Accelerated Aging Tests For Predicting Field Performance Of Electrocaloric Cooling

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling technology represents a promising alternative to conventional vapor-compression refrigeration systems, offering potential advantages in energy efficiency, environmental impact, and system miniaturization. The electrocaloric effect (ECE) refers to the reversible temperature change in a material when subjected to an applied electric field. This phenomenon was first observed in the 1930s but remained largely unexplored until recent decades when advances in materials science revitalized interest in its practical applications.

The evolution of electrocaloric cooling technology has accelerated significantly since the early 2000s, marked by the discovery of giant electrocaloric effects in thin films of ferroelectric materials. This breakthrough demonstrated temperature changes of several degrees Kelvin, substantially higher than previously observed, igniting renewed research interest. Subsequently, the field has expanded to explore various material classes including relaxor ferroelectrics, polymers, and ceramic-polymer composites, each offering distinct advantages for cooling applications.

Current research trajectories focus on enhancing the electrocaloric coefficient (temperature change per unit electric field), reducing hysteresis losses, and developing materials that operate efficiently at lower voltages. Additionally, significant effort is being directed toward understanding and mitigating aging effects that compromise long-term performance stability—a critical consideration for commercial viability.

The primary technical objectives in this domain include developing accelerated aging test protocols that accurately predict field performance of electrocaloric cooling systems. Such protocols must reliably compress time scales, allowing researchers to forecast material degradation and performance changes that would naturally occur over years of operation. This requires establishing correlations between accelerated test conditions and real-world operational environments.

Furthermore, research aims to identify key degradation mechanisms in electrocaloric materials, including fatigue from repeated electric field cycling, chemical decomposition, microstructural changes, and interfacial degradation. Understanding these mechanisms is essential for developing more resilient materials and designing systems that maintain cooling efficiency throughout their operational lifetime.

The ultimate goal is to establish standardized testing methodologies that enable meaningful comparison between different electrocaloric materials and cooling system designs. This standardization would facilitate more rapid advancement of the technology by providing clear benchmarks for performance evaluation and allowing researchers to focus on addressing the most critical limitations identified through systematic testing.

As global energy demands and environmental concerns continue to grow, electrocaloric cooling technology presents an opportunity to develop more sustainable thermal management solutions across multiple sectors, including consumer electronics, automotive applications, and building climate control systems.

The evolution of electrocaloric cooling technology has accelerated significantly since the early 2000s, marked by the discovery of giant electrocaloric effects in thin films of ferroelectric materials. This breakthrough demonstrated temperature changes of several degrees Kelvin, substantially higher than previously observed, igniting renewed research interest. Subsequently, the field has expanded to explore various material classes including relaxor ferroelectrics, polymers, and ceramic-polymer composites, each offering distinct advantages for cooling applications.

Current research trajectories focus on enhancing the electrocaloric coefficient (temperature change per unit electric field), reducing hysteresis losses, and developing materials that operate efficiently at lower voltages. Additionally, significant effort is being directed toward understanding and mitigating aging effects that compromise long-term performance stability—a critical consideration for commercial viability.

The primary technical objectives in this domain include developing accelerated aging test protocols that accurately predict field performance of electrocaloric cooling systems. Such protocols must reliably compress time scales, allowing researchers to forecast material degradation and performance changes that would naturally occur over years of operation. This requires establishing correlations between accelerated test conditions and real-world operational environments.

Furthermore, research aims to identify key degradation mechanisms in electrocaloric materials, including fatigue from repeated electric field cycling, chemical decomposition, microstructural changes, and interfacial degradation. Understanding these mechanisms is essential for developing more resilient materials and designing systems that maintain cooling efficiency throughout their operational lifetime.

The ultimate goal is to establish standardized testing methodologies that enable meaningful comparison between different electrocaloric materials and cooling system designs. This standardization would facilitate more rapid advancement of the technology by providing clear benchmarks for performance evaluation and allowing researchers to focus on addressing the most critical limitations identified through systematic testing.

As global energy demands and environmental concerns continue to grow, electrocaloric cooling technology presents an opportunity to develop more sustainable thermal management solutions across multiple sectors, including consumer electronics, automotive applications, and building climate control systems.

Market Analysis for Electrocaloric Cooling Solutions

The electrocaloric cooling market is experiencing significant growth potential as industries seek more environmentally friendly and energy-efficient cooling alternatives. Current market projections indicate that the global electrocaloric cooling market could reach substantial value by 2030, driven by increasing environmental regulations against traditional refrigerants and growing energy efficiency demands.

The primary market segments for electrocaloric cooling solutions include consumer electronics, automotive climate control systems, medical refrigeration, and commercial HVAC applications. Consumer electronics represents the fastest-growing segment due to the increasing need for compact, efficient cooling solutions in high-performance computing devices and smartphones.

Market research indicates that accelerated aging tests for electrocaloric materials are becoming crucial for manufacturers to validate product reliability and performance longevity. These tests directly impact market adoption rates, as they provide confidence in the technology's field performance—a critical factor for commercial viability.

