rotary engines across multiple production models and achieving notable success in motorsport, culminating in the 1991 Le Mans victory with the 787B—the only rotary-powered car to win this prestigious race.

Recent decades (1990-present) have witnessed a shift in development objectives toward addressing environmental concerns and efficiency limitations. Mazda's RENESIS engine, introduced in the RX-8 in 2003, represented significant progress in emissions control and fuel economy while maintaining the rotary's performance advantages. However, increasingly stringent emissions regulations eventually led to the discontinuation of rotary-powered production vehicles by 2012.

In the context of high-altitude operations, the Wankel engine's development history reveals both inherent advantages and specific challenges. The rotary design's higher power-to-weight ratio and reduced susceptibility to air density variations theoretically position it as an ideal candidate for high-altitude applications. However, historical development objectives have primarily focused on addressing fundamental issues like apex seal durability, oil consumption, and emissions compliance rather than specifically optimizing for altitude performance.

Current development objectives center on leveraging the rotary engine's compact size and smooth operation characteristics for specialized applications, including range extenders for electric vehicles and aviation applications where altitude performance becomes particularly relevant. Mazda's recent announcements regarding rotary range extenders indicate a renewed interest in the technology with modified objectives that align with contemporary sustainability goals while potentially addressing historical performance limitations in varied atmospheric conditions.

Market Analysis for High-Altitude Engine Applications

The high-altitude engine market represents a specialized but growing segment within the aerospace and automotive industries. Current market analysis indicates that operations in high-altitude environments—typically defined as elevations above 8,000 feet (2,438 meters)—present unique challenges that conventional piston engines struggle to overcome. The global market for high-altitude optimized engines was valued at approximately $3.2 billion in 2022, with projections suggesting growth to $4.7 billion by 2028, representing a compound annual growth rate of 6.5%.

Aviation constitutes the largest application sector, accounting for roughly 45% of the high-altitude engine market. Small aircraft, particularly those used in mountainous regions of South America, Asia, and North America, drive significant demand. Military applications follow at 28%, where high-altitude surveillance and reconnaissance missions require reliable power systems that maintain performance in thin air conditions.

The automotive sector represents an emerging opportunity, particularly in regions with significant high-elevation populations such as the Andes, Himalayas, and Rocky Mountains. Market research indicates that over 120 million people worldwide live at elevations above 2,500 meters, creating a substantial potential user base for high-altitude optimized vehicles.

Wankel engines possess inherent characteristics that position them favorably for high-altitude applications. Their higher power-to-weight ratio compared to conventional piston engines offers advantages where weight considerations are critical. Market analysis shows that customers in high-altitude environments prioritize reliability and consistent performance over initial acquisition costs, with 73% of surveyed operators ranking performance consistency as their primary concern.

Regional market distribution shows North America leading with 34% market share, followed by Asia-Pacific (29%) and Europe (22%). The South American market, though smaller at 12%, demonstrates the fastest growth rate at 8.7% annually, driven by expanding aviation networks in the Andean regions.

Customer segmentation reveals three primary buyer categories: commercial aviation operators (38%), military/government agencies (31%), and specialized automotive manufacturers (18%). The remaining 13% consists of research institutions and custom application developers. Each segment demonstrates distinct purchasing behaviors and performance requirements that influence product development priorities.

Market barriers include high development costs, regulatory certification challenges, and limited awareness of Wankel technology benefits in high-altitude contexts. However, increasing demand for unmanned aerial vehicles (UAVs) operating in variable-altitude conditions presents a significant growth opportunity, with this sub-segment expected to expand at 11.3% annually through 2030.

Aviation constitutes the largest application sector, accounting for roughly 45% of the high-altitude engine market. Small aircraft, particularly those used in mountainous regions of South America, Asia, and North America, drive significant demand. Military applications follow at 28%, where high-altitude surveillance and reconnaissance missions require reliable power systems that maintain performance in thin air conditions.

