Thermal Management Interfaces For Electrocaloric Cooling Systems

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Background and Objectives

Electrocaloric cooling represents a revolutionary approach to thermal management that has gained significant attention in recent decades. This technology leverages the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. The fundamental principle was first observed in the 1930s, but meaningful research acceleration only occurred in the early 2000s with the discovery of giant electrocaloric effects in thin films of ferroelectric materials.

The evolution of electrocaloric cooling technology has been driven by increasing demands for more energy-efficient and environmentally friendly cooling solutions. Traditional vapor-compression refrigeration systems, while effective, rely on refrigerants with high global warming potential and consume substantial energy. This has created an urgent need for alternative cooling technologies that can reduce environmental impact while maintaining or improving cooling efficiency.

Current research in electrocaloric cooling focuses on developing materials with enhanced electrocaloric properties, designing efficient thermal interfaces, and creating practical device architectures. The primary technical objective is to achieve cooling power densities and coefficients of performance that can compete with conventional cooling technologies. This requires addressing several interconnected challenges, particularly in thermal management interfaces which are critical for efficient heat transfer within these systems.

Thermal management interfaces in electrocaloric cooling systems serve as the crucial link between the electrocaloric material and the heat source/sink. These interfaces must facilitate rapid and efficient heat transfer to maximize the cooling effect generated by the electrocaloric material. The technical goal is to develop interfaces with minimal thermal resistance, high durability under cyclic operation, and compatibility with various electrocaloric materials.

The development trajectory of electrocaloric cooling technology indicates potential applications across multiple sectors, including electronics cooling, refrigeration, air conditioning, and specialized thermal management for medical and aerospace applications. Each application domain presents unique requirements and constraints that influence the design objectives for thermal management interfaces.

Recent advances in materials science, nanofabrication, and thermal engineering have opened new possibilities for enhancing the performance of these critical interfaces. The integration of novel materials such as graphene, carbon nanotubes, and engineered metamaterials offers promising avenues for overcoming current limitations in thermal conductivity and contact resistance.

The ultimate objective of research in this field is to establish electrocaloric cooling as a viable, sustainable alternative to conventional cooling technologies, with thermal management interfaces playing a pivotal role in achieving this transformation.

The evolution of electrocaloric cooling technology has been driven by increasing demands for more energy-efficient and environmentally friendly cooling solutions. Traditional vapor-compression refrigeration systems, while effective, rely on refrigerants with high global warming potential and consume substantial energy. This has created an urgent need for alternative cooling technologies that can reduce environmental impact while maintaining or improving cooling efficiency.

Current research in electrocaloric cooling focuses on developing materials with enhanced electrocaloric properties, designing efficient thermal interfaces, and creating practical device architectures. The primary technical objective is to achieve cooling power densities and coefficients of performance that can compete with conventional cooling technologies. This requires addressing several interconnected challenges, particularly in thermal management interfaces which are critical for efficient heat transfer within these systems.

Thermal management interfaces in electrocaloric cooling systems serve as the crucial link between the electrocaloric material and the heat source/sink. These interfaces must facilitate rapid and efficient heat transfer to maximize the cooling effect generated by the electrocaloric material. The technical goal is to develop interfaces with minimal thermal resistance, high durability under cyclic operation, and compatibility with various electrocaloric materials.

The development trajectory of electrocaloric cooling technology indicates potential applications across multiple sectors, including electronics cooling, refrigeration, air conditioning, and specialized thermal management for medical and aerospace applications. Each application domain presents unique requirements and constraints that influence the design objectives for thermal management interfaces.

Recent advances in materials science, nanofabrication, and thermal engineering have opened new possibilities for enhancing the performance of these critical interfaces. The integration of novel materials such as graphene, carbon nanotubes, and engineered metamaterials offers promising avenues for overcoming current limitations in thermal conductivity and contact resistance.

The ultimate objective of research in this field is to establish electrocaloric cooling as a viable, sustainable alternative to conventional cooling technologies, with thermal management interfaces playing a pivotal role in achieving this transformation.

Market Analysis for Thermal Management Solutions

The global thermal management market is experiencing significant growth, driven by the increasing demand for efficient cooling solutions across various industries. The market for thermal management interfaces specifically for electrocaloric cooling systems represents an emerging segment with substantial potential. Current market valuations indicate that the broader thermal management solutions market is expanding at a compound annual growth rate of approximately 8% and is projected to reach over $20 billion by 2028.

Electrocaloric cooling technology, as an environmentally friendly alternative to conventional vapor-compression refrigeration, is attracting considerable attention from both industrial and consumer sectors. Market research indicates that industries such as electronics, automotive, aerospace, and medical devices are the primary adopters of advanced thermal management solutions, with electrocaloric systems gaining traction due to their energy efficiency and reduced environmental impact.

