Design For Manufacturability In Electrocaloric Cooling Device Production

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

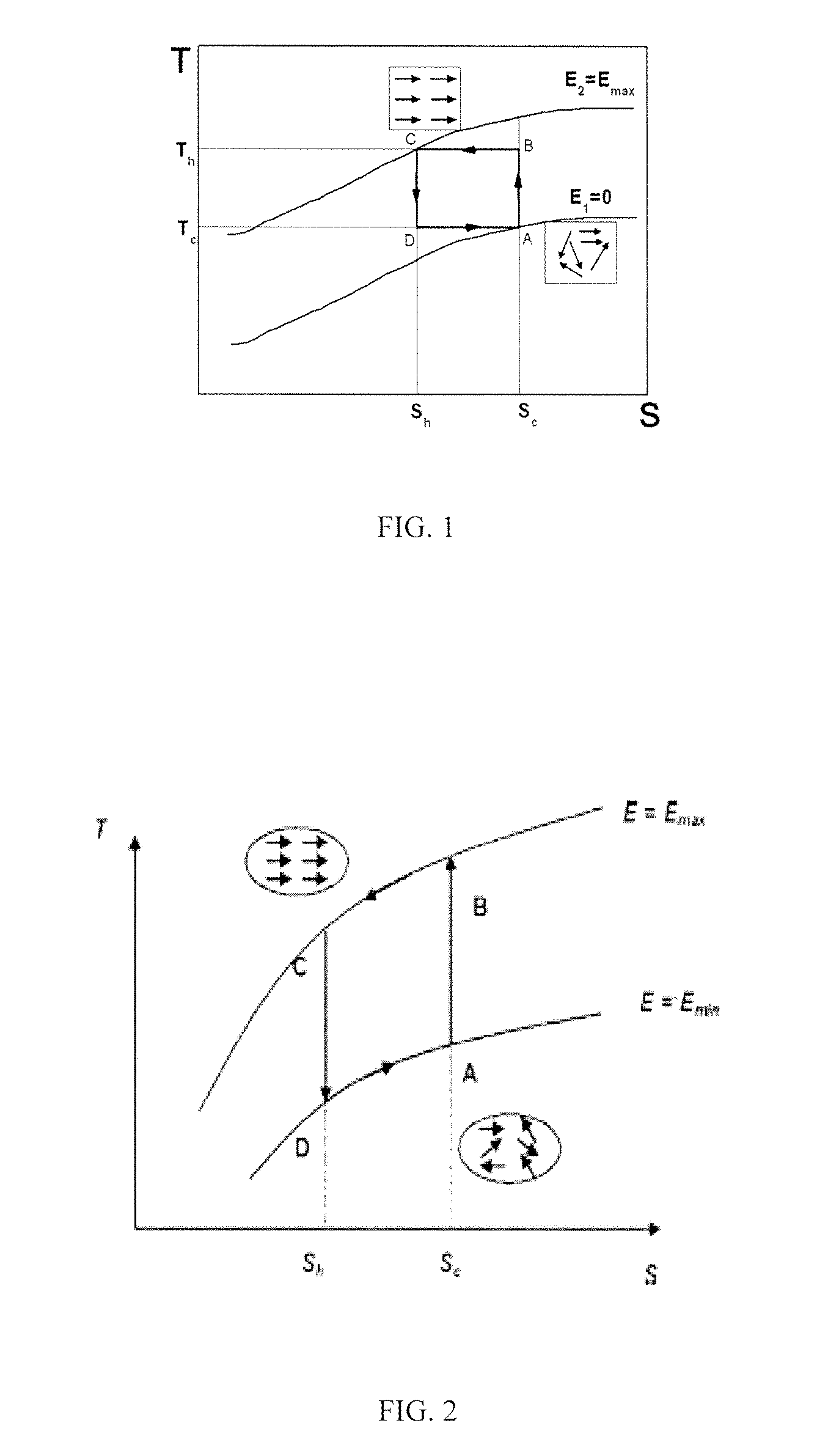

Electrocaloric cooling technology represents a significant advancement in the field of thermal management systems, emerging as a promising alternative to conventional vapor-compression refrigeration. This technology harnesses the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. The development of electrocaloric cooling dates back to the 1930s when the effect was first discovered, but significant research momentum has only built up in the past two decades due to advancements in material science and manufacturing capabilities.

The evolution of electrocaloric cooling technology has been marked by several key breakthroughs, particularly in material development. Early research focused primarily on ferroelectric ceramics, while recent innovations have expanded to include polymer-based electrocaloric materials and multilayer composites that demonstrate enhanced cooling performance. The technological trajectory indicates a steady improvement in cooling efficiency, with recent developments achieving temperature changes of several degrees Kelvin under practical electric field strengths.

Current research objectives in electrocaloric cooling technology center on addressing the manufacturability challenges that have hindered widespread commercial adoption. These objectives include developing scalable production methods for electrocaloric materials, designing efficient heat transfer mechanisms, and creating integrated cooling systems that can operate reliably under various conditions. Additionally, there is a focused effort to reduce production costs while maintaining performance standards to make these devices commercially viable.

The technical goals for electrocaloric cooling device production encompass several dimensions. First, enhancing the electrocaloric effect magnitude through material optimization and novel composite structures. Second, improving the thermal cycling frequency to increase cooling power density. Third, developing manufacturing processes that enable mass production while maintaining precise material properties and device geometries. Fourth, integrating these devices into practical cooling systems that can compete with conventional technologies in terms of efficiency, reliability, and cost.

Looking forward, the technology roadmap for electrocaloric cooling includes achieving higher temperature differentials, reducing operational voltage requirements, and extending device lifespan. Research is increasingly focused on developing environmentally friendly cooling solutions that eliminate the need for harmful refrigerants, aligning with global sustainability initiatives. The ultimate objective is to establish electrocaloric cooling as a viable, energy-efficient alternative to conventional cooling technologies across various applications, from consumer electronics to industrial refrigeration systems.

The evolution of electrocaloric cooling technology has been marked by several key breakthroughs, particularly in material development. Early research focused primarily on ferroelectric ceramics, while recent innovations have expanded to include polymer-based electrocaloric materials and multilayer composites that demonstrate enhanced cooling performance. The technological trajectory indicates a steady improvement in cooling efficiency, with recent developments achieving temperature changes of several degrees Kelvin under practical electric field strengths.

