Wankel Engine Torque Dynamics Under Load

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Wankel Engine Development History and Performance Objectives

The Wankel rotary engine represents one of the most innovative departures from conventional internal combustion engine design in automotive history. Developed by German engineer Felix Wankel, the first concept of this revolutionary engine emerged in the 1920s, though the practical development began in earnest during the 1950s at NSU Motorenwerke AG. The first working prototype, the DKM 54, was completed in 1957, marking the beginning of a new chapter in engine technology.

By 1963, NSU introduced the first production car powered by a Wankel engine, the NSU Spider. This milestone was followed by Mazda's licensing of the technology in 1961, leading to their first rotary-powered vehicle, the Cosmo Sport, launched in 1967. Mazda's commitment to the Wankel concept would prove instrumental in refining the technology over subsequent decades.

The Wankel engine's unique design offers several inherent advantages over reciprocating piston engines, particularly in terms of power-to-weight ratio and mechanical simplicity. With fewer moving parts and a smoother operation due to rotational rather than reciprocating motion, the engine delivers exceptional power density. Early performance objectives focused on harnessing these advantages while addressing challenges related to sealing, fuel efficiency, and emissions.

Throughout the 1970s and 1980s, significant engineering efforts were directed toward improving the rotor apex seals, which represented a critical weakness in early designs. These seals, subjected to varying thermal conditions and mechanical stresses, were essential for maintaining compression and efficiency. Mazda's continuous refinement culminated in the renowned 13B engine series, which powered multiple generations of the RX-7 sports car.

The performance objectives for Wankel engines have evolved considerably over time. Initial goals centered on maximizing power output and mechanical reliability, while later development phases increasingly focused on addressing fuel consumption concerns and meeting stringent emissions standards. The unique combustion characteristics of the Wankel design present specific challenges in these areas, particularly regarding hydrocarbon emissions and thermal efficiency.

Recent development efforts have concentrated on understanding and optimizing torque dynamics under various load conditions. Unlike conventional engines, the Wankel's eccentric shaft rotation creates distinctive torque characteristics that vary significantly with RPM and load. Engineers have employed advanced computational fluid dynamics and real-time monitoring systems to analyze these dynamics, aiming to enhance drivability and efficiency across diverse operating conditions.

Contemporary performance objectives include integrating the Wankel concept with hybrid electric systems, exploring hydrogen as an alternative fuel, and developing advanced materials to address traditional weaknesses. Mazda's announcement of the rotary engine's return as a range extender in electric vehicles represents a new chapter in the technology's evolution, demonstrating its continued relevance in an increasingly electrified automotive landscape.

By 1963, NSU introduced the first production car powered by a Wankel engine, the NSU Spider. This milestone was followed by Mazda's licensing of the technology in 1961, leading to their first rotary-powered vehicle, the Cosmo Sport, launched in 1967. Mazda's commitment to the Wankel concept would prove instrumental in refining the technology over subsequent decades.

The Wankel engine's unique design offers several inherent advantages over reciprocating piston engines, particularly in terms of power-to-weight ratio and mechanical simplicity. With fewer moving parts and a smoother operation due to rotational rather than reciprocating motion, the engine delivers exceptional power density. Early performance objectives focused on harnessing these advantages while addressing challenges related to sealing, fuel efficiency, and emissions.

Throughout the 1970s and 1980s, significant engineering efforts were directed toward improving the rotor apex seals, which represented a critical weakness in early designs. These seals, subjected to varying thermal conditions and mechanical stresses, were essential for maintaining compression and efficiency. Mazda's continuous refinement culminated in the renowned 13B engine series, which powered multiple generations of the RX-7 sports car.

The performance objectives for Wankel engines have evolved considerably over time. Initial goals centered on maximizing power output and mechanical reliability, while later development phases increasingly focused on addressing fuel consumption concerns and meeting stringent emissions standards. The unique combustion characteristics of the Wankel design present specific challenges in these areas, particularly regarding hydrocarbon emissions and thermal efficiency.