Consumer electronics represents the largest market segment, accounting for nearly 35% of the thermal management solutions market. This is followed by automotive applications at 25%, industrial equipment at 20%, and aerospace and defense at 15%. The remaining 5% is distributed across various other applications including medical devices and renewable energy systems.

Regional analysis shows North America and Asia-Pacific as the dominant markets for thermal management solutions. North America leads in research and development of electrocaloric technologies, while Asia-Pacific demonstrates the highest growth rate due to rapid industrialization and increasing electronic device production. Europe follows closely, driven by stringent environmental regulations promoting energy-efficient cooling technologies.

Market dynamics are influenced by several factors including increasing power densities in electronic devices, miniaturization trends, growing concerns about energy efficiency, and environmental regulations phasing out conventional refrigerants. These factors collectively create a favorable environment for the adoption of electrocaloric cooling systems and their associated thermal interface materials.

Customer requirements are evolving toward solutions that offer higher thermal conductivity, reliability, ease of application, and cost-effectiveness. There is a growing demand for thermal interface materials that can efficiently transfer heat in electrocaloric systems while maintaining long-term performance stability under thermal cycling conditions.

Competition in this market segment is intensifying with established thermal management companies expanding their portfolios to include electrocaloric-specific solutions, while startups are introducing innovative materials and designs. Market forecasts suggest that thermal interfaces specifically designed for electrocaloric cooling systems could grow at a rate exceeding 12% annually over the next five years, outpacing the broader thermal management market.

Electrocaloric cooling technology, as an environmentally friendly alternative to conventional vapor-compression refrigeration, is attracting considerable attention from both industrial and consumer sectors. Market research indicates that industries such as electronics, automotive, aerospace, and medical devices are the primary adopters of advanced thermal management solutions, with electrocaloric systems gaining traction due to their energy efficiency and reduced environmental impact.

Consumer electronics represents the largest market segment, accounting for nearly 35% of the thermal management solutions market. This is followed by automotive applications at 25%, industrial equipment at 20%, and aerospace and defense at 15%. The remaining 5% is distributed across various other applications including medical devices and renewable energy systems.

Regional analysis shows North America and Asia-Pacific as the dominant markets for thermal management solutions. North America leads in research and development of electrocaloric technologies, while Asia-Pacific demonstrates the highest growth rate due to rapid industrialization and increasing electronic device production. Europe follows closely, driven by stringent environmental regulations promoting energy-efficient cooling technologies.

Market dynamics are influenced by several factors including increasing power densities in electronic devices, miniaturization trends, growing concerns about energy efficiency, and environmental regulations phasing out conventional refrigerants. These factors collectively create a favorable environment for the adoption of electrocaloric cooling systems and their associated thermal interface materials.

Customer requirements are evolving toward solutions that offer higher thermal conductivity, reliability, ease of application, and cost-effectiveness. There is a growing demand for thermal interface materials that can efficiently transfer heat in electrocaloric systems while maintaining long-term performance stability under thermal cycling conditions.

Competition in this market segment is intensifying with established thermal management companies expanding their portfolios to include electrocaloric-specific solutions, while startups are introducing innovative materials and designs. Market forecasts suggest that thermal interfaces specifically designed for electrocaloric cooling systems could grow at a rate exceeding 12% annually over the next five years, outpacing the broader thermal management market.

Current Challenges in Thermal Interface Materials

Despite significant advancements in electrocaloric cooling technology, thermal interface materials (TIMs) remain a critical bottleneck in system performance. Current TIMs struggle to meet the demanding requirements of electrocaloric cooling systems, which require rapid and efficient heat transfer across interfaces while maintaining mechanical integrity under thermal cycling conditions. Conventional metal-based TIMs offer high thermal conductivity but poor compliance, while polymer-based alternatives provide better mechanical properties at the cost of reduced thermal performance.

The thermal contact resistance at material interfaces presents a fundamental challenge, with microscopic air gaps forming between imperfect surface contacts. These gaps significantly impede heat transfer, reducing overall system efficiency. Even high-performance commercial TIMs typically achieve thermal conductivities of only 3-8 W/m·K, far below what is theoretically optimal for electrocaloric applications that require values exceeding 15 W/m·K for maximum efficiency.

Durability under thermal cycling represents another major hurdle. Electrocaloric cooling systems operate with rapid temperature fluctuations, causing differential thermal expansion that leads to mechanical stress at interfaces. Current TIMs experience performance degradation over time, with studies showing up to 30% reduction in thermal conductivity after just 500 thermal cycles in demanding applications.

The trade-off between thermal conductivity and mechanical compliance remains unresolved. Rigid materials with high thermal conductivity fail to conform to surface irregularities, while compliant materials with good surface contact typically exhibit poor thermal performance. This fundamental dichotomy has limited the development of ideal interface materials for electrocaloric systems.

Manufacturing scalability presents additional challenges. Advanced TIMs incorporating novel materials like graphene, carbon nanotubes, or metal-matrix composites demonstrate promising thermal properties in laboratory settings but face significant barriers to cost-effective mass production. Current manufacturing techniques struggle to maintain consistent material properties and performance at scale.

