Wankel Engine vs. Gas Turbine: Efficiency Metrics

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary Engine Evolution and Performance Objectives

The Wankel rotary engine represents a significant departure from conventional reciprocating piston engines, with its development tracing back to Felix Wankel's initial concept in the 1920s and the first working prototype unveiled in 1957. This innovative design features a triangular rotor that revolves within an epitrochoid-shaped housing, creating combustion chambers that continuously change volume as the rotor moves. The evolution of this technology has been marked by periods of intense interest followed by relative dormancy, with notable commercial applications in vehicles like the Mazda RX series.

Gas turbines, by contrast, emerged from jet engine technology in the early 20th century, with significant development during World War II. These engines operate on the Brayton cycle, drawing in air, compressing it, adding fuel for combustion, and then expanding the resulting gases through a turbine to generate power. Their evolution has been characterized by steady improvements in materials science, aerodynamics, and combustion efficiency.

The performance objectives for both technologies have shifted significantly over time. Initially, the Wankel engine was celebrated for its high power-to-weight ratio, mechanical simplicity, and compact design. However, efficiency metrics revealed persistent challenges in fuel economy and emissions control, particularly regarding incomplete combustion and sealing issues at the rotor tips.

Gas turbines have traditionally excelled in applications requiring high power output and operational reliability, such as aviation and large-scale power generation. Their performance objectives have centered on thermal efficiency improvements, emissions reduction, and adaptability to various fuel types.

Current technological trajectories aim to address the inherent limitations of both systems. For Wankel engines, research focuses on advanced materials for improved sealing, modified combustion chamber geometries, and hybrid electric implementations to mitigate efficiency shortfalls. The performance target is to maintain the rotary engine's inherent advantages while achieving competitive fuel efficiency and meeting stringent emissions standards.

For gas turbines, development efforts concentrate on increasing operating temperatures through advanced cooling techniques and ceramic components, improving compressor and turbine aerodynamics, and developing more sophisticated combustion systems. The objective is to push thermal efficiency beyond 40% for small-scale applications while maintaining reliability.

The comparative efficiency metrics between these technologies reveal distinct operational profiles: Wankel engines offer simplicity and compactness but struggle with thermal efficiency (typically 15-25%), while gas turbines provide excellent power density and multi-fuel capability but face challenges in small-scale applications due to precision manufacturing requirements and thermal management complexities.

Gas turbines, by contrast, emerged from jet engine technology in the early 20th century, with significant development during World War II. These engines operate on the Brayton cycle, drawing in air, compressing it, adding fuel for combustion, and then expanding the resulting gases through a turbine to generate power. Their evolution has been characterized by steady improvements in materials science, aerodynamics, and combustion efficiency.

The performance objectives for both technologies have shifted significantly over time. Initially, the Wankel engine was celebrated for its high power-to-weight ratio, mechanical simplicity, and compact design. However, efficiency metrics revealed persistent challenges in fuel economy and emissions control, particularly regarding incomplete combustion and sealing issues at the rotor tips.

Gas turbines have traditionally excelled in applications requiring high power output and operational reliability, such as aviation and large-scale power generation. Their performance objectives have centered on thermal efficiency improvements, emissions reduction, and adaptability to various fuel types.

Current technological trajectories aim to address the inherent limitations of both systems. For Wankel engines, research focuses on advanced materials for improved sealing, modified combustion chamber geometries, and hybrid electric implementations to mitigate efficiency shortfalls. The performance target is to maintain the rotary engine's inherent advantages while achieving competitive fuel efficiency and meeting stringent emissions standards.

For gas turbines, development efforts concentrate on increasing operating temperatures through advanced cooling techniques and ceramic components, improving compressor and turbine aerodynamics, and developing more sophisticated combustion systems. The objective is to push thermal efficiency beyond 40% for small-scale applications while maintaining reliability.

The comparative efficiency metrics between these technologies reveal distinct operational profiles: Wankel engines offer simplicity and compactness but struggle with thermal efficiency (typically 15-25%), while gas turbines provide excellent power density and multi-fuel capability but face challenges in small-scale applications due to precision manufacturing requirements and thermal management complexities.