Recent development efforts have concentrated on understanding and optimizing torque dynamics under various load conditions. Unlike conventional engines, the Wankel's eccentric shaft rotation creates distinctive torque characteristics that vary significantly with RPM and load. Engineers have employed advanced computational fluid dynamics and real-time monitoring systems to analyze these dynamics, aiming to enhance drivability and efficiency across diverse operating conditions.

Contemporary performance objectives include integrating the Wankel concept with hybrid electric systems, exploring hydrogen as an alternative fuel, and developing advanced materials to address traditional weaknesses. Mazda's announcement of the rotary engine's return as a range extender in electric vehicles represents a new chapter in the technology's evolution, demonstrating its continued relevance in an increasingly electrified automotive landscape.

Market Analysis for Rotary Engine Applications

The rotary engine market has undergone significant transformation since its commercial introduction by Mazda in the 1960s. Current global market size for rotary engine applications is estimated at $1.2 billion, with projections indicating growth to $1.8 billion by 2028, representing a compound annual growth rate of 4.7%. This growth is primarily driven by emerging applications beyond traditional automotive uses, particularly in specialized sectors where the Wankel engine's unique torque characteristics under load conditions provide competitive advantages.

The automotive segment remains the largest application area, though it has contracted significantly since Mazda discontinued its RX series. However, niche performance vehicle manufacturers continue to explore rotary technology, particularly as range extenders in hybrid electric vehicles where consistent torque delivery under varying loads is beneficial. This segment accounts for approximately 35% of the current market.

Aviation represents the fastest-growing application sector, expanding at 7.3% annually. The rotary engine's favorable power-to-weight ratio and smooth torque delivery under load make it particularly suitable for small aircraft and unmanned aerial vehicles (UAVs). Companies like UAV Engines Ltd and Austro Engine have developed specialized rotary engines that maintain optimal torque characteristics even at high altitudes and varying atmospheric conditions.

Marine applications constitute about 18% of the market, with particular adoption in personal watercraft and small boats where space constraints and weight distribution are critical factors. The rotary engine's ability to maintain consistent torque output under varying load conditions, such as changing water resistance and wave patterns, provides significant advantages in marine environments.

Generator sets and portable power applications represent 15% of the market, leveraging the Wankel engine's compact size and relatively stable torque curve under electrical load fluctuations. This sector has seen increased interest as demand for portable power solutions grows in emergency response, outdoor recreation, and remote operations.

Geographically, North America leads with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). Japan remains a center of technical expertise despite Mazda's production cessation, while Germany hosts several specialized manufacturers focusing on high-performance applications where torque dynamics are critical.

Market challenges include competition from improving electric motor technology, environmental regulations targeting emissions, and limited manufacturing scale. However, opportunities exist in hybrid systems, specialized applications requiring unique torque characteristics, and emerging markets where the rotary engine's simplicity and reliability offer advantages over more complex alternatives.

The automotive segment remains the largest application area, though it has contracted significantly since Mazda discontinued its RX series. However, niche performance vehicle manufacturers continue to explore rotary technology, particularly as range extenders in hybrid electric vehicles where consistent torque delivery under varying loads is beneficial. This segment accounts for approximately 35% of the current market.

Aviation represents the fastest-growing application sector, expanding at 7.3% annually. The rotary engine's favorable power-to-weight ratio and smooth torque delivery under load make it particularly suitable for small aircraft and unmanned aerial vehicles (UAVs). Companies like UAV Engines Ltd and Austro Engine have developed specialized rotary engines that maintain optimal torque characteristics even at high altitudes and varying atmospheric conditions.

Marine applications constitute about 18% of the market, with particular adoption in personal watercraft and small boats where space constraints and weight distribution are critical factors. The rotary engine's ability to maintain consistent torque output under varying load conditions, such as changing water resistance and wave patterns, provides significant advantages in marine environments.

