What Role Does Coating Play in Silicon Photonics Packaging

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicon Photonics Coating Background and Objectives

Silicon photonics has emerged as a transformative technology in the semiconductor industry over the past two decades, enabling high-speed data transmission and processing through optical signals on silicon-based platforms. The integration of photonic components on silicon substrates represents a significant advancement in addressing bandwidth limitations of traditional electronic circuits while maintaining compatibility with CMOS manufacturing processes.

Coatings play a critical role in silicon photonics packaging, serving as essential functional layers that enable optimal device performance, reliability, and longevity. Historically, the evolution of coating technologies has closely followed the development trajectory of silicon photonics itself, with significant advancements occurring since the early 2000s when practical silicon photonic devices first demonstrated commercial viability.

The fundamental objective of coatings in silicon photonics packaging is multifaceted: to provide environmental protection against moisture, contaminants, and mechanical damage; to enhance optical performance through anti-reflection, high-reflection, or wavelength-specific filtering properties; and to ensure thermal stability across operating conditions. These objectives have become increasingly demanding as silicon photonics applications expand into data centers, telecommunications, sensing, and emerging quantum computing platforms.

Recent technological trends indicate a shift toward specialized coating solutions that address the unique challenges of photonic-electronic integration. The industry has moved from basic protective coatings to sophisticated multi-layer structures that simultaneously address optical, thermal, and mechanical requirements. This evolution reflects the growing complexity of photonic integrated circuits (PICs) and their deployment in increasingly diverse and demanding environments.

The technical goals for next-generation silicon photonics coatings focus on several key parameters: minimizing optical loss at interfaces, ensuring wavelength stability across temperature variations, providing hermetic sealing for sensitive components, and maintaining compatibility with automated high-volume manufacturing processes. Additionally, there is growing emphasis on developing coatings that can withstand the thermal cycling inherent in heterogeneous integration approaches.

Looking forward, coating technologies must evolve to support emerging silicon photonics applications in quantum computing, biosensing, and automotive LiDAR systems. These applications introduce new requirements such as ultra-low optical absorption, precise refractive index control, and long-term stability under extreme environmental conditions. The convergence of these technical objectives defines the current research landscape for silicon photonics coating technologies.

Coatings play a critical role in silicon photonics packaging, serving as essential functional layers that enable optimal device performance, reliability, and longevity. Historically, the evolution of coating technologies has closely followed the development trajectory of silicon photonics itself, with significant advancements occurring since the early 2000s when practical silicon photonic devices first demonstrated commercial viability.

The fundamental objective of coatings in silicon photonics packaging is multifaceted: to provide environmental protection against moisture, contaminants, and mechanical damage; to enhance optical performance through anti-reflection, high-reflection, or wavelength-specific filtering properties; and to ensure thermal stability across operating conditions. These objectives have become increasingly demanding as silicon photonics applications expand into data centers, telecommunications, sensing, and emerging quantum computing platforms.

Recent technological trends indicate a shift toward specialized coating solutions that address the unique challenges of photonic-electronic integration. The industry has moved from basic protective coatings to sophisticated multi-layer structures that simultaneously address optical, thermal, and mechanical requirements. This evolution reflects the growing complexity of photonic integrated circuits (PICs) and their deployment in increasingly diverse and demanding environments.

The technical goals for next-generation silicon photonics coatings focus on several key parameters: minimizing optical loss at interfaces, ensuring wavelength stability across temperature variations, providing hermetic sealing for sensitive components, and maintaining compatibility with automated high-volume manufacturing processes. Additionally, there is growing emphasis on developing coatings that can withstand the thermal cycling inherent in heterogeneous integration approaches.

Looking forward, coating technologies must evolve to support emerging silicon photonics applications in quantum computing, biosensing, and automotive LiDAR systems. These applications introduce new requirements such as ultra-low optical absorption, precise refractive index control, and long-term stability under extreme environmental conditions. The convergence of these technical objectives defines the current research landscape for silicon photonics coating technologies.