Environmental and regulatory concerns further complicate TIM development. Traditional high-performance TIMs often contain environmentally problematic components such as gallium-based liquid metals or materials with high embodied carbon. As regulatory frameworks evolve, developing sustainable alternatives that maintain performance becomes increasingly important.

The integration of TIMs into complex electrocaloric system architectures introduces additional design constraints. Interface materials must be compatible with system components, maintain performance under various operating conditions, and ideally contribute to system-level thermal management strategies rather than functioning as isolated components.

The thermal contact resistance at material interfaces presents a fundamental challenge, with microscopic air gaps forming between imperfect surface contacts. These gaps significantly impede heat transfer, reducing overall system efficiency. Even high-performance commercial TIMs typically achieve thermal conductivities of only 3-8 W/m·K, far below what is theoretically optimal for electrocaloric applications that require values exceeding 15 W/m·K for maximum efficiency.

Durability under thermal cycling represents another major hurdle. Electrocaloric cooling systems operate with rapid temperature fluctuations, causing differential thermal expansion that leads to mechanical stress at interfaces. Current TIMs experience performance degradation over time, with studies showing up to 30% reduction in thermal conductivity after just 500 thermal cycles in demanding applications.

The trade-off between thermal conductivity and mechanical compliance remains unresolved. Rigid materials with high thermal conductivity fail to conform to surface irregularities, while compliant materials with good surface contact typically exhibit poor thermal performance. This fundamental dichotomy has limited the development of ideal interface materials for electrocaloric systems.

Manufacturing scalability presents additional challenges. Advanced TIMs incorporating novel materials like graphene, carbon nanotubes, or metal-matrix composites demonstrate promising thermal properties in laboratory settings but face significant barriers to cost-effective mass production. Current manufacturing techniques struggle to maintain consistent material properties and performance at scale.

Environmental and regulatory concerns further complicate TIM development. Traditional high-performance TIMs often contain environmentally problematic components such as gallium-based liquid metals or materials with high embodied carbon. As regulatory frameworks evolve, developing sustainable alternatives that maintain performance becomes increasingly important.

The integration of TIMs into complex electrocaloric system architectures introduces additional design constraints. Interface materials must be compatible with system components, maintain performance under various operating conditions, and ideally contribute to system-level thermal management strategies rather than functioning as isolated components.

Current Thermal Interface Solutions for EC Systems

01 Advanced thermal interface materials

Advanced thermal interface materials are designed to enhance heat transfer between components in electronic devices. These materials include high-conductivity compounds, phase change materials, and composite structures that minimize thermal resistance at contact points. By improving thermal conductivity and ensuring better surface contact, these interfaces significantly enhance overall thermal efficiency in electronic systems and power devices.- Advanced thermal interface materials: Advanced thermal interface materials are designed to enhance heat transfer between components in electronic devices. These materials include high-conductivity compounds, phase change materials, and composite structures that minimize thermal resistance at contact points. By improving thermal conductivity and ensuring better surface contact, these interfaces significantly enhance overall thermal efficiency in electronic systems and power devices.

- Liquid cooling systems for thermal management: Liquid cooling systems provide superior thermal management for high-power electronic components. These systems utilize coolants that circulate through channels or heat exchangers to absorb and dissipate heat more efficiently than air cooling. Innovations in this area include microchannel designs, two-phase cooling techniques, and specialized coolant formulations that maximize heat transfer capacity while maintaining system reliability.

- Heat sink design optimization: Optimized heat sink designs enhance thermal efficiency through improved geometry, material selection, and surface treatments. Innovations include fin structures that maximize surface area, airflow patterns that reduce thermal resistance, and composite materials that balance weight with thermal conductivity. Advanced manufacturing techniques enable complex geometries that were previously impossible, resulting in heat sinks that provide superior thermal performance in compact spaces.

- Thermal management for semiconductor devices: Specialized thermal management solutions for semiconductor devices address the unique challenges of high-power density electronics. These include integrated cooling structures, on-chip thermal regulation, and advanced packaging techniques that minimize thermal resistance. By managing heat directly at the semiconductor level, these approaches prevent hotspots, improve device reliability, and enable higher performance operation without thermal throttling.

- Energy-efficient thermal management systems: Energy-efficient thermal management systems focus on optimizing overall system efficiency by reducing power consumption while maintaining effective cooling. These systems incorporate smart thermal control algorithms, variable cooling capacity based on load, and waste heat recovery mechanisms. By dynamically adjusting cooling parameters and utilizing passive cooling techniques where possible, these systems achieve the required thermal performance with minimal energy input.

