The Clamping Mechanism of the Shaft of the Oval Fitting Machine

A clamping mechanism and shaft technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, consumption, long time, etc., to facilitate the assembly process, save the time of cutting, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

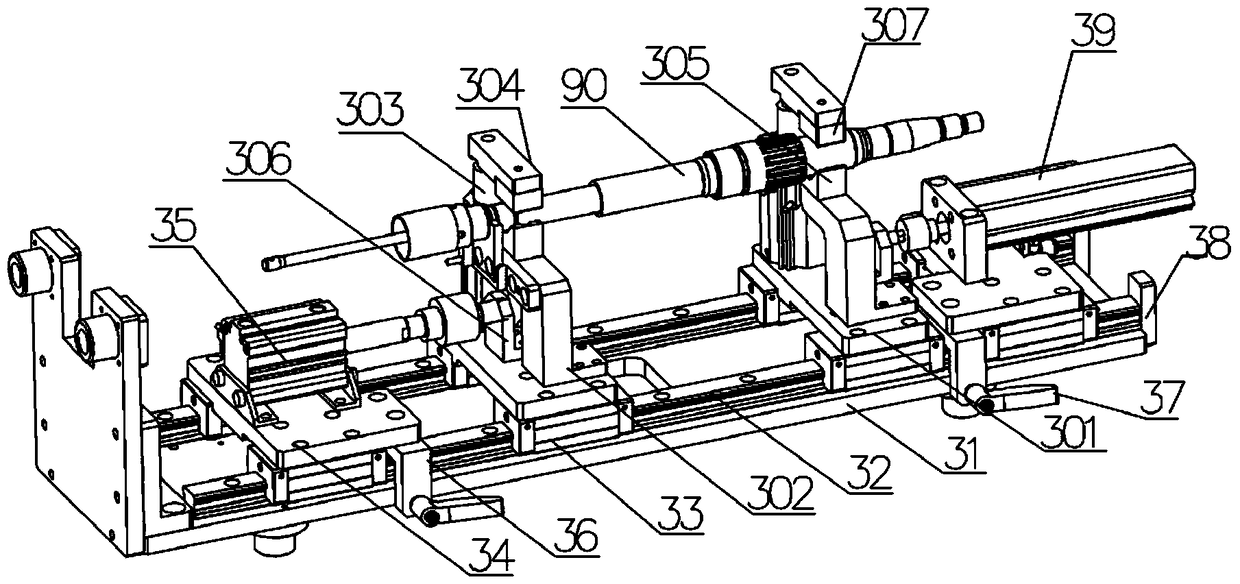

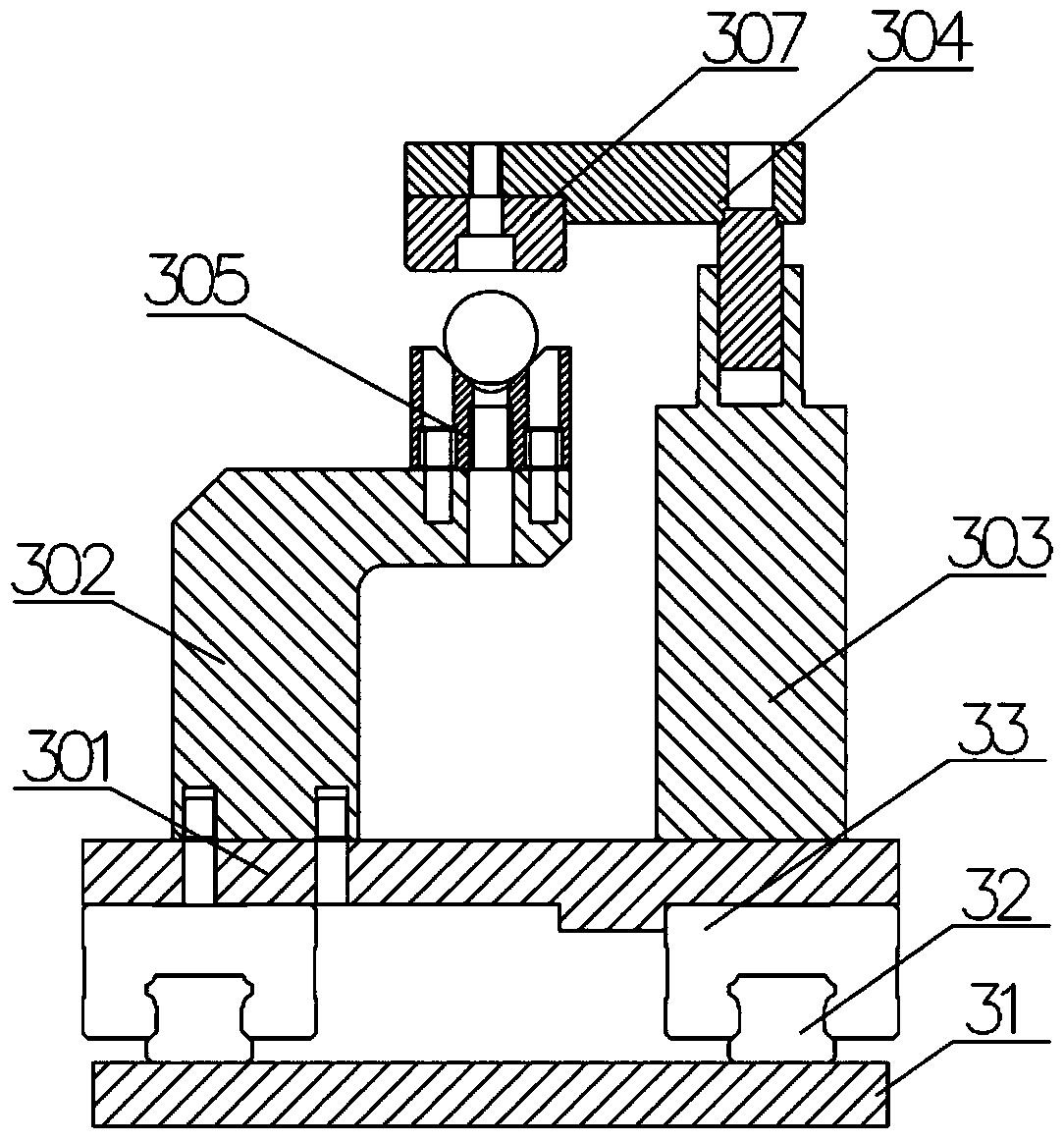

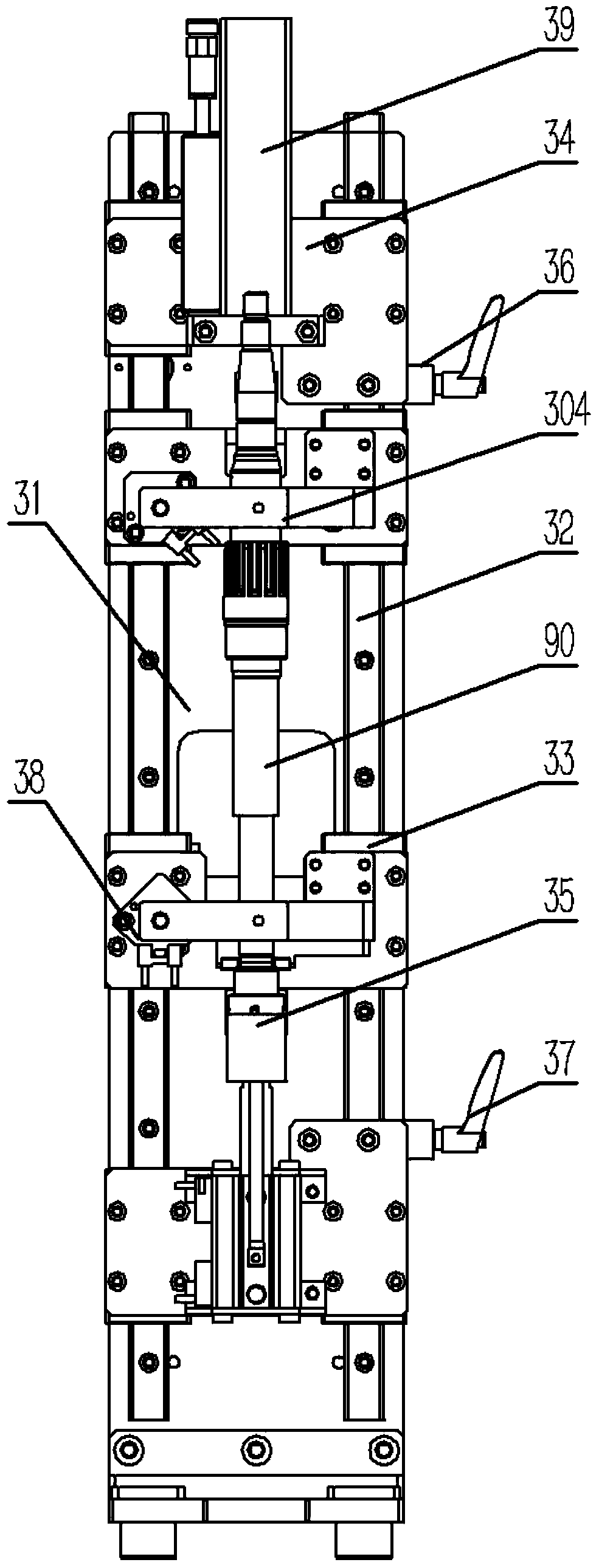

[0016] Example: see Figures 1 to 3 As shown, the clamping mechanism of the shaft of the ellipse fitting machine includes a base plate 31, two sets of guide rails 32 are fixed on the base plate 31, four sets of sliders 33 are inserted on the guide rails 32, and two sets of sliders 33 at the left and right ends of the guide rails 32 Be divided into and be fixed with cylinder mounting plate 34, be fixed with small stroke cylinder 35 on the cylinder mounting plate 34 of guide rail 32 left ends, be fixed with large stroke cylinder 39 on the cylinder mounting plate 34 of guide rail 32 right ends, described small stroke cylinder 35 and Push blocks 306 are fixed on the piston rods of the large-stroke cylinder 39, and two groups of push blocks 306 are respectively fixed on two clamp mounting plates 301, and an inverted L-shaped bracket 302 is fixed on one side of the upper end surface of the clamp mounting plate 301. A fixed block 305 with a V-shaped notch is fixed on the type bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com