Market Analysis for Coated Silicon Photonic Devices

The global market for coated silicon photonic devices is experiencing robust growth, driven by increasing demand for high-speed data transmission and processing capabilities. Current market valuations place the silicon photonics sector at approximately 1.5 billion USD in 2023, with coated components representing roughly 30% of this value. Industry analysts project a compound annual growth rate (CAGR) of 22-25% through 2030, potentially elevating the market value to over 6 billion USD.

Telecommunications and data center applications currently dominate market demand, collectively accounting for nearly 65% of coated silicon photonic device consumption. This concentration stems from the critical need for higher bandwidth, lower power consumption, and reduced latency in network infrastructure. Cloud service providers like Amazon Web Services, Microsoft Azure, and Google Cloud are significantly increasing their investments in silicon photonics technology to enhance data center interconnects.

Consumer electronics represents an emerging market segment with substantial growth potential, particularly as augmented reality (AR) and virtual reality (VR) applications gain mainstream adoption. Market research indicates that AR/VR applications utilizing silicon photonics could grow at a CAGR exceeding 30% over the next five years, creating new opportunities for specialized optical coatings.

Regional analysis reveals that North America currently leads market consumption at 42%, followed by Asia-Pacific at 35% and Europe at 18%. However, the Asia-Pacific region, particularly China, Taiwan, and Singapore, is demonstrating the fastest growth trajectory due to aggressive investments in telecommunications infrastructure and semiconductor manufacturing capabilities.

Customer segmentation shows distinct requirements across different sectors. Telecommunications operators prioritize reliability and longevity, while data center operators emphasize performance and energy efficiency. Consumer electronics manufacturers focus on miniaturization and cost-effectiveness. These varying priorities directly influence coating specifications and manufacturing processes.

Supply chain analysis indicates potential vulnerabilities in raw material sourcing for specialized coating materials. Several critical materials used in anti-reflection and hermetic coatings face supply constraints, with over 70% of production concentrated in specific geographic regions. This concentration presents both pricing volatility risks and potential supply disruptions.

Price sensitivity varies significantly across market segments. Enterprise and telecommunications customers demonstrate lower price sensitivity for high-performance coatings that enable substantial system-level benefits. In contrast, consumer applications remain highly price-sensitive, creating pressure for coating innovation that balances performance with cost-effectiveness.

Telecommunications and data center applications currently dominate market demand, collectively accounting for nearly 65% of coated silicon photonic device consumption. This concentration stems from the critical need for higher bandwidth, lower power consumption, and reduced latency in network infrastructure. Cloud service providers like Amazon Web Services, Microsoft Azure, and Google Cloud are significantly increasing their investments in silicon photonics technology to enhance data center interconnects.

Consumer electronics represents an emerging market segment with substantial growth potential, particularly as augmented reality (AR) and virtual reality (VR) applications gain mainstream adoption. Market research indicates that AR/VR applications utilizing silicon photonics could grow at a CAGR exceeding 30% over the next five years, creating new opportunities for specialized optical coatings.

Regional analysis reveals that North America currently leads market consumption at 42%, followed by Asia-Pacific at 35% and Europe at 18%. However, the Asia-Pacific region, particularly China, Taiwan, and Singapore, is demonstrating the fastest growth trajectory due to aggressive investments in telecommunications infrastructure and semiconductor manufacturing capabilities.

Customer segmentation shows distinct requirements across different sectors. Telecommunications operators prioritize reliability and longevity, while data center operators emphasize performance and energy efficiency. Consumer electronics manufacturers focus on miniaturization and cost-effectiveness. These varying priorities directly influence coating specifications and manufacturing processes.

Supply chain analysis indicates potential vulnerabilities in raw material sourcing for specialized coating materials. Several critical materials used in anti-reflection and hermetic coatings face supply constraints, with over 70% of production concentrated in specific geographic regions. This concentration presents both pricing volatility risks and potential supply disruptions.

Price sensitivity varies significantly across market segments. Enterprise and telecommunications customers demonstrate lower price sensitivity for high-performance coatings that enable substantial system-level benefits. In contrast, consumer applications remain highly price-sensitive, creating pressure for coating innovation that balances performance with cost-effectiveness.

