Wankel Engine vs. Piston Engine: Performance Benchmarks

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rotary and Piston Engine Development History and Objectives

The internal combustion engine has been a cornerstone of transportation and industrial power generation since the late 19th century. Two primary designs have dominated this landscape: the conventional piston engine and the rotary Wankel engine. Each represents distinct engineering philosophies with their own evolutionary paths and performance characteristics.

The piston engine's development began in earnest with Nikolaus Otto's four-stroke cycle engine in 1876, establishing the foundation for modern reciprocating engines. By the early 20th century, piston engines had evolved significantly, with innovations like overhead valves, improved carburetion, and more efficient combustion chambers. The post-World War II era saw rapid advancements in materials science, electronic fuel injection, and computer-controlled engine management systems, dramatically improving performance, efficiency, and emissions.

In contrast, the Wankel rotary engine emerged as a revolutionary alternative when Felix Wankel developed his first working prototype in 1957. NSU and later Mazda became the primary champions of this technology. The rotary engine's development peaked in the 1970s with Mazda's successful implementation in sports cars like the RX-7, offering high power output from a compact, lightweight design with fewer moving parts than conventional piston engines.

The technical evolution of both engine types has been driven by similar objectives: increasing power density, improving fuel efficiency, reducing emissions, enhancing reliability, and optimizing manufacturing costs. However, their approaches to achieving these goals differ fundamentally due to their distinct operating principles.

Performance benchmarking between these engine types reveals interesting contrasts. Traditionally, Wankel engines have excelled in power-to-weight ratio, smoothness of operation, and compact design. They typically deliver higher specific output (horsepower per liter of displacement) than comparable piston engines. However, they have historically struggled with fuel efficiency, oil consumption, and emissions compliance.

Piston engines, benefiting from over a century of continuous development and massive industry investment, have demonstrated superior fuel economy, better thermal efficiency, and more effective emissions control. Modern piston engines with technologies like direct injection, variable valve timing, and turbocharging have significantly narrowed the power density gap that once favored rotary designs.

The technological trajectory for both engine types continues to evolve in response to increasingly stringent emissions regulations and the push for greater efficiency. While the piston engine remains dominant in the market, niche applications for rotary technology persist, particularly where its unique characteristics offer compelling advantages.

The piston engine's development began in earnest with Nikolaus Otto's four-stroke cycle engine in 1876, establishing the foundation for modern reciprocating engines. By the early 20th century, piston engines had evolved significantly, with innovations like overhead valves, improved carburetion, and more efficient combustion chambers. The post-World War II era saw rapid advancements in materials science, electronic fuel injection, and computer-controlled engine management systems, dramatically improving performance, efficiency, and emissions.

In contrast, the Wankel rotary engine emerged as a revolutionary alternative when Felix Wankel developed his first working prototype in 1957. NSU and later Mazda became the primary champions of this technology. The rotary engine's development peaked in the 1970s with Mazda's successful implementation in sports cars like the RX-7, offering high power output from a compact, lightweight design with fewer moving parts than conventional piston engines.

The technical evolution of both engine types has been driven by similar objectives: increasing power density, improving fuel efficiency, reducing emissions, enhancing reliability, and optimizing manufacturing costs. However, their approaches to achieving these goals differ fundamentally due to their distinct operating principles.

Performance benchmarking between these engine types reveals interesting contrasts. Traditionally, Wankel engines have excelled in power-to-weight ratio, smoothness of operation, and compact design. They typically deliver higher specific output (horsepower per liter of displacement) than comparable piston engines. However, they have historically struggled with fuel efficiency, oil consumption, and emissions compliance.

Piston engines, benefiting from over a century of continuous development and massive industry investment, have demonstrated superior fuel economy, better thermal efficiency, and more effective emissions control. Modern piston engines with technologies like direct injection, variable valve timing, and turbocharging have significantly narrowed the power density gap that once favored rotary designs.

The technological trajectory for both engine types continues to evolve in response to increasingly stringent emissions regulations and the push for greater efficiency. While the piston engine remains dominant in the market, niche applications for rotary technology persist, particularly where its unique characteristics offer compelling advantages.

Market Analysis of Rotary and Piston Engine Applications

The global engine market continues to witness a dynamic interplay between rotary (Wankel) and piston engines across various application sectors. The automotive segment remains the largest market for both engine types, with piston engines dominating approximately 99% of passenger vehicles due to their established manufacturing infrastructure and reliability. However, rotary engines maintain niche applications in specialized vehicles where their compact size and smooth operation provide distinct advantages.

In the aviation sector, rotary engines have carved out a growing market share in ultralight aircraft and unmanned aerial vehicles (UAVs), where their high power-to-weight ratio offers significant benefits. This segment has experienced annual growth rates of 7-8% over the past five years, outpacing the broader aviation engine market's 3-4% growth.

Marine applications present another significant market, particularly for smaller watercraft where the rotary engine's compact design allows for more efficient space utilization. The recreational boating sector has shown increasing adoption of rotary solutions, though piston engines still command approximately 95% of the overall marine propulsion market.

The motorsport segment represents a premium niche where rotary engines have maintained a dedicated following. Despite their limited mainstream presence, rotary engines continue to be valued in racing applications for their high-revving capabilities and unique power delivery characteristics. This segment, while small in volume, drives significant innovation and brand value.

