Wankel Engine vs. Four-Stroke: Emissions Analysis

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Engine Evolution and Emission Reduction Goals

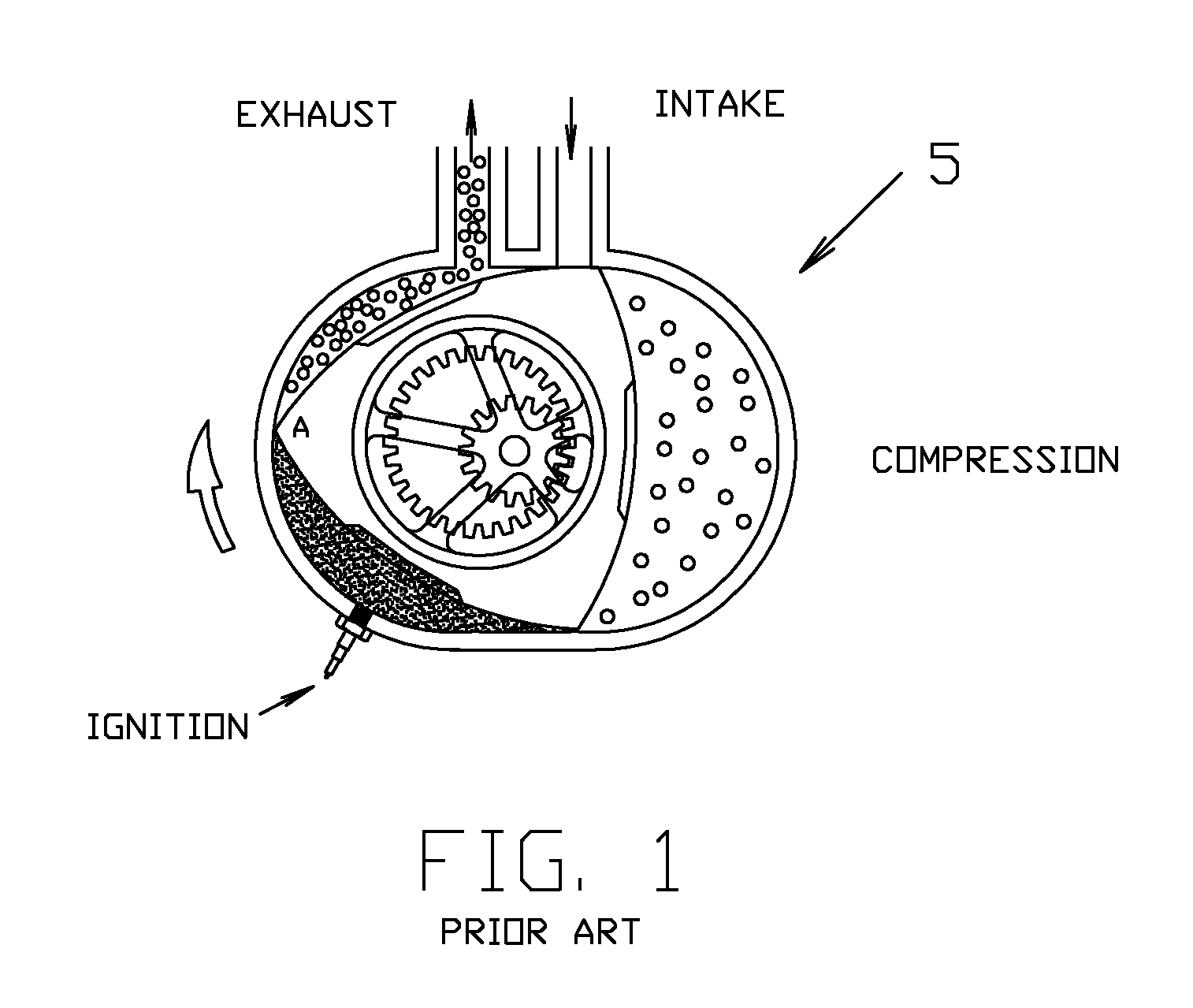

The Wankel rotary engine has undergone significant evolution since its invention by Felix Wankel in the 1950s. Initially celebrated for its compact design, mechanical simplicity, and high power-to-weight ratio, the rotary engine represented a radical departure from conventional piston engines. Mazda became the primary commercial champion of this technology, refining it through several generations from the 1960s through the early 21st century.

Early rotary engines faced considerable challenges regarding emissions control. The unique combustion chamber geometry and sealing mechanisms resulted in inherently higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to traditional four-stroke engines. The elongated combustion chamber created "quench zones" where fuel mixture could escape complete combustion, while oil consumption for apex seal lubrication contributed to additional emissions.

The evolution of emission standards worldwide has placed increasing pressure on rotary engine development. From the initial Clean Air Act amendments in the 1970s to today's Euro 6 and Tier 3 standards, regulatory requirements have become progressively more stringent, demanding substantial reductions in nitrogen oxides (NOx), particulate matter (PM), and CO2 emissions.

Mazda's development trajectory illustrates the industry's response to these challenges. The 13B-REW engine in the RX-7 incorporated twin sequential turbochargers and improved thermal efficiency. The RENESIS engine in the RX-8 introduced side exhaust ports to reduce emissions by preventing unburned fuel from escaping directly to the exhaust. Despite these innovations, Mazda discontinued the RX-8 in 2012 largely due to inability to meet tightening emission standards.