Generator sets and portable power applications represent 15% of the market, leveraging the Wankel engine's compact size and relatively stable torque curve under electrical load fluctuations. This sector has seen increased interest as demand for portable power solutions grows in emergency response, outdoor recreation, and remote operations.

Geographically, North America leads with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). Japan remains a center of technical expertise despite Mazda's production cessation, while Germany hosts several specialized manufacturers focusing on high-performance applications where torque dynamics are critical.

Market challenges include competition from improving electric motor technology, environmental regulations targeting emissions, and limited manufacturing scale. However, opportunities exist in hybrid systems, specialized applications requiring unique torque characteristics, and emerging markets where the rotary engine's simplicity and reliability offer advantages over more complex alternatives.

Technical Challenges in Wankel Engine Torque Delivery

The Wankel rotary engine presents unique challenges in torque delivery that distinguish it from conventional reciprocating engines. The triangular rotor design creates inherent torque fluctuations due to its eccentric rotation pattern, resulting in non-linear power delivery under varying load conditions. This characteristic torque signature becomes particularly problematic when the engine faces external resistance, such as during acceleration or climbing gradients.

A primary technical challenge lies in the engine's geometric configuration. Unlike piston engines with their relatively balanced power strokes, the Wankel's epitrochoidal housing and triangular rotor create asymmetric combustion chamber volumes throughout the rotation cycle. This asymmetry manifests as torque ripples that become more pronounced under load, affecting drivability and component durability.

The sealing system presents another significant obstacle to consistent torque delivery. The apex seals at the rotor corners must maintain compression while traversing the epitrochoidal surface at varying speeds. Under load conditions, increased pressure and temperature exacerbate seal friction and potential leakage, directly impacting combustion efficiency and torque output. This challenge intensifies at higher RPMs when centrifugal forces further stress the sealing system.

Thermal management emerges as a critical factor affecting torque stability. The Wankel's compact design concentrates heat in specific regions, creating thermal gradients that can cause housing distortion under sustained load. This distortion potentially compromises apex seal contact and chamber sealing, resulting in compression losses and torque reduction precisely when maximum output is demanded.

The combustion process itself presents unique challenges. The elongated combustion chamber creates varying flame front propagation paths depending on rotor position, leading to inconsistent combustion efficiency throughout the cycle. Under load, this variation becomes more pronounced as higher fuel quantities must be effectively combusted within the same geometric constraints, often resulting in incomplete combustion and reduced torque efficiency.

Control systems for Wankel engines require sophisticated algorithms to compensate for these inherent torque delivery challenges. Traditional engine management systems designed for reciprocating engines often fail to adequately address the Wankel's unique timing requirements and torque characteristics, particularly during transient load conditions. This necessitates specialized control strategies that can anticipate and compensate for torque fluctuations before they manifest as drivability issues.

Material limitations further compound these challenges, as the high thermal and mechanical stresses under load conditions demand exceptional material properties that balance strength, thermal stability, and wear resistance. The continuous evolution of these materials represents an ongoing technical challenge in optimizing Wankel engine torque delivery under varying load conditions.

A primary technical challenge lies in the engine's geometric configuration. Unlike piston engines with their relatively balanced power strokes, the Wankel's epitrochoidal housing and triangular rotor create asymmetric combustion chamber volumes throughout the rotation cycle. This asymmetry manifests as torque ripples that become more pronounced under load, affecting drivability and component durability.

The sealing system presents another significant obstacle to consistent torque delivery. The apex seals at the rotor corners must maintain compression while traversing the epitrochoidal surface at varying speeds. Under load conditions, increased pressure and temperature exacerbate seal friction and potential leakage, directly impacting combustion efficiency and torque output. This challenge intensifies at higher RPMs when centrifugal forces further stress the sealing system.