Market Analysis for High-Efficiency Propulsion Systems

The global market for high-efficiency propulsion systems is experiencing significant growth, driven by increasing environmental regulations, rising fuel costs, and growing consumer demand for more sustainable transportation options. The comparison between Wankel engines and gas turbines represents a critical segment within this evolving landscape, with each technology offering distinct advantages for different applications.

Current market valuations indicate that the high-efficiency propulsion systems market exceeds $300 billion globally, with projected annual growth rates between 5-7% through 2030. Within this broader market, rotary engines like the Wankel design occupy a specialized niche valued at approximately $12 billion, while gas turbines command a substantially larger market share of around $85 billion, primarily due to their established presence in aviation and power generation.

Consumer and industrial demand patterns reveal interesting trends when comparing these technologies. Wankel engines are experiencing renewed interest in specific applications where their compact size, smooth operation, and power-to-weight ratio provide competitive advantages. These include unmanned aerial vehicles (UAVs), range extenders for electric vehicles, and specialized marine applications. Market research indicates a 15% year-over-year growth in these niche applications.

Gas turbines continue to dominate in commercial aviation, military applications, and large-scale power generation. Their market is characterized by high barriers to entry, significant R&D investments, and long product development cycles. Recent efficiency improvements have strengthened their market position, with next-generation turbines showing 20-25% better fuel efficiency compared to models from a decade ago.

Regional market analysis reveals interesting geographical variations. North America and Europe lead in research and development of high-efficiency variants of both technologies, while Asia-Pacific markets show the fastest adoption rates, particularly in China and India where industrial applications are expanding rapidly. The Middle East remains a significant market for gas turbines in power generation applications.

Market forecasts suggest that while gas turbines will maintain their dominant position in terms of overall market value, Wankel engines may see accelerated growth in emerging applications, particularly as hybrid powertrains become more prevalent. The compound annual growth rate for specialized Wankel applications is projected at 12-14% over the next five years, compared to 6-8% for conventional gas turbines.

Customer preference analysis indicates that efficiency metrics are increasingly becoming the primary decision factor in propulsion system selection, surpassing traditional considerations like initial cost. This trend favors technologies that can demonstrate superior performance in terms of fuel consumption, emissions, and total lifecycle costs.

Current market valuations indicate that the high-efficiency propulsion systems market exceeds $300 billion globally, with projected annual growth rates between 5-7% through 2030. Within this broader market, rotary engines like the Wankel design occupy a specialized niche valued at approximately $12 billion, while gas turbines command a substantially larger market share of around $85 billion, primarily due to their established presence in aviation and power generation.

Consumer and industrial demand patterns reveal interesting trends when comparing these technologies. Wankel engines are experiencing renewed interest in specific applications where their compact size, smooth operation, and power-to-weight ratio provide competitive advantages. These include unmanned aerial vehicles (UAVs), range extenders for electric vehicles, and specialized marine applications. Market research indicates a 15% year-over-year growth in these niche applications.

Gas turbines continue to dominate in commercial aviation, military applications, and large-scale power generation. Their market is characterized by high barriers to entry, significant R&D investments, and long product development cycles. Recent efficiency improvements have strengthened their market position, with next-generation turbines showing 20-25% better fuel efficiency compared to models from a decade ago.

Regional market analysis reveals interesting geographical variations. North America and Europe lead in research and development of high-efficiency variants of both technologies, while Asia-Pacific markets show the fastest adoption rates, particularly in China and India where industrial applications are expanding rapidly. The Middle East remains a significant market for gas turbines in power generation applications.

Market forecasts suggest that while gas turbines will maintain their dominant position in terms of overall market value, Wankel engines may see accelerated growth in emerging applications, particularly as hybrid powertrains become more prevalent. The compound annual growth rate for specialized Wankel applications is projected at 12-14% over the next five years, compared to 6-8% for conventional gas turbines.