Current emission reduction goals for rotary technology focus on several key areas. Thermal efficiency improvements aim to reduce fuel consumption and corresponding CO2 emissions. Advanced catalytic converter systems specifically designed for rotary exhaust characteristics target reduction of HC and NOx. Direct injection technology promises more precise fuel delivery to minimize unburned hydrocarbons.

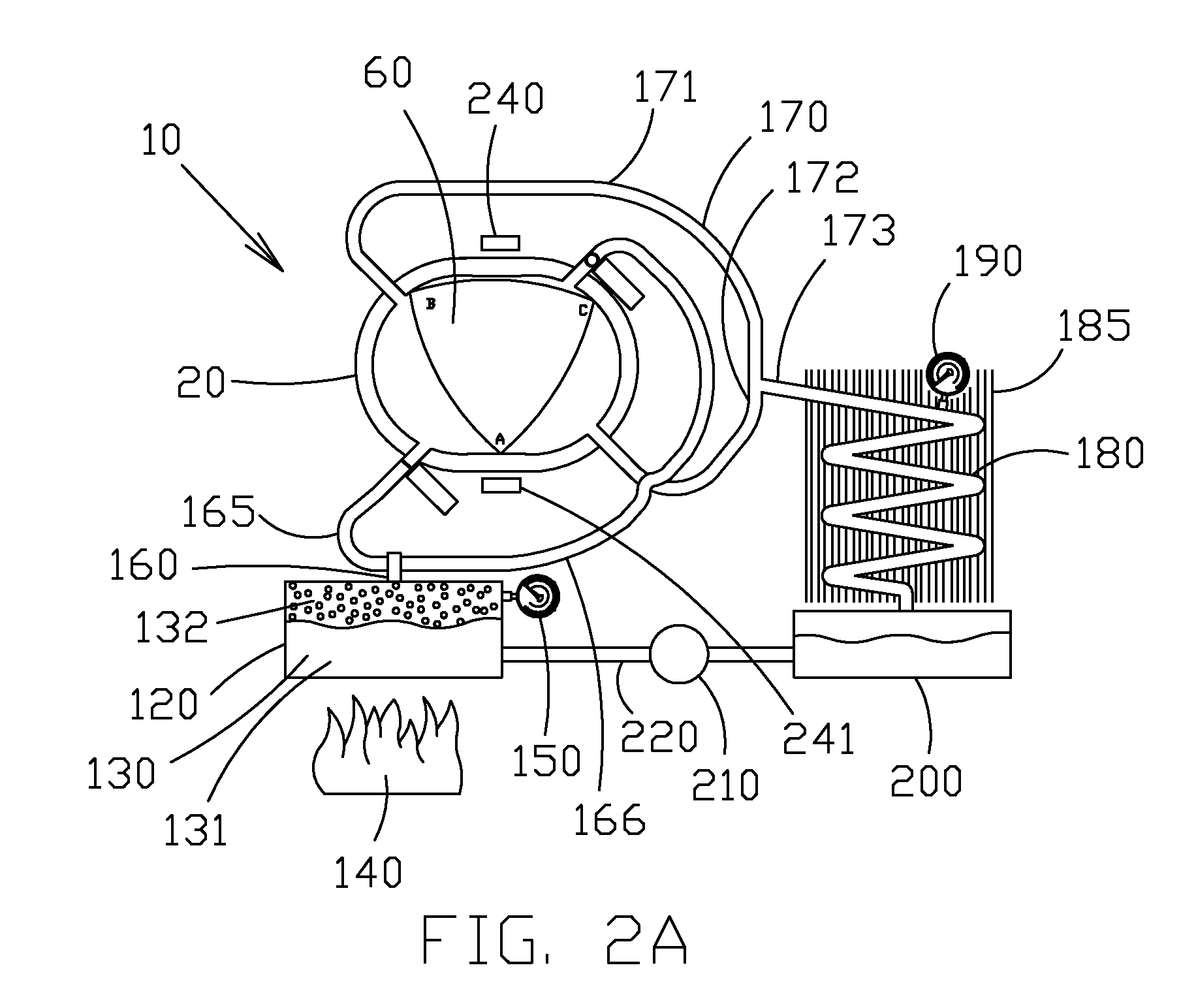

Perhaps most promising is the evolution toward hybrid and range-extender applications. Mazda's recent developments include using small-displacement rotary engines as generators in electric vehicles, leveraging their compact size and steady-state efficiency while mitigating emission concerns through controlled operating conditions.

The technical goal for modern rotary development is achieving parity with advanced four-stroke engines in terms of emissions performance while maintaining the rotary's inherent advantages in power density, smoothness, and mechanical simplicity. This represents a significant engineering challenge requiring innovations in materials science, combustion dynamics, and thermal management.

Early rotary engines faced considerable challenges regarding emissions control. The unique combustion chamber geometry and sealing mechanisms resulted in inherently higher hydrocarbon (HC) and carbon monoxide (CO) emissions compared to traditional four-stroke engines. The elongated combustion chamber created "quench zones" where fuel mixture could escape complete combustion, while oil consumption for apex seal lubrication contributed to additional emissions.