02 Liquid cooling systems for thermal management

Liquid cooling systems offer superior thermal efficiency compared to traditional air cooling methods. These systems utilize coolants that circulate through heat exchangers to absorb and dissipate heat from high-power components. The implementation includes microchannels, cold plates, and specialized flow designs that optimize heat transfer rates while maintaining compact form factors, making them ideal for high-performance computing and power electronics applications.Expand Specific Solutions03 Thermal management in semiconductor packaging

Semiconductor packaging technologies incorporate specialized thermal management interfaces to address heat dissipation challenges. These include integrated heat spreaders, thermal vias, and embedded cooling solutions that efficiently transfer heat away from semiconductor dies. Advanced packaging designs focus on minimizing thermal resistance pathways and optimizing material selection to enhance thermal efficiency while maintaining electrical performance and reliability.Expand Specific Solutions04 Energy-efficient thermal management control systems

Intelligent control systems optimize thermal management by dynamically adjusting cooling parameters based on real-time temperature monitoring. These systems incorporate sensors, microcontrollers, and adaptive algorithms that balance cooling performance with energy consumption. By implementing predictive thermal modeling and variable cooling strategies, these control systems maximize thermal efficiency while minimizing power usage in various electronic and industrial applications.Expand Specific Solutions05 Novel materials for enhanced thermal conductivity

Research into novel materials has yielded significant improvements in thermal interface performance. These materials include graphene-based composites, carbon nanotubes, metal-matrix composites, and engineered polymers with enhanced thermal properties. By manipulating material structures at the nano and micro scales, these innovations achieve superior thermal conductivity while addressing challenges related to mechanical compliance, long-term reliability, and manufacturing scalability.Expand Specific Solutions

Leading Companies in Electrocaloric Cooling Industry

The electrocaloric cooling systems market is currently in an early growth phase, with increasing interest driven by demands for more efficient thermal management solutions. The global market size is projected to expand significantly as energy efficiency regulations tighten worldwide. Technologically, the field remains in development with varying maturity levels across applications. Leading players include Gentherm, which leverages its automotive thermal management expertise; Laird Technologies, specializing in thermal interface materials; and Phononic, pioneering solid-state cooling technologies. Traditional thermal management companies like Parker-Hannifin and Henkel are expanding their portfolios, while technology giants such as IBM and Microsoft are exploring applications for data centers. Automotive manufacturers including Ford, Jaguar Land Rover, and Geely are investigating electrocaloric solutions for electric vehicle thermal management, indicating cross-industry adoption potential.

Gentherm, Inc.

Technical Solution: Gentherm has pioneered advanced thermal management interfaces for electrocaloric cooling systems through their Climate Control Seat (CCS) technology. Their approach integrates specialized thermal interface materials with proprietary heat distribution networks to maximize the efficiency of electrocaloric cooling elements. Gentherm's solution features multi-layer composite interfaces that optimize thermal conductivity while minimizing electrical resistance, crucial for electrocaloric material performance. The company has developed patented microstructured interface designs that increase contact surface area by up to 300% compared to conventional flat interfaces, significantly enhancing heat transfer rates. Their thermal management systems incorporate phase-change materials at critical junction points to buffer temperature fluctuations and maintain consistent cooling performance. Gentherm's interfaces are specifically engineered to accommodate the unique thermal expansion characteristics of electrocaloric materials during operation cycles.

Strengths: Extensive automotive industry experience provides practical implementation knowledge, highly optimized for human comfort applications, and proven durability in harsh operating environments. Weaknesses: Solutions primarily focused on relatively low-power applications like seat cooling rather than high-capacity industrial cooling systems.

Laird Technologies, Inc.

Technical Solution: Laird Technologies has developed specialized thermal management interfaces for electrocaloric cooling systems that focus on maximizing thermal conductivity while maintaining electrical isolation. Their solution incorporates advanced ceramic-polymer composite materials with tailored thermal expansion coefficients to match electrocaloric elements, reducing interface stress during thermal cycling. Laird's thermal interfaces feature precision-engineered microporous structures that optimize contact area while minimizing thermal resistance across junction points. The company has pioneered thin-film deposition techniques for creating ultra-thin (sub-10 micron) interface layers that significantly reduce thermal resistance compared to conventional bonding methods. Their thermal management systems include specialized heat spreading technologies that efficiently distribute thermal energy across the entire electrocaloric element surface, preventing hotspots and improving overall system efficiency. Laird has also developed automated manufacturing processes for consistent, high-quality interface application at commercial scales.

Strengths: Exceptional thermal conductivity (>20 W/m·K) while maintaining electrical isolation properties, highly customizable solutions for different electrocaloric material types, and established manufacturing capabilities for high-volume production. Weaknesses: Higher cost compared to conventional thermal interface materials and potential challenges with long-term reliability under extreme thermal cycling conditions.