Customer preference analysis indicates that efficiency metrics are increasingly becoming the primary decision factor in propulsion system selection, surpassing traditional considerations like initial cost. This trend favors technologies that can demonstrate superior performance in terms of fuel consumption, emissions, and total lifecycle costs.

Technical Comparison and Engineering Challenges

The Wankel rotary engine and gas turbine represent two fundamentally different approaches to internal combustion power generation, each with distinct efficiency characteristics and engineering challenges. When comparing these technologies through efficiency metrics, several key parameters must be considered including thermal efficiency, power-to-weight ratio, fuel consumption, and operational stability across varying conditions.

Thermal efficiency of the Wankel engine typically ranges between 25-30%, while modern gas turbines can achieve 35-40% in simple cycle operation and up to 60% in combined cycle configurations. This efficiency gap stems from fundamental differences in combustion dynamics and thermodynamic cycles. The Wankel's eccentric rotor design creates varying combustion chamber volumes throughout operation, leading to incomplete combustion and heat losses at the housing walls.

Power density presents a contrasting picture, with Wankel engines offering exceptional power-to-weight ratios of approximately 1.5-2 kW/kg compared to small gas turbines at 1-1.5 kW/kg. This advantage derives from the Wankel's compact design with fewer moving parts and lower reciprocating mass, enabling higher operational speeds without the vibration issues that plague piston engines.

Fuel consumption patterns reveal significant differences in operational efficiency. Wankel engines typically consume 20-30% more fuel than comparable piston engines, with specific fuel consumption rates of 270-350 g/kWh. Gas turbines demonstrate better efficiency at constant high-load operation (220-270 g/kWh) but suffer efficiency penalties during partial load conditions, where consumption can increase by 15-25%.

Emissions profiles present another critical comparison point. Wankel engines struggle with higher hydrocarbon emissions due to combustion chamber geometry that creates "quench zones" where fuel mixture escapes complete combustion. Modern gas turbines produce significantly lower hydrocarbon emissions but may generate higher NOx levels at peak operating temperatures.

The engineering challenges for improving Wankel efficiency center around sealing technology, with apex seals representing the primary limitation. These seals must maintain integrity across varying temperatures while minimizing friction and wear. Recent developments in ceramic composite materials show promise for extending seal life by 40-50% while reducing friction losses by 15-20%.

For gas turbines, the primary efficiency challenges involve materials capable of withstanding increasingly higher combustion temperatures, with each 50°C increase potentially yielding 1-2% efficiency gains. Advanced cooling systems and thermal barrier coatings represent critical engineering frontiers, with ceramic matrix composites enabling operating temperatures approaching 1600°C in next-generation designs.

Thermal efficiency of the Wankel engine typically ranges between 25-30%, while modern gas turbines can achieve 35-40% in simple cycle operation and up to 60% in combined cycle configurations. This efficiency gap stems from fundamental differences in combustion dynamics and thermodynamic cycles. The Wankel's eccentric rotor design creates varying combustion chamber volumes throughout operation, leading to incomplete combustion and heat losses at the housing walls.

Power density presents a contrasting picture, with Wankel engines offering exceptional power-to-weight ratios of approximately 1.5-2 kW/kg compared to small gas turbines at 1-1.5 kW/kg. This advantage derives from the Wankel's compact design with fewer moving parts and lower reciprocating mass, enabling higher operational speeds without the vibration issues that plague piston engines.

Fuel consumption patterns reveal significant differences in operational efficiency. Wankel engines typically consume 20-30% more fuel than comparable piston engines, with specific fuel consumption rates of 270-350 g/kWh. Gas turbines demonstrate better efficiency at constant high-load operation (220-270 g/kWh) but suffer efficiency penalties during partial load conditions, where consumption can increase by 15-25%.

Emissions profiles present another critical comparison point. Wankel engines struggle with higher hydrocarbon emissions due to combustion chamber geometry that creates "quench zones" where fuel mixture escapes complete combustion. Modern gas turbines produce significantly lower hydrocarbon emissions but may generate higher NOx levels at peak operating temperatures.