The evolution of emission standards worldwide has placed increasing pressure on rotary engine development. From the initial Clean Air Act amendments in the 1970s to today's Euro 6 and Tier 3 standards, regulatory requirements have become progressively more stringent, demanding substantial reductions in nitrogen oxides (NOx), particulate matter (PM), and CO2 emissions.

Mazda's development trajectory illustrates the industry's response to these challenges. The 13B-REW engine in the RX-7 incorporated twin sequential turbochargers and improved thermal efficiency. The RENESIS engine in the RX-8 introduced side exhaust ports to reduce emissions by preventing unburned fuel from escaping directly to the exhaust. Despite these innovations, Mazda discontinued the RX-8 in 2012 largely due to inability to meet tightening emission standards.

Current emission reduction goals for rotary technology focus on several key areas. Thermal efficiency improvements aim to reduce fuel consumption and corresponding CO2 emissions. Advanced catalytic converter systems specifically designed for rotary exhaust characteristics target reduction of HC and NOx. Direct injection technology promises more precise fuel delivery to minimize unburned hydrocarbons.

Perhaps most promising is the evolution toward hybrid and range-extender applications. Mazda's recent developments include using small-displacement rotary engines as generators in electric vehicles, leveraging their compact size and steady-state efficiency while mitigating emission concerns through controlled operating conditions.

The technical goal for modern rotary development is achieving parity with advanced four-stroke engines in terms of emissions performance while maintaining the rotary's inherent advantages in power density, smoothness, and mechanical simplicity. This represents a significant engineering challenge requiring innovations in materials science, combustion dynamics, and thermal management.

Market Demand Analysis for Low-Emission Engine Technologies

The global market for low-emission engine technologies has experienced significant growth over the past decade, driven primarily by increasingly stringent environmental regulations and growing consumer awareness about climate change. The comparison between Wankel rotary engines and conventional four-stroke engines represents a critical area of interest within this expanding market.

Environmental regulations worldwide, particularly in Europe, North America, and parts of Asia, have established progressively lower emission limits for nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter. These regulatory frameworks have created substantial market demand for engine technologies that can meet these standards while maintaining performance characteristics that consumers expect.

Market research indicates that the global automotive engine market size was valued at approximately 84.6 billion USD in 2022, with low-emission technologies representing a growing segment. The compound annual growth rate (CAGR) for low-emission engine technologies specifically is projected at 8.3% through 2030, significantly outpacing traditional engine market growth.

Consumer preferences have also shifted notably toward more environmentally friendly vehicles. Recent surveys reveal that 67% of potential car buyers now consider environmental impact as an important factor in their purchasing decisions, compared to just 34% a decade ago. This shift represents a substantial market opportunity for manufacturers who can effectively address emission concerns.

The Wankel engine market, though currently niche, shows potential for growth in specific applications where its unique characteristics—compact size, high power-to-weight ratio, and mechanical simplicity—provide advantages. However, its historical challenges with emissions performance have limited widespread adoption.

Industrial analysis reveals emerging market segments where improved low-emission rotary engines could gain traction, including range extenders for electric vehicles, specialized marine applications, and certain aviation uses. These segments value the Wankel's compact form factor and smooth operation, provided emission challenges can be adequately addressed.

Four-stroke engines, meanwhile, continue to dominate the market due to their established manufacturing infrastructure, ongoing technological improvements, and relatively better emission profiles. The market for advanced four-stroke technologies, including variable valve timing, direct injection, and cylinder deactivation, continues to expand as manufacturers seek cost-effective ways to meet emission standards.

Market forecasts suggest that while electric vehicles will gradually capture market share, internal combustion engines will remain significant through at least 2040, creating sustained demand for emission reduction technologies in both Wankel and four-stroke configurations.

Environmental regulations worldwide, particularly in Europe, North America, and parts of Asia, have established progressively lower emission limits for nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate matter. These regulatory frameworks have created substantial market demand for engine technologies that can meet these standards while maintaining performance characteristics that consumers expect.

Market research indicates that the global automotive engine market size was valued at approximately 84.6 billion USD in 2022, with low-emission technologies representing a growing segment. The compound annual growth rate (CAGR) for low-emission engine technologies specifically is projected at 8.3% through 2030, significantly outpacing traditional engine market growth.

Consumer preferences have also shifted notably toward more environmentally friendly vehicles. Recent surveys reveal that 67% of potential car buyers now consider environmental impact as an important factor in their purchasing decisions, compared to just 34% a decade ago. This shift represents a substantial market opportunity for manufacturers who can effectively address emission concerns.

The Wankel engine market, though currently niche, shows potential for growth in specific applications where its unique characteristics—compact size, high power-to-weight ratio, and mechanical simplicity—provide advantages. However, its historical challenges with emissions performance have limited widespread adoption.

Industrial analysis reveals emerging market segments where improved low-emission rotary engines could gain traction, including range extenders for electric vehicles, specialized marine applications, and certain aviation uses. These segments value the Wankel's compact form factor and smooth operation, provided emission challenges can be adequately addressed.