Regional analysis shows North America and Europe leading in research and development investments, while Asia-Pacific demonstrates the fastest market growth rate due to expanding manufacturing capabilities and increasing adoption of green technologies. China, Japan, and South Korea are emerging as key markets with substantial government support for next-generation cooling technologies.

Customer demand analysis reveals that potential adopters prioritize three key factors: reliability demonstrated through accelerated aging tests, energy efficiency improvements over conventional cooling systems, and cost competitiveness. Current market barriers include high initial manufacturing costs, limited material performance data from long-term field applications, and technical challenges in scaling production.

The competitive landscape features both established HVAC manufacturers exploring electrocaloric technology integration and specialized startups focused exclusively on electrocaloric material development. Strategic partnerships between material science companies and cooling system manufacturers are becoming increasingly common to accelerate commercialization.

Market penetration strategies heavily depend on demonstrating reliable performance through standardized accelerated aging protocols. Companies that can establish correlations between accelerated testing results and actual field performance gain significant competitive advantages in securing early adopter contracts and investment funding.

Pricing trends suggest that while current electrocaloric solutions command premium pricing, costs are expected to decrease by approximately 30% over the next five years as manufacturing processes mature and economies of scale are achieved. This cost reduction trajectory will be critical for broader market adoption beyond premium applications.

The primary market segments for electrocaloric cooling solutions include consumer electronics, automotive climate control systems, medical refrigeration, and commercial HVAC applications. Consumer electronics represents the fastest-growing segment due to the increasing need for compact, efficient cooling solutions in high-performance computing devices and smartphones.

Market research indicates that accelerated aging tests for electrocaloric materials are becoming crucial for manufacturers to validate product reliability and performance longevity. These tests directly impact market adoption rates, as they provide confidence in the technology's field performance—a critical factor for commercial viability.

Regional analysis shows North America and Europe leading in research and development investments, while Asia-Pacific demonstrates the fastest market growth rate due to expanding manufacturing capabilities and increasing adoption of green technologies. China, Japan, and South Korea are emerging as key markets with substantial government support for next-generation cooling technologies.

Customer demand analysis reveals that potential adopters prioritize three key factors: reliability demonstrated through accelerated aging tests, energy efficiency improvements over conventional cooling systems, and cost competitiveness. Current market barriers include high initial manufacturing costs, limited material performance data from long-term field applications, and technical challenges in scaling production.

The competitive landscape features both established HVAC manufacturers exploring electrocaloric technology integration and specialized startups focused exclusively on electrocaloric material development. Strategic partnerships between material science companies and cooling system manufacturers are becoming increasingly common to accelerate commercialization.

Market penetration strategies heavily depend on demonstrating reliable performance through standardized accelerated aging protocols. Companies that can establish correlations between accelerated testing results and actual field performance gain significant competitive advantages in securing early adopter contracts and investment funding.

Pricing trends suggest that while current electrocaloric solutions command premium pricing, costs are expected to decrease by approximately 30% over the next five years as manufacturing processes mature and economies of scale are achieved. This cost reduction trajectory will be critical for broader market adoption beyond premium applications.

Current Challenges in Accelerated Aging Test Methodologies

Despite significant advancements in electrocaloric cooling technology, accelerated aging test methodologies face substantial challenges that impede accurate prediction of field performance. The primary difficulty lies in establishing correlation between accelerated test conditions and real-world operational environments. Current methodologies often fail to account for the complex interplay of thermal, electrical, and mechanical stresses that electrocaloric materials experience during actual operation cycles.

Temperature cycling protocols present particular challenges, as they must simulate thousands of heating and cooling cycles while maintaining relevance to real-world conditions. Many existing protocols either over-stress materials, leading to failure modes not encountered in practice, or under-stress them, missing critical degradation mechanisms that emerge over extended use periods.

Electric field application during accelerated testing represents another significant hurdle. Electrocaloric materials require precise electric field control to induce the desired thermal changes, but maintaining consistent field application during accelerated aging tests has proven technically challenging. Current methodologies struggle to replicate the exact field patterns experienced during normal operation, particularly when scaling time parameters.

Material interface degradation assessment remains inadequately addressed in existing protocols. The interfaces between electrocaloric materials and electrodes or heat exchange surfaces often represent critical failure points, yet accelerated testing frequently fails to capture the subtle degradation mechanisms occurring at these boundaries.

Data interpretation frameworks lack standardization across the industry. Different research groups and manufacturers employ varied metrics and analytical approaches, making cross-comparison of results problematic. This absence of standardized evaluation criteria hampers technology advancement and commercial adoption.

Time compression models for electrocaloric materials remain underdeveloped compared to other technologies. The unique combination of electrical, thermal, and mechanical stresses in these systems requires specialized mathematical models to translate accelerated test results into meaningful lifetime predictions.

Environmental factor simulation presents additional complications. Real-world electrocaloric cooling systems encounter varying humidity, vibration, and ambient temperature conditions that prove difficult to incorporate into accelerated test protocols without introducing confounding variables.