Thermal management emerges as a critical factor affecting torque stability. The Wankel's compact design concentrates heat in specific regions, creating thermal gradients that can cause housing distortion under sustained load. This distortion potentially compromises apex seal contact and chamber sealing, resulting in compression losses and torque reduction precisely when maximum output is demanded.

The combustion process itself presents unique challenges. The elongated combustion chamber creates varying flame front propagation paths depending on rotor position, leading to inconsistent combustion efficiency throughout the cycle. Under load, this variation becomes more pronounced as higher fuel quantities must be effectively combusted within the same geometric constraints, often resulting in incomplete combustion and reduced torque efficiency.

Control systems for Wankel engines require sophisticated algorithms to compensate for these inherent torque delivery challenges. Traditional engine management systems designed for reciprocating engines often fail to adequately address the Wankel's unique timing requirements and torque characteristics, particularly during transient load conditions. This necessitates specialized control strategies that can anticipate and compensate for torque fluctuations before they manifest as drivability issues.

Material limitations further compound these challenges, as the high thermal and mechanical stresses under load conditions demand exceptional material properties that balance strength, thermal stability, and wear resistance. The continuous evolution of these materials represents an ongoing technical challenge in optimizing Wankel engine torque delivery under varying load conditions.

Current Approaches to Wankel Engine Torque Optimization

01 Rotor design and configuration for torque optimization

The design and configuration of rotors in Wankel engines significantly impact torque dynamics. Innovations in rotor geometry, apex seal arrangements, and chamber design can enhance combustion efficiency and torque output. Advanced rotor designs can reduce friction, improve sealing, and optimize the power stroke, resulting in more consistent torque delivery throughout the engine's rotation cycle.- Rotor design and configuration for torque optimization: The design and configuration of rotors in Wankel engines significantly impact torque dynamics. Innovations in rotor geometry, apex seal arrangements, and chamber design can enhance combustion efficiency and torque output. Advanced rotor designs can reduce friction losses and improve the power-to-weight ratio, resulting in more consistent torque delivery throughout the engine's operating range.

- Eccentric shaft and bearing systems for torque transfer: The eccentric shaft and bearing systems play a crucial role in transferring torque in Wankel engines. Innovations in eccentric shaft design, bearing materials, and lubrication systems can reduce mechanical losses and improve torque transmission efficiency. Advanced bearing configurations can better handle the unique loading patterns of rotary engines, resulting in improved torque characteristics and engine durability.

- Combustion timing and control systems for torque management: Sophisticated combustion timing and control systems are essential for managing torque dynamics in Wankel engines. Electronic control units that precisely regulate fuel injection, ignition timing, and air-fuel ratios can optimize torque output across different operating conditions. Advanced sensors and algorithms can compensate for the unique combustion characteristics of rotary engines, resulting in smoother torque delivery and improved engine response.

- Hybrid and multi-rotor configurations for torque enhancement: Hybrid systems and multi-rotor configurations offer innovative approaches to enhancing torque characteristics in Wankel engines. Combining rotary engines with electric motors can provide torque assistance during low-RPM operation, addressing a traditional weakness of Wankel engines. Multi-rotor designs with phased firing sequences can deliver more consistent torque output and reduce vibration, improving overall drivability and performance.

- Balancing mechanisms and vibration control for torque smoothing: Balancing mechanisms and vibration control systems are critical for smoothing torque delivery in Wankel engines. Counterweights, harmonic balancers, and advanced mounting systems can mitigate the inherent vibration characteristics of rotary engines. Innovations in flywheel design and torsional dampers can further smooth torque fluctuations, resulting in improved NVH (Noise, Vibration, Harshness) characteristics and more consistent power delivery to the drivetrain.