Emerging markets in Asia-Pacific, particularly China and India, are showing increased interest in both engine technologies, with the region projected to become the fastest-growing market for specialized engine applications over the next decade. These markets are particularly receptive to hybrid solutions that leverage the strengths of both engine types.

The industrial equipment sector presents another significant application area, with small rotary engines finding increased adoption in portable generators and specialized power equipment. This market segment values the rotary engine's vibration characteristics and compact form factor, growing at approximately 5% annually.

From a regional perspective, North America and Europe remain the largest markets for premium rotary engine applications, while conventional piston engines maintain their dominance across all regions. Japan continues to be a center of excellence for rotary engine development, despite Mazda's intermittent production of rotary-powered vehicles.

The aftermarket and maintenance ecosystem shows distinct differences between the two engine types, with piston engines benefiting from a more extensive support network and parts availability, while rotary engines command premium service rates due to specialized maintenance requirements.

In the aviation sector, rotary engines have carved out a growing market share in ultralight aircraft and unmanned aerial vehicles (UAVs), where their high power-to-weight ratio offers significant benefits. This segment has experienced annual growth rates of 7-8% over the past five years, outpacing the broader aviation engine market's 3-4% growth.

Marine applications present another significant market, particularly for smaller watercraft where the rotary engine's compact design allows for more efficient space utilization. The recreational boating sector has shown increasing adoption of rotary solutions, though piston engines still command approximately 95% of the overall marine propulsion market.

The motorsport segment represents a premium niche where rotary engines have maintained a dedicated following. Despite their limited mainstream presence, rotary engines continue to be valued in racing applications for their high-revving capabilities and unique power delivery characteristics. This segment, while small in volume, drives significant innovation and brand value.

Emerging markets in Asia-Pacific, particularly China and India, are showing increased interest in both engine technologies, with the region projected to become the fastest-growing market for specialized engine applications over the next decade. These markets are particularly receptive to hybrid solutions that leverage the strengths of both engine types.

The industrial equipment sector presents another significant application area, with small rotary engines finding increased adoption in portable generators and specialized power equipment. This market segment values the rotary engine's vibration characteristics and compact form factor, growing at approximately 5% annually.

From a regional perspective, North America and Europe remain the largest markets for premium rotary engine applications, while conventional piston engines maintain their dominance across all regions. Japan continues to be a center of excellence for rotary engine development, despite Mazda's intermittent production of rotary-powered vehicles.

The aftermarket and maintenance ecosystem shows distinct differences between the two engine types, with piston engines benefiting from a more extensive support network and parts availability, while rotary engines command premium service rates due to specialized maintenance requirements.

Technical Challenges and Global Development Status

The Wankel rotary engine and conventional piston engine represent two fundamentally different approaches to internal combustion technology, each facing distinct technical challenges. The Wankel engine, despite its compact design and smooth operation, continues to struggle with apex seal durability issues. These seals experience extreme thermal stress and friction, resulting in accelerated wear and compromised compression over time. Engineering solutions have progressed from basic carbon seals to advanced ceramic-composite materials, yet the fundamental challenge persists.

Fuel efficiency remains another significant hurdle for Wankel engines, with inherent thermodynamic limitations causing higher fuel consumption compared to piston counterparts. The elongated combustion chamber creates suboptimal flame propagation and incomplete combustion, while the rotor housing's large surface area increases heat loss. These factors contribute to efficiency ratings typically 15-20% lower than comparable piston engines.

Emissions compliance presents an increasingly critical challenge as global regulations tighten. The Wankel's inherent oil consumption and combustion characteristics produce higher hydrocarbon and NOx emissions. This has forced manufacturers like Mazda to implement complex emission control systems, adding cost and complexity while reducing overall efficiency advantages.

Conventional piston engines face their own set of challenges, primarily centered around power-to-weight ratios and mechanical complexity. With numerous moving parts, piston engines require sophisticated manufacturing processes and precise tolerances, increasing production costs and potential failure points. Recent advancements in materials science and manufacturing have mitigated these issues but not eliminated them entirely.

Globally, piston engine development remains dominant, with major automotive manufacturers across North America, Europe, and Asia investing heavily in refinement technologies like direct injection, variable valve timing, and cylinder deactivation. These innovations have significantly improved efficiency and emissions performance, strengthening the piston engine's market position.

Wankel development, meanwhile, has become geographically concentrated, with Japan (particularly Mazda) maintaining the strongest research presence. Limited development continues in specialized applications across Germany and the United States, primarily for UAVs, range extenders, and niche vehicles where the rotary's power-density advantages outweigh efficiency concerns.

Recent technological convergence has seen hybrid applications emerge as a promising direction, with Mazda's e-Skyactiv R-EV using a rotary engine as a compact range extender for electric vehicles. This approach leverages the Wankel's size and weight advantages while mitigating its efficiency drawbacks through limited operational cycles.

Fuel efficiency remains another significant hurdle for Wankel engines, with inherent thermodynamic limitations causing higher fuel consumption compared to piston counterparts. The elongated combustion chamber creates suboptimal flame propagation and incomplete combustion, while the rotor housing's large surface area increases heat loss. These factors contribute to efficiency ratings typically 15-20% lower than comparable piston engines.