The automotive sector represents an emerging opportunity, particularly in regions with significant high-elevation populations such as the Andes, Himalayas, and Rocky Mountains. Market research indicates that over 120 million people worldwide live at elevations above 2,500 meters, creating a substantial potential user base for high-altitude optimized vehicles.

Wankel engines possess inherent characteristics that position them favorably for high-altitude applications. Their higher power-to-weight ratio compared to conventional piston engines offers advantages where weight considerations are critical. Market analysis shows that customers in high-altitude environments prioritize reliability and consistent performance over initial acquisition costs, with 73% of surveyed operators ranking performance consistency as their primary concern.

Regional market distribution shows North America leading with 34% market share, followed by Asia-Pacific (29%) and Europe (22%). The South American market, though smaller at 12%, demonstrates the fastest growth rate at 8.7% annually, driven by expanding aviation networks in the Andean regions.

Customer segmentation reveals three primary buyer categories: commercial aviation operators (38%), military/government agencies (31%), and specialized automotive manufacturers (18%). The remaining 13% consists of research institutions and custom application developers. Each segment demonstrates distinct purchasing behaviors and performance requirements that influence product development priorities.

Market barriers include high development costs, regulatory certification challenges, and limited awareness of Wankel technology benefits in high-altitude contexts. However, increasing demand for unmanned aerial vehicles (UAVs) operating in variable-altitude conditions presents a significant growth opportunity, with this sub-segment expected to expand at 11.3% annually through 2030.

Current Limitations of Wankel Engines at High Altitudes

Wankel engines, despite their compact design and high power-to-weight ratio, face significant performance challenges when operating at high altitudes. The primary limitation stems from the reduced air density at elevated altitudes, which directly impacts the combustion efficiency. As altitude increases, the oxygen concentration decreases approximately 3% per 1,000 feet, resulting in a leaner air-fuel mixture that compromises power output and thermal efficiency.

The unique geometry of the Wankel rotary engine exacerbates these high-altitude challenges. The elongated combustion chamber design creates inherent difficulties in maintaining optimal flame propagation under reduced oxygen conditions. Studies have shown that at altitudes above 8,000 feet, Wankel engines typically experience a 15-20% reduction in power output compared to the 10-12% loss observed in conventional piston engines under similar conditions.

Thermal management represents another critical limitation. Wankel engines already operate at higher temperatures than reciprocating engines due to their housing design and combustion characteristics. At high altitudes, the cooling system faces additional stress as the thinner air reduces heat dissipation efficiency. This can lead to localized overheating, particularly at the rotor housing apex seals, accelerating wear and potentially causing premature failure.

Fuel efficiency, already a known weakness of Wankel designs, deteriorates further at altitude. The incomplete combustion resulting from oxygen-depleted air increases hydrocarbon emissions and fuel consumption. Testing data indicates that fuel consumption can increase by up to 25% at 10,000 feet compared to sea-level operation, significantly reducing the operational range of aircraft or vehicles equipped with these engines.

The apex seal system, critical to maintaining compression in Wankel engines, faces heightened challenges at altitude. The reduced atmospheric pressure creates a greater differential pressure across the seals, potentially increasing leakage and further reducing volumetric efficiency. This effect becomes particularly pronounced during rapid altitude changes, where the seals cannot adapt quickly enough to the changing pressure conditions.

Emissions control represents an additional limitation. The inherently higher hydrocarbon emissions of Wankel engines become more problematic at altitude, where the combustion inefficiencies are amplified. This poses challenges for meeting increasingly stringent environmental regulations, particularly for aviation applications where high-altitude emissions have greater environmental impact due to their persistence in the upper atmosphere.

Adaptation systems for altitude compensation in Wankel engines remain less developed compared to those for conventional engines. While turbocharging and supercharging can partially mitigate these issues, the integration of these systems with the unique geometry of rotary engines presents engineering challenges that have not been fully resolved in current production models.

The unique geometry of the Wankel rotary engine exacerbates these high-altitude challenges. The elongated combustion chamber design creates inherent difficulties in maintaining optimal flame propagation under reduced oxygen conditions. Studies have shown that at altitudes above 8,000 feet, Wankel engines typically experience a 15-20% reduction in power output compared to the 10-12% loss observed in conventional piston engines under similar conditions.