Current Coating Technologies and Challenges

Silicon photonics packaging currently employs several coating technologies, each serving specific functions in optical, mechanical, and environmental protection. Anti-reflective (AR) coatings represent one of the most widely used technologies, typically consisting of multiple dielectric layers designed to minimize reflection at specific wavelengths. These coatings achieve reflectivity below 0.5% at target wavelengths, significantly improving optical coupling efficiency between silicon photonic devices and optical fibers.

Hermetic coatings, including thin films of silicon nitride, silicon dioxide, and aluminum oxide, provide essential protection against moisture and contaminants. These coatings are typically deposited using plasma-enhanced chemical vapor deposition (PECVD) or atomic layer deposition (ALD), achieving thicknesses between 50nm and 1μm with excellent uniformity and pinhole-free coverage.

Metallic coatings serve dual purposes in silicon photonics packaging. Gold, aluminum, and copper coatings function as reflective surfaces for optical routing and as electrical contacts for active components. These are typically deposited through sputtering or evaporation techniques, with thicknesses ranging from 100nm to several microns depending on the application requirements.

Despite these advancements, significant challenges persist in coating technologies for silicon photonics. Thermal expansion mismatch between coating materials and silicon substrates creates stress that can lead to delamination or cracking during thermal cycling. This issue becomes particularly problematic in applications requiring operation across wide temperature ranges.

Uniformity control presents another major challenge, especially for complex 3D structures common in advanced silicon photonic devices. Achieving consistent coating thickness and composition across high-aspect-ratio features remains difficult with conventional deposition methods, often resulting in performance variations across the device.

Adhesion issues between coating materials and silicon or other substrate materials continue to challenge manufacturers, particularly in harsh environment applications where thermal cycling and mechanical stress are common. Current solutions often involve adhesion promotion layers, which add complexity and cost to the manufacturing process.

Scalability and cost-effectiveness of advanced coating technologies represent significant hurdles for mass production. Techniques like ALD offer excellent quality but at slower deposition rates and higher costs compared to traditional methods, creating a trade-off between performance and production efficiency that the industry continues to navigate.

Hermetic coatings, including thin films of silicon nitride, silicon dioxide, and aluminum oxide, provide essential protection against moisture and contaminants. These coatings are typically deposited using plasma-enhanced chemical vapor deposition (PECVD) or atomic layer deposition (ALD), achieving thicknesses between 50nm and 1μm with excellent uniformity and pinhole-free coverage.

Metallic coatings serve dual purposes in silicon photonics packaging. Gold, aluminum, and copper coatings function as reflective surfaces for optical routing and as electrical contacts for active components. These are typically deposited through sputtering or evaporation techniques, with thicknesses ranging from 100nm to several microns depending on the application requirements.

Despite these advancements, significant challenges persist in coating technologies for silicon photonics. Thermal expansion mismatch between coating materials and silicon substrates creates stress that can lead to delamination or cracking during thermal cycling. This issue becomes particularly problematic in applications requiring operation across wide temperature ranges.

Uniformity control presents another major challenge, especially for complex 3D structures common in advanced silicon photonic devices. Achieving consistent coating thickness and composition across high-aspect-ratio features remains difficult with conventional deposition methods, often resulting in performance variations across the device.

Adhesion issues between coating materials and silicon or other substrate materials continue to challenge manufacturers, particularly in harsh environment applications where thermal cycling and mechanical stress are common. Current solutions often involve adhesion promotion layers, which add complexity and cost to the manufacturing process.

Scalability and cost-effectiveness of advanced coating technologies represent significant hurdles for mass production. Techniques like ALD offer excellent quality but at slower deposition rates and higher costs compared to traditional methods, creating a trade-off between performance and production efficiency that the industry continues to navigate.

State-of-the-Art Coating Solutions for Photonic Packaging

01 Protective coatings for silicon photonic components

Various protective coating materials are applied to silicon photonic components to shield them from environmental factors and enhance reliability. These coatings protect sensitive optical elements from moisture, dust, and mechanical damage while maintaining optical performance. Materials such as polymers, dielectrics, and hermetic seals are strategically applied to provide environmental protection without compromising the optical path or signal integrity.- Protective coatings for silicon photonic components: Various protective coatings are applied to silicon photonic components to shield them from environmental factors and enhance reliability. These coatings include hermetic seals, conformal coatings, and passivation layers that protect against moisture, contaminants, and mechanical stress. The protective materials are selected for their compatibility with silicon photonics and ability to maintain optical performance while providing long-term protection in various operating conditions.