Emissions compliance presents an increasingly critical challenge as global regulations tighten. The Wankel's inherent oil consumption and combustion characteristics produce higher hydrocarbon and NOx emissions. This has forced manufacturers like Mazda to implement complex emission control systems, adding cost and complexity while reducing overall efficiency advantages.

Conventional piston engines face their own set of challenges, primarily centered around power-to-weight ratios and mechanical complexity. With numerous moving parts, piston engines require sophisticated manufacturing processes and precise tolerances, increasing production costs and potential failure points. Recent advancements in materials science and manufacturing have mitigated these issues but not eliminated them entirely.

Globally, piston engine development remains dominant, with major automotive manufacturers across North America, Europe, and Asia investing heavily in refinement technologies like direct injection, variable valve timing, and cylinder deactivation. These innovations have significantly improved efficiency and emissions performance, strengthening the piston engine's market position.

Wankel development, meanwhile, has become geographically concentrated, with Japan (particularly Mazda) maintaining the strongest research presence. Limited development continues in specialized applications across Germany and the United States, primarily for UAVs, range extenders, and niche vehicles where the rotary's power-density advantages outweigh efficiency concerns.

Recent technological convergence has seen hybrid applications emerge as a promising direction, with Mazda's e-Skyactiv R-EV using a rotary engine as a compact range extender for electric vehicles. This approach leverages the Wankel's size and weight advantages while mitigating its efficiency drawbacks through limited operational cycles.

Current Performance Benchmarking Methodologies

01 Comparative performance characteristics of Wankel and piston engines

Wankel engines and conventional piston engines exhibit different performance characteristics. Wankel engines typically offer higher power-to-weight ratios, smoother operation due to fewer moving parts, and more compact design. Piston engines generally provide better fuel efficiency, durability, and lower emissions. These fundamental differences affect their applications in various vehicles and machinery, with each engine type having distinct advantages in specific operational contexts.- Comparative Performance Analysis of Wankel and Piston Engines: Studies comparing the performance characteristics of Wankel rotary engines and conventional piston engines reveal distinct advantages and limitations of each design. Wankel engines typically offer higher power-to-weight ratios, smoother operation due to fewer moving parts, and more compact design. Piston engines generally provide better fuel efficiency and lower emissions. These comparative analyses help engineers understand the optimal applications for each engine type based on performance requirements.

- Efficiency Improvements in Rotary Engine Design: Innovations in Wankel rotary engine design focus on addressing traditional efficiency limitations. These improvements include enhanced sealing systems to reduce gas leakage, modified combustion chamber geometries for better fuel burning, and advanced cooling systems to manage thermal loads. Such developments aim to overcome the historical disadvantages of rotary engines while maintaining their inherent benefits of compact size and mechanical simplicity.

- Hybrid Integration of Wankel and Piston Technologies: Hybrid systems combining elements of both Wankel and piston engine technologies represent an innovative approach to powertrain design. These systems may use a Wankel engine as a range extender for electric vehicles, or incorporate rotary principles into conventional piston engine architectures. Such integrations aim to leverage the strengths of both engine types while mitigating their respective weaknesses, potentially offering improved overall performance and efficiency.

- Advanced Materials and Manufacturing for Engine Performance: The application of advanced materials and manufacturing techniques significantly impacts both Wankel and piston engine performance. Ceramic coatings, composite materials, and precision-engineered components enhance durability, reduce friction, and improve thermal management. Modern manufacturing methods like 3D printing and precision machining enable more complex geometries and tighter tolerances, contributing to performance gains in both engine types.

- Emissions Control and Environmental Performance: Addressing emissions challenges is crucial for both Wankel and piston engine technologies. Innovations in this area include advanced catalytic converters, exhaust gas recirculation systems, and combustion optimization techniques specifically tailored to each engine type. While piston engines have traditionally held an advantage in emissions control, modern developments in Wankel technology are narrowing this gap through improved sealing systems and combustion chamber designs.

02 Efficiency improvements in rotary and reciprocating engines

Various technological innovations have been developed to enhance the efficiency of both Wankel rotary and conventional piston engines. These improvements include advanced sealing systems to reduce friction losses, optimized combustion chamber designs, and innovative cooling systems. Modified rotor geometries in Wankel engines and advanced valve timing mechanisms in piston engines contribute to better fuel economy and increased power output while reducing emissions and extending engine lifespan.Expand Specific Solutions03 Hybrid and combined engine systems

Hybrid systems that combine elements of both Wankel and piston engines have been developed to leverage the advantages of each design. These hybrid configurations may use rotary engines as range extenders for electric vehicles or incorporate both engine types in tandem for specific performance requirements. Such combined systems can optimize power delivery, fuel efficiency, and operational flexibility while minimizing the inherent disadvantages of each individual engine type.Expand Specific Solutions04 Thermal management and cooling solutions

Effective thermal management is crucial for both Wankel and piston engines to maintain optimal performance. Wankel engines face unique cooling challenges due to their compact design and concentrated heat zones, requiring specialized cooling systems. Advanced cooling solutions include improved coolant circulation pathways, enhanced heat exchanger designs, and innovative materials with superior thermal conductivity. These thermal management strategies help prevent overheating, reduce thermal stress, and maintain consistent performance under varying operating conditions.Expand Specific Solutions05 Emissions control and environmental performance