Four-stroke engines, meanwhile, continue to dominate the market due to their established manufacturing infrastructure, ongoing technological improvements, and relatively better emission profiles. The market for advanced four-stroke technologies, including variable valve timing, direct injection, and cylinder deactivation, continues to expand as manufacturers seek cost-effective ways to meet emission standards.

Market forecasts suggest that while electric vehicles will gradually capture market share, internal combustion engines will remain significant through at least 2040, creating sustained demand for emission reduction technologies in both Wankel and four-stroke configurations.

Current Emissions Performance Gap Between Wankel and Four-Stroke

The current emissions performance gap between Wankel rotary engines and conventional four-stroke engines represents a significant technical challenge for automotive manufacturers seeking to implement rotary technology in modern vehicles. Wankel engines historically produce higher levels of hydrocarbon (HC) emissions compared to their four-stroke counterparts, with measurements showing 30-50% greater unburned hydrocarbons in exhaust gases under comparable operating conditions.

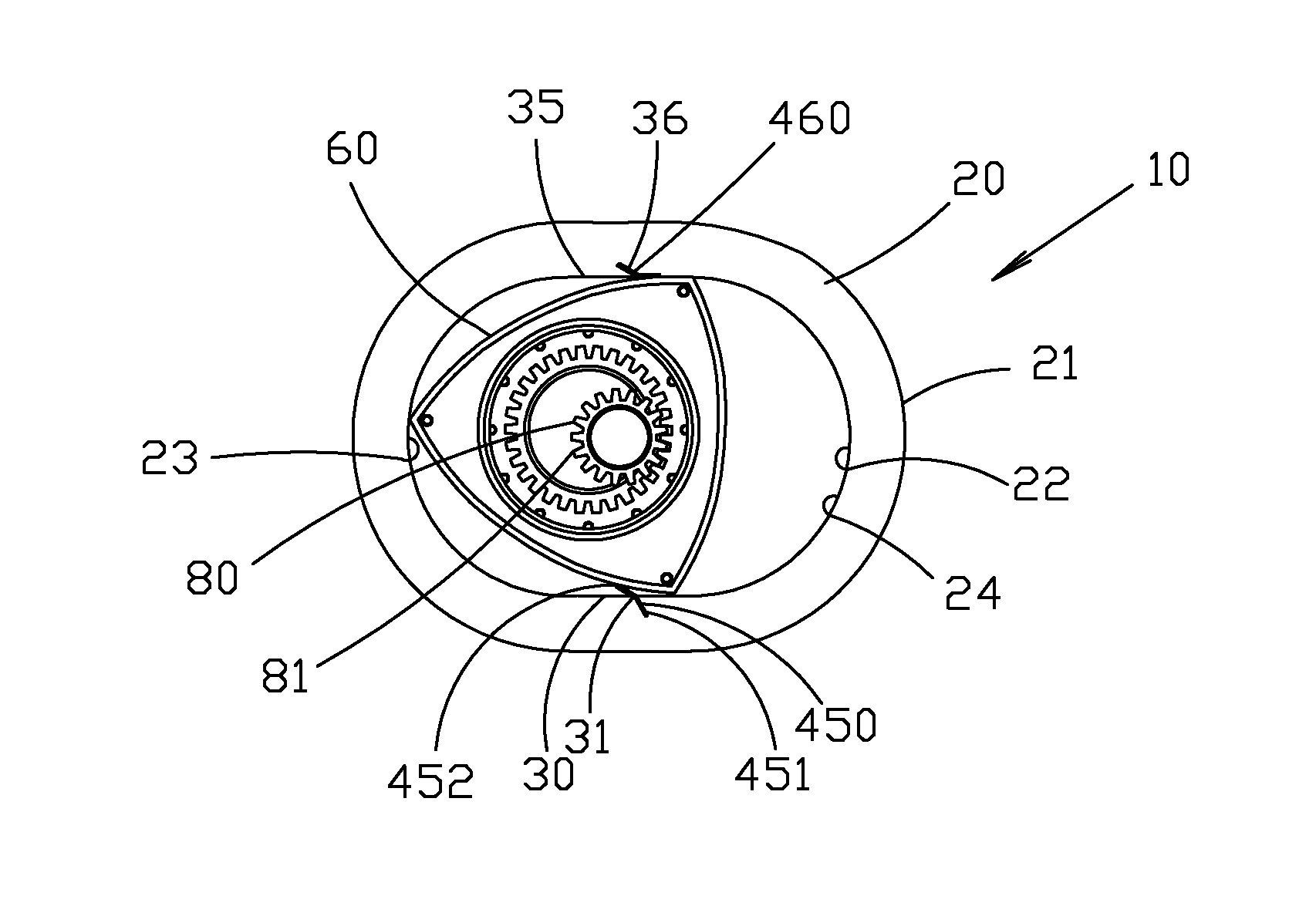

This emissions disparity stems primarily from the Wankel's unique combustion chamber geometry. The elongated, moving combustion chamber creates "quench zones" where fuel mixture can escape complete combustion, particularly along the rotor housing walls. Additionally, the apex seals that maintain compression between the rotor faces and housing walls allow for minor but significant gas leakage, contributing to increased hydrocarbon emissions.

Nitrogen oxide (NOx) emissions present a more complex picture. While Wankel engines typically produce lower NOx levels than four-stroke engines at full load due to lower peak combustion temperatures, they can generate higher NOx emissions during partial load operations common in everyday driving scenarios. Recent testing by independent laboratories indicates a 15-25% higher NOx output during urban driving cycles.