Current research objectives in electrocaloric cooling technology center on addressing the manufacturability challenges that have hindered widespread commercial adoption. These objectives include developing scalable production methods for electrocaloric materials, designing efficient heat transfer mechanisms, and creating integrated cooling systems that can operate reliably under various conditions. Additionally, there is a focused effort to reduce production costs while maintaining performance standards to make these devices commercially viable.

The technical goals for electrocaloric cooling device production encompass several dimensions. First, enhancing the electrocaloric effect magnitude through material optimization and novel composite structures. Second, improving the thermal cycling frequency to increase cooling power density. Third, developing manufacturing processes that enable mass production while maintaining precise material properties and device geometries. Fourth, integrating these devices into practical cooling systems that can compete with conventional technologies in terms of efficiency, reliability, and cost.

Looking forward, the technology roadmap for electrocaloric cooling includes achieving higher temperature differentials, reducing operational voltage requirements, and extending device lifespan. Research is increasingly focused on developing environmentally friendly cooling solutions that eliminate the need for harmful refrigerants, aligning with global sustainability initiatives. The ultimate objective is to establish electrocaloric cooling as a viable, energy-efficient alternative to conventional cooling technologies across various applications, from consumer electronics to industrial refrigeration systems.

Market Analysis for Electrocaloric Cooling Solutions

The global market for cooling technologies is experiencing significant transformation, driven by increasing environmental concerns and regulatory pressures on conventional vapor-compression cooling systems. Electrocaloric cooling technology represents an emerging alternative with substantial market potential, particularly as energy efficiency standards become more stringent worldwide. Current market projections indicate the alternative cooling technologies sector could reach $20 billion by 2030, with electrocaloric solutions potentially capturing 15-20% of this growing segment.

Consumer electronics represents the most promising initial market for electrocaloric cooling solutions, with particular applications in thermal management for high-performance computing devices, smartphones, and wearable technology. This segment values the compact form factor and potential noise reduction benefits that electrocaloric systems offer compared to conventional cooling methods.

The commercial refrigeration sector presents another substantial opportunity, especially as businesses face increasing pressure to reduce their environmental footprint. Market research indicates that approximately 30% of commercial refrigeration operators are actively seeking alternative cooling technologies that can reduce energy consumption while maintaining performance standards.

HVAC applications represent the largest potential market by volume, though adoption timelines may be longer due to established infrastructure and higher reliability requirements. Early adoption is expected in premium residential and specialized commercial applications where energy efficiency and environmental considerations command price premiums.

Competitive analysis reveals that the market currently lacks dominant players specifically in electrocaloric cooling, creating an opportunity for first-mover advantage. Several startups and research institutions have demonstrated promising prototypes, but few have achieved commercial-scale manufacturing capabilities. This manufacturing gap represents both a challenge and an opportunity for organizations with strong production expertise.

Regional market analysis shows North America and Europe leading in terms of research investment and potential early adoption, driven by stricter environmental regulations and higher consumer willingness to pay for sustainable technologies. The Asia-Pacific region, particularly China and South Korea, demonstrates rapidly growing interest, supported by government initiatives promoting green technology development.

Market barriers include current production costs that exceed conventional cooling technologies by approximately 2.5-3 times, though this gap is expected to narrow with manufacturing scale and material innovations. Consumer awareness remains limited, necessitating educational marketing approaches to communicate the long-term economic and environmental benefits of electrocaloric cooling solutions.

The market timing appears favorable for strategic investment in manufacturing capabilities, as technological readiness coincides with increasing regulatory pressure on conventional cooling technologies containing high-GWP refrigerants. Organizations that can solve the design for manufacturability challenges in electrocaloric cooling devices are positioned to capture significant market share in this emerging field.

Consumer electronics represents the most promising initial market for electrocaloric cooling solutions, with particular applications in thermal management for high-performance computing devices, smartphones, and wearable technology. This segment values the compact form factor and potential noise reduction benefits that electrocaloric systems offer compared to conventional cooling methods.

The commercial refrigeration sector presents another substantial opportunity, especially as businesses face increasing pressure to reduce their environmental footprint. Market research indicates that approximately 30% of commercial refrigeration operators are actively seeking alternative cooling technologies that can reduce energy consumption while maintaining performance standards.

HVAC applications represent the largest potential market by volume, though adoption timelines may be longer due to established infrastructure and higher reliability requirements. Early adoption is expected in premium residential and specialized commercial applications where energy efficiency and environmental considerations command price premiums.

Competitive analysis reveals that the market currently lacks dominant players specifically in electrocaloric cooling, creating an opportunity for first-mover advantage. Several startups and research institutions have demonstrated promising prototypes, but few have achieved commercial-scale manufacturing capabilities. This manufacturing gap represents both a challenge and an opportunity for organizations with strong production expertise.

Regional market analysis shows North America and Europe leading in terms of research investment and potential early adoption, driven by stricter environmental regulations and higher consumer willingness to pay for sustainable technologies. The Asia-Pacific region, particularly China and South Korea, demonstrates rapidly growing interest, supported by government initiatives promoting green technology development.

Market barriers include current production costs that exceed conventional cooling technologies by approximately 2.5-3 times, though this gap is expected to narrow with manufacturing scale and material innovations. Consumer awareness remains limited, necessitating educational marketing approaches to communicate the long-term economic and environmental benefits of electrocaloric cooling solutions.

The market timing appears favorable for strategic investment in manufacturing capabilities, as technological readiness coincides with increasing regulatory pressure on conventional cooling technologies containing high-GWP refrigerants. Organizations that can solve the design for manufacturability challenges in electrocaloric cooling devices are positioned to capture significant market share in this emerging field.

Manufacturing Challenges and Technical Constraints

The manufacturing of electrocaloric cooling devices presents significant technical challenges that must be addressed to achieve commercial viability. Current production methods face limitations in scaling from laboratory prototypes to mass production, primarily due to the complex integration of multiple material layers and components required for effective electrocaloric functionality.

Material processing represents a critical constraint, as electrocaloric materials—typically specialized ceramics or polymers—require precise composition control and uniform properties throughout the device. Manufacturing inconsistencies in material quality can lead to substantial variations in cooling performance, with studies showing up to 30% efficiency reduction from minor compositional deviations. Additionally, these materials often require specialized handling during production due to their sensitivity to environmental conditions.

Electrode deposition and patterning present another significant manufacturing hurdle. The electrodes must maintain excellent electrical contact with the electrocaloric material while withstanding repeated thermal cycling and high electric fields. Current deposition techniques struggle to achieve the necessary uniformity across large surface areas, limiting device size and cooling capacity. The interface between electrodes and active materials frequently develops defects during thermal cycling, leading to performance degradation over time.