Validation methodologies for accelerated aging tests suffer from insufficient field data. The relatively nascent state of electrocaloric cooling technology means limited long-term performance data exists to validate accelerated testing approaches, creating a circular problem where test development is hindered by the very lack of data it aims to replace.

Temperature cycling protocols present particular challenges, as they must simulate thousands of heating and cooling cycles while maintaining relevance to real-world conditions. Many existing protocols either over-stress materials, leading to failure modes not encountered in practice, or under-stress them, missing critical degradation mechanisms that emerge over extended use periods.

Electric field application during accelerated testing represents another significant hurdle. Electrocaloric materials require precise electric field control to induce the desired thermal changes, but maintaining consistent field application during accelerated aging tests has proven technically challenging. Current methodologies struggle to replicate the exact field patterns experienced during normal operation, particularly when scaling time parameters.

Material interface degradation assessment remains inadequately addressed in existing protocols. The interfaces between electrocaloric materials and electrodes or heat exchange surfaces often represent critical failure points, yet accelerated testing frequently fails to capture the subtle degradation mechanisms occurring at these boundaries.

Data interpretation frameworks lack standardization across the industry. Different research groups and manufacturers employ varied metrics and analytical approaches, making cross-comparison of results problematic. This absence of standardized evaluation criteria hampers technology advancement and commercial adoption.

Time compression models for electrocaloric materials remain underdeveloped compared to other technologies. The unique combination of electrical, thermal, and mechanical stresses in these systems requires specialized mathematical models to translate accelerated test results into meaningful lifetime predictions.

Environmental factor simulation presents additional complications. Real-world electrocaloric cooling systems encounter varying humidity, vibration, and ambient temperature conditions that prove difficult to incorporate into accelerated test protocols without introducing confounding variables.

Validation methodologies for accelerated aging tests suffer from insufficient field data. The relatively nascent state of electrocaloric cooling technology means limited long-term performance data exists to validate accelerated testing approaches, creating a circular problem where test development is hindered by the very lack of data it aims to replace.

Established Accelerated Aging Test Protocols for Cooling Systems

01 Environmental simulation methods for accelerated aging tests

Various environmental factors such as temperature, humidity, UV radiation, and chemical exposure can be simulated in laboratory settings to accelerate the aging process of materials and products. These controlled conditions allow researchers to predict long-term field performance in a shorter timeframe. The methods typically involve exposing test specimens to extreme conditions that exceed normal operating parameters to induce accelerated degradation mechanisms similar to those occurring in real-world applications.- Environmental simulation methods for accelerated aging: Various environmental factors such as temperature, humidity, UV radiation, and chemical exposure can be simulated in laboratory settings to accelerate the aging process of materials and products. These controlled conditions allow researchers to predict long-term field performance in a shorter timeframe. The methods typically involve exposing test specimens to extreme conditions that exceed normal operating parameters to induce accelerated degradation mechanisms similar to those occurring in real-world applications.

- Correlation models between accelerated tests and field performance: Mathematical models and algorithms are developed to establish correlations between accelerated aging test results and actual field performance. These models consider various degradation mechanisms and environmental factors to create predictive frameworks. By analyzing data from both accelerated tests and real-world performance, researchers can develop conversion factors and statistical methods to accurately translate accelerated aging results into reliable field performance predictions.

- Equipment and apparatus for accelerated aging testing: Specialized equipment and apparatus are designed for conducting accelerated aging tests under controlled conditions. These include environmental chambers, weatherometers, thermal cycling units, and mechanical stress applicators. The equipment can simulate multiple aging factors simultaneously or in sequence to better replicate real-world conditions. Advanced monitoring systems are integrated to collect real-time data on material degradation and performance changes during the accelerated aging process.

- Industry-specific accelerated aging protocols: Different industries have developed specialized accelerated aging protocols tailored to their specific products and performance requirements. These protocols consider the unique environmental stressors and failure modes relevant to each application area. Standardized testing methods have been established for electronics, pharmaceuticals, construction materials, automotive components, and medical devices, among others, to ensure consistent evaluation of field performance through accelerated testing.

- Data analysis and lifetime prediction techniques: Advanced data analysis techniques are employed to interpret accelerated aging test results and predict product lifetime in field conditions. These include statistical methods, machine learning algorithms, and physics-based modeling approaches. By analyzing degradation patterns and failure mechanisms observed during accelerated testing, researchers can extrapolate performance trends and establish reliability metrics that correlate with expected field performance over extended time periods.