- Optical coupling enhancement coatings: Specialized coatings are used to improve optical coupling efficiency between silicon photonic waveguides and optical fibers or other components. These include anti-reflective coatings, index-matching materials, and gradient-index layers that minimize insertion loss at interfaces. Such coatings help overcome the refractive index mismatch between silicon and other optical materials, enabling more efficient light transmission and reducing back-reflections that can degrade signal quality.

- Thermal management coatings: Thermal management coatings are applied in silicon photonics packaging to dissipate heat and maintain stable operating temperatures. These include thermally conductive materials, heat-spreading layers, and thermal interface materials that improve heat transfer from active components to heat sinks or substrates. Such coatings help prevent performance degradation due to thermal effects and enhance the reliability and lifetime of temperature-sensitive photonic devices.

- Integration coatings for hybrid assemblies: Specialized coatings facilitate the integration of silicon photonics with electronic components in hybrid assemblies. These include adhesion promotion layers, planarization coatings, and interface materials that enable heterogeneous integration of different material systems. Such coatings address challenges in combining silicon photonics with CMOS electronics, III-V materials, or other optical components, ensuring mechanical stability and electrical/optical performance across material boundaries.

- Wavelength-specific optical coatings: Wavelength-specific optical coatings are applied to silicon photonic components to manipulate light behavior at targeted wavelengths. These include dichroic filters, wavelength-selective reflectors, and bandpass coatings that enable wavelength division multiplexing and other spectral management functions. Such coatings allow silicon photonic packages to process multiple wavelengths simultaneously, enhancing bandwidth capacity and enabling advanced optical signal processing capabilities.

02 Anti-reflective coatings for optical interfaces

Anti-reflective coatings are applied to optical interfaces in silicon photonics packaging to minimize light reflection and maximize transmission efficiency. These specialized coatings consist of single or multiple layers with precisely controlled thicknesses and refractive indices. By reducing back-reflection at material boundaries, these coatings enhance coupling efficiency between optical fibers, waveguides, and other photonic components, resulting in improved signal quality and reduced insertion loss.Expand Specific Solutions03 Thermal management coatings for silicon photonics

Thermal management coatings are employed in silicon photonics packaging to address heat dissipation challenges. These specialized coatings help regulate temperature by enhancing thermal conductivity or providing insulation where needed. By managing heat effectively, these coatings prevent performance degradation, wavelength drift, and premature failure of temperature-sensitive photonic components. Materials with high thermal conductivity or specific heat-directing properties are strategically applied to critical areas of the photonic package.Expand Specific Solutions04 Hermetic sealing coatings for photonic packages

Hermetic sealing coatings provide critical protection for silicon photonic components by creating an impermeable barrier against moisture, gases, and contaminants. These specialized coatings typically employ materials like metals, glass, or advanced polymers to create a complete seal around sensitive optical components. The hermetic packaging approach extends device lifetime by preventing degradation mechanisms that occur in the presence of environmental factors, particularly important for applications requiring long-term reliability in harsh environments.Expand Specific Solutions05 Optical coupling enhancement coatings

Specialized coatings are applied to improve optical coupling efficiency between different components in silicon photonic packages. These coatings modify the interface properties to better match optical modes and refractive indices between dissimilar materials such as optical fibers, waveguides, and active devices. By optimizing the transition between components, these coatings minimize insertion losses, reduce back-reflections, and enhance overall system performance. Various materials with specific optical properties are selected based on the particular coupling requirements.Expand Specific Solutions

Leading Companies in Photonic Packaging Coatings

Silicon photonics packaging is currently in a growth phase, with the market expected to expand significantly due to increasing demand for high-speed data transmission and optical interconnects. The coating technology plays a critical role in ensuring optical performance, reliability, and environmental protection of silicon photonic devices. Major players like Taiwan Semiconductor Manufacturing Co., IBM, and GlobalFoundries are advancing mature coating solutions for commercial applications, while research institutions such as Huazhong University of Science & Technology and CNRS are developing next-generation coating technologies. Companies like EFFECT Photonics and Aeponyx are innovating in specialized coating techniques for improved optical coupling and hermetic sealing. The competitive landscape shows a mix of established semiconductor manufacturers and emerging photonics specialists, with coating technology becoming a key differentiator in achieving higher performance and lower costs in silicon photonics applications.