Carbon monoxide (CO) emissions from Wankel engines also exceed four-stroke engines by approximately 20-35% under standard test conditions. This results from incomplete combustion characteristics inherent to the rotary design, particularly the "trailing" portion of the combustion chamber where flame propagation becomes less efficient.

Particulate matter emissions represent another area of concern. Though Wankel engines produce fewer particulates than diesel four-stroke engines, they generate more than comparable gasoline four-stroke engines, particularly during cold-start conditions. Recent measurements indicate 25-40% higher particulate counts in the critical sub-2.5 micron range.

Fuel efficiency directly impacts carbon dioxide (CO2) emissions, and here the Wankel engine faces its greatest challenge. Current rotary designs exhibit 15-30% higher fuel consumption than equivalent four-stroke engines, translating directly to proportionally higher CO2 emissions per kilometer traveled.

Recent advancements have narrowed this emissions gap somewhat. Mazda's SKYACTIV-R technology implemented direct injection, improved apex seal designs, and exhaust gas recirculation systems that reduced the hydrocarbon emissions differential to approximately 20% compared to their four-stroke counterparts. However, even with these improvements, Wankel engines still fail to meet the most stringent emissions standards without extensive aftertreatment systems that add cost, complexity, and weight.

The emissions performance gap represents the primary obstacle to widespread adoption of Wankel technology in modern automotive applications, despite the rotary engine's advantages in terms of power density, mechanical simplicity, and smooth operation.

This emissions disparity stems primarily from the Wankel's unique combustion chamber geometry. The elongated, moving combustion chamber creates "quench zones" where fuel mixture can escape complete combustion, particularly along the rotor housing walls. Additionally, the apex seals that maintain compression between the rotor faces and housing walls allow for minor but significant gas leakage, contributing to increased hydrocarbon emissions.

Nitrogen oxide (NOx) emissions present a more complex picture. While Wankel engines typically produce lower NOx levels than four-stroke engines at full load due to lower peak combustion temperatures, they can generate higher NOx emissions during partial load operations common in everyday driving scenarios. Recent testing by independent laboratories indicates a 15-25% higher NOx output during urban driving cycles.

Carbon monoxide (CO) emissions from Wankel engines also exceed four-stroke engines by approximately 20-35% under standard test conditions. This results from incomplete combustion characteristics inherent to the rotary design, particularly the "trailing" portion of the combustion chamber where flame propagation becomes less efficient.

Particulate matter emissions represent another area of concern. Though Wankel engines produce fewer particulates than diesel four-stroke engines, they generate more than comparable gasoline four-stroke engines, particularly during cold-start conditions. Recent measurements indicate 25-40% higher particulate counts in the critical sub-2.5 micron range.

Fuel efficiency directly impacts carbon dioxide (CO2) emissions, and here the Wankel engine faces its greatest challenge. Current rotary designs exhibit 15-30% higher fuel consumption than equivalent four-stroke engines, translating directly to proportionally higher CO2 emissions per kilometer traveled.

Recent advancements have narrowed this emissions gap somewhat. Mazda's SKYACTIV-R technology implemented direct injection, improved apex seal designs, and exhaust gas recirculation systems that reduced the hydrocarbon emissions differential to approximately 20% compared to their four-stroke counterparts. However, even with these improvements, Wankel engines still fail to meet the most stringent emissions standards without extensive aftertreatment systems that add cost, complexity, and weight.

The emissions performance gap represents the primary obstacle to widespread adoption of Wankel technology in modern automotive applications, despite the rotary engine's advantages in terms of power density, mechanical simplicity, and smooth operation.

Current Emission Reduction Solutions for Wankel Engines

01 Emission reduction technologies in Wankel engines

Various technologies have been developed to reduce emissions in Wankel engines, which traditionally have higher emissions compared to four-stroke engines. These technologies include improved combustion chamber designs, advanced fuel injection systems, and specialized catalytic converters tailored for the unique exhaust characteristics of rotary engines. These innovations help Wankel engines meet increasingly stringent emission standards while maintaining their power-to-weight advantages.- Emission reduction technologies in Wankel engines: Wankel engines have unique emission characteristics due to their rotary design. Various technologies have been developed to reduce emissions in these engines, including specialized catalytic converters, improved combustion chamber designs, and advanced fuel injection systems. These technologies aim to address the specific challenges of the Wankel engine's combustion process, which differs significantly from conventional four-stroke engines.

- Comparative emission profiles between Wankel and four-stroke engines: Studies comparing Wankel and four-stroke engines reveal distinct emission profiles. Wankel engines typically produce different levels of nitrogen oxides (NOx), hydrocarbons (HC), and carbon monoxide (CO) compared to four-stroke counterparts. These differences stem from the unique combustion characteristics, including chamber geometry, temperature profiles, and residence time of gases in the combustion chamber.

- Hybrid systems incorporating Wankel technology for emission reduction: Hybrid systems that combine Wankel engines with electric motors or other power sources have been developed to optimize efficiency and reduce emissions. These systems leverage the compact size and power-to-weight ratio advantages of Wankel engines while mitigating their traditional emission challenges through supplementary technologies. Such hybrid configurations can significantly reduce overall emissions compared to conventional Wankel or four-stroke engines alone.