Addressing emissions challenges is critical for both Wankel and piston engines to meet increasingly stringent environmental regulations. Wankel engines traditionally struggle with higher hydrocarbon emissions due to their combustion chamber geometry, while piston engines face their own emissions challenges. Advanced technologies such as direct injection systems, exhaust gas recirculation, catalytic converters specifically designed for each engine type, and optimized combustion processes help reduce environmental impact while maintaining performance characteristics.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The Wankel vs. Piston Engine competition landscape is currently in a mature development phase, with the piston engine dominating the market due to its established manufacturing infrastructure and widespread adoption. The global market for rotary engines remains niche, estimated at less than 5% of the overall internal combustion engine market. From a technological maturity perspective, traditional piston engines benefit from decades of refinement by major players like Toyota, Mazda, and Pratt & Whitney Canada, while Wankel technology, despite its performance advantages, faces efficiency and emissions challenges. Companies like Mazda (historically the primary Wankel advocate), Achates Power, and Great Wall Motor continue research into alternative engine architectures, with specialized applications emerging in sectors requiring compact power solutions.

Achates Power, Inc.

Technical Solution: Achates Power has developed an innovative opposed-piston engine (OPE) technology that represents a significant evolution in piston engine design to compete with both conventional piston and Wankel engines. Their opposed-piston architecture eliminates the cylinder head, valvetrain, and associated components, resulting in a more efficient and compact design. The Achates engine features two pistons per cylinder working in opposition, with ports for intake and exhaust exposed as the pistons reach their outer positions. This design achieves compression ratios of 18:1 or higher while maintaining lower peak combustion temperatures. Independent testing has demonstrated that Achates' engines achieve 30-50% better fuel efficiency than conventional diesel engines and up to 30% lower carbon dioxide emissions. The company has successfully demonstrated their technology in heavy-duty truck applications, achieving 55% brake thermal efficiency—significantly higher than both conventional piston engines (typically 42-46%) and Wankel designs (typically 25-30%).

Strengths: Exceptional thermal efficiency (up to 55%), significantly reduced NOx and particulate emissions, fewer parts than conventional engines leading to potential reliability improvements, and higher power density than traditional diesel engines. Weaknesses: Requires specialized manufacturing processes different from mainstream engine production, limited commercial deployment history compared to conventional designs, and challenges in adapting to smaller displacement applications.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced piston engine technologies that directly compete with Wankel performance benchmarks. Their Dynamic Force Engine platform achieves 40% thermal efficiency in conventional applications and 41% in hybrid configurations through high compression ratios (13:1 to 14:1), reduced friction, and optimized intake systems. Toyota's D-4S dual injection system combines direct and port fuel injection to maximize power and efficiency across all operating conditions. Their variable valve timing intelligence system (VVT-i) optimizes valve timing across the RPM range, improving both low-end torque and high-end power. Toyota has also pioneered production of the Atkinson cycle engines for hybrid vehicles, sacrificing some power density for significant efficiency gains. Their latest piston engines achieve specific outputs of 80-100 hp per liter while maintaining reliability and meeting stringent emissions standards.

Strengths: Superior fuel efficiency (typically 20-30% better than comparable Wankel engines), better emissions performance, higher torque at lower RPM ranges, and proven long-term durability with lower maintenance costs. Weaknesses: More complex design with more moving parts, larger physical size for equivalent power output, and greater NVH (noise, vibration, harshness) challenges requiring additional engineering solutions.