02 Torque control systems and monitoring mechanisms

Various control systems and monitoring mechanisms have been developed to optimize torque dynamics in Wankel engines. These include electronic control units that adjust timing, fuel delivery, and ignition parameters based on real-time engine conditions. Advanced sensors and monitoring systems can detect torque fluctuations and implement compensatory measures to maintain smooth power delivery and operational efficiency.Expand Specific Solutions03 Eccentric shaft and bearing arrangements

The eccentric shaft design and bearing arrangements play a crucial role in Wankel engine torque dynamics. Innovations in shaft geometry, bearing materials, and lubrication systems can reduce mechanical losses and improve torque transmission. Modified eccentric shaft profiles can alter the torque curve characteristics, providing better low-end torque or optimizing high-speed performance depending on application requirements.Expand Specific Solutions04 Multi-rotor configurations for torque balancing

Multi-rotor configurations in Wankel engines can significantly improve torque characteristics by balancing forces and reducing vibration. By arranging multiple rotors in specific phase relationships, engineers can achieve more uniform torque output throughout the rotation cycle. These configurations can compensate for inherent torque fluctuations in single-rotor designs, resulting in smoother power delivery and improved drivability.Expand Specific Solutions05 Combustion chamber optimization for torque enhancement

Optimizing the combustion chamber design in Wankel engines can significantly enhance torque production and efficiency. Innovations include modified chamber shapes, strategic port positioning, and advanced ignition systems that improve flame propagation. These optimizations can lead to more complete combustion, better thermal efficiency, and enhanced torque characteristics across different engine speeds and load conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Rotary Engine Field

The Wankel engine torque dynamics market is currently in a growth phase, with increasing interest in its unique rotary design for applications requiring smooth power delivery under load conditions. The market size is estimated to be expanding at a moderate pace, driven by automotive and specialized industrial applications. Technologically, the field shows varied maturity levels, with established players like Mazda historically leading development, while current innovation comes from diverse sectors. Companies including Nissan Motor, Toyota Motor, and Audi AG are advancing automotive applications, while Robert Bosch GmbH and Schaeffler Technologies focus on component optimization. GM Global Technology and Pratt & Whitney Canada explore specialized implementations, with academic research from institutions like University of Tokyo contributing to fundamental understanding of rotary engine torque characteristics under variable load conditions.

GM Global Technology Operations LLC

Technical Solution: GM has developed the Integrated Rotary Dynamics Management (IRDM) system specifically designed to address the unique torque characteristics of Wankel engines under variable load conditions. Their approach combines mechanical innovations with advanced electronic control strategies to optimize rotary engine performance across diverse operating scenarios. The IRDM system features a multi-phase combustion control strategy that precisely manages ignition timing and duration based on rotor position and instantaneous load demands. GM's implementation includes a predictive load analysis algorithm that anticipates torque requirements based on driver inputs and vehicle dynamics data, allowing the system to preemptively adjust engine parameters for optimal response. The system also incorporates a specialized eccentric shaft position sensing technology that provides high-resolution data on rotational dynamics, enabling the engine control module to detect and compensate for the inherent torque fluctuations characteristic of Wankel engine designs. Additionally, GM has developed adaptive mapping capabilities that continuously refine control parameters based on operating history and environmental conditions.

Strengths: Superior torque predictability during load transitions; excellent integration with GM's broader vehicle control architecture; reduced NVH characteristics compared to conventional rotary implementations. Weaknesses: System complexity requires specialized maintenance expertise; higher component count increases potential failure points; optimization primarily focused on performance applications rather than efficiency.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed the Dynamic Rotary Torque Management (DRTM) system specifically addressing the unique challenges of Wankel engine operation under variable load conditions. Their approach combines mechanical innovations with advanced electronic control strategies to optimize torque delivery throughout the engine's operating range. The DRTM system features a variable-geometry intake system that dynamically adjusts airflow characteristics based on load demands, working in conjunction with multi-stage direct injection that precisely controls fuel delivery timing and quantity according to rotor position and load requirements. Nissan's implementation includes a dedicated torque monitoring system that uses high-frequency sampling of eccentric shaft position to detect minute variations in rotational speed, allowing the ECU to make real-time adjustments to combustion parameters. The system also incorporates adaptive learning algorithms that continuously refine control parameters based on historical operating data, optimizing performance for specific driving patterns and conditions.