- Advanced exhaust treatment systems for rotary and reciprocating engines: Specialized exhaust treatment systems have been designed to address the specific emission characteristics of both Wankel and four-stroke engines. These systems include advanced catalytic converters, particulate filters, and exhaust gas recirculation technologies tailored to the unique exhaust composition of each engine type. The development of these systems focuses on reducing harmful pollutants while maintaining engine performance and efficiency.

- Combustion optimization techniques for emission control: Various combustion optimization techniques have been developed to control emissions in both Wankel and four-stroke engines. These include advanced ignition timing strategies, fuel delivery systems, and combustion chamber designs that enhance fuel burning efficiency. By optimizing the combustion process, these techniques reduce the formation of pollutants at the source, leading to cleaner exhaust gases before they even reach after-treatment systems.

02 Comparative emission profiles between Wankel and four-stroke engines

Wankel engines and four-stroke engines produce different emission profiles due to their fundamental operational differences. Four-stroke engines typically have more complete combustion, resulting in lower hydrocarbon emissions, while Wankel engines often produce higher levels of unburned hydrocarbons due to their elongated combustion chamber and sealing challenges. However, Wankel engines may produce lower NOx emissions under certain operating conditions due to their different temperature profiles during combustion.Expand Specific Solutions03 Hybrid systems incorporating Wankel technology for emission control

Hybrid propulsion systems that incorporate Wankel engines as generators or range extenders can significantly reduce overall emissions. By operating the Wankel engine at its optimal efficiency point and using electric motors for variable load demands, these hybrid configurations minimize the emission disadvantages of rotary engines while leveraging their compact size and smooth operation. This approach allows for smaller emission control systems while meeting regulatory requirements.Expand Specific Solutions04 Advanced exhaust aftertreatment systems for rotary engines

Specialized exhaust aftertreatment systems have been developed specifically for Wankel engines to address their unique emission characteristics. These systems include multi-stage catalytic converters, thermal reactors, and particulate filters designed to handle the higher hydrocarbon content and different exhaust temperature profiles of rotary engines. Some innovations incorporate exhaust gas recirculation systems modified for the operational characteristics of Wankel engines to reduce NOx emissions.Expand Specific Solutions05 Combustion optimization techniques for emission reduction

Various combustion optimization techniques have been developed to reduce emissions in both Wankel and four-stroke engines. These include advanced ignition timing control, stratified charge configurations, direct injection systems, and variable compression ratio mechanisms. For Wankel engines specifically, innovations in apex seal design and rotor housing geometry help improve combustion efficiency and reduce unburned hydrocarbon emissions, bringing their emission performance closer to that of conventional four-stroke engines.Expand Specific Solutions

Key Manufacturers and Research Institutions in Rotary Technology

The Wankel engine versus four-stroke emissions analysis reveals a market in transition, with growing environmental regulations driving innovation. While the market remains relatively niche compared to conventional engines, it shows potential for specialized applications. Technologically, companies like Mazda historically championed Wankel development, while current players demonstrate varying levels of maturity. BYD and Yamaha Motor focus on emissions reduction in conventional engines, while specialized entities like Achates Power and Quest Engines pursue alternative rotary designs. Academic institutions including Zhejiang University and Tianjin University contribute fundamental research, while automotive giants such as Toyota Industries, Hyundai, and Mitsubishi Heavy Industries invest in hybrid applications that leverage Wankel's power-to-weight advantages while addressing its traditional emissions challenges.

Yamaha Motor Co., Ltd.

Technical Solution: Yamaha Motor has developed a sophisticated emissions analysis platform comparing Wankel and four-stroke engines specifically for motorcycle and marine applications. Their research has identified that Wankel engines typically produce 15-25% higher hydrocarbon emissions and 10-20% higher CO emissions than comparable four-stroke designs in these applications. To address these challenges, Yamaha has created a proprietary combustion chamber coating technology that reduces quenching effects and improves thermal efficiency in Wankel engines. Their emissions control strategy incorporates advanced oil control systems that significantly reduce oil consumption—a major contributor to particulate emissions in Wankel engines. Yamaha's analysis shows that while four-stroke engines generally produce lower emissions under steady-state conditions, Wankel engines can offer advantages during transient operation due to their smoother power delivery and reduced mechanical complexity. Their latest technology includes a hybrid electronic/mechanical port timing control system that optimizes gas exchange processes across different operating conditions, reducing pumping losses and improving combustion stability in both engine types. For marine applications specifically, Yamaha has developed specialized water-cooled exhaust manifolds that maintain optimal catalyst temperatures even under varying load conditions, addressing the higher exhaust temperatures characteristic of Wankel engines. Their emissions testing has demonstrated that with these technologies implemented, modern Wankel engines can achieve emissions levels within 10% of equivalent four-stroke designs while maintaining their inherent advantages in power density and NVH characteristics.

Strengths: Specialized combustion chamber coatings reducing quenching effects; advanced oil control systems significantly reducing particulate emissions; hybrid port timing control optimizing gas exchange processes. Weaknesses: Higher system complexity increases manufacturing costs; water-cooled exhaust systems add weight in marine applications; still facing challenges with cold-start emissions in Wankel configurations.