Heat exchange system integration poses complex manufacturing challenges. Efficient heat transfer requires intimate thermal contact between the electrocaloric elements and heat exchange surfaces, yet maintaining electrical isolation simultaneously. Current manufacturing approaches often result in thermal interface resistances that significantly reduce overall system efficiency. Industry data indicates that thermal interface optimization could improve cooling efficiency by up to 40%.

Assembly and packaging processes face limitations in maintaining the precise alignment of multiple layers while ensuring robust electrical connections and thermal interfaces. The need for hermetic sealing to prevent moisture ingress—which can catastrophically degrade performance—adds another layer of manufacturing complexity. Current assembly techniques often rely on manual processes that are difficult to scale.

Quality control represents a substantial constraint, as detecting internal defects in assembled devices requires sophisticated non-destructive testing methods not yet optimized for high-volume production. The lack of standardized testing protocols for electrocaloric performance further complicates manufacturing process development and validation.

Cost considerations remain a significant barrier, with current manufacturing approaches requiring expensive materials and precision equipment. The complex multi-step production process results in high labor costs and yield issues. Analysis indicates that manufacturing costs need to decrease by approximately 60-70% to achieve price points competitive with conventional cooling technologies.

Material processing represents a critical constraint, as electrocaloric materials—typically specialized ceramics or polymers—require precise composition control and uniform properties throughout the device. Manufacturing inconsistencies in material quality can lead to substantial variations in cooling performance, with studies showing up to 30% efficiency reduction from minor compositional deviations. Additionally, these materials often require specialized handling during production due to their sensitivity to environmental conditions.

Electrode deposition and patterning present another significant manufacturing hurdle. The electrodes must maintain excellent electrical contact with the electrocaloric material while withstanding repeated thermal cycling and high electric fields. Current deposition techniques struggle to achieve the necessary uniformity across large surface areas, limiting device size and cooling capacity. The interface between electrodes and active materials frequently develops defects during thermal cycling, leading to performance degradation over time.

Heat exchange system integration poses complex manufacturing challenges. Efficient heat transfer requires intimate thermal contact between the electrocaloric elements and heat exchange surfaces, yet maintaining electrical isolation simultaneously. Current manufacturing approaches often result in thermal interface resistances that significantly reduce overall system efficiency. Industry data indicates that thermal interface optimization could improve cooling efficiency by up to 40%.

Assembly and packaging processes face limitations in maintaining the precise alignment of multiple layers while ensuring robust electrical connections and thermal interfaces. The need for hermetic sealing to prevent moisture ingress—which can catastrophically degrade performance—adds another layer of manufacturing complexity. Current assembly techniques often rely on manual processes that are difficult to scale.

Quality control represents a substantial constraint, as detecting internal defects in assembled devices requires sophisticated non-destructive testing methods not yet optimized for high-volume production. The lack of standardized testing protocols for electrocaloric performance further complicates manufacturing process development and validation.

Cost considerations remain a significant barrier, with current manufacturing approaches requiring expensive materials and precision equipment. The complex multi-step production process results in high labor costs and yield issues. Analysis indicates that manufacturing costs need to decrease by approximately 60-70% to achieve price points competitive with conventional cooling technologies.

Current DFM Approaches for Electrocaloric Devices

01 Material selection and fabrication for electrocaloric devices

The selection of appropriate electrocaloric materials and their fabrication methods are crucial for manufacturing efficient cooling devices. These materials, typically ferroelectric or relaxor ferroelectric polymers and ceramics, need to exhibit strong electrocaloric effects at operating temperatures. Advanced fabrication techniques such as thin film deposition, multilayer structures, and composite material formation can enhance the electrocaloric performance. Proper material processing ensures optimal thermal and electrical properties necessary for effective heat transfer in cooling applications.- Manufacturing techniques for electrocaloric cooling devices: Various manufacturing techniques are employed to produce electrocaloric cooling devices, including specialized fabrication methods for the active electrocaloric materials and their integration into functional cooling systems. These techniques focus on creating reliable interfaces between the electrocaloric materials and heat exchange components, ensuring proper electrical connections, and maintaining structural integrity during thermal cycling. Advanced manufacturing processes such as additive manufacturing, thin film deposition, and precision assembly are utilized to achieve the required dimensional tolerances and performance characteristics.

- Material selection and processing for electrocaloric elements: The selection and processing of materials for electrocaloric cooling devices significantly impacts their manufacturability and performance. Key considerations include the choice of electrocaloric materials with high temperature change coefficients, methods for enhancing their electrocaloric properties through doping or compositional engineering, and techniques for processing these materials into forms suitable for device integration. Materials must be processed to maintain their electrocaloric properties while being compatible with manufacturing processes and able to withstand operational stresses during thermal cycling and electric field application.

- Design considerations for scalable production: Designing electrocaloric cooling devices for scalable production involves considerations of component standardization, assembly simplification, and manufacturing process optimization. Effective designs incorporate features that facilitate automated assembly, minimize the number of components, and reduce manufacturing complexity. Considerations include the geometry of heat exchange surfaces, electrical connection methods, and thermal interface materials. Designs must balance performance requirements with manufacturing constraints to enable cost-effective mass production while maintaining cooling efficiency.

- System integration and assembly techniques: The integration and assembly of electrocaloric cooling systems present unique manufacturing challenges that must be addressed for commercial viability. These include methods for creating effective thermal interfaces between electrocaloric elements and heat exchangers, techniques for electrical connection and insulation, and approaches for fluid handling in active regenerative systems. Assembly techniques must ensure proper alignment of components, reliable electrical connections, and effective thermal pathways while maintaining manufacturing efficiency and product reliability.

- Quality control and testing methodologies: Quality control and testing methodologies are essential for ensuring the reliability and performance of manufactured electrocaloric cooling devices. These include techniques for measuring electrocaloric properties of materials, methods for evaluating thermal performance of assembled devices, and approaches for accelerated life testing. Testing protocols must verify electrical safety, thermal performance, and mechanical durability under various operating conditions. In-line inspection techniques and non-destructive testing methods are developed to identify manufacturing defects and ensure consistent product quality.

