High-Performance Electrocaloric Materials For Compact Electrocaloric Cooling

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

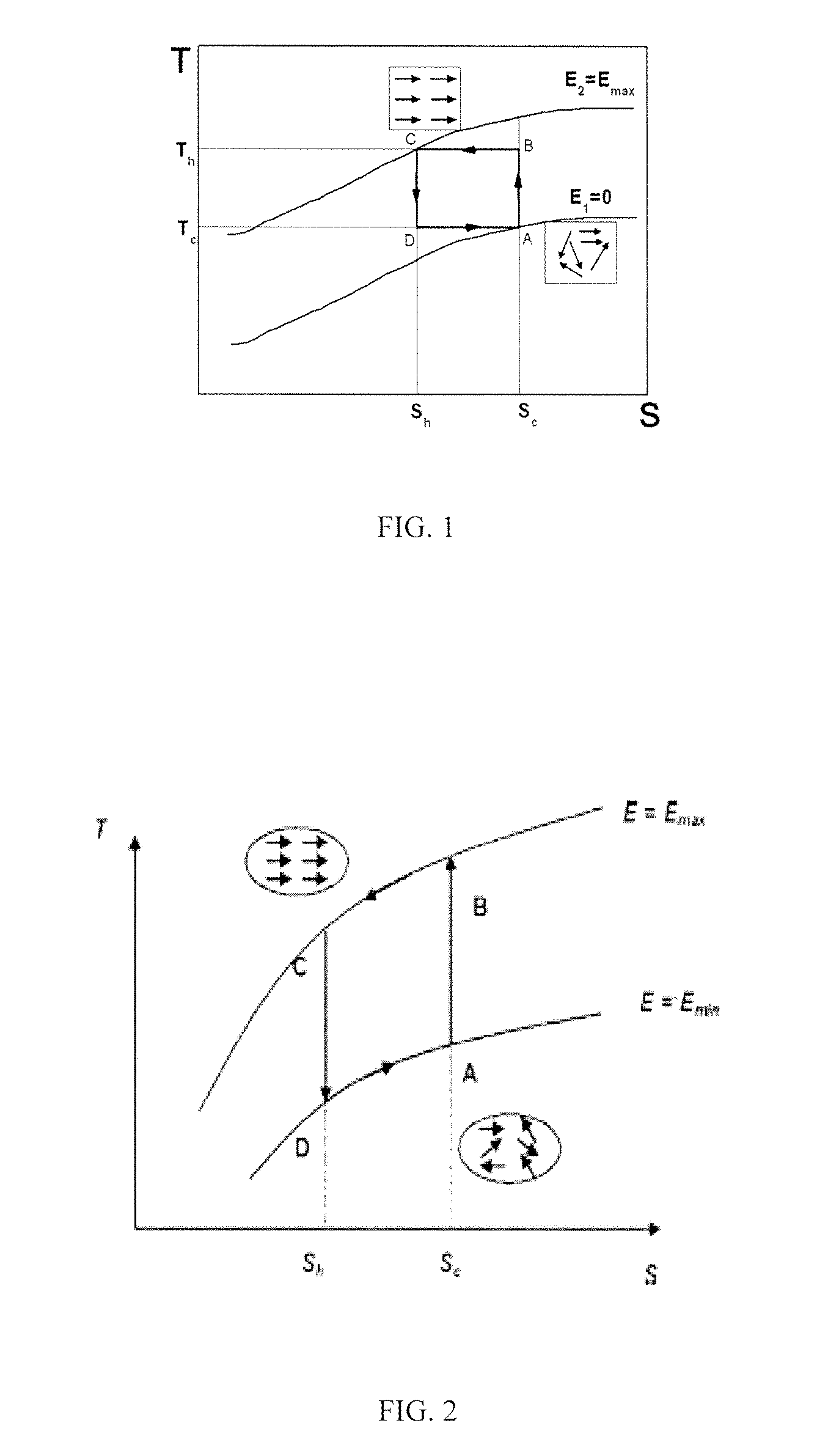

Electrocaloric cooling technology represents a promising alternative to conventional vapor-compression refrigeration systems, which have dominated cooling applications for over a century. The fundamental principle behind electrocaloric cooling is the electrocaloric effect (ECE), a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. This effect was first discovered in the 1930s but remained largely unexplored until the early 2000s when significant advancements in materials science renewed interest in its practical applications.

The evolution of electrocaloric technology has been marked by several key developments. Initially, the observed temperature changes were too small for practical cooling applications. However, a breakthrough came in 2006 when researchers demonstrated giant electrocaloric effects in thin films of lead zirconate titanate (PZT), achieving temperature changes of over 12°C. This discovery catalyzed intensive research efforts worldwide, focusing on identifying materials with enhanced electrocaloric properties and developing efficient cooling devices.

Current research trends are primarily directed toward developing high-performance electrocaloric materials that can operate at lower voltages while producing larger temperature changes. Ferroelectric polymers, relaxor ferroelectrics, and multilayer ceramic capacitors have emerged as promising candidates due to their superior electrocaloric properties and potential for integration into compact cooling systems.