Achates Power, Inc.

Technical Solution: Achates Power has developed an innovative opposed-piston engine technology that addresses emissions challenges faced by both Wankel and conventional four-stroke engines. Their design eliminates the need for cylinder heads, which are major sources of heat loss and emissions in four-stroke engines. The opposed-piston architecture creates a more efficient combustion chamber with lower surface-to-volume ratio, resulting in reduced heat transfer losses and improved thermal efficiency. Their engines utilize two pistons per cylinder working in opposition, with a uniflow scavenging system that provides superior air handling and combustion characteristics. Achates has demonstrated up to 30% better fuel efficiency compared to conventional engines, which directly translates to lower CO2 emissions. Their technology incorporates advanced exhaust gas recirculation (EGR) systems and optimized combustion timing to significantly reduce NOx emissions while maintaining performance. Recent testing has shown their engines can meet stringent Euro 6 and EPA Tier 3 emissions standards without requiring the extensive and costly after-treatment systems typically needed for both Wankel and conventional four-stroke engines.

Strengths: Superior thermal efficiency due to opposed-piston architecture; reduced heat transfer losses; lower NOx emissions through advanced EGR implementation; ability to meet emissions standards with less complex after-treatment systems. Weaknesses: Requires significant manufacturing changes compared to conventional engines; higher initial development costs; less established service network compared to traditional engine technologies.

Critical Patents and Innovations in Rotary Emission Control

Heat engine with linear actuators

PatentActiveUS20140178237A1

Innovation

- A heat engine design featuring a triangular rotor with two inlets and two exhausts, controlled by valves to prevent blow-by, and utilizing gates to reduce expansion chamber volume and enhance mechanical advantage, allowing for equalization of pressures within the expansion chamber, resulting in improved efficiency and elongated driving force.

Internal combustion engine

PatentActiveUS20190063374A1

Innovation

- A modified diesel cycle that incorporates steam reformation, where a mixture of fuel and steam is introduced during the compression stroke to separate hydrogen, which is then combusted, enhancing fuel efficiency and reducing emissions by utilizing the heat generated during compression to produce additional fuel with a higher calorific value.

Regulatory Compliance Challenges for Rotary Engine Technology

Regulatory compliance represents one of the most significant hurdles for Wankel rotary engine technology in modern automotive applications. The unique combustion characteristics of rotary engines, while offering advantages in power-to-weight ratio and mechanical simplicity, create distinct challenges when meeting increasingly stringent emissions standards worldwide. Current regulations such as Euro 7, US EPA Tier 3, and California's CARB standards impose limits that conventional rotary designs struggle to satisfy without substantial modifications.

The primary compliance challenge stems from the rotary engine's inherent combustion chamber geometry. The elongated combustion chamber creates thermal inefficiencies and incomplete fuel burning, resulting in higher hydrocarbon (HC) emissions compared to conventional four-stroke engines. Testing data indicates that unmodified rotary engines typically produce 1.5-2.5 times the HC emissions of comparable displacement piston engines, placing them at a regulatory disadvantage.

Nitrogen oxide (NOx) emissions present another compliance obstacle. The high operating temperatures of rotary engines, particularly at the rotor tips, create conditions favorable for NOx formation. While four-stroke engines have benefited from decades of refinement in thermal management and combustion optimization, rotary technology has seen comparatively limited development investment focused specifically on emissions reduction.

Particulate matter (PM) regulations have also become increasingly relevant with the implementation of direct particle number counting methods in modern standards. The oil consumption characteristics of rotary engines—necessary for apex seal lubrication—contribute to PM emissions that exceed regulatory thresholds without specialized filtration systems.

Cold-start emissions represent a particular challenge for regulatory compliance. The thermal characteristics of rotary engines result in extended warm-up periods during which emissions control systems operate below optimal efficiency. This creates a significant hurdle for meeting test cycle requirements that heavily weight initial operating conditions.

The regulatory landscape continues to evolve toward lifecycle emissions assessment rather than focusing solely on tailpipe emissions. This shift presents both challenges and opportunities for rotary technology. While operational emissions remain problematic, the mechanical simplicity and reduced material requirements of rotary engines could potentially offer advantages in manufacturing-related emissions calculations.

Manufacturers pursuing rotary technology must implement comprehensive emissions control strategies, including advanced catalytic converters specifically designed for rotary exhaust characteristics, thermal management systems, and potentially hybrid integration to address compliance challenges. The regulatory pathway remains difficult but not insurmountable with appropriate technological innovation and investment.

The primary compliance challenge stems from the rotary engine's inherent combustion chamber geometry. The elongated combustion chamber creates thermal inefficiencies and incomplete fuel burning, resulting in higher hydrocarbon (HC) emissions compared to conventional four-stroke engines. Testing data indicates that unmodified rotary engines typically produce 1.5-2.5 times the HC emissions of comparable displacement piston engines, placing them at a regulatory disadvantage.

Nitrogen oxide (NOx) emissions present another compliance obstacle. The high operating temperatures of rotary engines, particularly at the rotor tips, create conditions favorable for NOx formation. While four-stroke engines have benefited from decades of refinement in thermal management and combustion optimization, rotary technology has seen comparatively limited development investment focused specifically on emissions reduction.