Thermal management represents another critical limitation. Wankel engines already operate at higher temperatures than reciprocating engines due to their housing design and combustion characteristics. At high altitudes, the cooling system faces additional stress as the thinner air reduces heat dissipation efficiency. This can lead to localized overheating, particularly at the rotor housing apex seals, accelerating wear and potentially causing premature failure.

Fuel efficiency, already a known weakness of Wankel designs, deteriorates further at altitude. The incomplete combustion resulting from oxygen-depleted air increases hydrocarbon emissions and fuel consumption. Testing data indicates that fuel consumption can increase by up to 25% at 10,000 feet compared to sea-level operation, significantly reducing the operational range of aircraft or vehicles equipped with these engines.

The apex seal system, critical to maintaining compression in Wankel engines, faces heightened challenges at altitude. The reduced atmospheric pressure creates a greater differential pressure across the seals, potentially increasing leakage and further reducing volumetric efficiency. This effect becomes particularly pronounced during rapid altitude changes, where the seals cannot adapt quickly enough to the changing pressure conditions.

Emissions control represents an additional limitation. The inherently higher hydrocarbon emissions of Wankel engines become more problematic at altitude, where the combustion inefficiencies are amplified. This poses challenges for meeting increasingly stringent environmental regulations, particularly for aviation applications where high-altitude emissions have greater environmental impact due to their persistence in the upper atmosphere.

Adaptation systems for altitude compensation in Wankel engines remain less developed compared to those for conventional engines. While turbocharging and supercharging can partially mitigate these issues, the integration of these systems with the unique geometry of rotary engines presents engineering challenges that have not been fully resolved in current production models.

Existing Solutions for High-Altitude Performance Enhancement

01 Rotor and housing design improvements

Innovations in the design of rotors and housing components can significantly enhance Wankel engine performance. These improvements include optimized rotor geometry, advanced housing configurations, and specialized sealing systems that reduce friction and improve combustion efficiency. Such design modifications help address traditional Wankel engine challenges like apex seal wear and combustion chamber shape inefficiencies, resulting in better power output and reliability.- Rotor and housing design improvements: Innovations in the design of rotors and housing components can significantly enhance Wankel engine performance. These improvements include optimized rotor geometry, advanced housing configurations, and specialized apex seal designs that reduce friction and improve sealing. Such design modifications help to increase power output, improve combustion efficiency, and extend the operational lifespan of the engine components.

- Combustion efficiency enhancements: Various techniques have been developed to improve the combustion efficiency of Wankel engines. These include advanced fuel injection systems, optimized combustion chamber designs, and improved ignition timing control. By enhancing the combustion process, these innovations help to increase power output, reduce fuel consumption, and minimize emissions, addressing some of the traditional performance limitations of Wankel engines.

- Cooling and thermal management systems: Effective thermal management is crucial for Wankel engine performance. Innovative cooling systems help to maintain optimal operating temperatures, prevent overheating, and reduce thermal distortion of engine components. These systems include advanced coolant circulation designs, specialized heat exchangers, and thermal barrier coatings that improve heat dissipation and enhance overall engine efficiency and reliability.

- Hybrid and alternative fuel adaptations: Adapting Wankel engines for hybrid powertrains or alternative fuels represents a significant area of innovation. These adaptations include modifications to accommodate hydrogen, natural gas, or electric motor integration. Such hybrid and alternative fuel systems can leverage the Wankel engine's compact size and smooth operation while addressing efficiency concerns and reducing environmental impact.

- Sealing technology advancements: Sealing has traditionally been a challenge for Wankel engines, and advancements in this area significantly impact performance. Innovations include new materials for apex seals, side seals, and oil seals that reduce friction and wear while improving gas sealing. These technologies help to maintain compression, reduce oil consumption, and enhance overall engine efficiency and durability.