Advanced Semiconductor Engineering, Inc.

Technical Solution: ASE has developed comprehensive coating solutions for silicon photonics packaging that address both optical performance and reliability requirements. Their approach incorporates multiple coating technologies tailored to different package elements: conformal parylene coatings for environmental protection, anti-reflective dielectric stacks for optical interfaces, and specialized underfill materials that combine optical transparency with mechanical support. ASE's coating processes are integrated into their fan-out wafer-level packaging (FOWLP) platform, enabling cost-effective manufacturing of silicon photonics devices. Their coatings are engineered to maintain optical alignment during temperature cycling by carefully matching coefficient of thermal expansion (CTE) between materials. ASE has pioneered low-temperature deposition techniques that prevent damage to temperature-sensitive photonic components while achieving excellent adhesion and uniformity. Their coating solutions include specialized edge treatments that minimize light scattering at waveguide facets, reducing coupling losses by up to 2dB compared to uncoated interfaces. ASE's approach enables hermetic or near-hermetic protection while maintaining optical transparency at key wavelengths, supporting applications from data communications to automotive lidar[9][10].

Strengths: Integration with established advanced packaging infrastructure enables volume manufacturing; comprehensive approach addresses multiple packaging challenges simultaneously. Weaknesses: Coating processes add additional manufacturing steps that may impact yield; some solutions require trade-offs between optical performance and environmental protection.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed advanced anti-reflective coating (ARC) technologies specifically for silicon photonics packaging that significantly reduce optical losses at interfaces. Their solution incorporates multi-layer dielectric coatings with precisely controlled thicknesses in the nanometer range to achieve optimal refractive index matching between silicon and other materials in the optical path. TSMC's approach includes specialized coating processes compatible with their advanced semiconductor manufacturing lines, allowing for wafer-level application of optical coatings that maintain integrity during subsequent packaging steps. Their technology enables hermetic sealing while preserving optical transparency at key wavelengths (1310nm and 1550nm), critical for telecommunications applications. TSMC has also pioneered thermally stable coating materials that can withstand the temperature cycling during packaging processes without delamination or optical property changes[1][3].

Strengths: Integration with established semiconductor manufacturing processes enables high-volume production; precise thickness control achieves superior optical performance. Weaknesses: Proprietary coating materials may increase costs; specialized equipment requirements limit manufacturing flexibility for smaller volume applications.

Key Coating Patents and Technical Innovations

Coatings for increasing colour vibrancy and methods of applying same

PatentInactiveUS20170066934A1

Innovation

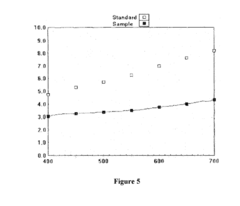

- A translucent coating comprising silica particles and binder solids, specifically anionic amorphous silica in an aqueous sol dispersion, applied at a density of 0.5 to 10 g/m², with a silica:binder ratio of 50:1 by weight, enhances color vibrancy by scattering light and reducing substrate absorption.

Coating solution for use in production of electrophotographic photoreceptor, electrophotographic photoreceptor, and image formation device

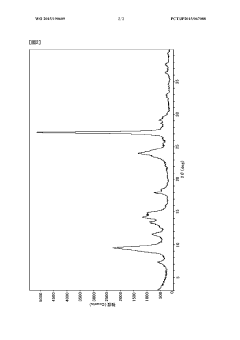

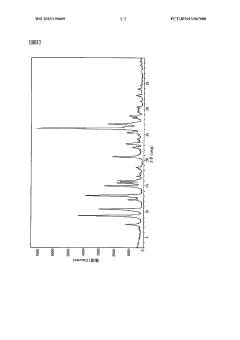

PatentWO2015190609A1

Innovation

- A coating liquid containing a charge transport substance with a specific structure, a binder resin, and a particulate silicon compound, where the silicon compound is surface-treated and dispersed to achieve excellent dispersion stability without the need for additional redispersion, even with high concentrations of particulate silicon.