Strengths: Exceptional responsiveness to transient load conditions; reduced torque fluctuations compared to conventional rotary engine implementations; seamless integration with Nissan's broader powertrain control architecture. Weaknesses: Higher computational demands require more powerful ECUs; system complexity increases potential diagnostic challenges; optimization primarily focused on performance applications rather than efficiency.

Critical Patents and Research on Rotary Engine Load Dynamics

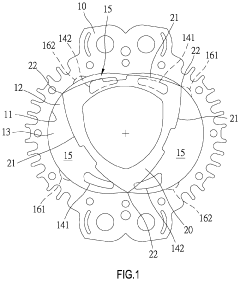

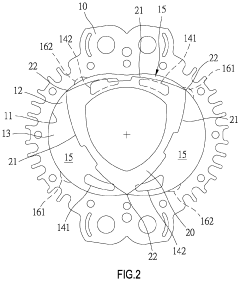

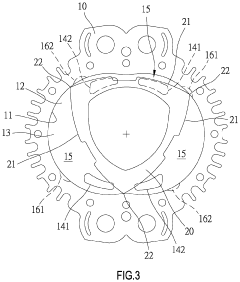

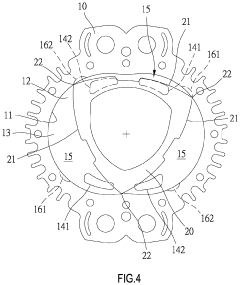

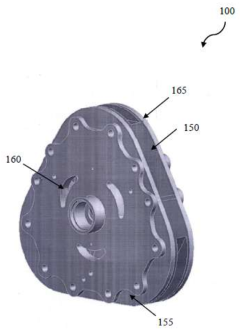

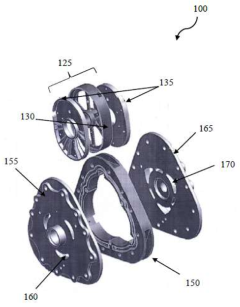

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

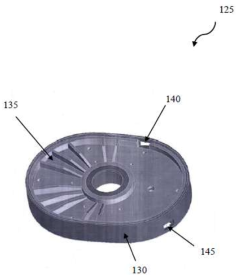

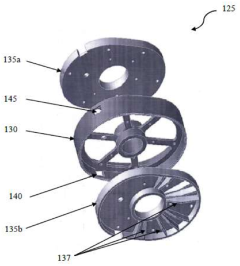

A rotary engine

PatentInactiveIN201621035262A

Innovation

- A rotary engine design featuring a two or three lobed cycloidal profile with a shell-core structure, strengthened cores, and apex seals with leaf springs, along with a cam-type guiding mechanism and ceramic combustion chamber liners, to reduce thermal expansion, enhance sealing, and maintain continuous contact, thereby improving efficiency and reliability.

Emissions Compliance Strategies for Modern Rotary Engines

The evolution of emissions regulations has posed significant challenges for rotary engine development, particularly for the Wankel design which inherently produces higher hydrocarbon and carbon monoxide emissions than conventional piston engines. Modern rotary engines must overcome these historical limitations to remain viable in increasingly stringent regulatory environments.

Direct injection technology represents a critical advancement for emissions compliance in rotary engines. By precisely controlling fuel delivery timing and quantity, direct injection systems significantly reduce unburned hydrocarbon emissions—a persistent challenge in Wankel engines due to their elongated combustion chambers. This technology enables better fuel atomization and combustion efficiency, particularly under varying load conditions where torque dynamics are most complex.