02 Correlation models between accelerated aging and field performance

Mathematical and statistical models are developed to establish correlations between accelerated aging test results and actual field performance. These models consider various degradation mechanisms and environmental factors to create predictive algorithms that can translate laboratory data into reliable field performance estimates. The correlation models often incorporate historical field data, material properties, and environmental parameters to improve prediction accuracy and reliability.Expand Specific Solutions03 Equipment and apparatus for conducting accelerated aging tests

Specialized equipment and apparatus are designed to conduct accelerated aging tests under controlled conditions. These include environmental chambers, weatherometers, thermal cycling units, and mechanical stress applicators that can simulate various environmental and operational stresses. The equipment often features advanced monitoring and control systems to maintain precise test conditions and collect real-time data on material degradation and performance changes.Expand Specific Solutions04 Data analysis and performance prediction methodologies

Advanced data analysis techniques are employed to interpret accelerated aging test results and predict long-term field performance. These methodologies include statistical analysis, machine learning algorithms, and computational modeling to process large datasets generated during testing. The analysis focuses on identifying degradation patterns, failure modes, and performance thresholds to establish reliable lifetime predictions and maintenance schedules for products and materials.Expand Specific Solutions05 Industry-specific accelerated aging protocols

Different industries have developed specialized accelerated aging protocols tailored to their specific products and performance requirements. These protocols define standardized test conditions, procedures, and evaluation criteria to ensure consistent and comparable results across different testing facilities. Industry-specific protocols consider the unique environmental stresses, operational conditions, and failure mechanisms relevant to particular applications, such as electronics, pharmaceuticals, construction materials, or automotive components.Expand Specific Solutions

Leading Companies and Research Institutions in Electrocaloric Technology

Electrocaloric cooling technology is currently in the early development stage, with a growing market expected to reach significant scale as energy efficiency demands increase globally. The technology maturity remains moderate, with key players advancing at different rates. Research institutions like Korea Research Institute of Chemical Technology and universities (Huazhong University of Science & Technology, Sichuan University) are driving fundamental research, while industrial giants including Siemens AG and Mitsubishi Heavy Industries are developing practical applications. State Grid entities from China are exploring grid-level implementations, suggesting potential for large-scale deployment. Companies like ATLAS Material Testing Technology are contributing specialized testing methodologies crucial for reliability assessment. The competitive landscape shows a balance between academic research and industrial development, with accelerated aging tests becoming critical for commercial viability.

Korea Research Institute of Chemical Technology

Technical Solution: The Korea Research Institute of Chemical Technology (KRICT) has developed a comprehensive accelerated aging test framework specifically for electrocaloric materials and cooling systems. Their approach combines multiple stress factors including thermal cycling, electrical field cycling, and mechanical stress to simulate long-term operational conditions. KRICT's methodology employs custom-designed test chambers that can apply precise electrical fields (up to 100 kV/cm) while simultaneously controlling temperature profiles and mechanical loading. Their testing protocols typically involve 24-hour cycles that simulate years of operational wear through intensified conditions. A key innovation in KRICT's approach is their use of in-situ characterization techniques that monitor material properties during the aging process, including dielectric constant, polarization, and thermal conductivity changes. This allows researchers to identify degradation mechanisms as they occur rather than only measuring end-of-life properties. KRICT has established correlation factors between accelerated test results and field performance based on extensive validation studies with industrial partners.

Strengths: Sophisticated in-situ monitoring capabilities that provide insight into degradation mechanisms, strong materials science expertise particularly in polymer-based electrocaloric materials, and established correlations between accelerated tests and real-world performance. Weaknesses: Testing methodology may overemphasize electrical degradation while underrepresenting mechanical fatigue effects that occur in actual cooling systems over extended periods.

Siemens AG

Technical Solution: Siemens AG has developed a comprehensive accelerated aging test platform for electrocaloric cooling systems that integrates both hardware and software components. Their approach utilizes environmental chambers capable of precise temperature control (±0.05°C) combined with programmable power electronics that can simulate various electrical load profiles and field strengths. Siemens' testing methodology incorporates a multi-stress approach where thermal cycling, humidity exposure, electrical cycling, and mechanical vibration are applied simultaneously or in carefully designed sequences to replicate real-world operating conditions. A distinguishing feature of Siemens' approach is their digital twin modeling that runs alongside physical testing, continuously refining predictive algorithms based on measured degradation rates. This allows for more accurate extrapolation from accelerated test data to expected field performance. Their test protocols typically include 1000-hour accelerated aging sequences that simulate 5-7 years of operational life, with interim characterization of key performance parameters including cooling capacity, energy efficiency ratio, and response time degradation.

Strengths: Integrated digital twin modeling enhances predictive accuracy, comprehensive multi-stress testing capabilities, and extensive experience with electromechanical system reliability testing. Weaknesses: Testing methodology may be overly conservative in some aspects, potentially overestimating failure rates compared to actual field performance, and the complex test setup requires significant expertise to implement correctly.