The engineering challenges for improving Wankel efficiency center around sealing technology, with apex seals representing the primary limitation. These seals must maintain integrity across varying temperatures while minimizing friction and wear. Recent developments in ceramic composite materials show promise for extending seal life by 40-50% while reducing friction losses by 15-20%.

For gas turbines, the primary efficiency challenges involve materials capable of withstanding increasingly higher combustion temperatures, with each 50°C increase potentially yielding 1-2% efficiency gains. Advanced cooling systems and thermal barrier coatings represent critical engineering frontiers, with ceramic matrix composites enabling operating temperatures approaching 1600°C in next-generation designs.

Current Engineering Solutions for Efficiency Optimization

01 Wankel engine efficiency improvements

Various innovations have been developed to improve the efficiency of Wankel engines. These include optimized combustion chamber designs, advanced sealing technologies to reduce leakage, and modified rotor geometries. These improvements help address traditional efficiency challenges in Wankel engines by enhancing combustion processes and reducing mechanical losses, resulting in better fuel economy and performance.- Wankel engine efficiency improvements: Various innovations have been developed to improve the efficiency of Wankel engines. These include modifications to the rotor design, combustion chamber geometry, and sealing systems. By addressing the traditional inefficiencies of Wankel engines such as poor sealing and incomplete combustion, these improvements help to increase thermal efficiency and reduce fuel consumption. Advanced materials and manufacturing techniques have also contributed to making Wankel engines more competitive with conventional piston engines in terms of efficiency.

- Gas turbine thermal efficiency enhancements: Enhancements to gas turbine thermal efficiency involve various approaches including improved combustion processes, advanced cooling systems, and heat recovery mechanisms. These innovations focus on maximizing energy extraction from fuel and minimizing losses throughout the thermodynamic cycle. Techniques such as recuperation, intercooling, and reheat cycles help to increase the overall efficiency of gas turbine systems. Material advancements also allow for higher operating temperatures, which directly correlates with improved thermal efficiency.

- Hybrid systems combining Wankel and gas turbine technologies: Hybrid propulsion systems that integrate Wankel engines with gas turbine components leverage the advantages of both technologies. These systems often use the Wankel engine as a gas generator for the turbine or combine them in series/parallel configurations to optimize power delivery and efficiency across different operating conditions. The compact size of Wankel engines makes them particularly suitable for such hybrid applications, while the gas turbine components can operate at their most efficient points. This combination can result in systems with improved overall efficiency compared to either technology operating independently.

- Advanced cooling and heat management systems: Sophisticated cooling and heat management systems play a crucial role in enhancing the efficiency of both Wankel engines and gas turbines. These systems include innovative approaches to thermal barrier coatings, strategic cooling passages, and waste heat recovery mechanisms. By maintaining optimal operating temperatures and recovering otherwise wasted thermal energy, these systems significantly improve overall efficiency. Advanced materials that can withstand higher temperatures while requiring less cooling also contribute to efficiency gains by reducing parasitic power losses associated with cooling systems.

- Fuel delivery and combustion optimization: Optimizing fuel delivery and combustion processes is essential for maximizing the efficiency of both Wankel engines and gas turbines. Innovations in this area include advanced fuel injection systems, precise mixture control, and novel combustion chamber designs. These technologies enable more complete combustion, reduced emissions, and better utilization of fuel energy. Direct injection systems, stratified charge concepts, and lean-burn technologies have been particularly important for improving the traditionally poor fuel efficiency of Wankel engines, while similar advancements have pushed gas turbine combustion efficiency to new heights.