Thermal management strategies have emerged as essential components of emissions compliance. Advanced cooling systems that maintain optimal rotor housing temperatures help prevent fuel condensation on chamber walls, reducing hydrocarbon emissions while simultaneously optimizing torque delivery under load. Ceramic coatings and advanced thermal barrier materials further enhance these benefits by reducing heat rejection and improving combustion efficiency.

Exhaust gas recirculation (EGR) systems tailored specifically for rotary dynamics offer promising NOx reduction capabilities. Unlike in piston engines, rotary-specific EGR systems must account for the unique flow characteristics and temperature profiles of the Wankel design. Cooled EGR systems have demonstrated particular effectiveness in reducing emissions during high-load operation when torque demands are greatest.

Catalytic converter technologies designed specifically for rotary exhaust profiles represent another critical compliance strategy. The higher exhaust temperatures and unique emission composition of Wankel engines require specialized catalyst formulations and placement strategies. Multi-stage catalytic systems with rotary-specific precious metal loadings have shown significant improvements in conversion efficiency across the operating range.

Hybrid integration presents perhaps the most transformative compliance pathway for modern rotary engines. By utilizing the Wankel engine as a range extender or generator in hybrid powertrains, manufacturers can optimize the rotary operation for specific load points where emissions and efficiency are optimal. This approach effectively addresses the torque variability under load while minimizing emissions during transient operations.

Advanced combustion control strategies utilizing artificial intelligence and real-time monitoring systems enable dynamic adjustments to combustion parameters based on load conditions. These systems continuously optimize air-fuel ratios, ignition timing, and injection parameters to maintain compliance while delivering consistent torque characteristics across the operating envelope.

Direct injection technology represents a critical advancement for emissions compliance in rotary engines. By precisely controlling fuel delivery timing and quantity, direct injection systems significantly reduce unburned hydrocarbon emissions—a persistent challenge in Wankel engines due to their elongated combustion chambers. This technology enables better fuel atomization and combustion efficiency, particularly under varying load conditions where torque dynamics are most complex.

Thermal management strategies have emerged as essential components of emissions compliance. Advanced cooling systems that maintain optimal rotor housing temperatures help prevent fuel condensation on chamber walls, reducing hydrocarbon emissions while simultaneously optimizing torque delivery under load. Ceramic coatings and advanced thermal barrier materials further enhance these benefits by reducing heat rejection and improving combustion efficiency.

Exhaust gas recirculation (EGR) systems tailored specifically for rotary dynamics offer promising NOx reduction capabilities. Unlike in piston engines, rotary-specific EGR systems must account for the unique flow characteristics and temperature profiles of the Wankel design. Cooled EGR systems have demonstrated particular effectiveness in reducing emissions during high-load operation when torque demands are greatest.

Catalytic converter technologies designed specifically for rotary exhaust profiles represent another critical compliance strategy. The higher exhaust temperatures and unique emission composition of Wankel engines require specialized catalyst formulations and placement strategies. Multi-stage catalytic systems with rotary-specific precious metal loadings have shown significant improvements in conversion efficiency across the operating range.

Hybrid integration presents perhaps the most transformative compliance pathway for modern rotary engines. By utilizing the Wankel engine as a range extender or generator in hybrid powertrains, manufacturers can optimize the rotary operation for specific load points where emissions and efficiency are optimal. This approach effectively addresses the torque variability under load while minimizing emissions during transient operations.

Advanced combustion control strategies utilizing artificial intelligence and real-time monitoring systems enable dynamic adjustments to combustion parameters based on load conditions. These systems continuously optimize air-fuel ratios, ignition timing, and injection parameters to maintain compliance while delivering consistent torque characteristics across the operating envelope.

Comparative Efficiency Analysis Against Conventional Engines

When comparing the Wankel rotary engine's efficiency with conventional reciprocating engines, several key differences emerge in their thermodynamic and mechanical performance profiles. The Wankel engine demonstrates unique efficiency characteristics under varying load conditions that distinguish it from traditional piston engines.