Key Patents in Electrocaloric Interface Technology

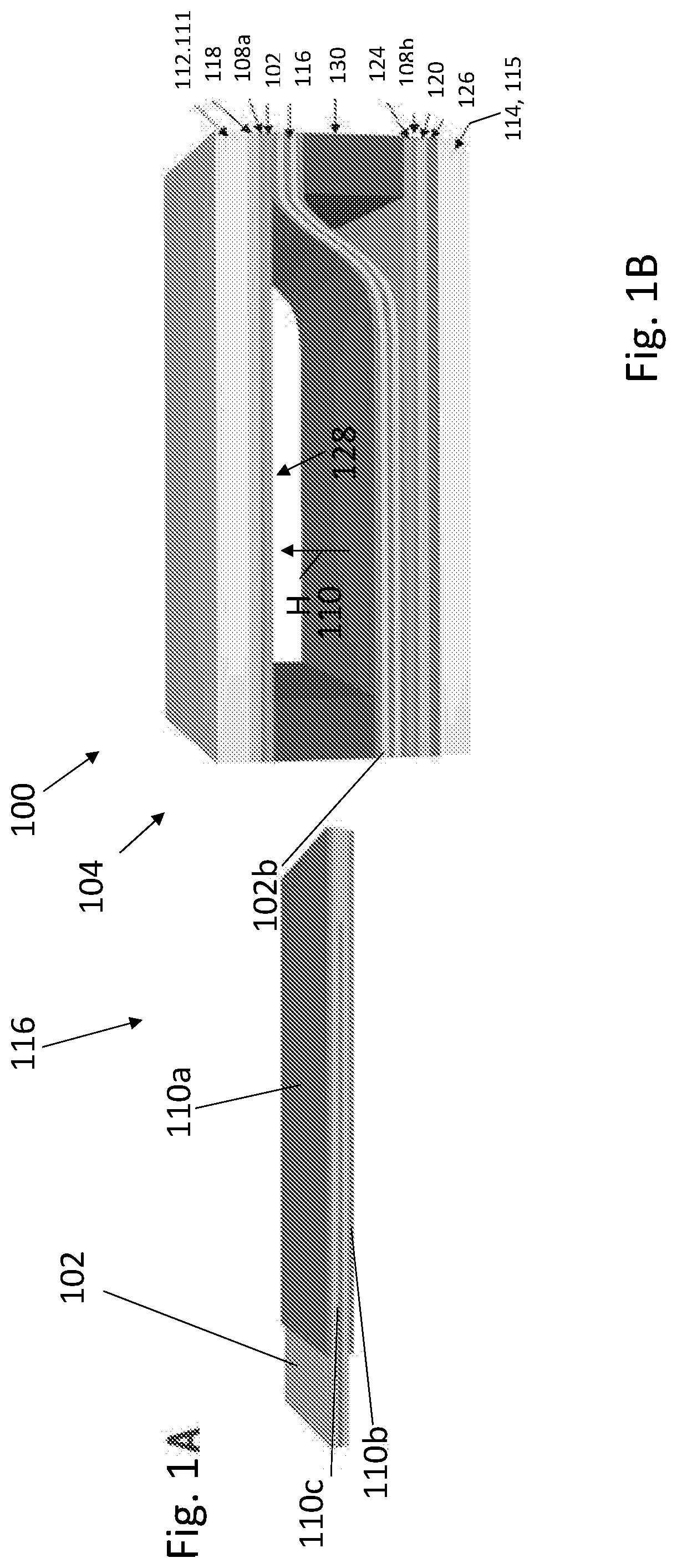

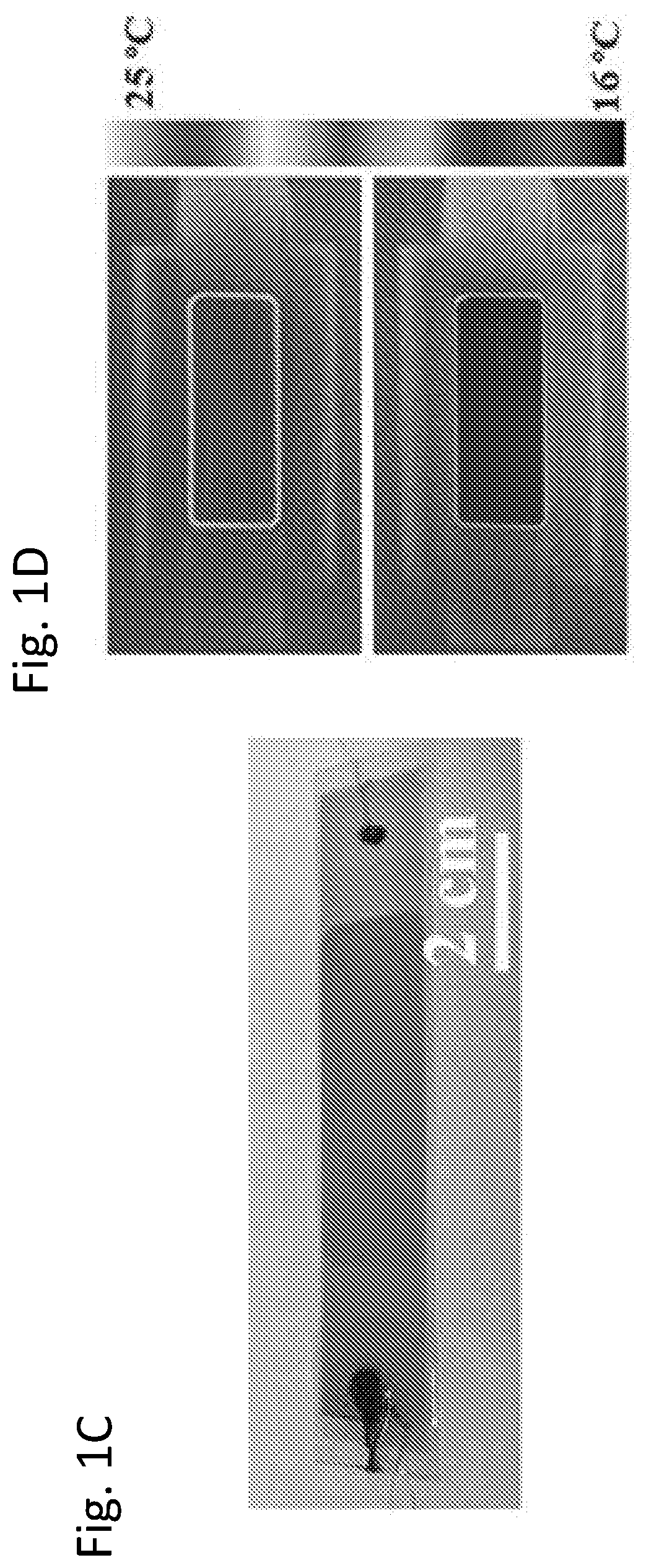

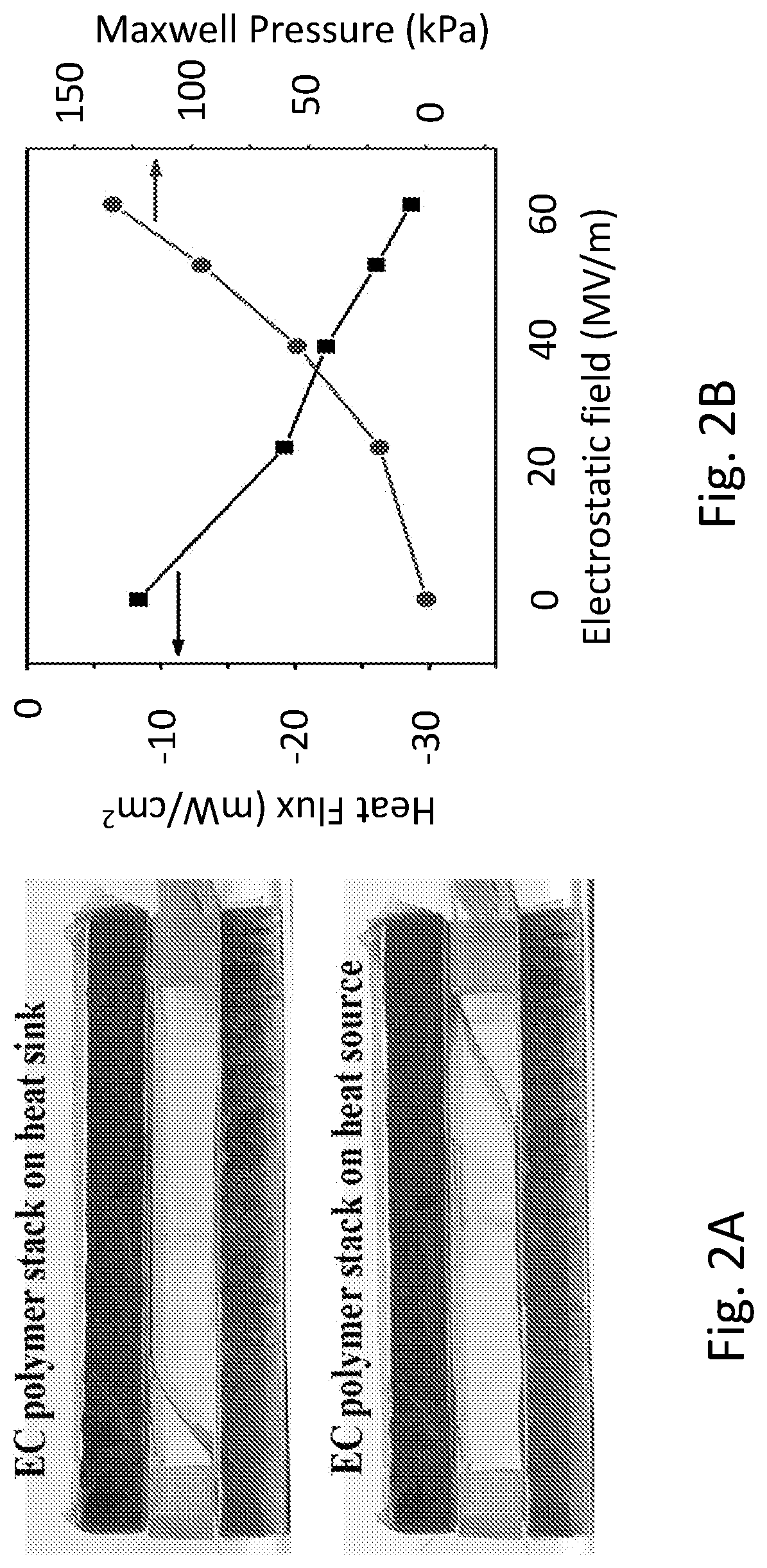

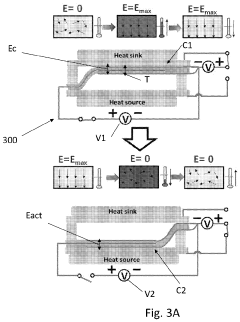

Electrocaloric cooling with electrostatic actuation

PatentWO2018208680A9

Innovation

- A solid-state heat transporting device utilizing a flexible electrocaloric polymer film coupled with an electrostatic actuation mechanism, allowing for controlled heat transfer by changing the shape or position of the film to form intimate thermal contacts with heat sources and sinks, thereby enhancing heat flux and reducing parasitic power consumption.

Electrocaloric cooling with electrostatic actuation

PatentActiveUS20210071917A1

Innovation

- A solid-state heat transporting device using a flexible electrocaloric polymer film coupled with an electrostatic actuation mechanism for controlled heat transfer, allowing for efficient heat absorption and release, and conformability to various surfaces, achieving high specific cooling power and COP.

Environmental Impact and Sustainability Factors

Electrocaloric cooling systems represent a promising alternative to conventional vapor-compression refrigeration technologies, offering potential advantages in energy efficiency and environmental impact. The thermal management interfaces in these systems play a crucial role not only in performance but also in determining their overall environmental footprint and sustainability profile.

The primary environmental benefit of electrocaloric cooling systems lies in their elimination of hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential (GWP). Traditional cooling systems rely on these compounds, which can have GWP values thousands of times greater than CO2. The solid-state nature of electrocaloric materials eliminates this source of emissions, potentially reducing direct greenhouse gas contributions from the cooling sector.