Critical Patents and Literature on Electrocaloric Material Degradation

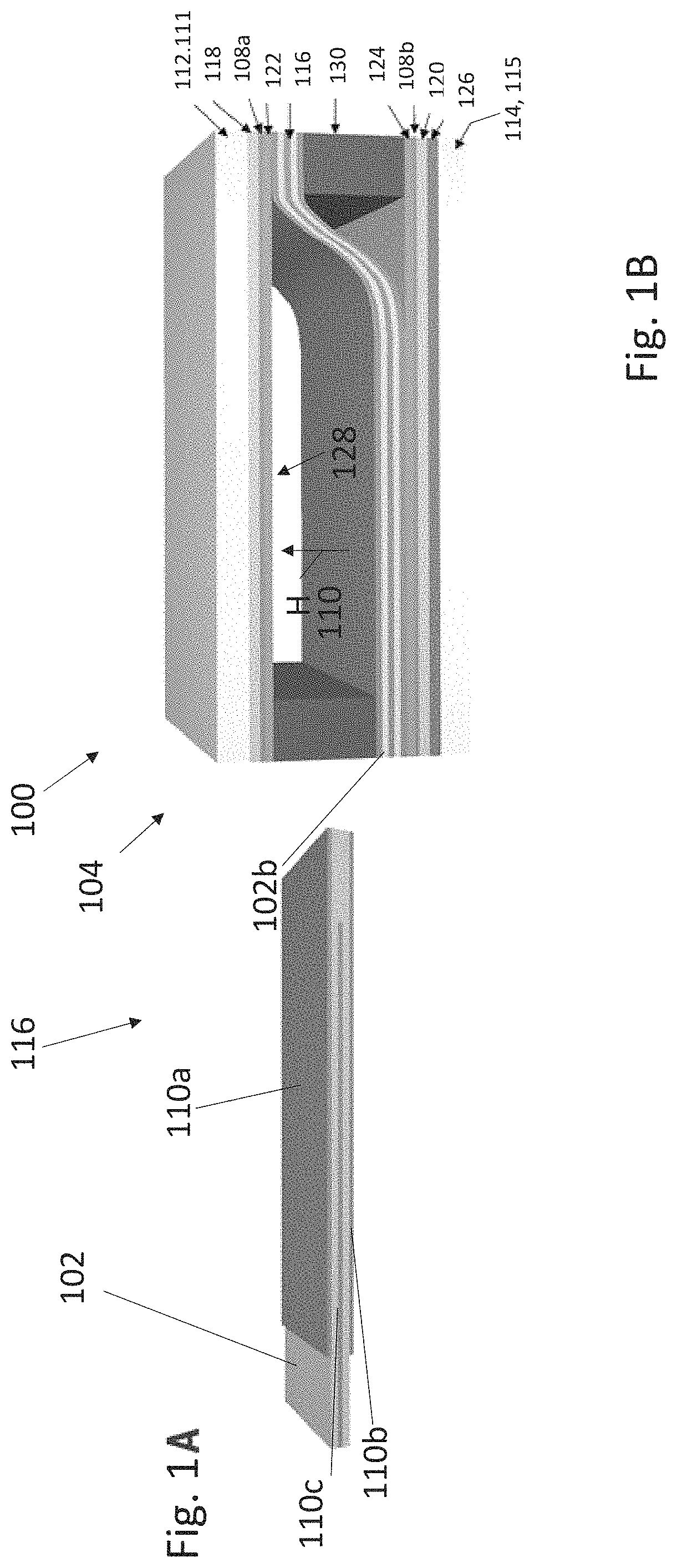

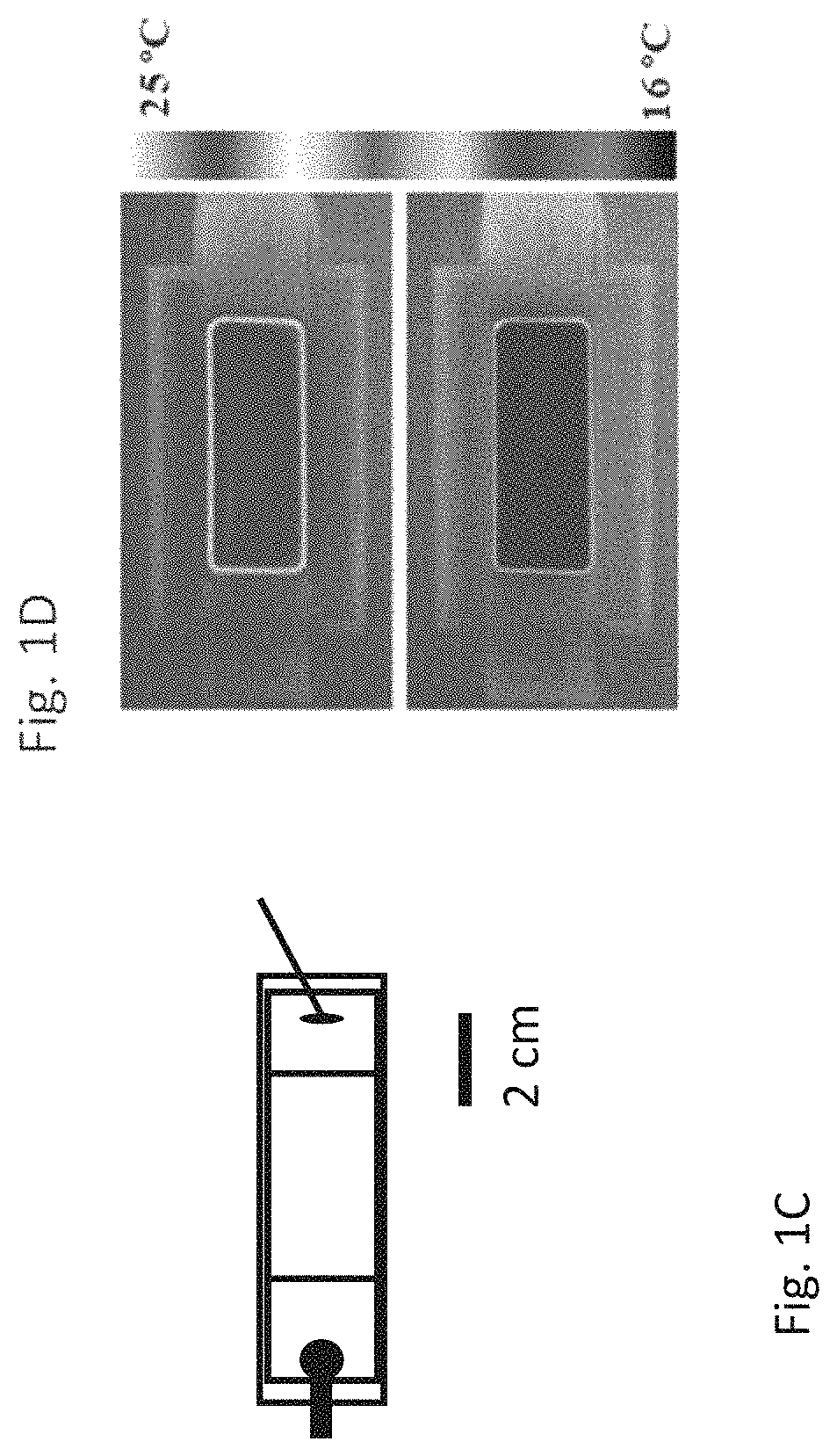

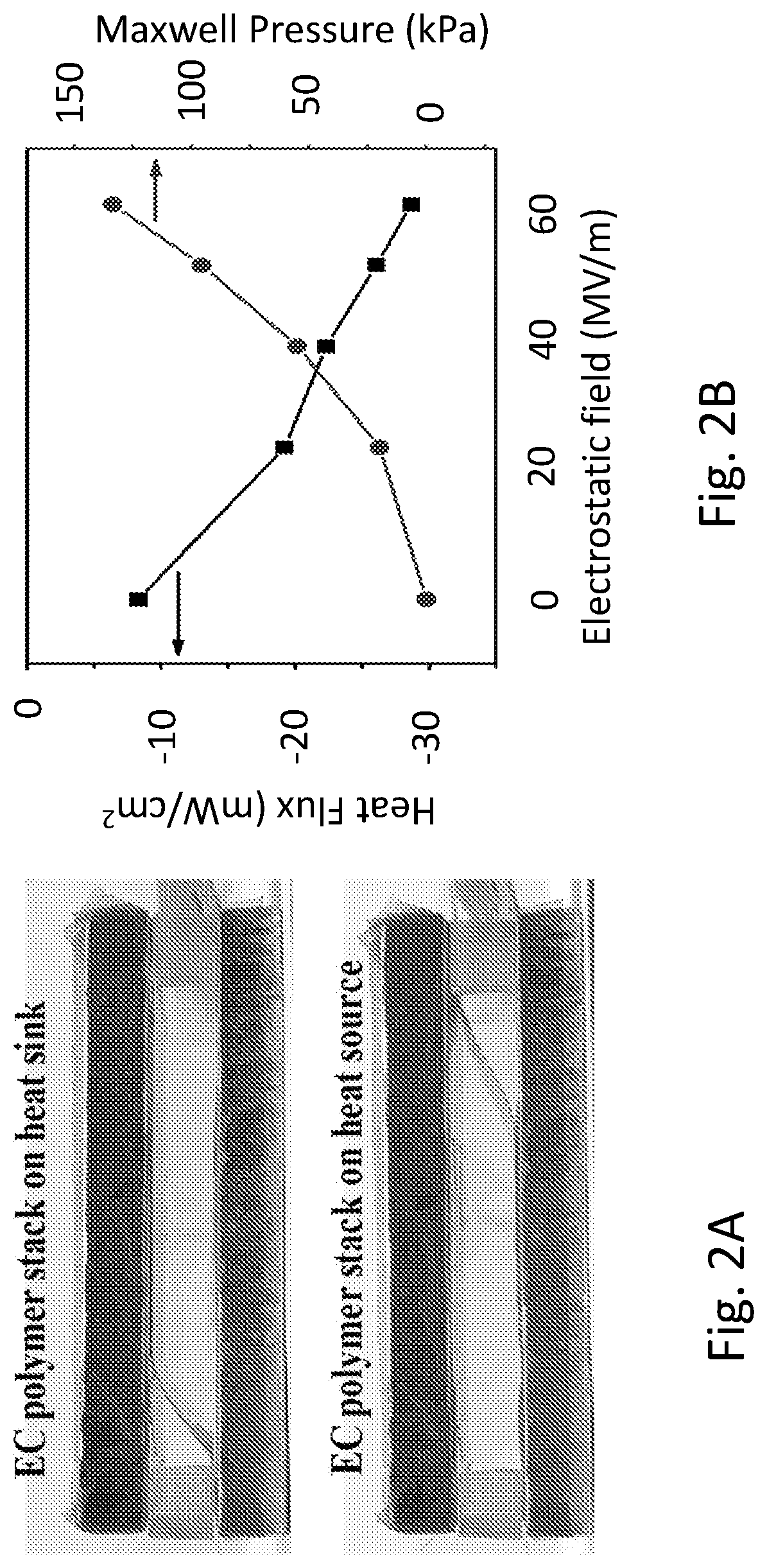

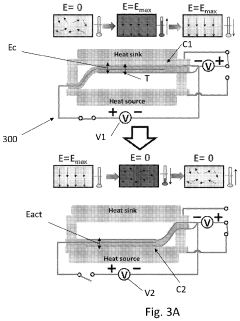

Electrocaloric cooling with electrostatic actuation

PatentActiveUS11397031B2

Innovation

- A solid-state heat transporting device utilizing a flexible electrocaloric polymer film coupled with an electrostatic actuation mechanism, allowing for controlled heat transfer between heat sources and sinks by altering the shape or position of the film to enhance thermal contact and reduce parasitic power consumption.

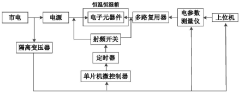

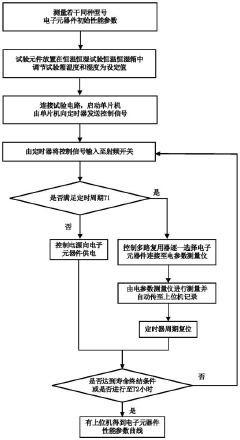

Continuous measurement system for accelerated aging of electronic component

PatentPendingCN117969985A

Innovation

- A continuous measurement system for accelerated aging of electronic components is designed. It uses radio frequency switches and multiplexers to periodically control the connection between the constant temperature and humidity box and the electrical parameter measuring instrument to avoid waiting for the cooling and heating processes and realize the continuous measurement of electronic components. Measurement.

Reliability Standards and Certification Requirements

The reliability standards and certification requirements for electrocaloric cooling systems represent a critical framework for ensuring consistent performance and safety across the industry. Currently, there is no unified global standard specifically designed for electrocaloric technology, requiring manufacturers to comply with a patchwork of existing cooling system regulations and broader electronic device standards.