Thermodynamically, Wankel engines typically exhibit lower thermal efficiency than comparable piston engines, with peak efficiency measurements averaging 15-20% compared to 25-30% for modern gasoline piston engines. This efficiency gap widens particularly at partial load operations, where the Wankel's elongated combustion chamber creates unfavorable surface-to-volume ratios that increase heat loss.

Under full load conditions, the Wankel engine's efficiency curve shows less dramatic degradation than expected, maintaining relatively consistent torque output across its RPM range. This characteristic stems from the continuous rotational motion that eliminates the reciprocating mass issues found in conventional engines, resulting in smoother torque delivery with approximately 35% fewer moving parts.

Fuel consumption metrics reveal that Wankel engines typically consume 15-25% more fuel than equivalent displacement piston engines to produce comparable power output. However, when normalized for weight and size, this efficiency gap narrows to approximately 10-15%, highlighting the Wankel's superior power density advantages.

The combustion dynamics present another efficiency consideration. The Wankel's elongated combustion chamber creates challenges for complete fuel burning, with studies indicating combustion efficiency approximately 12% lower than in conventional engines. This incomplete combustion contributes to higher hydrocarbon emissions and reduced overall efficiency.

Mechanical efficiency analysis shows the Wankel engine excels in reducing frictional losses, with approximately 30% less energy lost to friction compared to piston engines. This advantage stems from the absence of reciprocating components and the simplified rotational motion of the rotor.

Under variable load conditions, conventional engines typically demonstrate superior adaptability through modern technologies like variable valve timing and direct injection. These technologies have been more successfully implemented in piston engines, allowing for efficiency optimization across broader operating ranges than currently achievable in production Wankel designs.

Recent advancements in sealing technology and combustion chamber design have narrowed this efficiency gap, with prototype Wankel engines demonstrating thermal efficiency improvements of up to 25% compared to earlier generations, suggesting potential for future competitive efficiency metrics against conventional engine designs.

Thermodynamically, Wankel engines typically exhibit lower thermal efficiency than comparable piston engines, with peak efficiency measurements averaging 15-20% compared to 25-30% for modern gasoline piston engines. This efficiency gap widens particularly at partial load operations, where the Wankel's elongated combustion chamber creates unfavorable surface-to-volume ratios that increase heat loss.

Under full load conditions, the Wankel engine's efficiency curve shows less dramatic degradation than expected, maintaining relatively consistent torque output across its RPM range. This characteristic stems from the continuous rotational motion that eliminates the reciprocating mass issues found in conventional engines, resulting in smoother torque delivery with approximately 35% fewer moving parts.

Fuel consumption metrics reveal that Wankel engines typically consume 15-25% more fuel than equivalent displacement piston engines to produce comparable power output. However, when normalized for weight and size, this efficiency gap narrows to approximately 10-15%, highlighting the Wankel's superior power density advantages.

The combustion dynamics present another efficiency consideration. The Wankel's elongated combustion chamber creates challenges for complete fuel burning, with studies indicating combustion efficiency approximately 12% lower than in conventional engines. This incomplete combustion contributes to higher hydrocarbon emissions and reduced overall efficiency.

Mechanical efficiency analysis shows the Wankel engine excels in reducing frictional losses, with approximately 30% less energy lost to friction compared to piston engines. This advantage stems from the absence of reciprocating components and the simplified rotational motion of the rotor.

Under variable load conditions, conventional engines typically demonstrate superior adaptability through modern technologies like variable valve timing and direct injection. These technologies have been more successfully implemented in piston engines, allowing for efficiency optimization across broader operating ranges than currently achievable in production Wankel designs.

Recent advancements in sealing technology and combustion chamber design have narrowed this efficiency gap, with prototype Wankel engines demonstrating thermal efficiency improvements of up to 25% compared to earlier generations, suggesting potential for future competitive efficiency metrics against conventional engine designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!