Material selection for thermal interfaces significantly impacts the sustainability profile of these systems. Current high-performance thermal interface materials often incorporate metals like indium, gallium, and rare earth elements that face supply constraints and have energy-intensive extraction processes. Life cycle assessments indicate that the environmental burden of these materials can offset some of the operational benefits if not carefully managed.

Manufacturing processes for specialized thermal interfaces typically require precision engineering and controlled environments, resulting in embodied energy that must be considered in sustainability evaluations. Advanced manufacturing techniques such as additive manufacturing may offer pathways to reduce material waste and energy consumption during production, though these approaches remain in developmental stages for high-performance thermal interfaces.

Durability and longevity of thermal interfaces directly affect system lifetime and replacement frequency. Thermal cycling in electrocaloric systems creates particular challenges for interface materials, as repeated expansion and contraction can lead to degradation over time. Innovations in self-healing interfaces and composite materials with enhanced fatigue resistance show promise for extending operational lifespans, thereby reducing waste generation and resource consumption associated with system replacement.

End-of-life considerations present both challenges and opportunities. Many current high-performance thermal interface materials contain components that are difficult to separate and recycle. Design for disassembly and material recovery should be prioritized in next-generation interface development. Biodegradable alternatives for certain interface components are emerging in research settings, though performance trade-offs currently limit their application in high-demand cooling scenarios.

Energy efficiency improvements enabled by optimized thermal interfaces translate directly to reduced operational carbon footprints. Analysis suggests that a 10% improvement in thermal interface conductivity can yield 3-7% overall system efficiency gains, depending on application parameters and operating conditions.

The primary environmental benefit of electrocaloric cooling systems lies in their elimination of hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential (GWP). Traditional cooling systems rely on these compounds, which can have GWP values thousands of times greater than CO2. The solid-state nature of electrocaloric materials eliminates this source of emissions, potentially reducing direct greenhouse gas contributions from the cooling sector.

Material selection for thermal interfaces significantly impacts the sustainability profile of these systems. Current high-performance thermal interface materials often incorporate metals like indium, gallium, and rare earth elements that face supply constraints and have energy-intensive extraction processes. Life cycle assessments indicate that the environmental burden of these materials can offset some of the operational benefits if not carefully managed.

Manufacturing processes for specialized thermal interfaces typically require precision engineering and controlled environments, resulting in embodied energy that must be considered in sustainability evaluations. Advanced manufacturing techniques such as additive manufacturing may offer pathways to reduce material waste and energy consumption during production, though these approaches remain in developmental stages for high-performance thermal interfaces.