02 Heat transfer mechanisms and thermal management

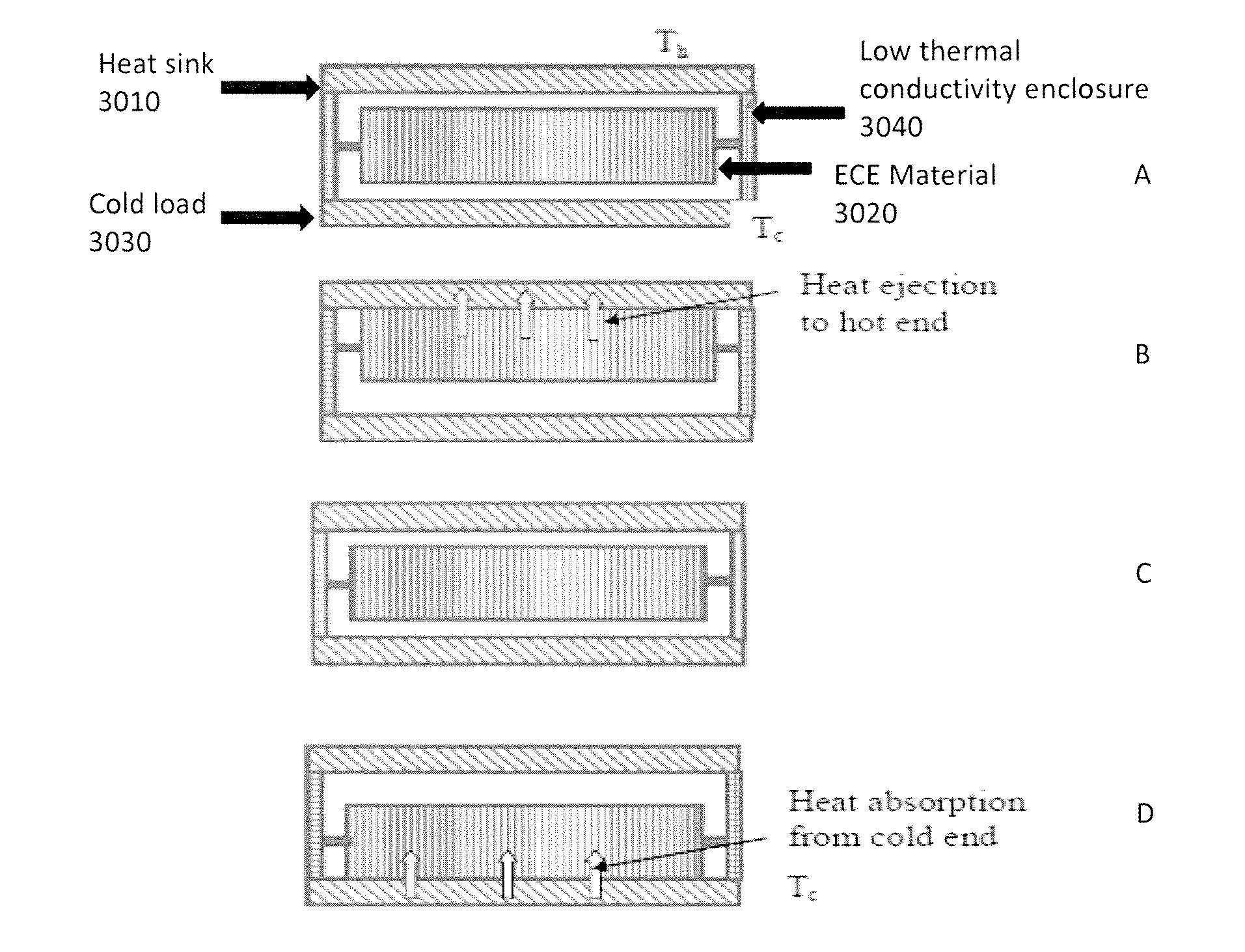

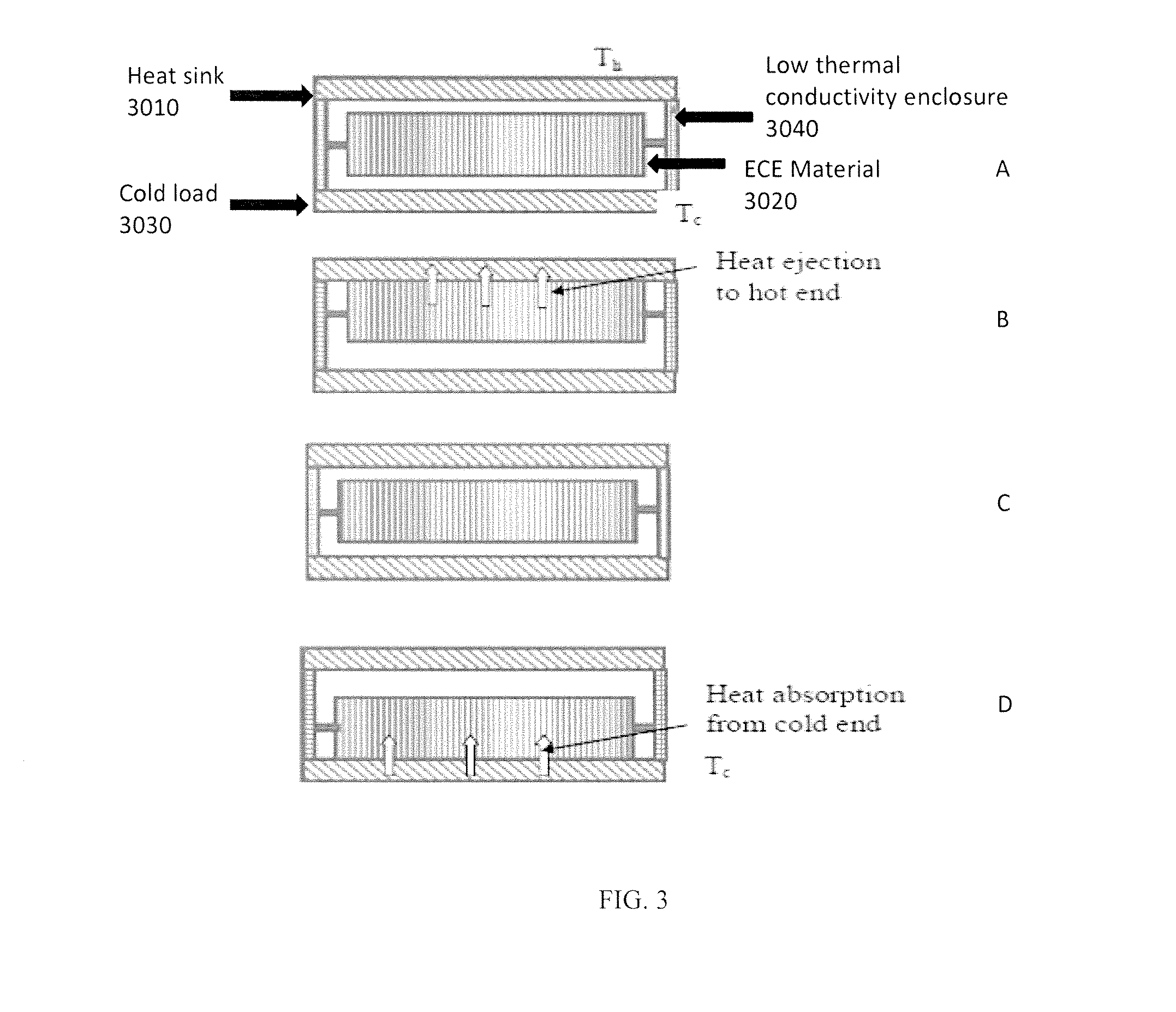

Effective heat transfer mechanisms are essential for electrocaloric cooling devices to function efficiently. This includes the design of heat exchangers, thermal switches, and fluid circulation systems that facilitate the movement of heat from the cold side to the hot side. Thermal management strategies involve optimizing the contact between the electrocaloric material and heat transfer surfaces, minimizing thermal resistance, and implementing efficient heat dissipation methods. These mechanisms directly impact the cooling capacity and coefficient of performance of the electrocaloric devices.Expand Specific Solutions03 Device architecture and system integration

The architecture of electrocaloric cooling devices encompasses the physical arrangement and integration of components into a functional system. This includes the design of electrode configurations, electrical connections, and mechanical support structures. System integration involves incorporating the electrocaloric elements into practical cooling applications, addressing issues such as size constraints, weight limitations, and compatibility with existing systems. Advanced architectures may include cascaded designs, regenerative cycles, or hybrid systems that combine electrocaloric cooling with other technologies to enhance overall performance.Expand Specific Solutions04 Manufacturing processes and scalability

Manufacturing processes for electrocaloric cooling devices must address challenges related to mass production, cost-effectiveness, and quality control. These processes include techniques for material synthesis, component fabrication, assembly, and testing. Scalability considerations involve adapting laboratory-scale fabrication methods to industrial production while maintaining performance characteristics. Advanced manufacturing approaches such as additive manufacturing, roll-to-roll processing, and automated assembly can improve production efficiency and reduce costs, making electrocaloric cooling technology more commercially viable.Expand Specific Solutions05 Control systems and operational efficiency

Control systems for electrocaloric cooling devices manage the application of electric fields, timing of thermal cycles, and overall system operation to maximize cooling efficiency. These systems include sensors, power electronics, and control algorithms that optimize the electrocaloric effect under varying conditions. Operational efficiency improvements focus on reducing energy consumption, minimizing losses, and extending device lifespan. Advanced control strategies may incorporate adaptive algorithms, predictive modeling, or integration with smart building systems to enhance performance in real-world applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Electrocaloric cooling device production is currently in an early growth phase, with the market expected to expand significantly as manufacturers overcome design for manufacturability (DFM) challenges. The global market remains relatively small but shows promising growth potential due to increasing demand for energy-efficient cooling solutions. From a technical maturity perspective, companies like Siemens AG, Robert Bosch GmbH, and Carrier Corp. are leading development