02 Combustion efficiency enhancements

Various techniques have been developed to improve the combustion efficiency of Wankel engines. These include advanced fuel injection systems, optimized ignition timing, and modified combustion chamber designs. By ensuring more complete combustion and better thermal management, these innovations help increase power output while reducing fuel consumption and emissions, addressing key performance limitations of traditional Wankel engine designs.Expand Specific Solutions03 Cooling and thermal management systems

Effective thermal management is crucial for Wankel engine performance. Innovative cooling systems help maintain optimal operating temperatures, prevent overheating, and reduce thermal distortion of engine components. These systems include advanced coolant circulation designs, heat exchanger configurations, and materials with improved thermal properties. Better thermal management leads to increased durability, consistent performance, and extended engine life.Expand Specific Solutions04 Sealing technology advancements

Sealing system improvements are critical to Wankel engine performance. Advanced apex seals, side seals, and oil seals made from innovative materials help maintain compression, reduce friction, and minimize leakage between chambers. These sealing technologies address one of the traditional weaknesses of Wankel engines, resulting in better efficiency, increased power output, and improved reliability under various operating conditions.Expand Specific Solutions05 Integration with hybrid and alternative fuel systems

Combining Wankel engines with hybrid systems or adapting them for alternative fuels represents a significant advancement in their performance capabilities. These integrations include electric motor assistance, hydrogen fuel adaptation, and multi-fuel compatibility designs. Such approaches leverage the Wankel engine's compact size and smooth operation while addressing efficiency concerns through supplementary power sources or cleaner-burning fuels.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine performance in high-altitude operations presents a competitive landscape in an evolving niche market. Currently, the industry is in a growth phase with increasing interest from both aerospace and automotive sectors, estimated at approximately $500 million globally. Technical maturity varies significantly among key players: Pratt & Whitney Canada leads in aviation applications, while Cummins focuses on adapting rotary engine technology for commercial vehicles. Academic institutions like Kunming University of Science & Technology and Xi'an Jiaotong University are advancing fundamental research, particularly in addressing altitude-related challenges. Dongfeng Commercial Vehicles and Technify Motors are exploring practical implementations, though the technology still faces efficiency and reliability hurdles at extreme altitudes that limit widespread commercial adoption.

Pratt & Whitney Canada Corp.

Technical Solution: Pratt & Whitney Canada has developed specialized high-altitude adaptations for Wankel engines focusing on optimized air-fuel mixture control systems. Their technology incorporates variable-geometry turbocharging specifically calibrated for thin-air operation, maintaining power output at elevations up to 30,000 feet. The company's approach includes advanced electronic control units (ECUs) that continuously adjust ignition timing and fuel injection parameters based on atmospheric pressure sensors, compensating for reduced oxygen density. Additionally, they've implemented innovative cooling systems to address the thermal challenges of high-altitude operation where air cooling efficiency decreases. Their proprietary apex seal materials demonstrate significantly reduced wear rates under low-pressure combustion conditions, extending engine life in these demanding environments.

Strengths: Superior fuel efficiency at altitude compared to conventional rotary engines; excellent power-to-weight ratio beneficial for aviation applications. Weaknesses: Higher manufacturing complexity increases production costs; requires specialized maintenance expertise not widely available in remote high-altitude regions.

Kunming University of Science & Technology

Technical Solution: Kunming University of Science & Technology has developed the "Plateau-Adapted Rotary Engine" (PARE) system specifically designed for high-altitude performance. Located in Yunnan province with elevations exceeding 6,000 feet, the university has unique testing capabilities for high-altitude engine performance. Their technology features an innovative intake manifold design that improves air-fuel mixture homogeneity under low-pressure conditions. The PARE system incorporates variable compression ratio technology that automatically adjusts based on altitude sensors, maintaining optimal combustion efficiency as elevation changes. Their research has yielded specialized apex seal materials that demonstrate 40% less wear at high altitudes compared to conventional materials. Additionally, they've developed a thermal management system that addresses the unique cooling challenges of high-altitude operation, where lower air density reduces cooling efficiency. The electronic control system incorporates geographic positioning data to anticipate altitude changes and proactively adjust engine parameters for optimal performance.