Durability and longevity of thermal interfaces directly affect system lifetime and replacement frequency. Thermal cycling in electrocaloric systems creates particular challenges for interface materials, as repeated expansion and contraction can lead to degradation over time. Innovations in self-healing interfaces and composite materials with enhanced fatigue resistance show promise for extending operational lifespans, thereby reducing waste generation and resource consumption associated with system replacement.

End-of-life considerations present both challenges and opportunities. Many current high-performance thermal interface materials contain components that are difficult to separate and recycle. Design for disassembly and material recovery should be prioritized in next-generation interface development. Biodegradable alternatives for certain interface components are emerging in research settings, though performance trade-offs currently limit their application in high-demand cooling scenarios.

Energy efficiency improvements enabled by optimized thermal interfaces translate directly to reduced operational carbon footprints. Analysis suggests that a 10% improvement in thermal interface conductivity can yield 3-7% overall system efficiency gains, depending on application parameters and operating conditions.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of thermal management interfaces for electrocaloric cooling systems presents significant challenges that must be addressed to enable widespread commercial adoption. Current production methods for high-performance thermal interfaces remain largely laboratory-focused, with limited throughput capabilities that restrict mass production potential. The transition from small-scale prototyping to industrial-scale manufacturing requires substantial process optimization and automation integration.

Material selection significantly impacts manufacturing costs, with specialized thermal interface materials often commanding premium prices. High-performance metallic interfaces utilizing copper or aluminum with engineered microstructures can cost 5-10 times more than conventional thermal pastes. Advanced composite interfaces incorporating graphene, carbon nanotubes, or phase change materials further escalate costs, though their superior thermal performance may justify the investment for high-value applications.

Production volume economics reveal promising cost reduction pathways. Analysis indicates that scaling production from laboratory quantities to industrial volumes could potentially reduce unit costs by 60-75% through economies of scale, process optimization, and supply chain integration. However, this requires significant initial capital investment in specialized equipment and production facilities, creating a barrier to market entry for smaller manufacturers.

Equipment requirements for precision manufacturing of thermal interfaces include high-precision deposition systems, controlled atmosphere processing chambers, and advanced quality control instrumentation. The estimated capital expenditure for a medium-scale production line ranges from $2-5 million, with additional costs for facility modifications and environmental controls.

Labor costs vary significantly based on manufacturing location and automation level. Highly automated production lines reduce direct labor costs but require skilled technicians for maintenance and operation. Current estimates suggest labor represents 15-25% of total production costs in semi-automated facilities, decreasing to 5-10% in fully automated operations.

Supply chain considerations reveal potential bottlenecks in sourcing specialized materials and components. The limited number of suppliers for high-performance thermal interface materials creates pricing vulnerabilities and potential delivery delays. Developing alternative material sources and standardizing component specifications would enhance manufacturing resilience and cost stability.

Emerging manufacturing technologies, including additive manufacturing and roll-to-roll processing, show promise for reducing production costs while enhancing design flexibility. These approaches could potentially reduce material waste by 30-40% compared to traditional subtractive manufacturing methods, though they require further development to match the thermal performance of conventional techniques.

Material selection significantly impacts manufacturing costs, with specialized thermal interface materials often commanding premium prices. High-performance metallic interfaces utilizing copper or aluminum with engineered microstructures can cost 5-10 times more than conventional thermal pastes. Advanced composite interfaces incorporating graphene, carbon nanotubes, or phase change materials further escalate costs, though their superior thermal performance may justify the investment for high-value applications.

Production volume economics reveal promising cost reduction pathways. Analysis indicates that scaling production from laboratory quantities to industrial volumes could potentially reduce unit costs by 60-75% through economies of scale, process optimization, and supply chain integration. However, this requires significant initial capital investment in specialized equipment and production facilities, creating a barrier to market entry for smaller manufacturers.

Equipment requirements for precision manufacturing of thermal interfaces include high-precision deposition systems, controlled atmosphere processing chambers, and advanced quality control instrumentation. The estimated capital expenditure for a medium-scale production line ranges from $2-5 million, with additional costs for facility modifications and environmental controls.

Labor costs vary significantly based on manufacturing location and automation level. Highly automated production lines reduce direct labor costs but require skilled technicians for maintenance and operation. Current estimates suggest labor represents 15-25% of total production costs in semi-automated facilities, decreasing to 5-10% in fully automated operations.

Supply chain considerations reveal potential bottlenecks in sourcing specialized materials and components. The limited number of suppliers for high-performance thermal interface materials creates pricing vulnerabilities and potential delivery delays. Developing alternative material sources and standardizing component specifications would enhance manufacturing resilience and cost stability.

Emerging manufacturing technologies, including additive manufacturing and roll-to-roll processing, show promise for reducing production costs while enhancing design flexibility. These approaches could potentially reduce material waste by 30-40% compared to traditional subtractive manufacturing methods, though they require further development to match the thermal performance of conventional techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!