Critical Patents and Innovations in Engine Design

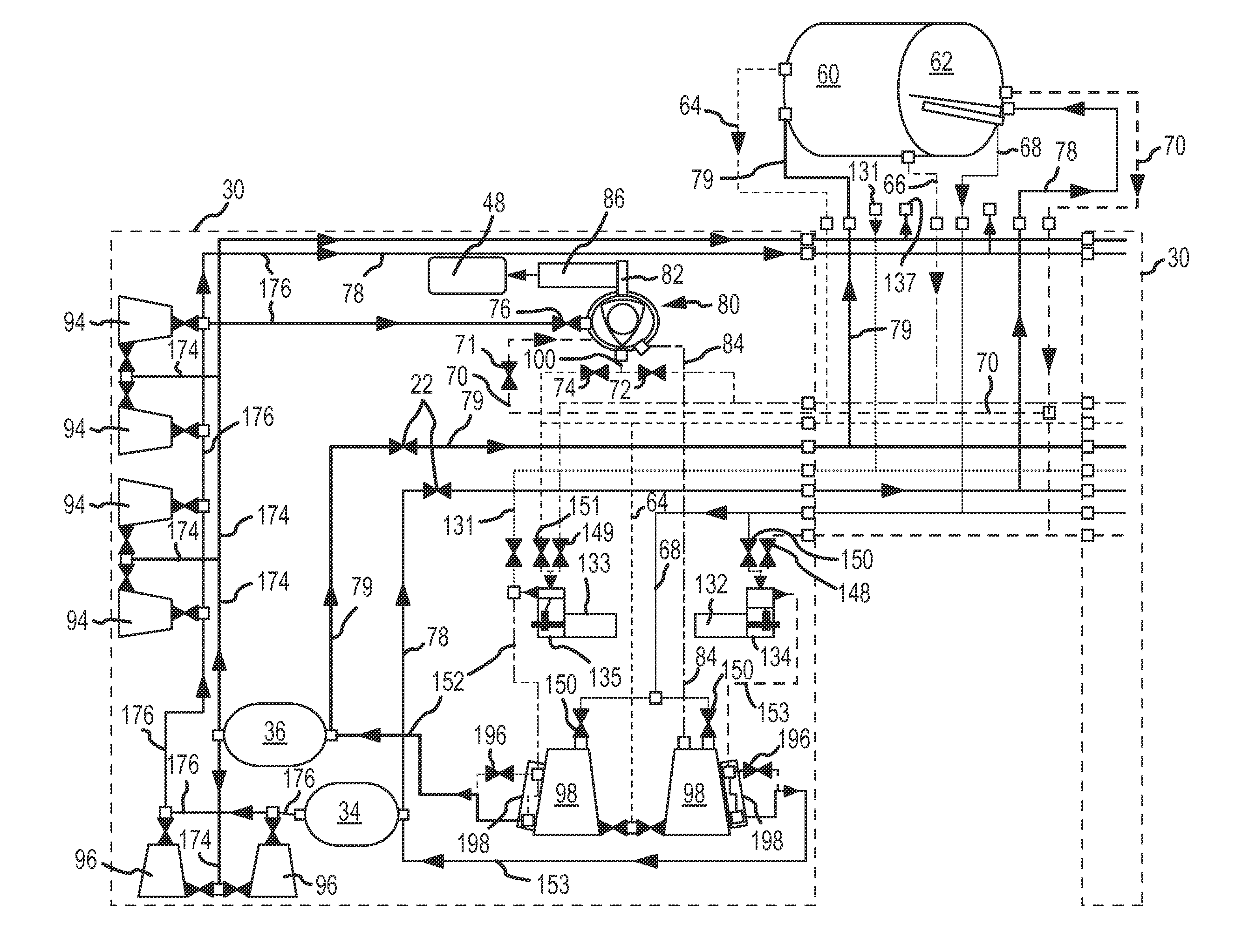

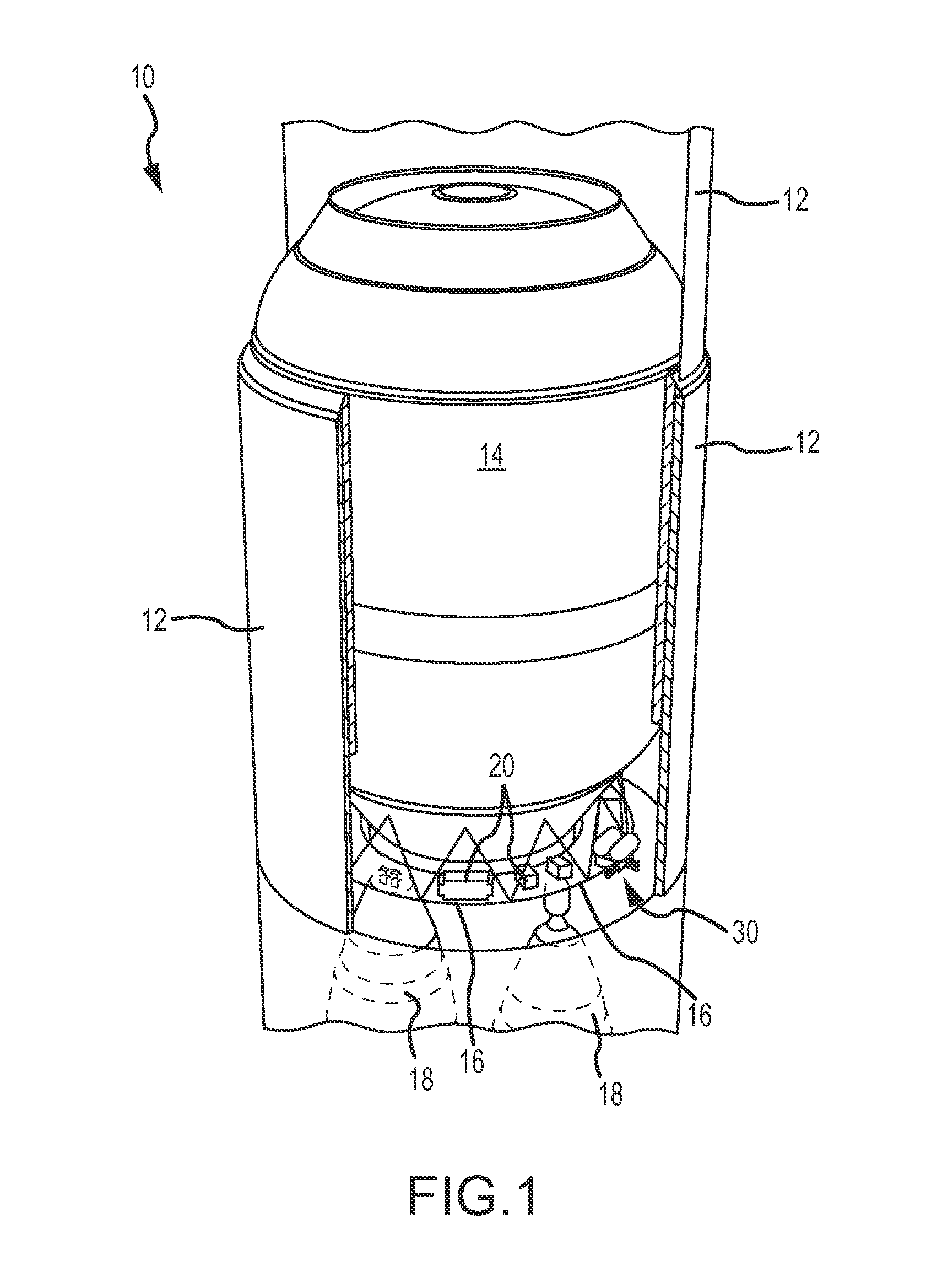

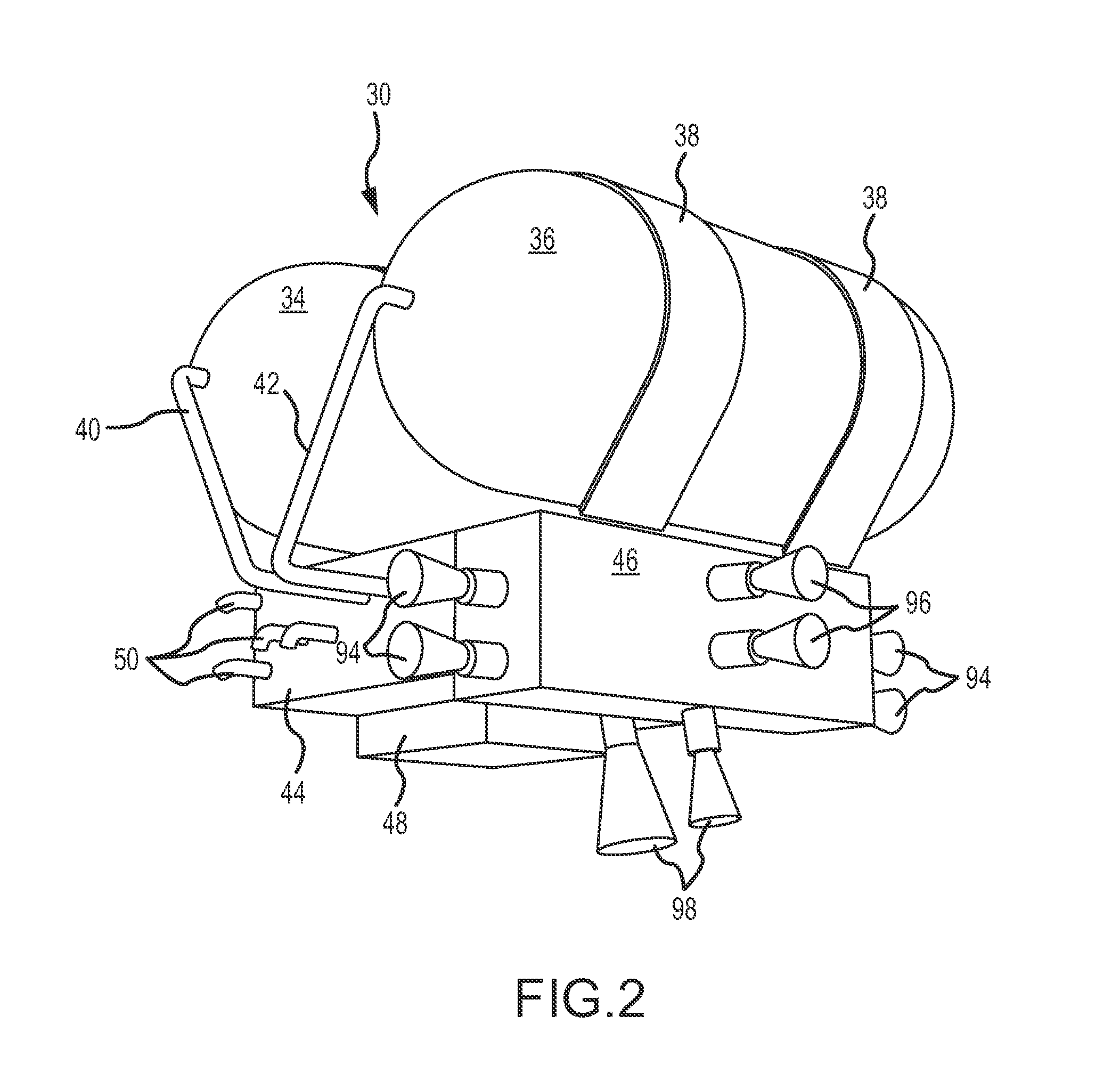

Integrated vehicle fluids

PatentActiveUS20120227374A1

Innovation

- An integrated vehicle fluid (IVF) module that utilizes waste ullage gases from hydrogen and oxygen tanks to power an internal combustion engine, providing power for attitude control, propellant settling, tank pressurization, and venting, reducing the need for external fluids and minimizing mass penalties by recycling and efficiently using ullage gases.