The International Electrotechnical Commission (IEC) provides several relevant standards that apply to cooling technologies, including IEC 60335 for household appliances and IEC 62552 for refrigerating appliances. These standards establish baseline requirements for electrical safety, energy efficiency, and mechanical durability that electrocaloric systems must meet. However, they lack specific provisions for the unique characteristics of electrocaloric materials and their degradation mechanisms.

ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) Standard 72 offers testing protocols for commercial refrigerators that can be adapted for electrocaloric systems, particularly regarding temperature stability and energy consumption measurements. The organization is currently reviewing potential amendments to include emerging cooling technologies like electrocaloric systems.

For accelerated aging tests specifically, IEC 60068 provides a foundation for environmental testing procedures, including temperature cycling, humidity exposure, and mechanical stress that can be modified for electrocaloric materials. These tests typically require systems to maintain at least 80% of initial cooling capacity after simulated aging equivalent to 5-7 years of field operation.

Certification pathways currently available include UL (Underwriters Laboratories) certification in North America, CE marking in Europe, and CCC certification in China. Each requires different testing protocols and performance thresholds. UL 250, for example, outlines safety requirements for refrigeration systems that electrocaloric technologies must satisfy, though with significant adaptation.

The Energy Star program represents another important certification target, requiring cooling systems to demonstrate energy efficiency at least 10% better than standard models. As electrocaloric cooling promises theoretical efficiency improvements, meeting these standards could provide market advantages, but requires standardized testing methodologies not yet established.

