Heat source device for drying moist products

A wet and product technology, applied in the agricultural field, can solve problems such as poor humidification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

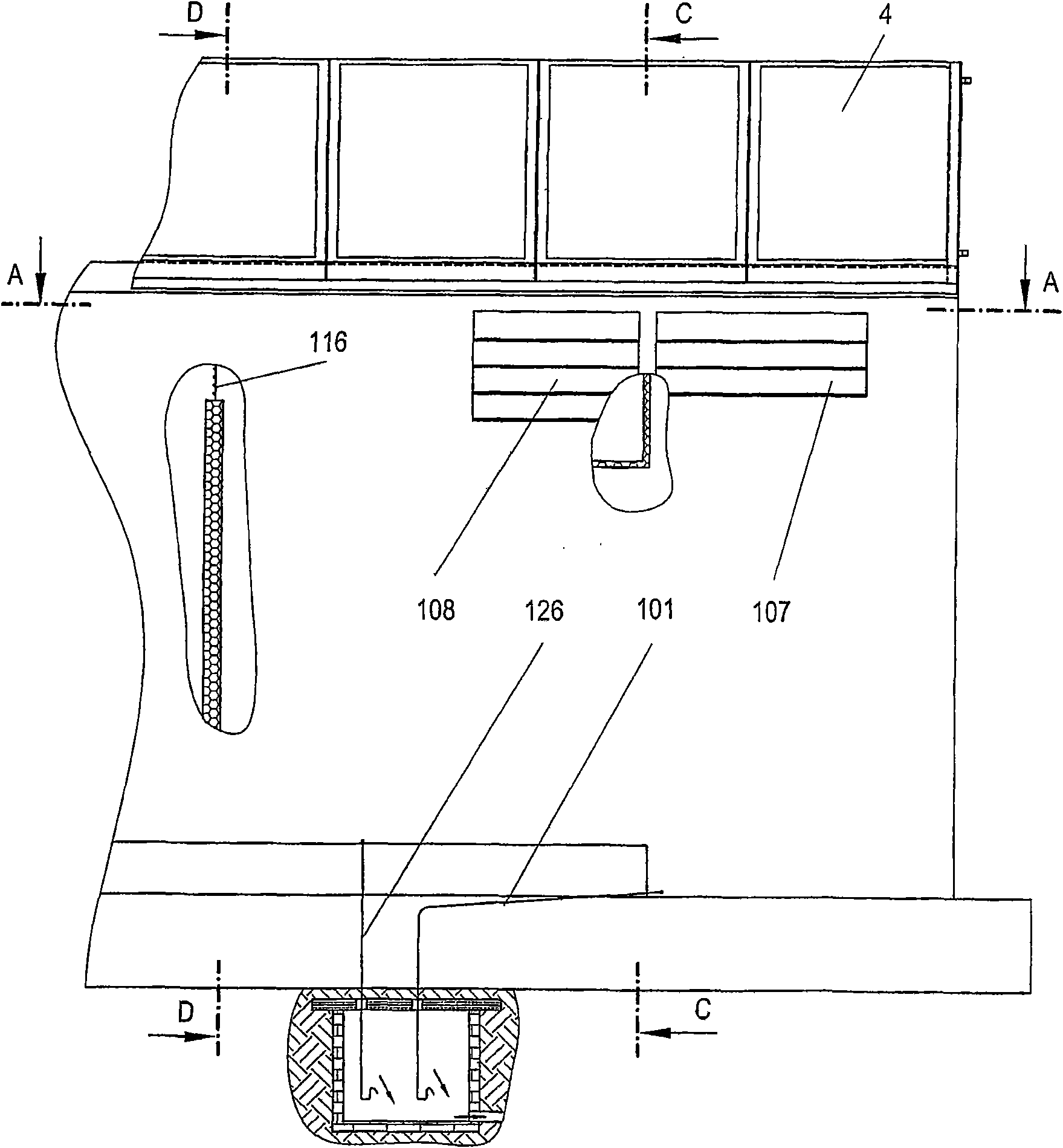

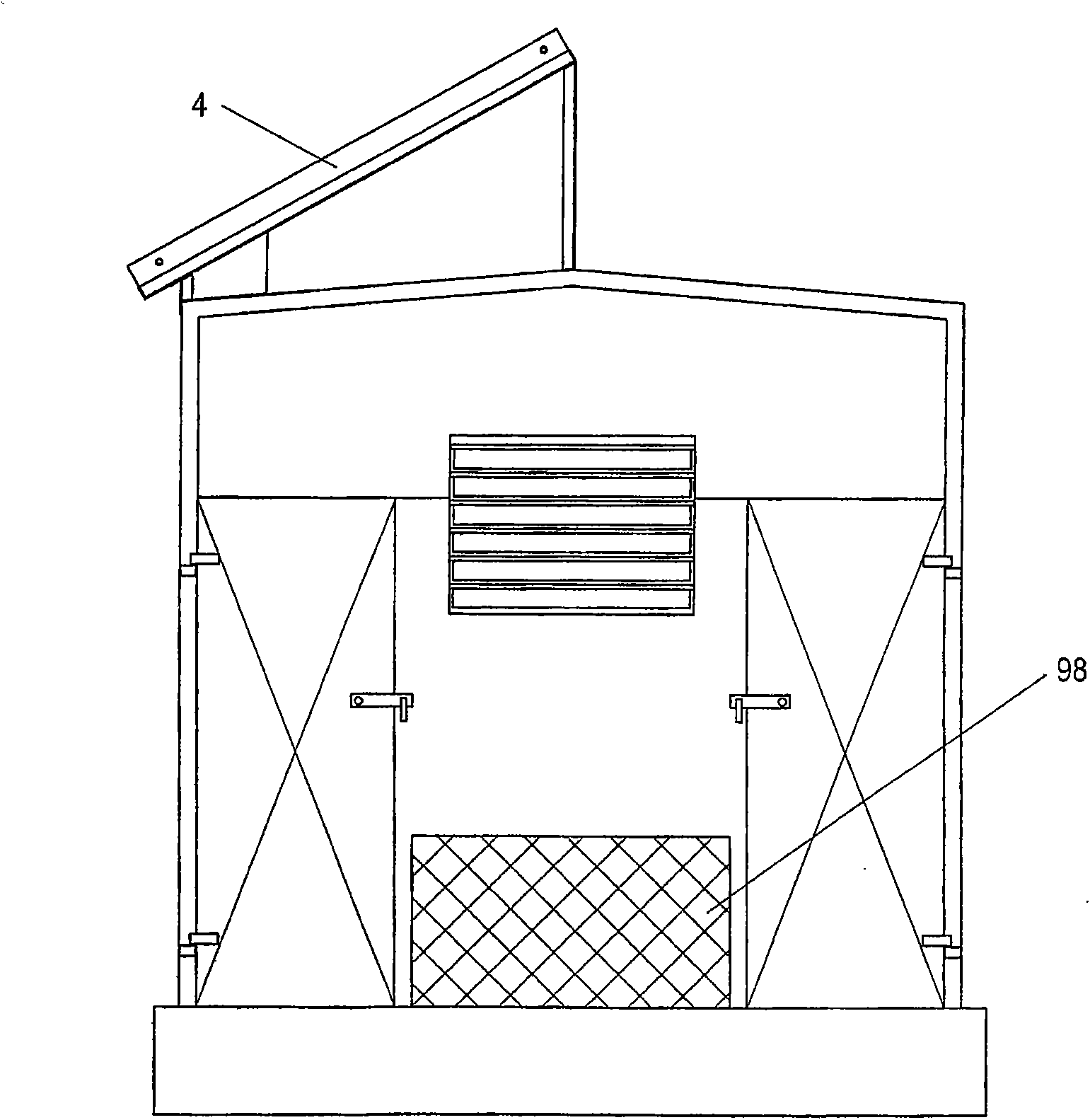

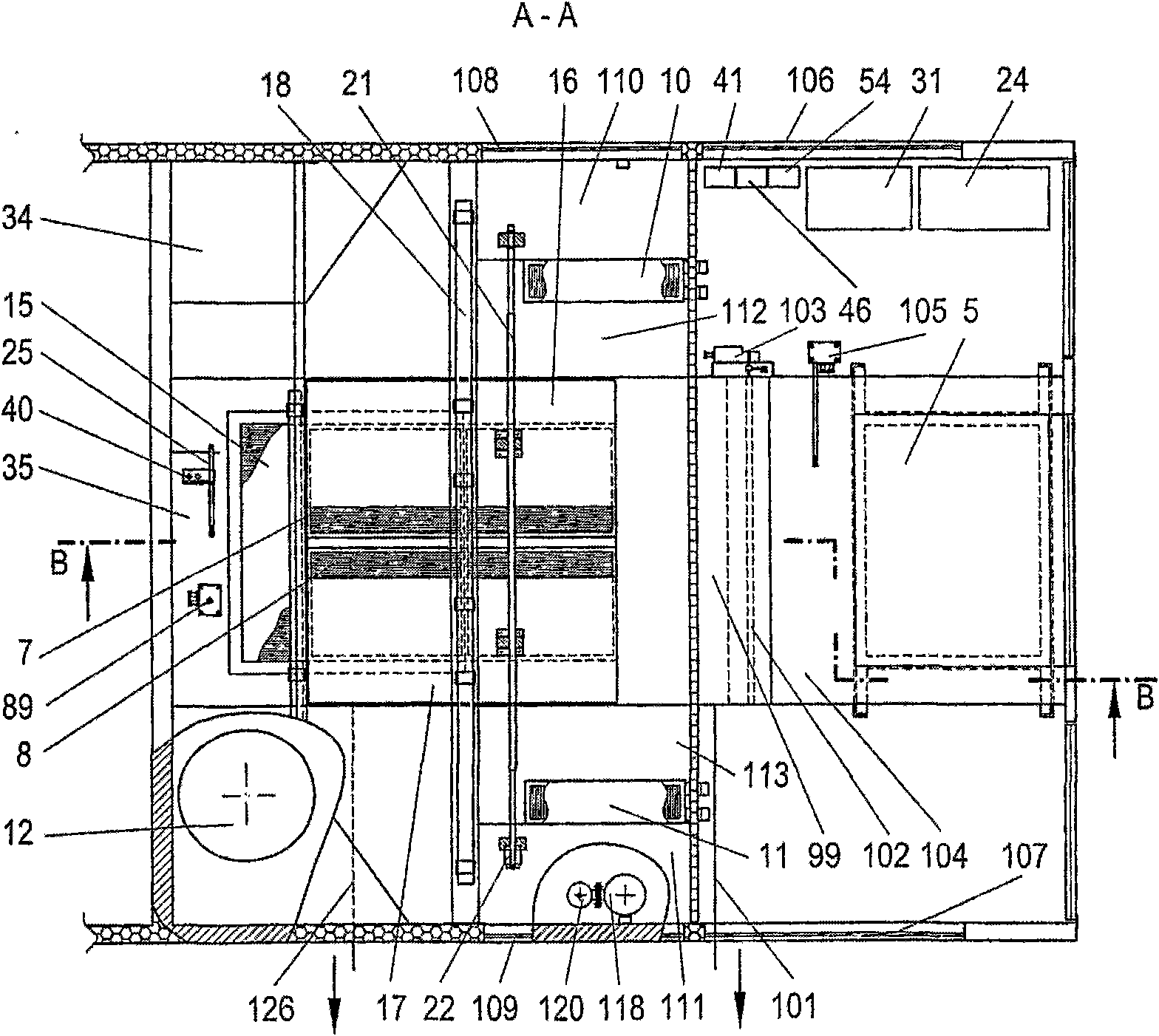

[0016] The tobacco dryer 1 includes a drying cabin 2 and a drying cabin 3. The tobacco leaf strings to be dried are stuffed into a cigarette rack or container and loaded into the drying cabin 3. The structure of the drying cabin 3 is similar to that of the tobacco dryer. The dryer cabins are made and supplied by the manufacturer with the same construction and need no further introduction.

[0017] Tobacco drying is divided into a moisture-unremoved area and a moisture-removed area, and the moisture from the tobacco drying cabin 3 is removed in the moisture-removed area. The yellowing of tobacco leaves occurs in the area where the water is not removed, and the color fixing of tobacco leaves and the drying of tobacco leaves and tobacco stems occur in the area of water removal.

[0018] When drying tobacco, tobacco manufacturers accept the drying technology of tobacco production and drying instructors, which can be applied to tobacco leaves of different maturity and different p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com