efforts, focusing on scalable production techniques and material optimization. General Electric Company and Mitsubishi Materials Corp. are advancing component miniaturization, while automotive manufacturers including Volkswagen AG, BMW, and Mercedes-Benz are exploring applications for vehicle thermal management systems. The technology is transitioning from research to commercialization, with key challenges in materials processing, assembly automation, and quality control being addressed through collaborative industry-academic partnerships.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced manufacturing approach for electrocaloric cooling devices that integrates multilayer ceramic capacitors (MLCCs) with specialized heat exchange systems. Their process utilizes precision automated assembly lines with in-line quality control monitoring to ensure consistent production of high-performance electrocaloric elements. The company employs a proprietary sintering technique that optimizes the grain structure of electrocaloric materials, enhancing their cooling efficiency while maintaining mechanical stability. Bosch's manufacturing system incorporates adaptive thermal management during production to minimize internal stresses in the ceramic materials, resulting in devices with longer operational lifetimes and more reliable performance under thermal cycling conditions. Their DFM approach includes modular design principles that allow for scalable production volumes while maintaining tight tolerances across critical components.

Strengths: Exceptional quality control systems and established global manufacturing infrastructure enable consistent high-volume production. Their extensive experience with automotive-grade reliability requirements translates well to electrocaloric cooling reliability. Weaknesses: Higher production costs compared to conventional cooling technologies may limit market penetration in price-sensitive segments.

Carrier Corp.

Technical Solution: Carrier has pioneered a manufacturing framework specifically for electrocaloric cooling systems that focuses on system integration and assembly optimization. Their approach incorporates specialized electrode deposition techniques that enhance the interface between the electrocaloric material and the electrical contacts, reducing contact resistance and improving overall system efficiency. Carrier's manufacturing process employs precision fluid channel fabrication methods that optimize heat transfer from the electrocaloric elements to the working fluid. The company has developed a modular assembly system that allows for rapid reconfiguration of production lines to accommodate different device geometries and cooling capacities. Their DFM strategy includes comprehensive thermal simulation during the design phase to identify potential manufacturing challenges before they reach production, significantly reducing development cycles and improving first-pass yield rates.

Strengths: Extensive experience in HVAC systems integration provides valuable insights for electrocaloric cooling device manufacturability and practical implementation. Their established distribution channels offer clear pathways to market. Weaknesses: Less experience with advanced ceramic materials manufacturing compared to some competitors may require additional partnerships or technology acquisition.

