Flushing a tool for closed well operation and an associated method

a technology for flushing tools and wells, applied in earth drilling, sealing/packing, wellbore/well accessories, etc., can solve the problems of large equipment and operational costs, large manufacturing, operation and maintenance costs, and large equipment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

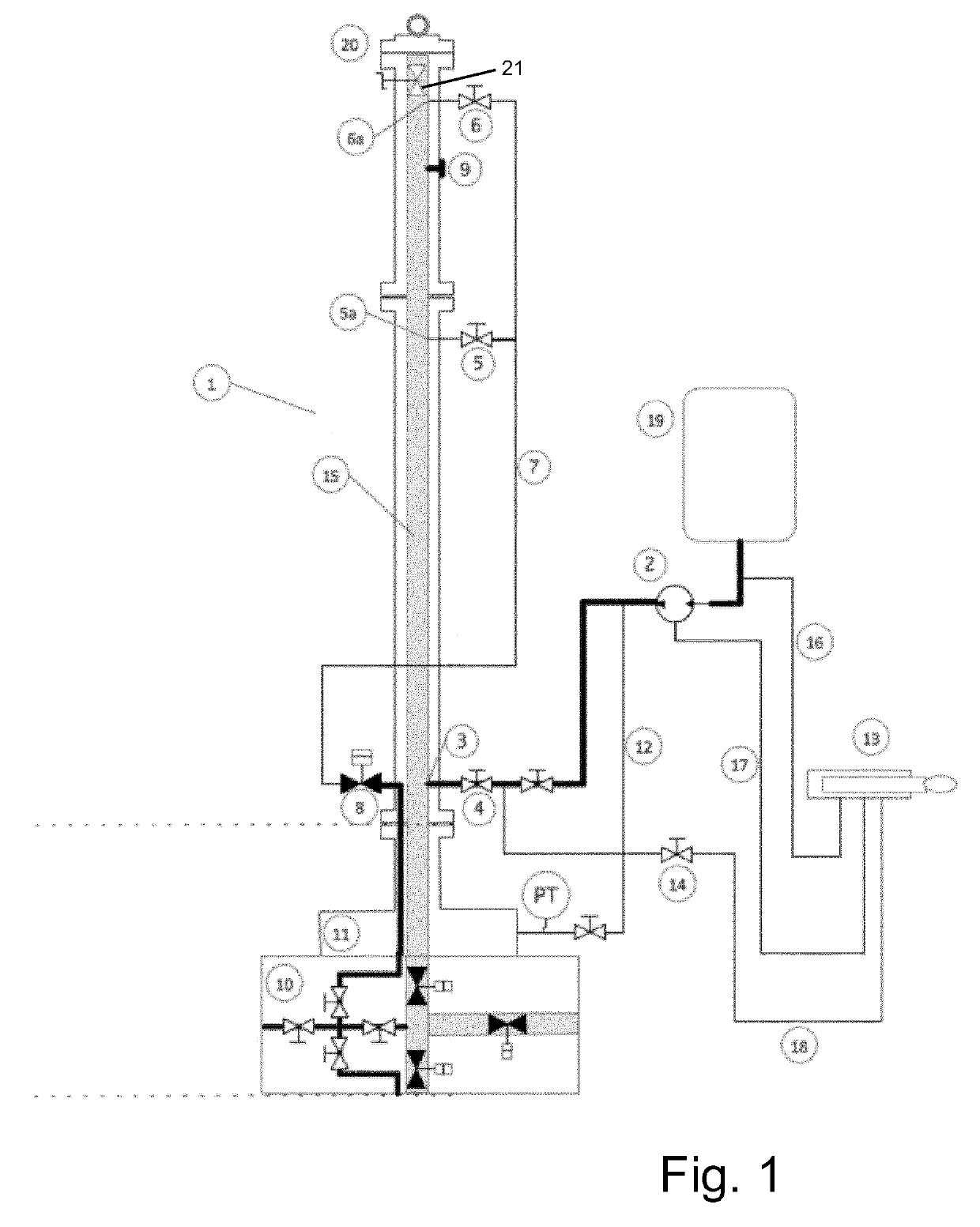

[0042]FIG. 1 is a principle sketch of the invention, where the purpose is to flush out potential hydrocarbons in the main bore (15) of the tool (1). The figure shows a VXT (10), which typically comprises valves in the production bore and the annulus / service bore for control of the first annulus (A-annulus) of the well. A mechanical adapter (11) is shown which normally is used for adaptation of the tool to various connection geometries for different XTs but is mainly an extension of the vertical main bore and annulus to the XT. The flushing is based on the tool having with it a reservoir (19) which contains typically a hydrate inhibiting agent, such as mono-ethylene glycol (MEG), methanol or appropriate mixtures with water. The reservoir is moreover pressure compensated with respect to the environment pressure, which is the hydrostatic liquid column of the seawater depth. A known membrane can advantageously be used in this context. The liquid in the reservoir is then pumped into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com