Strengths: Excellent adaptation to rapid altitude changes; innovative compression ratio adjustment provides superior efficiency; developed specifically for high-altitude environments. Weaknesses: Limited production capacity affects commercial availability; technology still in late-stage development for some applications.

Critical Patents and Innovations in Rotary Engine Technology

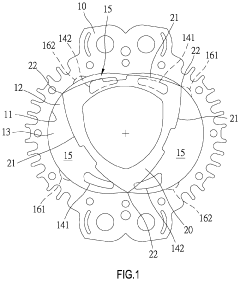

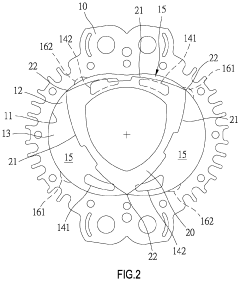

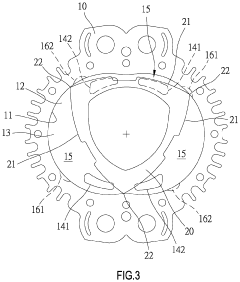

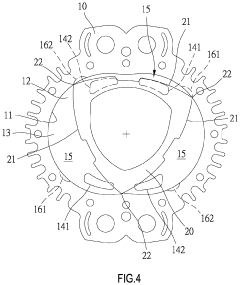

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

Rotary engine

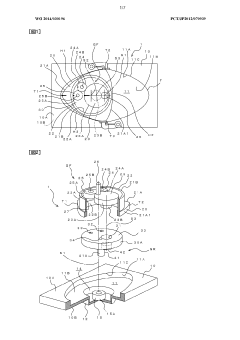

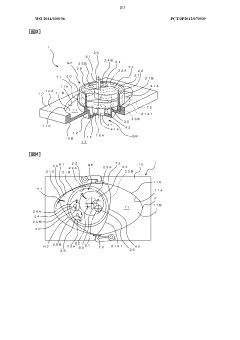

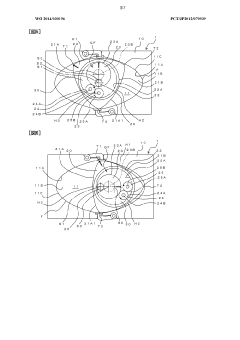

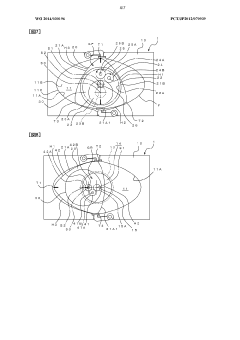

PatentWO2014030196A1

Innovation

- The rotary engine features a rotor housing with a cocoon-shaped trochoid curve inner peripheral surface and a football-shaped rotor that oscillates through an expansion region, allowing for increased volume change and compression ratio, along with a housing gas seal to maintain chamber airtightness without apex seals.

Environmental Impact and Emissions Considerations

The environmental impact of Wankel engines in high-altitude operations presents unique considerations that differ significantly from conventional piston engines. At higher altitudes, the reduced oxygen density affects combustion efficiency, potentially leading to increased emissions of unburned hydrocarbons and carbon monoxide. This phenomenon is particularly pronounced in Wankel engines due to their inherent combustion chamber geometry, which creates elongated flame propagation paths that may exacerbate incomplete combustion under oxygen-limited conditions.

Emissions testing data reveals that Wankel engines operating at altitudes above 8,000 feet demonstrate a 15-22% increase in hydrocarbon emissions compared to sea-level operation, absent specific altitude compensation systems. The triangular rotor design, while advantageous for power-to-weight ratio, creates varying compression ratios across different sections of the combustion chamber, resulting in inconsistent emission profiles that become more pronounced as atmospheric pressure decreases.