Critical Patents and Technical Literature Review

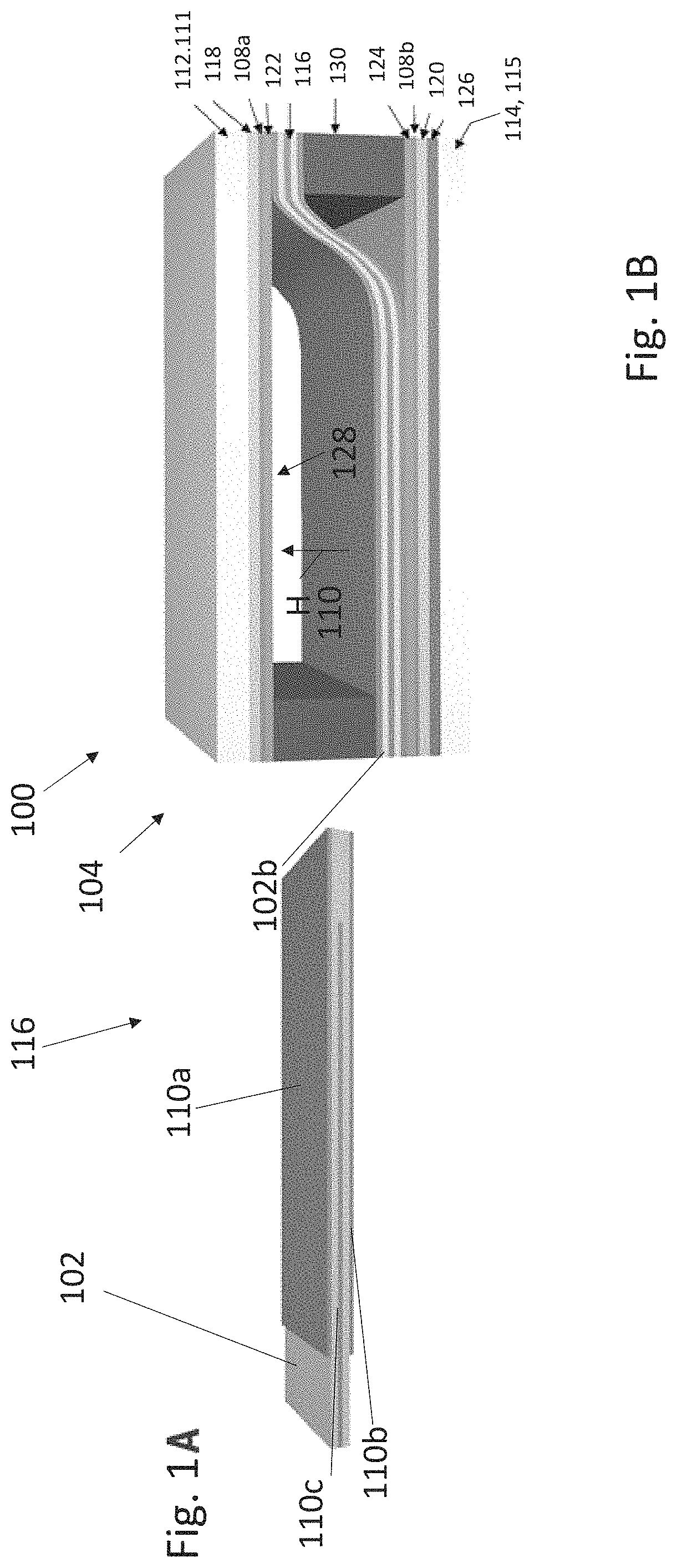

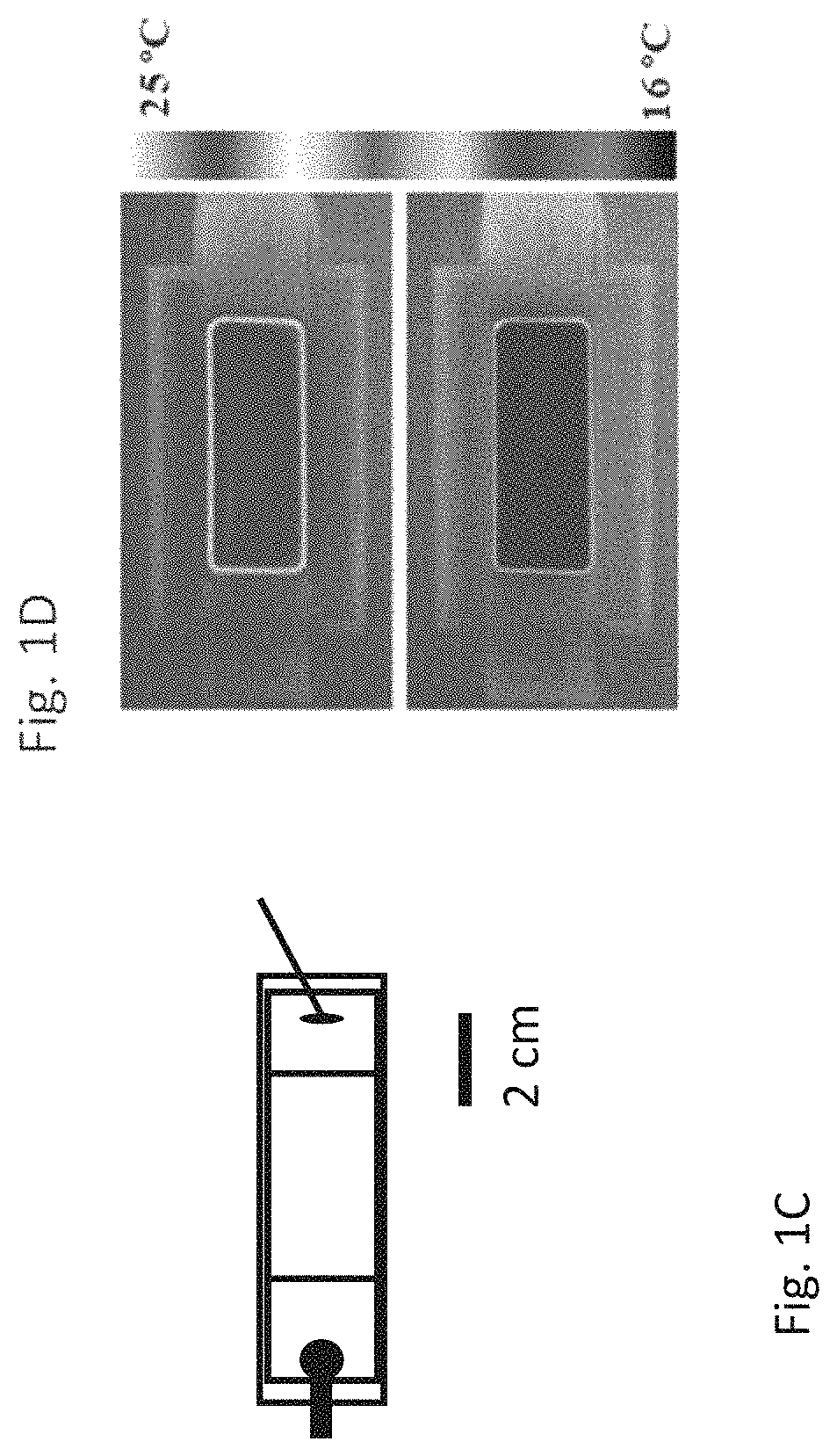

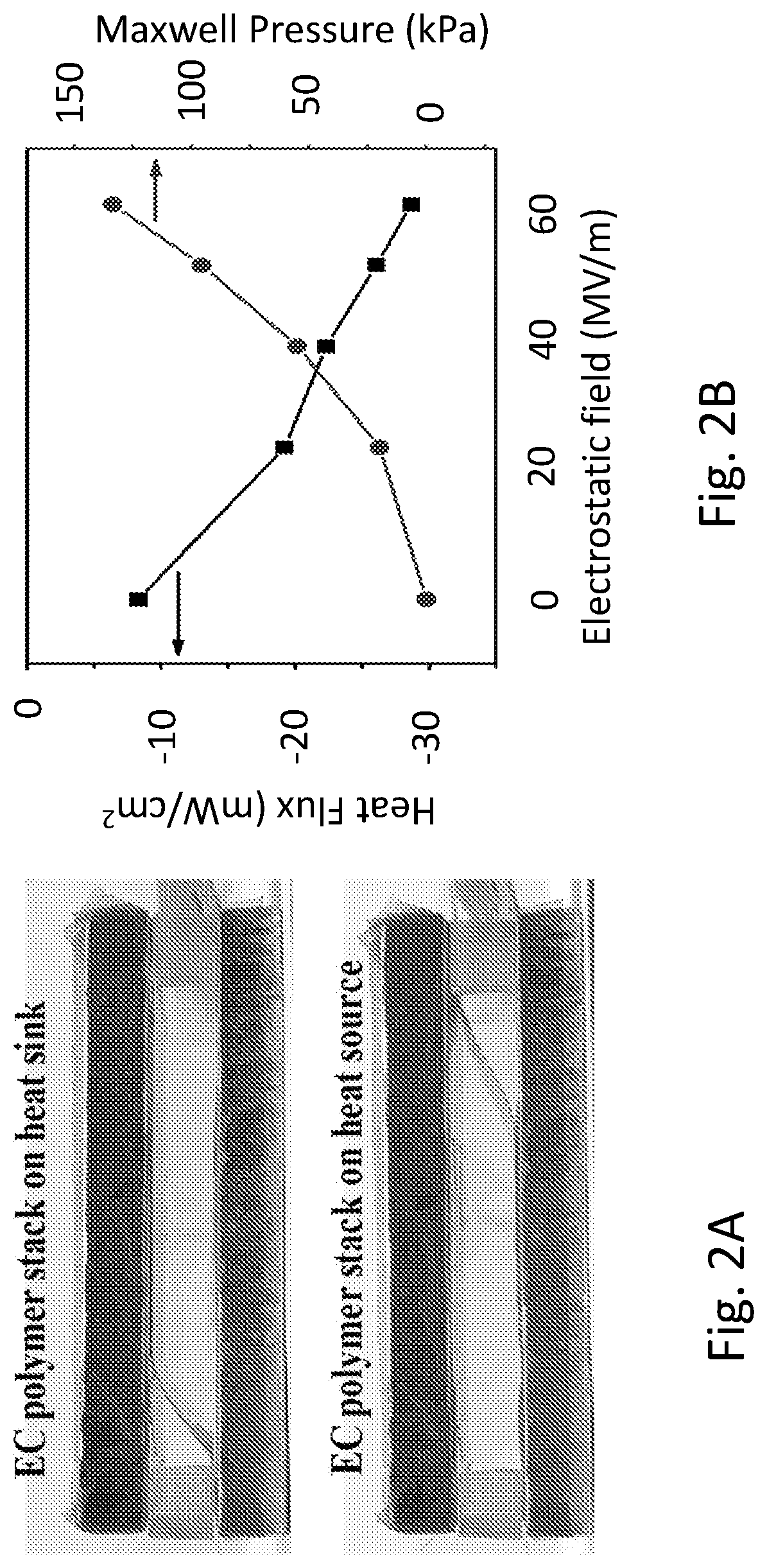

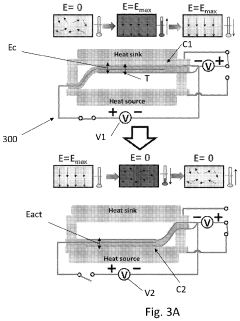

Electrocaloric cooling with electrostatic actuation

PatentActiveUS11397031B2

Innovation

- A solid-state heat transporting device utilizing a flexible electrocaloric polymer film coupled with an electrostatic actuation mechanism, allowing for controlled heat transfer between heat sources and sinks by altering the shape or position of the film to enhance thermal contact and reduce parasitic power consumption.

Cooling device including an electrocaloric composite

PatentInactiveUS20150027132A1

Innovation

- The use of high thermal conductivity electrocaloric composites, comprising electrocaloric polymers and electrically insulating fillers, which enhance thermal conductivity while maintaining the electrocaloric effect, allowing for improved cooling device performance and efficiency.

Supply Chain Optimization Strategies

The optimization of supply chain strategies for electrocaloric cooling device production requires a comprehensive approach that addresses the unique challenges of this emerging technology. Material sourcing represents a critical component, as specialized electrocaloric materials with precise compositions are essential for device performance. Establishing relationships with multiple qualified suppliers can mitigate supply risks while implementing just-in-time inventory systems specifically calibrated for these specialized materials helps reduce carrying costs without compromising production schedules.

Manufacturing process integration demands careful coordination between component production and assembly operations. The implementation of advanced manufacturing execution systems (MES) enables real-time tracking of components throughout the production cycle, facilitating prompt identification and resolution of bottlenecks. Cross-functional teams comprising supply chain specialists, manufacturing engineers, and quality control personnel should collaborate to streamline workflows and minimize production delays.

Quality control integration throughout the supply chain is paramount for electrocaloric cooling devices. Implementing supplier certification programs ensures incoming materials meet stringent specifications, while distributed quality checkpoints throughout the manufacturing process help identify defects early. This approach significantly reduces rework costs and enhances overall product reliability.

Logistics optimization presents unique challenges due to the sensitivity of certain electrocaloric materials. Temperature-controlled transportation may be necessary for specific components, requiring specialized logistics partners with experience in handling temperature-sensitive materials. Regional distribution centers strategically positioned near manufacturing facilities can reduce lead times and transportation costs while improving responsiveness to market demands.