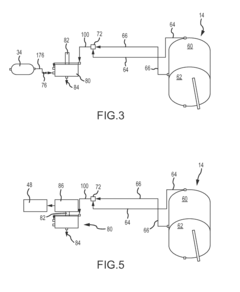

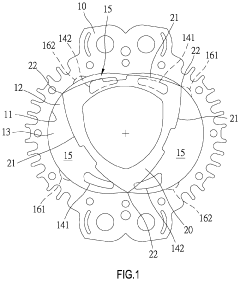

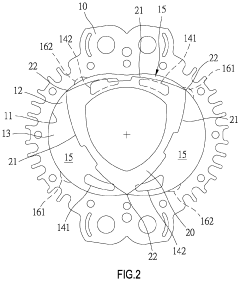

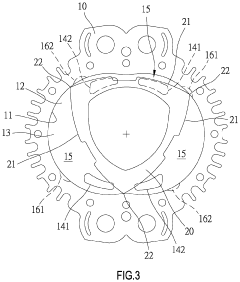

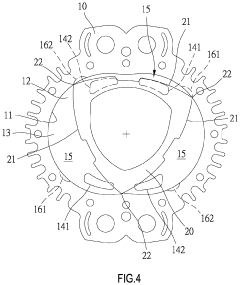

Pistonless rotary motor for air compressor

PatentActiveUS20220282622A1

Innovation

- Incorporating radially spaced grooves in the peripheral wall of the rotor cavity, with first grooves configured to release pressurized air at the top dead center during the compression stroke and second grooves for releasing air during the exhaust stroke, allowing for controlled pressure management and reduced air resistance.

Emissions Regulations Impact on Engine Development

Emissions regulations have become a pivotal factor in the evolution of internal combustion engine technology, significantly influencing the development trajectories of both Wankel rotary engines and conventional piston engines. Since the 1970s, increasingly stringent emissions standards across global markets have forced manufacturers to continuously adapt their engine designs to reduce harmful pollutants.

For Wankel engines, emissions compliance has presented particularly challenging obstacles. The rotary design's inherent characteristics—including elongated combustion chambers and higher surface-to-volume ratios—contribute to incomplete combustion and increased hydrocarbon emissions. These engines typically exhibit 15-40% higher hydrocarbon emissions than comparable piston engines, creating a substantial regulatory hurdle.

Piston engines have demonstrated greater adaptability to emissions requirements through technological innovations. The implementation of direct injection, variable valve timing, exhaust gas recirculation (EGR), and advanced catalytic converters has enabled piston engines to achieve substantial emissions reductions while maintaining or improving performance metrics. These adaptations have allowed piston engines to remain compliant with increasingly strict standards such as Euro 6, US Tier 3, and China 6.

The regulatory landscape has evolved dramatically over the past decade, with particular focus on nitrogen oxides (NOx), particulate matter, and carbon dioxide emissions. The introduction of Real Driving Emissions (RDE) testing in Europe and similar protocols in other regions has further challenged manufacturers to ensure emissions compliance across all operating conditions, not merely in laboratory settings.

Mazda's efforts to maintain Wankel engine viability illustrate the regulatory impact. Their SKYACTIV-R technology incorporated direct injection, improved sealing technology, and exhaust after-treatment systems specifically to address emissions challenges. Despite these innovations, Mazda ultimately suspended production of rotary-powered vehicles in 2012, only recently reintroducing the technology in a limited range-extender application for electric vehicles.

The regulatory pressure has accelerated the development of hybrid powertrains incorporating both engine types. Wankel engines, with their compact size and smooth operation, have found potential new applications as range extenders in hybrid electric vehicles, where they can operate at optimal fixed speeds to minimize emissions while providing supplementary power generation.

Looking forward, upcoming regulations such as Euro 7 and equivalent standards in North America and Asia will further tighten emissions requirements, potentially accelerating the transition toward electrification. This regulatory trajectory suggests that future development of both engine types will increasingly focus on hybridization strategies or specialized applications where their unique characteristics provide specific advantages within a broader electrified powertrain ecosystem.

For Wankel engines, emissions compliance has presented particularly challenging obstacles. The rotary design's inherent characteristics—including elongated combustion chambers and higher surface-to-volume ratios—contribute to incomplete combustion and increased hydrocarbon emissions. These engines typically exhibit 15-40% higher hydrocarbon emissions than comparable piston engines, creating a substantial regulatory hurdle.

Piston engines have demonstrated greater adaptability to emissions requirements through technological innovations. The implementation of direct injection, variable valve timing, exhaust gas recirculation (EGR), and advanced catalytic converters has enabled piston engines to achieve substantial emissions reductions while maintaining or improving performance metrics. These adaptations have allowed piston engines to remain compliant with increasingly strict standards such as Euro 6, US Tier 3, and China 6.

The regulatory landscape has evolved dramatically over the past decade, with particular focus on nitrogen oxides (NOx), particulate matter, and carbon dioxide emissions. The introduction of Real Driving Emissions (RDE) testing in Europe and similar protocols in other regions has further challenged manufacturers to ensure emissions compliance across all operating conditions, not merely in laboratory settings.