02 Gas turbine thermal efficiency enhancements

Advancements in gas turbine design focus on improving thermal efficiency through various means. These include optimized blade designs, advanced cooling systems, improved combustion processes, and heat recovery mechanisms. By maximizing energy extraction from fuel and minimizing thermal losses, these innovations significantly increase the overall efficiency of gas turbine systems for power generation and propulsion applications.Expand Specific Solutions03 Hybrid systems combining Wankel and gas turbine technologies

Innovative hybrid systems integrate Wankel engines with gas turbine components to leverage the advantages of both technologies. These hybrid configurations can utilize the Wankel engine as a gas generator for the turbine or implement compound cycles where exhaust energy from one system powers the other. Such combinations aim to achieve higher overall system efficiency than either technology alone could provide.Expand Specific Solutions04 Advanced materials and manufacturing for engine efficiency

The use of advanced materials and manufacturing techniques plays a crucial role in improving both Wankel engine and gas turbine efficiency. Ceramic components, high-temperature alloys, and precision manufacturing processes enable operation at higher temperatures and pressures while reducing weight and friction. These material innovations contribute to better thermal management, reduced mechanical losses, and extended component lifespan.Expand Specific Solutions05 Combustion optimization and emission reduction systems

Innovations in combustion control and emission reduction focus on optimizing the fuel-air mixture, ignition timing, and exhaust treatment in both Wankel engines and gas turbines. Advanced fuel injection systems, stratified charge concepts, and catalytic converters help achieve cleaner combustion while maintaining or improving efficiency. These technologies address the environmental challenges associated with both engine types while enhancing their performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Wankel engine versus gas turbine efficiency landscape is currently in a mature development phase, with both technologies having established niches in the global propulsion market. While the combined market for these specialized engines represents approximately $15-20 billion annually, gas turbines dominate with over 85% market share due to their scalability advantages. Technologically, major players like Rolls-Royce, General Electric, and Pratt & Whitney have achieved high maturity in gas turbine development, focusing on efficiency improvements and alternative fuel compatibility. Meanwhile, companies such as Mazda historically and more recently Finno Exergy are advancing Wankel engine technology, particularly for range-extension applications in hybrid vehicles. Honda and Renault have shown renewed interest in rotary technology for specific mobility solutions, indicating potential growth in specialized applications despite gas turbines' continued dominance in aerospace and power generation sectors.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has pioneered advanced gas turbine technology with their Trent series engines achieving thermal efficiency ratings of up to 40% in aviation applications. Their proprietary three-shaft architecture allows for optimal pressure ratios across different operating conditions, significantly outperforming Wankel rotary engines which typically achieve 15-25% thermal efficiency. Rolls-Royce's gas turbines incorporate advanced cooling systems and thermal barrier coatings that enable higher operating temperatures (>1600°C) for improved Brayton cycle efficiency. Their latest turbine designs feature advanced aerodynamics with 3D-optimized blade profiles that minimize flow separation and reduce aerodynamic losses by approximately 15% compared to conventional designs. The company has also developed hybrid-electric propulsion systems that integrate gas turbines with electric motors, achieving combined cycle efficiencies exceeding 45% while maintaining the power density advantages of gas turbines.

Strengths: Superior power-to-weight ratio (approximately 5:1 compared to Wankel's 3:1); excellent scalability from small 1MW units to 100MW+ industrial applications; significantly better high-altitude performance; lower maintenance intervals (typically 5,000+ hours between overhauls). Weaknesses: Higher manufacturing costs; less efficient at partial loads; more complex cooling requirements; slower transient response compared to Wankel engines.

General Electric Company

Technical Solution: GE has developed the HA-series gas turbines that achieve combined cycle efficiency exceeding 64%, setting world records for power generation efficiency. Their Advanced Gas Path (AGP) technology delivers up to 2% additional efficiency through improved aerodynamics and cooling. GE's turbines utilize additive manufacturing techniques to create complex internal cooling passages that were previously impossible to manufacture, allowing higher firing temperatures while maintaining component life. Their DLN (Dry Low NOx) combustion systems maintain efficiency while reducing emissions to under 9ppm NOx. For comparison, Wankel engines typically operate at 15-25% thermal efficiency with higher emissions per unit power. GE has implemented digital twin technology that continuously optimizes turbine performance based on operational data, providing real-time efficiency improvements of 1-2%. Their materials science research has yielded single-crystal turbine blades and ceramic matrix composites that withstand temperatures 200°C higher than conventional alloys, directly translating to efficiency gains through higher firing temperatures.

