A prefabricated energy-saving house profile

An energy-saving housing and prefabricated technology, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of easy loosening of joints, increase of construction costs, and inability to guarantee, so as to achieve the best thermal insulation, windproof and water-proof performance, not easy to loosen, and guarantee The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

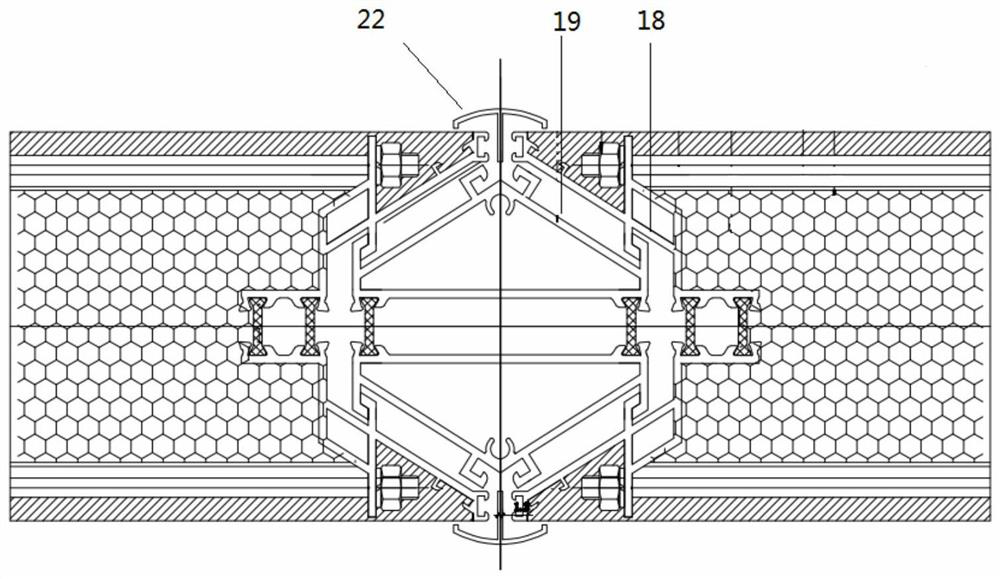

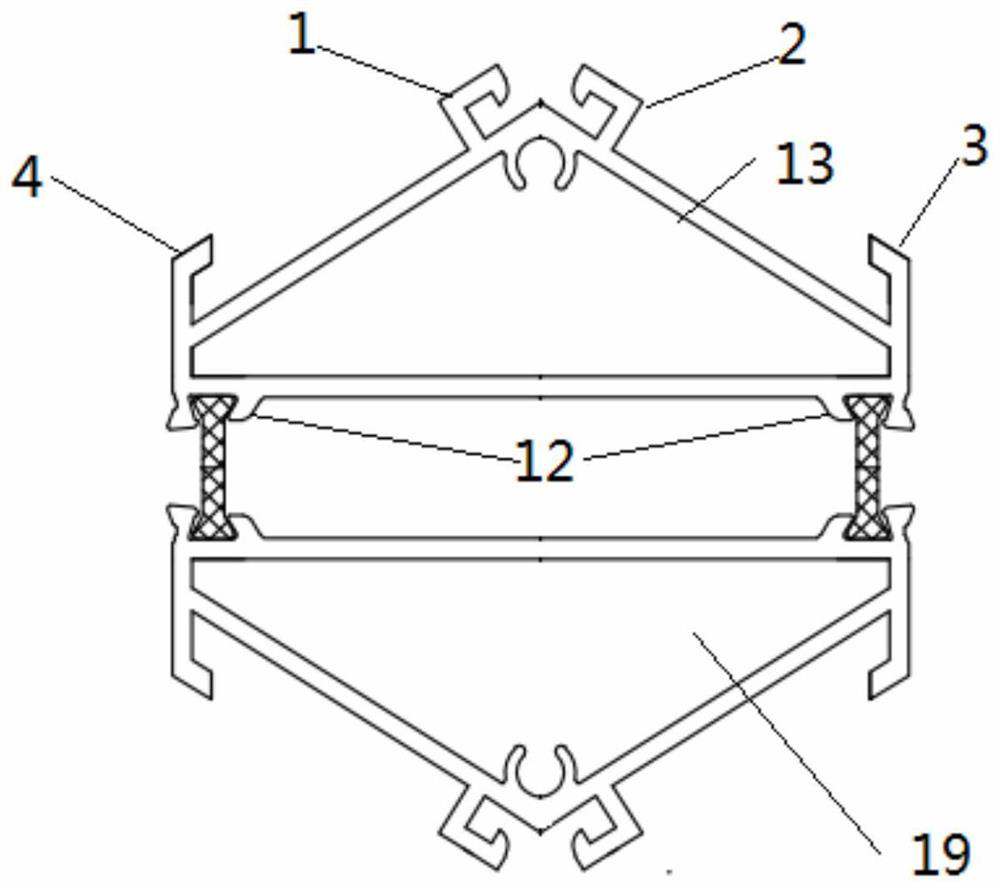

[0024] combine figure 1 , figure 2 , image 3 , to describe the schematic diagram of the installation structure between the panels.

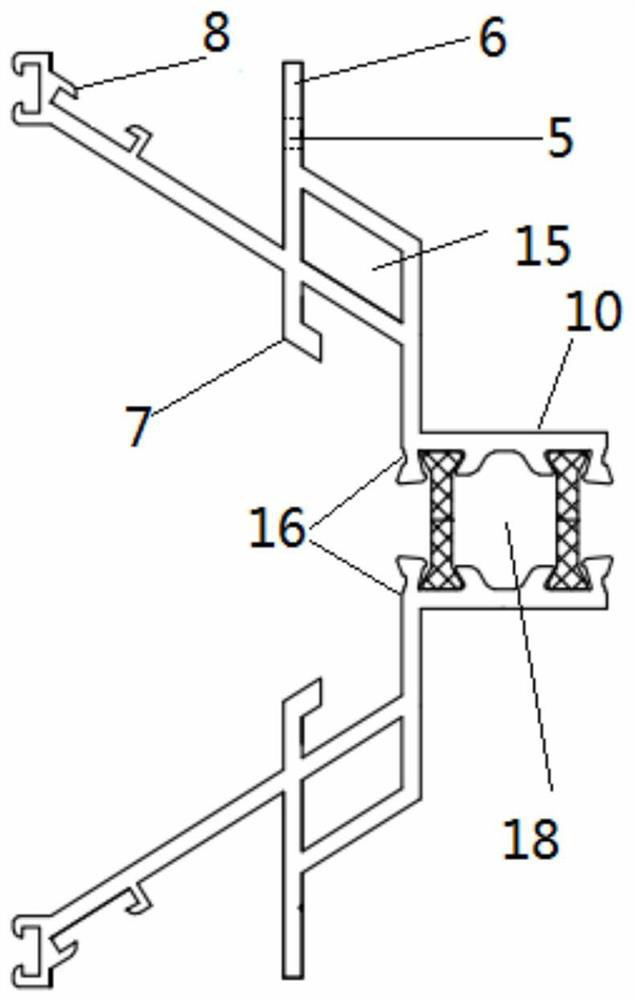

[0025] Such as figure 1 As shown, a prefabricated energy-saving house profile includes a plate, a spliced pipe fitting 19, a connecting plate, and a closing frame 18. A group B sealing strip slot 16 is arranged on the side of the right angle, and a parallelogram fixing cavity 15 is arranged on the side of the right angle substrate 10 away from the group B sealing strip slot 16, and the parallelogram fixing cavity 15 is far away from the short side of the side of the right angle substrate 10 Two-way extension, one side is provided with a reinforcing plate 6, the other side is provided with a fifth buckle 7, the parallelogram fixed cavity 15 extends outwards from a long side close to the groove 16 of the sealing strip of group B, and the end is provided with a composite card Groove 8, two right-angled substrates 10 are mirror-symmetrical al...

Embodiment 2

[0032] according to Figure 5 , Image 6 Describe how the sheet is attached to the fixed surface.

[0033] As shown in the figure, a prefabricated energy-saving house profile includes a plate, upper and lower spliced pipe fittings 20, a connecting plate, and a closing frame 18. A group B sealing strip slot 16 is provided on the right angle side of the right-angle substrate 10, and a parallelogram fixing cavity 15 is provided on the side of the right-angle substrate 10 away from the group B sealing strip slot 16, and the parallelogram fixing cavity 15 is far away from the side of the right-angle substrate 10 The short side extends in both directions, one side is provided with a reinforcing plate 6, and the other side is provided with a fifth buckle 7, and the parallelogram fixed cavity 15 extends outwards near a long side of the sealing strip groove 16 of the group B, and its end is provided with There are composite card slots 8, and two right-angled substrates 10 are mirro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com