Environmental Impact of Photonic Coating Materials

The environmental impact of photonic coating materials in silicon photonics packaging represents a critical consideration as this technology scales toward mass production. Traditional coating processes often involve hazardous chemicals such as heavy metals, solvents, and rare earth elements that pose significant environmental risks throughout their lifecycle. Materials like lead-based compounds and certain metal oxides used in anti-reflection coatings can leach into soil and water systems if improperly disposed of, creating long-term ecological damage.

Manufacturing processes for photonic coatings typically require substantial energy consumption, particularly in vacuum deposition techniques that demand high temperatures and specialized equipment. These energy-intensive processes contribute to the carbon footprint of silicon photonic devices, challenging the industry's sustainability claims. Additionally, many coating procedures utilize perfluorinated compounds and other persistent chemicals that resist environmental degradation and bioaccumulate in ecosystems.

Water usage presents another environmental concern, as coating processes often require ultra-pure water for cleaning and processing steps. The purification and subsequent treatment of contaminated wastewater generate additional environmental burdens, particularly in regions facing water scarcity. Chemical waste streams containing coating residues require specialized handling and disposal protocols to prevent environmental contamination.

Recent industry trends show promising developments in environmentally conscious alternatives. Bio-based polymers and water-soluble coating materials are emerging as sustainable substitutes for traditional petrochemical-derived compounds. These materials offer comparable optical performance while significantly reducing toxicity and environmental persistence. Several leading manufacturers have begun implementing green chemistry principles in their coating formulations, eliminating substances of high concern and reducing solvent usage.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of photonic materials. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have prompted manufacturers to develop compliant coating alternatives. Similarly, initiatives like the Electronic Product Environmental Assessment Tool (EPEAT) are driving adoption of environmentally preferable materials in electronic components including photonic packages.

End-of-life considerations for silicon photonic devices with specialized coatings remain challenging. The complex material composition often complicates recycling efforts, as separation of nanoscale coating layers from substrates requires specialized processes. Industry consortia are developing standardized approaches to improve recyclability and reduce the environmental burden of disposed photonic components, though significant work remains to establish truly circular material flows for these advanced technologies.

Manufacturing processes for photonic coatings typically require substantial energy consumption, particularly in vacuum deposition techniques that demand high temperatures and specialized equipment. These energy-intensive processes contribute to the carbon footprint of silicon photonic devices, challenging the industry's sustainability claims. Additionally, many coating procedures utilize perfluorinated compounds and other persistent chemicals that resist environmental degradation and bioaccumulate in ecosystems.

Water usage presents another environmental concern, as coating processes often require ultra-pure water for cleaning and processing steps. The purification and subsequent treatment of contaminated wastewater generate additional environmental burdens, particularly in regions facing water scarcity. Chemical waste streams containing coating residues require specialized handling and disposal protocols to prevent environmental contamination.

Recent industry trends show promising developments in environmentally conscious alternatives. Bio-based polymers and water-soluble coating materials are emerging as sustainable substitutes for traditional petrochemical-derived compounds. These materials offer comparable optical performance while significantly reducing toxicity and environmental persistence. Several leading manufacturers have begun implementing green chemistry principles in their coating formulations, eliminating substances of high concern and reducing solvent usage.

Regulatory frameworks worldwide are increasingly addressing the environmental impact of photonic materials. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have prompted manufacturers to develop compliant coating alternatives. Similarly, initiatives like the Electronic Product Environmental Assessment Tool (EPEAT) are driving adoption of environmentally preferable materials in electronic components including photonic packages.

End-of-life considerations for silicon photonic devices with specialized coatings remain challenging. The complex material composition often complicates recycling efforts, as separation of nanoscale coating layers from substrates requires specialized processes. Industry consortia are developing standardized approaches to improve recyclability and reduce the environmental burden of disposed photonic components, though significant work remains to establish truly circular material flows for these advanced technologies.