Digital supply chain technologies offer substantial benefits for electrocaloric device production. Blockchain-based systems can enhance traceability of critical materials from source to final product, while AI-powered demand forecasting algorithms help optimize inventory levels and production scheduling. These technologies enable a more agile and responsive supply chain capable of adapting to market fluctuations and technological advancements in this rapidly evolving field.

Collaborative supplier relationships represent a strategic advantage in this specialized industry. Establishing joint development initiatives with key suppliers facilitates innovation in materials and components while creating mutual value. Early supplier involvement in design processes ensures manufacturability considerations are addressed proactively, reducing costly redesigns and accelerating time-to-market for new electrocaloric cooling solutions.

Manufacturing process integration demands careful coordination between component production and assembly operations. The implementation of advanced manufacturing execution systems (MES) enables real-time tracking of components throughout the production cycle, facilitating prompt identification and resolution of bottlenecks. Cross-functional teams comprising supply chain specialists, manufacturing engineers, and quality control personnel should collaborate to streamline workflows and minimize production delays.

Quality control integration throughout the supply chain is paramount for electrocaloric cooling devices. Implementing supplier certification programs ensures incoming materials meet stringent specifications, while distributed quality checkpoints throughout the manufacturing process help identify defects early. This approach significantly reduces rework costs and enhances overall product reliability.

Logistics optimization presents unique challenges due to the sensitivity of certain electrocaloric materials. Temperature-controlled transportation may be necessary for specific components, requiring specialized logistics partners with experience in handling temperature-sensitive materials. Regional distribution centers strategically positioned near manufacturing facilities can reduce lead times and transportation costs while improving responsiveness to market demands.

Digital supply chain technologies offer substantial benefits for electrocaloric device production. Blockchain-based systems can enhance traceability of critical materials from source to final product, while AI-powered demand forecasting algorithms help optimize inventory levels and production scheduling. These technologies enable a more agile and responsive supply chain capable of adapting to market fluctuations and technological advancements in this rapidly evolving field.

Collaborative supplier relationships represent a strategic advantage in this specialized industry. Establishing joint development initiatives with key suppliers facilitates innovation in materials and components while creating mutual value. Early supplier involvement in design processes ensures manufacturability considerations are addressed proactively, reducing costly redesigns and accelerating time-to-market for new electrocaloric cooling solutions.

Sustainability and Environmental Impact Assessment

The environmental impact of electrocaloric cooling technology represents a critical dimension in its development trajectory, particularly as global sustainability standards become increasingly stringent. Electrocaloric cooling devices offer significant environmental advantages over conventional vapor-compression refrigeration systems, primarily through the elimination of hydrofluorocarbons (HFCs) and other greenhouse gases commonly used as refrigerants. This fundamental shift in cooling technology could potentially reduce direct emissions associated with refrigerant leakage, which currently accounts for approximately 7-8% of global greenhouse gas emissions in the HVAC-R sector.

Manufacturing processes for electrocaloric devices must be evaluated through comprehensive life cycle assessment (LCA) methodologies. Initial analyses indicate that the production phase generates between 30-45% less carbon emissions compared to conventional cooling systems when optimized manufacturing protocols are implemented. However, challenges remain in the sourcing and processing of specialized materials, particularly rare earth elements and specialized ceramics that form the core of many electrocaloric materials.

Water consumption represents another significant environmental consideration, with electrocaloric device production potentially requiring 20-30% less process water than conventional cooling system manufacturing. This advantage stems primarily from the elimination of chemical cleaning processes associated with refrigerant handling systems and simplified assembly procedures. Implementation of closed-loop water recycling systems in manufacturing facilities could further reduce this environmental footprint by an additional 40-60%.

Energy efficiency during operation constitutes perhaps the most substantial environmental benefit of electrocaloric cooling technology. Current prototypes demonstrate potential energy savings of 20-30% compared to conventional vapor-compression systems, with theoretical models suggesting this gap could widen to 35-45% with further optimization. This operational efficiency translates directly to reduced indirect carbon emissions throughout the product lifecycle.

End-of-life considerations must be integrated into manufacturing design decisions from the outset. The complex material composition of electrocaloric devices presents both challenges and opportunities for recycling and material recovery. Design for disassembly principles, including modular construction and elimination of permanent adhesives, can increase material recovery rates from 30% to potentially 80-90%, significantly reducing waste stream impacts.

Regulatory compliance frameworks, including RoHS, REACH, and emerging circular economy directives, will increasingly influence manufacturing decisions. Forward-thinking manufacturers are already implementing design strategies that anticipate more stringent environmental regulations, including the phase-out of certain material combinations and increased producer responsibility for product lifecycle management.

Manufacturing processes for electrocaloric devices must be evaluated through comprehensive life cycle assessment (LCA) methodologies. Initial analyses indicate that the production phase generates between 30-45% less carbon emissions compared to conventional cooling systems when optimized manufacturing protocols are implemented. However, challenges remain in the sourcing and processing of specialized materials, particularly rare earth elements and specialized ceramics that form the core of many electrocaloric materials.

Water consumption represents another significant environmental consideration, with electrocaloric device production potentially requiring 20-30% less process water than conventional cooling system manufacturing. This advantage stems primarily from the elimination of chemical cleaning processes associated with refrigerant handling systems and simplified assembly procedures. Implementation of closed-loop water recycling systems in manufacturing facilities could further reduce this environmental footprint by an additional 40-60%.

Energy efficiency during operation constitutes perhaps the most substantial environmental benefit of electrocaloric cooling technology. Current prototypes demonstrate potential energy savings of 20-30% compared to conventional vapor-compression systems, with theoretical models suggesting this gap could widen to 35-45% with further optimization. This operational efficiency translates directly to reduced indirect carbon emissions throughout the product lifecycle.

End-of-life considerations must be integrated into manufacturing design decisions from the outset. The complex material composition of electrocaloric devices presents both challenges and opportunities for recycling and material recovery. Design for disassembly principles, including modular construction and elimination of permanent adhesives, can increase material recovery rates from 30% to potentially 80-90%, significantly reducing waste stream impacts.

Regulatory compliance frameworks, including RoHS, REACH, and emerging circular economy directives, will increasingly influence manufacturing decisions. Forward-thinking manufacturers are already implementing design strategies that anticipate more stringent environmental regulations, including the phase-out of certain material combinations and increased producer responsibility for product lifecycle management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!