Industry consortiums like the Green Cooling Initiative and the International Institute of Refrigeration are working to develop electrocaloric-specific standards, with draft proposals expected within the next 18-24 months. These emerging standards will likely incorporate specialized accelerated aging protocols that address the unique degradation mechanisms of electrocaloric materials, including polarization fatigue, interface degradation, and thermal cycling effects.

The International Electrotechnical Commission (IEC) provides several relevant standards that apply to cooling technologies, including IEC 60335 for household appliances and IEC 62552 for refrigerating appliances. These standards establish baseline requirements for electrical safety, energy efficiency, and mechanical durability that electrocaloric systems must meet. However, they lack specific provisions for the unique characteristics of electrocaloric materials and their degradation mechanisms.

ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) Standard 72 offers testing protocols for commercial refrigerators that can be adapted for electrocaloric systems, particularly regarding temperature stability and energy consumption measurements. The organization is currently reviewing potential amendments to include emerging cooling technologies like electrocaloric systems.

For accelerated aging tests specifically, IEC 60068 provides a foundation for environmental testing procedures, including temperature cycling, humidity exposure, and mechanical stress that can be modified for electrocaloric materials. These tests typically require systems to maintain at least 80% of initial cooling capacity after simulated aging equivalent to 5-7 years of field operation.