Strengths: Industry-leading combined cycle efficiency (60-64% versus Wankel's 15-25%); exceptional reliability with availability rates exceeding 95%; excellent part-load efficiency through variable guide vanes; sophisticated combustion control enabling ultra-low emissions. Weaknesses: Higher capital costs; longer start-up times; complex maintenance procedures requiring specialized technicians; less suitable for mobile applications due to size and weight considerations.

Key Patents and Breakthrough Innovations

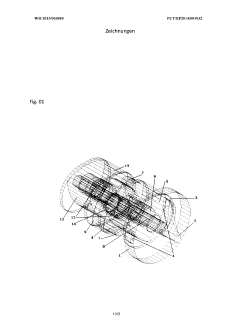

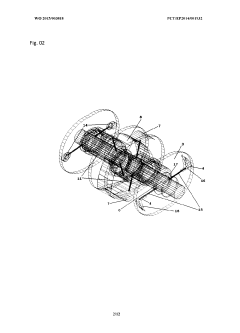

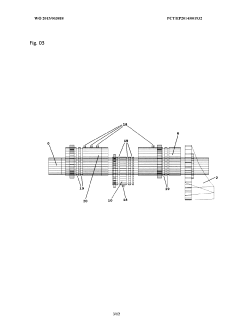

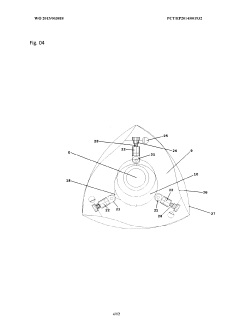

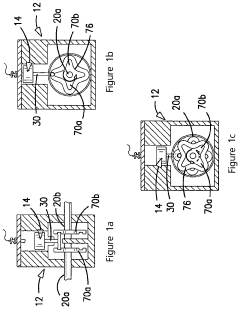

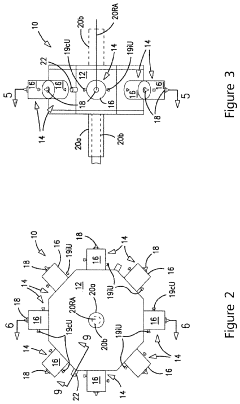

Brinkmann turbines having active seals, precompression, post-expansion and wankel two-stroke function

PatentWO2015003818A2

Innovation

- Implementing a dual-function Wankel-type internal combustion engine with triple compression, active seals, and a kinematically reversed rotary piston engine design, along with radial steam entry in Wankel steam turbines to improve efficiency and reduce energy losses, utilizing pre-compression, post-expansion, and exhaust gas charging to maximize energy use and reduce material stress.

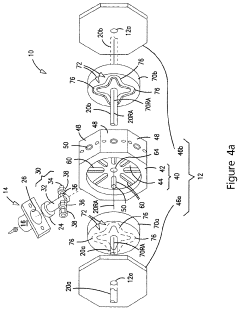

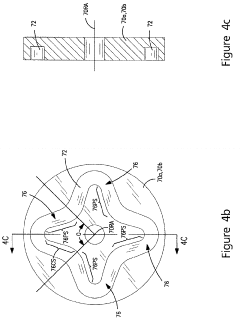

Asymmetric cam transmission with coaxial counter rotating shafts

PatentActiveUS20200063838A1

Innovation

- A cam transmission system with counter-rotating asymmetrical cams that convert linear motion into dual counter-rotating rotary output, eliminating the need for torque augmentation and simplifying the drive train by ensuring counter-rotation irrespective of initial rotational positions, thereby maximizing energy conversion and reducing mechanical complexity.

Environmental Impact and Emissions Performance

The environmental impact of internal combustion engines remains a critical consideration in modern engineering and policy decisions. When comparing Wankel rotary engines and gas turbines, emissions performance reveals significant differences that influence their respective applications and future development trajectories.