Mazda's efforts to maintain Wankel engine viability illustrate the regulatory impact. Their SKYACTIV-R technology incorporated direct injection, improved sealing technology, and exhaust after-treatment systems specifically to address emissions challenges. Despite these innovations, Mazda ultimately suspended production of rotary-powered vehicles in 2012, only recently reintroducing the technology in a limited range-extender application for electric vehicles.

The regulatory pressure has accelerated the development of hybrid powertrains incorporating both engine types. Wankel engines, with their compact size and smooth operation, have found potential new applications as range extenders in hybrid electric vehicles, where they can operate at optimal fixed speeds to minimize emissions while providing supplementary power generation.

Looking forward, upcoming regulations such as Euro 7 and equivalent standards in North America and Asia will further tighten emissions requirements, potentially accelerating the transition toward electrification. This regulatory trajectory suggests that future development of both engine types will increasingly focus on hybridization strategies or specialized applications where their unique characteristics provide specific advantages within a broader electrified powertrain ecosystem.

Materials Science Advancements for Engine Manufacturing

The evolution of engine manufacturing has been significantly influenced by advancements in materials science. Traditional piston engines have benefited from decades of material refinement, while Wankel rotary engines present unique material challenges due to their distinctive operating principles. Recent developments in high-temperature ceramics have shown promising results for both engine types, particularly in addressing the sealing issues that have historically plagued Wankel designs.

Carbon fiber reinforced polymers (CFRPs) have revolutionized engine component manufacturing, offering substantial weight reduction while maintaining structural integrity. When applied to Wankel engines, these materials have demonstrated up to 15% weight reduction compared to conventional materials, contributing to improved power-to-weight ratios. Piston engines have similarly benefited, though the weight advantage is less pronounced at approximately 8-10% reduction.

Thermal barrier coatings (TBCs) represent another significant advancement, with zirconia-based ceramics showing exceptional performance in both engine types. In Wankel engines, these coatings have extended apex seal life by 40-60% in laboratory testing, addressing one of the most persistent reliability concerns. Piston engines utilizing similar coatings have demonstrated 5-7% improvements in thermal efficiency.

Nano-engineered surface treatments have emerged as a game-changing technology for reducing friction and wear. Diamond-like carbon (DLC) coatings applied to Wankel rotor housings have reduced friction coefficients by up to 30%, translating to measurable efficiency gains. Similar treatments in piston engines have shown comparable friction reduction but with more modest overall performance improvements due to the different motion dynamics.

Advanced aluminum-silicon alloys with precisely controlled microstructures have enabled better heat dissipation in both engine types. Wankel engines benefit disproportionately from these materials, showing 12-15% improved heat management compared to 7-9% in piston configurations. This advantage helps mitigate the traditionally higher operating temperatures of rotary designs.

Self-healing materials represent the cutting edge of engine manufacturing technology. Experimental polymer composites with embedded microcapsules have shown the ability to repair minor surface damage automatically. While still in development stages, these materials could potentially extend engine component lifespans by 25-30% in both engine types, with particular benefits for the high-stress components in Wankel engines.

Comparative performance benchmarks indicate that while piston engines still maintain advantages in overall durability, the materials science gap is narrowing. Wankel engines leveraging these advanced materials demonstrate competitive performance metrics while maintaining their inherent advantages in smoothness and power density.

Carbon fiber reinforced polymers (CFRPs) have revolutionized engine component manufacturing, offering substantial weight reduction while maintaining structural integrity. When applied to Wankel engines, these materials have demonstrated up to 15% weight reduction compared to conventional materials, contributing to improved power-to-weight ratios. Piston engines have similarly benefited, though the weight advantage is less pronounced at approximately 8-10% reduction.

Thermal barrier coatings (TBCs) represent another significant advancement, with zirconia-based ceramics showing exceptional performance in both engine types. In Wankel engines, these coatings have extended apex seal life by 40-60% in laboratory testing, addressing one of the most persistent reliability concerns. Piston engines utilizing similar coatings have demonstrated 5-7% improvements in thermal efficiency.

Nano-engineered surface treatments have emerged as a game-changing technology for reducing friction and wear. Diamond-like carbon (DLC) coatings applied to Wankel rotor housings have reduced friction coefficients by up to 30%, translating to measurable efficiency gains. Similar treatments in piston engines have shown comparable friction reduction but with more modest overall performance improvements due to the different motion dynamics.

Advanced aluminum-silicon alloys with precisely controlled microstructures have enabled better heat dissipation in both engine types. Wankel engines benefit disproportionately from these materials, showing 12-15% improved heat management compared to 7-9% in piston configurations. This advantage helps mitigate the traditionally higher operating temperatures of rotary designs.

Self-healing materials represent the cutting edge of engine manufacturing technology. Experimental polymer composites with embedded microcapsules have shown the ability to repair minor surface damage automatically. While still in development stages, these materials could potentially extend engine component lifespans by 25-30% in both engine types, with particular benefits for the high-stress components in Wankel engines.

Comparative performance benchmarks indicate that while piston engines still maintain advantages in overall durability, the materials science gap is narrowing. Wankel engines leveraging these advanced materials demonstrate competitive performance metrics while maintaining their inherent advantages in smoothness and power density.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!