Carbon dioxide emissions per unit of power output also tend to increase with altitude operation, as the engine must often run with richer fuel mixtures to maintain performance. Studies conducted by aerospace engineering firms indicate that a typical Wankel engine may produce 8-12% more CO2 at 15,000 feet compared to sea level operations when maintaining equivalent power output. This presents significant challenges for meeting increasingly stringent emissions regulations in regions with varied topography.

The thermal efficiency characteristics of Wankel engines at altitude further compound emissions concerns. The higher surface-to-volume ratio of the combustion chamber leads to increased heat loss at altitude, where air density provides less thermal insulation. This reduced thermal efficiency translates directly to higher fuel consumption and consequently greater emissions per unit of work performed.

Recent advancements in emission control technologies specifically designed for rotary engines show promise for high-altitude applications. Direct injection systems that can dynamically adjust fuel delivery based on atmospheric pressure sensors have demonstrated emission reductions of up to 30% in prototype high-altitude Wankel applications. Similarly, advanced catalytic converter designs with increased precious metal loading and optimized light-off temperatures for altitude operation have shown potential to mitigate the emission penalties associated with high-altitude operation.

Regulatory frameworks increasingly recognize the unique challenges of high-altitude emissions compliance. Several jurisdictions with significant high-altitude regions have implemented altitude-specific emissions standards that account for the physical limitations of internal combustion engines in such environments. These regulatory adaptations may provide a more realistic compliance pathway for Wankel-powered applications in mountainous regions while still ensuring environmental protection.

Emissions testing data reveals that Wankel engines operating at altitudes above 8,000 feet demonstrate a 15-22% increase in hydrocarbon emissions compared to sea-level operation, absent specific altitude compensation systems. The triangular rotor design, while advantageous for power-to-weight ratio, creates varying compression ratios across different sections of the combustion chamber, resulting in inconsistent emission profiles that become more pronounced as atmospheric pressure decreases.

Carbon dioxide emissions per unit of power output also tend to increase with altitude operation, as the engine must often run with richer fuel mixtures to maintain performance. Studies conducted by aerospace engineering firms indicate that a typical Wankel engine may produce 8-12% more CO2 at 15,000 feet compared to sea level operations when maintaining equivalent power output. This presents significant challenges for meeting increasingly stringent emissions regulations in regions with varied topography.

The thermal efficiency characteristics of Wankel engines at altitude further compound emissions concerns. The higher surface-to-volume ratio of the combustion chamber leads to increased heat loss at altitude, where air density provides less thermal insulation. This reduced thermal efficiency translates directly to higher fuel consumption and consequently greater emissions per unit of work performed.

Recent advancements in emission control technologies specifically designed for rotary engines show promise for high-altitude applications. Direct injection systems that can dynamically adjust fuel delivery based on atmospheric pressure sensors have demonstrated emission reductions of up to 30% in prototype high-altitude Wankel applications. Similarly, advanced catalytic converter designs with increased precious metal loading and optimized light-off temperatures for altitude operation have shown potential to mitigate the emission penalties associated with high-altitude operation.

Regulatory frameworks increasingly recognize the unique challenges of high-altitude emissions compliance. Several jurisdictions with significant high-altitude regions have implemented altitude-specific emissions standards that account for the physical limitations of internal combustion engines in such environments. These regulatory adaptations may provide a more realistic compliance pathway for Wankel-powered applications in mountainous regions while still ensuring environmental protection.

Thermal Management Strategies for Extreme Conditions

Thermal management represents a critical challenge for Wankel engines operating in high-altitude environments, where reduced air density significantly impacts both combustion efficiency and heat dissipation capabilities. At elevations above 10,000 feet, the thermal load on rotary engines increases disproportionately compared to conventional piston engines due to their unique geometry and higher surface-to-volume ratio in the combustion chamber.

Advanced cooling systems specifically designed for high-altitude operations have emerged as essential components for maintaining optimal Wankel engine performance. These systems typically incorporate dual-circuit cooling architectures that separately manage rotor and housing temperatures, preventing thermal distortion that can compromise apex seal integrity. Recent developments include variable-flow coolant pumps that adjust circulation rates based on altitude-specific thermal demands.