Certification pathways currently available include UL (Underwriters Laboratories) certification in North America, CE marking in Europe, and CCC certification in China. Each requires different testing protocols and performance thresholds. UL 250, for example, outlines safety requirements for refrigeration systems that electrocaloric technologies must satisfy, though with significant adaptation.

The Energy Star program represents another important certification target, requiring cooling systems to demonstrate energy efficiency at least 10% better than standard models. As electrocaloric cooling promises theoretical efficiency improvements, meeting these standards could provide market advantages, but requires standardized testing methodologies not yet established.

Industry consortiums like the Green Cooling Initiative and the International Institute of Refrigeration are working to develop electrocaloric-specific standards, with draft proposals expected within the next 18-24 months. These emerging standards will likely incorporate specialized accelerated aging protocols that address the unique degradation mechanisms of electrocaloric materials, including polarization fatigue, interface degradation, and thermal cycling effects.

Environmental Impact and Sustainability Considerations

Electrocaloric cooling technology represents a promising alternative to conventional vapor-compression refrigeration systems, offering potential environmental benefits through the elimination of harmful refrigerants. The environmental impact assessment of accelerated aging tests for electrocaloric cooling systems reveals several critical sustainability considerations that must be addressed during development and implementation phases.

The primary environmental advantage of electrocaloric cooling lies in its solid-state operation, which eliminates the need for hydrofluorocarbons (HFCs) and other greenhouse gases commonly used in traditional cooling systems. These conventional refrigerants can have global warming potentials thousands of times greater than CO2. By contrast, electrocaloric materials typically consist of lead-free ceramics or polymers with significantly lower environmental footprints throughout their lifecycle.

Accelerated aging tests themselves present environmental considerations. These tests often require specialized environmental chambers that consume substantial energy during operation. The energy intensity of these testing protocols must be factored into lifecycle assessments when evaluating the overall sustainability of electrocaloric technology development. Implementing energy-efficient testing protocols and utilizing renewable energy sources for test facilities can mitigate these impacts.

Material sustainability represents another critical dimension. Many promising electrocaloric materials contain rare earth elements or other critical materials with supply chain vulnerabilities and extraction impacts. Accelerated aging tests should therefore evaluate not only performance degradation but also potential material leaching or degradation that could pose environmental risks. Developing tests that specifically address end-of-life scenarios and recyclability would enhance the comprehensive sustainability assessment.

The correlation between accelerated aging results and actual field performance has direct implications for product longevity and waste reduction. More accurate predictive models derived from these tests can prevent premature product failures, extending useful life and reducing electronic waste. This aspect of sustainability should be explicitly incorporated into test design and evaluation criteria.

Water consumption during manufacturing and testing processes presents another environmental consideration. Some accelerated aging protocols may require significant water resources for cooling or humidity control. Water-efficient test designs and closed-loop systems can minimize this impact while still providing reliable performance predictions.

Finally, the broader environmental benefits of electrocaloric cooling should inform test development priorities. Accelerated aging protocols should specifically evaluate performance parameters most relevant to energy efficiency and carbon footprint reduction, ensuring that environmental benefits are maintained throughout the product lifecycle despite aging effects.

The primary environmental advantage of electrocaloric cooling lies in its solid-state operation, which eliminates the need for hydrofluorocarbons (HFCs) and other greenhouse gases commonly used in traditional cooling systems. These conventional refrigerants can have global warming potentials thousands of times greater than CO2. By contrast, electrocaloric materials typically consist of lead-free ceramics or polymers with significantly lower environmental footprints throughout their lifecycle.

Accelerated aging tests themselves present environmental considerations. These tests often require specialized environmental chambers that consume substantial energy during operation. The energy intensity of these testing protocols must be factored into lifecycle assessments when evaluating the overall sustainability of electrocaloric technology development. Implementing energy-efficient testing protocols and utilizing renewable energy sources for test facilities can mitigate these impacts.

Material sustainability represents another critical dimension. Many promising electrocaloric materials contain rare earth elements or other critical materials with supply chain vulnerabilities and extraction impacts. Accelerated aging tests should therefore evaluate not only performance degradation but also potential material leaching or degradation that could pose environmental risks. Developing tests that specifically address end-of-life scenarios and recyclability would enhance the comprehensive sustainability assessment.

The correlation between accelerated aging results and actual field performance has direct implications for product longevity and waste reduction. More accurate predictive models derived from these tests can prevent premature product failures, extending useful life and reducing electronic waste. This aspect of sustainability should be explicitly incorporated into test design and evaluation criteria.

Water consumption during manufacturing and testing processes presents another environmental consideration. Some accelerated aging protocols may require significant water resources for cooling or humidity control. Water-efficient test designs and closed-loop systems can minimize this impact while still providing reliable performance predictions.

Finally, the broader environmental benefits of electrocaloric cooling should inform test development priorities. Accelerated aging protocols should specifically evaluate performance parameters most relevant to energy efficiency and carbon footprint reduction, ensuring that environmental benefits are maintained throughout the product lifecycle despite aging effects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!