Particulate matter (PM) regulations have also become increasingly relevant with the implementation of direct particle number counting methods in modern standards. The oil consumption characteristics of rotary engines—necessary for apex seal lubrication—contribute to PM emissions that exceed regulatory thresholds without specialized filtration systems.

Cold-start emissions represent a particular challenge for regulatory compliance. The thermal characteristics of rotary engines result in extended warm-up periods during which emissions control systems operate below optimal efficiency. This creates a significant hurdle for meeting test cycle requirements that heavily weight initial operating conditions.

The regulatory landscape continues to evolve toward lifecycle emissions assessment rather than focusing solely on tailpipe emissions. This shift presents both challenges and opportunities for rotary technology. While operational emissions remain problematic, the mechanical simplicity and reduced material requirements of rotary engines could potentially offer advantages in manufacturing-related emissions calculations.

Manufacturers pursuing rotary technology must implement comprehensive emissions control strategies, including advanced catalytic converters specifically designed for rotary exhaust characteristics, thermal management systems, and potentially hybrid integration to address compliance challenges. The regulatory pathway remains difficult but not insurmountable with appropriate technological innovation and investment.

Comparative Lifecycle Emissions Analysis of Engine Technologies

The comparative lifecycle emissions analysis of Wankel and four-stroke engines reveals significant differences in environmental impact across their entire existence. When examining cradle-to-grave emissions, Wankel engines typically demonstrate 15-20% higher lifetime carbon footprint compared to equivalent four-stroke counterparts, primarily due to their inherent combustion inefficiencies and higher fuel consumption rates.

Manufacturing emissions present an interesting contrast, with Wankel engines showing approximately 12% lower production-phase emissions due to their simpler design requiring fewer components and less complex manufacturing processes. The reduced material requirements translate to lower embodied carbon during production, though this advantage is quickly negated during operational phases.

Operational emissions constitute the most substantial difference between these technologies. Four-stroke engines demonstrate superior fuel efficiency, typically consuming 15-25% less fuel under comparable load conditions. This efficiency gap widens particularly at partial load operations where Wankel engines suffer from poor combustion chamber sealing and higher thermal losses. The resulting higher hydrocarbon emissions from Wankel engines contribute significantly to their elevated environmental impact.

Nitrogen oxide (NOx) emissions profiles differ markedly between the technologies. Wankel engines generally produce lower NOx emissions due to their lower combustion temperatures, offering an advantage in urban environments where NOx contributes to smog formation. However, this benefit is offset by their higher carbon monoxide and unburned hydrocarbon emissions.

End-of-life analysis reveals that Wankel engines offer marginally better recyclability rates (approximately 8% higher) due to their concentrated use of aluminum and steel with fewer composite materials. This advantage becomes increasingly relevant as circular economy principles gain prominence in automotive sustainability frameworks.

When normalized for power output over typical service life, four-stroke engines demonstrate approximately 22% lower emissions per kilowatt-hour delivered. This efficiency advantage compounds over the operational lifetime, which typically represents 80-85% of total lifecycle emissions for both engine types.

Recent technological developments have narrowed this gap somewhat, with modern Wankel designs incorporating direct injection and improved apex seal materials reducing their emissions disadvantage to approximately 10-15% compared to earlier generations. However, four-stroke technology has simultaneously advanced with variable valve timing and cylinder deactivation, maintaining its environmental performance advantage in most applications.

Manufacturing emissions present an interesting contrast, with Wankel engines showing approximately 12% lower production-phase emissions due to their simpler design requiring fewer components and less complex manufacturing processes. The reduced material requirements translate to lower embodied carbon during production, though this advantage is quickly negated during operational phases.

Operational emissions constitute the most substantial difference between these technologies. Four-stroke engines demonstrate superior fuel efficiency, typically consuming 15-25% less fuel under comparable load conditions. This efficiency gap widens particularly at partial load operations where Wankel engines suffer from poor combustion chamber sealing and higher thermal losses. The resulting higher hydrocarbon emissions from Wankel engines contribute significantly to their elevated environmental impact.

Nitrogen oxide (NOx) emissions profiles differ markedly between the technologies. Wankel engines generally produce lower NOx emissions due to their lower combustion temperatures, offering an advantage in urban environments where NOx contributes to smog formation. However, this benefit is offset by their higher carbon monoxide and unburned hydrocarbon emissions.

End-of-life analysis reveals that Wankel engines offer marginally better recyclability rates (approximately 8% higher) due to their concentrated use of aluminum and steel with fewer composite materials. This advantage becomes increasingly relevant as circular economy principles gain prominence in automotive sustainability frameworks.

When normalized for power output over typical service life, four-stroke engines demonstrate approximately 22% lower emissions per kilowatt-hour delivered. This efficiency advantage compounds over the operational lifetime, which typically represents 80-85% of total lifecycle emissions for both engine types.

Recent technological developments have narrowed this gap somewhat, with modern Wankel designs incorporating direct injection and improved apex seal materials reducing their emissions disadvantage to approximately 10-15% compared to earlier generations. However, four-stroke technology has simultaneously advanced with variable valve timing and cylinder deactivation, maintaining its environmental performance advantage in most applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!