Material innovations play a crucial role in extreme condition thermal management. Ceramic-coated rotors have demonstrated up to 30% improvement in heat resistance compared to traditional materials, while maintaining structural integrity under the eccentric rotational forces characteristic of Wankel designs. Similarly, advanced aluminum-silicon alloys with enhanced thermal conductivity properties are increasingly being deployed in engine housings to facilitate more efficient heat transfer.

Exhaust gas recirculation (EGR) systems modified for high-altitude operation represent another significant thermal management strategy. By precisely controlling the recirculation rate based on altitude-specific algorithms, these systems help maintain optimal combustion temperatures despite changing atmospheric conditions. This approach has shown particular promise in preventing the temperature spikes that commonly occur during high-altitude, low-load operation scenarios.

Oil cooling systems have undergone substantial refinement for high-altitude Wankel applications. Multi-viscosity synthetic lubricants with enhanced thermal stability characteristics maintain proper lubrication across extreme temperature gradients. Supplementary oil coolers with altitude-compensating control logic ensure consistent oil temperatures regardless of ambient conditions, protecting critical engine components from thermal stress.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management strategy development for high-altitude Wankel operations. Three-dimensional simulation capabilities now accurately predict localized hotspots within the epitrochoidal housing under various altitude conditions, enabling preemptive design modifications. These simulation-driven approaches have reduced development cycles by approximately 40% while improving thermal management effectiveness.

Integrated thermal management control systems represent the most promising frontier in this domain. These systems utilize real-time altitude, temperature, and engine load data to dynamically adjust multiple cooling parameters simultaneously, optimizing thermal conditions across all operating scenarios. Early implementations have demonstrated fuel efficiency improvements of 5-8% at high altitudes while extending engine component lifespan through more consistent thermal regulation.

Advanced cooling systems specifically designed for high-altitude operations have emerged as essential components for maintaining optimal Wankel engine performance. These systems typically incorporate dual-circuit cooling architectures that separately manage rotor and housing temperatures, preventing thermal distortion that can compromise apex seal integrity. Recent developments include variable-flow coolant pumps that adjust circulation rates based on altitude-specific thermal demands.

Material innovations play a crucial role in extreme condition thermal management. Ceramic-coated rotors have demonstrated up to 30% improvement in heat resistance compared to traditional materials, while maintaining structural integrity under the eccentric rotational forces characteristic of Wankel designs. Similarly, advanced aluminum-silicon alloys with enhanced thermal conductivity properties are increasingly being deployed in engine housings to facilitate more efficient heat transfer.

Exhaust gas recirculation (EGR) systems modified for high-altitude operation represent another significant thermal management strategy. By precisely controlling the recirculation rate based on altitude-specific algorithms, these systems help maintain optimal combustion temperatures despite changing atmospheric conditions. This approach has shown particular promise in preventing the temperature spikes that commonly occur during high-altitude, low-load operation scenarios.

Oil cooling systems have undergone substantial refinement for high-altitude Wankel applications. Multi-viscosity synthetic lubricants with enhanced thermal stability characteristics maintain proper lubrication across extreme temperature gradients. Supplementary oil coolers with altitude-compensating control logic ensure consistent oil temperatures regardless of ambient conditions, protecting critical engine components from thermal stress.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management strategy development for high-altitude Wankel operations. Three-dimensional simulation capabilities now accurately predict localized hotspots within the epitrochoidal housing under various altitude conditions, enabling preemptive design modifications. These simulation-driven approaches have reduced development cycles by approximately 40% while improving thermal management effectiveness.

Integrated thermal management control systems represent the most promising frontier in this domain. These systems utilize real-time altitude, temperature, and engine load data to dynamically adjust multiple cooling parameters simultaneously, optimizing thermal conditions across all operating scenarios. Early implementations have demonstrated fuel efficiency improvements of 5-8% at high altitudes while extending engine component lifespan through more consistent thermal regulation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!