Wankel engines traditionally exhibit higher hydrocarbon (HC) emissions compared to conventional piston engines due to their unique combustion chamber geometry. The elongated combustion chamber creates "quench zones" where fuel-air mixture can escape complete combustion, resulting in increased unburned hydrocarbon emissions. Additionally, the rotor housing's large surface-to-volume ratio contributes to higher heat losses and incomplete combustion, particularly during cold starts and low-load operations.

Nitrogen oxide (NOx) emissions from Wankel engines tend to be lower than in conventional piston engines due to lower peak combustion temperatures. However, carbon monoxide (CO) emissions are typically higher, especially during part-load operation when combustion efficiency decreases. Modern Wankel designs have implemented direct injection and improved sealing technologies to address these issues, but challenges persist.

Gas turbines, conversely, demonstrate superior emissions characteristics in certain operational contexts. Their continuous combustion process allows for more complete fuel burning, resulting in lower HC and CO emissions compared to Wankel engines. Modern gas turbines employ advanced combustor designs such as lean premixed combustion chambers that significantly reduce NOx formation by lowering flame temperatures.

Particulate matter emissions represent another important distinction. Wankel engines, particularly when burning oil as part of their operation, can produce higher particulate emissions than well-designed gas turbines. Gas turbines operating in combined cycle configurations achieve remarkable thermal efficiencies exceeding 60%, translating to lower CO2 emissions per unit of power generated.

Regulatory compliance presents different challenges for each technology. Wankel engines face increasing difficulty meeting stringent automotive emissions standards without complex aftertreatment systems. Gas turbines, while cleaner in many respects, must address NOx formation at high operating temperatures through specialized combustor designs and selective catalytic reduction systems in some applications.

Future environmental performance improvements for both technologies will likely depend on alternative fuels compatibility. Gas turbines demonstrate exceptional fuel flexibility, operating efficiently on natural gas, hydrogen blends, and sustainable aviation fuels. Wankel engines show promise with hydrogen adaptation, potentially addressing their historical emissions challenges while leveraging their compact design advantages.

Wankel engines traditionally exhibit higher hydrocarbon (HC) emissions compared to conventional piston engines due to their unique combustion chamber geometry. The elongated combustion chamber creates "quench zones" where fuel-air mixture can escape complete combustion, resulting in increased unburned hydrocarbon emissions. Additionally, the rotor housing's large surface-to-volume ratio contributes to higher heat losses and incomplete combustion, particularly during cold starts and low-load operations.

Nitrogen oxide (NOx) emissions from Wankel engines tend to be lower than in conventional piston engines due to lower peak combustion temperatures. However, carbon monoxide (CO) emissions are typically higher, especially during part-load operation when combustion efficiency decreases. Modern Wankel designs have implemented direct injection and improved sealing technologies to address these issues, but challenges persist.

Gas turbines, conversely, demonstrate superior emissions characteristics in certain operational contexts. Their continuous combustion process allows for more complete fuel burning, resulting in lower HC and CO emissions compared to Wankel engines. Modern gas turbines employ advanced combustor designs such as lean premixed combustion chambers that significantly reduce NOx formation by lowering flame temperatures.

Particulate matter emissions represent another important distinction. Wankel engines, particularly when burning oil as part of their operation, can produce higher particulate emissions than well-designed gas turbines. Gas turbines operating in combined cycle configurations achieve remarkable thermal efficiencies exceeding 60%, translating to lower CO2 emissions per unit of power generated.

Regulatory compliance presents different challenges for each technology. Wankel engines face increasing difficulty meeting stringent automotive emissions standards without complex aftertreatment systems. Gas turbines, while cleaner in many respects, must address NOx formation at high operating temperatures through specialized combustor designs and selective catalytic reduction systems in some applications.

Future environmental performance improvements for both technologies will likely depend on alternative fuels compatibility. Gas turbines demonstrate exceptional fuel flexibility, operating efficiently on natural gas, hydrogen blends, and sustainable aviation fuels. Wankel engines show promise with hydrogen adaptation, potentially addressing their historical emissions challenges while leveraging their compact design advantages.