Reliability Testing Standards for Coated Photonic Components

Reliability testing standards for coated photonic components in silicon photonics packaging have evolved significantly to address the unique challenges posed by the integration of optical and electronic systems. These standards are crucial for ensuring the long-term performance and durability of coated components under various environmental and operational conditions.

The industry has established several key testing protocols that specifically target coating integrity in photonic integrated circuits (PICs). The Telcordia GR-1221 and GR-468 standards, originally developed for telecommunications equipment, have been adapted to address silicon photonics coating reliability. These standards outline procedures for temperature cycling, humidity resistance, and mechanical shock testing that are particularly relevant to assessing coating adhesion and stability.

MIL-STD-883 methods, while primarily designed for microelectronics, have been modified to evaluate hermetic sealing and environmental protection provided by coatings in photonic packages. These adaptations include specialized tests for optical transmission stability under thermal stress and accelerated aging conditions.

The International Electrotechnical Commission (IEC) has developed the IEC 60068 series that includes specific protocols for testing the effects of salt spray, solar radiation, and chemical contamination on optical coatings. These tests are particularly important for evaluating anti-reflective and protective coatings used in silicon photonics applications.

For high-power photonic applications, additional standards such as ISO 11254 address laser-induced damage thresholds of optical coatings. These standards help quantify how coatings perform under intense light conditions, which is critical for applications involving high-power signal transmission or sensing.

Recent developments include the emergence of specialized testing protocols for quantum efficiency and spectral stability of coatings used in silicon photonics. The ASTM F1892 standard for measuring thin film stress has been adapted to evaluate coating-induced stress in silicon waveguides, which can significantly impact optical performance.

Industry consortia like the Photonics Components Reliability Consortium (PCRC) have established standardized accelerated life testing methodologies specifically for coated photonic components. These include highly accelerated stress testing (HAST) and highly accelerated temperature and humidity stress testing (HTHST) protocols designed to predict long-term reliability in compressed timeframes.

Compliance with these standards is increasingly becoming a requirement for component suppliers in the silicon photonics ecosystem, as system integrators demand proven reliability metrics before incorporating components into mission-critical applications in telecommunications, data centers, and sensing systems.

The industry has established several key testing protocols that specifically target coating integrity in photonic integrated circuits (PICs). The Telcordia GR-1221 and GR-468 standards, originally developed for telecommunications equipment, have been adapted to address silicon photonics coating reliability. These standards outline procedures for temperature cycling, humidity resistance, and mechanical shock testing that are particularly relevant to assessing coating adhesion and stability.

MIL-STD-883 methods, while primarily designed for microelectronics, have been modified to evaluate hermetic sealing and environmental protection provided by coatings in photonic packages. These adaptations include specialized tests for optical transmission stability under thermal stress and accelerated aging conditions.

The International Electrotechnical Commission (IEC) has developed the IEC 60068 series that includes specific protocols for testing the effects of salt spray, solar radiation, and chemical contamination on optical coatings. These tests are particularly important for evaluating anti-reflective and protective coatings used in silicon photonics applications.

For high-power photonic applications, additional standards such as ISO 11254 address laser-induced damage thresholds of optical coatings. These standards help quantify how coatings perform under intense light conditions, which is critical for applications involving high-power signal transmission or sensing.

Recent developments include the emergence of specialized testing protocols for quantum efficiency and spectral stability of coatings used in silicon photonics. The ASTM F1892 standard for measuring thin film stress has been adapted to evaluate coating-induced stress in silicon waveguides, which can significantly impact optical performance.

Industry consortia like the Photonics Components Reliability Consortium (PCRC) have established standardized accelerated life testing methodologies specifically for coated photonic components. These include highly accelerated stress testing (HAST) and highly accelerated temperature and humidity stress testing (HTHST) protocols designed to predict long-term reliability in compressed timeframes.

Compliance with these standards is increasingly becoming a requirement for component suppliers in the silicon photonics ecosystem, as system integrators demand proven reliability metrics before incorporating components into mission-critical applications in telecommunications, data centers, and sensing systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!