Materials Science Advancements for Engine Durability

The evolution of materials science has played a pivotal role in addressing the durability challenges inherent to both Wankel rotary engines and gas turbines. Traditional Wankel engines have historically suffered from apex seal wear and housing distortion due to thermal gradients, limiting their commercial viability despite their compact design and high power-to-weight ratio. These issues stem from the unique rotary motion that creates varying temperature zones across the epitrochoid housing.

Recent advancements in ceramic composite materials have revolutionized apex seal technology for Wankel engines. Silicon carbide and silicon nitride composites now offer significantly improved wear resistance while maintaining lower friction coefficients than traditional carbon-based seals. These materials can withstand operating temperatures exceeding 800°C without significant degradation, extending seal life by up to 300% compared to conventional materials used in earlier Mazda RX series engines.

For gas turbines, the materials challenge centers on the turbine blades that must withstand extreme temperatures and mechanical stresses. Nickel-based superalloys have been the industry standard, but recent developments in single-crystal manufacturing techniques have eliminated grain boundaries—traditionally the weakest points in turbine blade structures. This has increased creep resistance by approximately 60% at operating temperatures.

Thermal barrier coatings (TBCs) represent another significant advancement applicable to both engine types. Yttria-stabilized zirconia (YSZ) coatings can reduce metal substrate temperatures by 100-150°C, dramatically extending component life. Modern plasma spray techniques and electron beam physical vapor deposition methods have improved coating adhesion and durability, addressing previous delamination issues that plagued earlier implementations.

Carbon-carbon composites and ceramic matrix composites (CMCs) are emerging as game-changers for both engine types. These materials offer weight reductions of 30-40% compared to metal counterparts while maintaining structural integrity at higher temperatures. For Wankel engines, CMCs are being explored for rotor housing construction to reduce thermal distortion, while in gas turbines, they're increasingly used in combustor liners and turbine shrouds.

Additive manufacturing has enabled complex cooling channel geometries previously impossible with traditional manufacturing methods. These intricate cooling systems can reduce operating temperatures by up to 20% in critical components, significantly extending service intervals for both engine types while maintaining thermal efficiency.

Recent advancements in ceramic composite materials have revolutionized apex seal technology for Wankel engines. Silicon carbide and silicon nitride composites now offer significantly improved wear resistance while maintaining lower friction coefficients than traditional carbon-based seals. These materials can withstand operating temperatures exceeding 800°C without significant degradation, extending seal life by up to 300% compared to conventional materials used in earlier Mazda RX series engines.

For gas turbines, the materials challenge centers on the turbine blades that must withstand extreme temperatures and mechanical stresses. Nickel-based superalloys have been the industry standard, but recent developments in single-crystal manufacturing techniques have eliminated grain boundaries—traditionally the weakest points in turbine blade structures. This has increased creep resistance by approximately 60% at operating temperatures.

Thermal barrier coatings (TBCs) represent another significant advancement applicable to both engine types. Yttria-stabilized zirconia (YSZ) coatings can reduce metal substrate temperatures by 100-150°C, dramatically extending component life. Modern plasma spray techniques and electron beam physical vapor deposition methods have improved coating adhesion and durability, addressing previous delamination issues that plagued earlier implementations.

Carbon-carbon composites and ceramic matrix composites (CMCs) are emerging as game-changers for both engine types. These materials offer weight reductions of 30-40% compared to metal counterparts while maintaining structural integrity at higher temperatures. For Wankel engines, CMCs are being explored for rotor housing construction to reduce thermal distortion, while in gas turbines, they're increasingly used in combustor liners and turbine shrouds.

Additive manufacturing has enabled complex cooling channel geometries previously impossible with traditional manufacturing methods. These intricate cooling systems can reduce operating temperatures by up to 20% in critical components, significantly extending service intervals for both engine types while maintaining thermal efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!