The primary technical objective in this field is to develop electrocaloric materials capable of producing temperature changes exceeding 10°C under electric fields below 100 V/μm, with high energy efficiency and reliability over thousands of cooling cycles. Additionally, these materials must be environmentally friendly, cost-effective, and compatible with existing manufacturing processes to facilitate commercial adoption.

Another critical goal is the miniaturization of cooling systems for applications in electronics, where conventional cooling technologies face significant limitations due to size constraints. Compact electrocaloric cooling devices could potentially address thermal management challenges in high-performance computing, mobile devices, and other electronic systems where heat dissipation is becoming increasingly problematic.

Beyond electronics cooling, the technology aims to revolutionize refrigeration and air conditioning sectors by offering an environmentally sustainable alternative to conventional systems that rely on refrigerants with high global warming potential. Electrocaloric cooling systems operate without greenhouse gases and potentially with higher energy efficiency, aligning with global efforts to reduce carbon emissions and combat climate change.

The ultimate vision for electrocaloric cooling technology is to develop scalable, energy-efficient cooling solutions that can be tailored for applications ranging from microelectronics to building-scale air conditioning systems, thereby addressing cooling needs across multiple sectors while minimizing environmental impact.

The evolution of electrocaloric technology has been marked by several key developments. Initially, the observed temperature changes were too small for practical cooling applications. However, a breakthrough came in 2006 when researchers demonstrated giant electrocaloric effects in thin films of lead zirconate titanate (PZT), achieving temperature changes of over 12°C. This discovery catalyzed intensive research efforts worldwide, focusing on identifying materials with enhanced electrocaloric properties and developing efficient cooling devices.

Current research trends are primarily directed toward developing high-performance electrocaloric materials that can operate at lower voltages while producing larger temperature changes. Ferroelectric polymers, relaxor ferroelectrics, and multilayer ceramic capacitors have emerged as promising candidates due to their superior electrocaloric properties and potential for integration into compact cooling systems.

The primary technical objective in this field is to develop electrocaloric materials capable of producing temperature changes exceeding 10°C under electric fields below 100 V/μm, with high energy efficiency and reliability over thousands of cooling cycles. Additionally, these materials must be environmentally friendly, cost-effective, and compatible with existing manufacturing processes to facilitate commercial adoption.

Another critical goal is the miniaturization of cooling systems for applications in electronics, where conventional cooling technologies face significant limitations due to size constraints. Compact electrocaloric cooling devices could potentially address thermal management challenges in high-performance computing, mobile devices, and other electronic systems where heat dissipation is becoming increasingly problematic.

Beyond electronics cooling, the technology aims to revolutionize refrigeration and air conditioning sectors by offering an environmentally sustainable alternative to conventional systems that rely on refrigerants with high global warming potential. Electrocaloric cooling systems operate without greenhouse gases and potentially with higher energy efficiency, aligning with global efforts to reduce carbon emissions and combat climate change.

The ultimate vision for electrocaloric cooling technology is to develop scalable, energy-efficient cooling solutions that can be tailored for applications ranging from microelectronics to building-scale air conditioning systems, thereby addressing cooling needs across multiple sectors while minimizing environmental impact.

Market Analysis for Energy-Efficient Cooling Solutions

The global cooling market is experiencing a significant shift towards energy-efficient solutions, driven by increasing environmental concerns, stringent regulations, and rising energy costs. The conventional vapor-compression cooling systems, which dominate approximately 90% of the current market, are facing challenges due to their high energy consumption and use of environmentally harmful refrigerants. This creates a substantial opportunity for alternative cooling technologies such as electrocaloric cooling systems.

The market for energy-efficient cooling solutions is projected to grow at a compound annual growth rate (CAGR) of 8.2% from 2023 to 2030, reaching a market value of $38.3 billion by 2030. This growth is particularly pronounced in regions with hot climates and rapidly developing economies, including Southeast Asia, India, and parts of Africa and Latin America, where cooling demand is expected to triple by 2050.

Commercial and residential building sectors represent the largest market segments for energy-efficient cooling technologies, accounting for approximately 65% of the total market share. The industrial sector follows with 20%, while transportation and specialized applications make up the remaining 15%. Within these segments, there is increasing demand for compact, efficient cooling solutions that can be integrated into existing infrastructure with minimal modifications.

Electrocaloric cooling technology, particularly using high-performance electrocaloric materials, addresses several key market needs. These systems offer potential energy efficiency improvements of 20-30% compared to conventional technologies, significantly reducing operational costs and environmental impact. The compact nature of electrocaloric cooling systems also makes them ideal for space-constrained applications in urban environments and for integration into electronic devices.

Consumer willingness to pay for energy-efficient cooling solutions has shown positive trends, with surveys indicating that 58% of consumers are willing to pay a premium of 10-15% for cooling systems that offer substantial energy savings. This is reinforced by government incentives and rebate programs in many countries, which can offset 15-30% of the initial investment costs for energy-efficient cooling technologies.

Market barriers include high initial costs, with electrocaloric systems currently estimated to be 2-3 times more expensive than conventional systems, though this gap is expected to narrow with technological advancements and economies of scale. Additionally, there is limited awareness among potential end-users about the benefits of electrocaloric cooling technology, necessitating educational marketing approaches and demonstration projects.

The competitive landscape includes traditional HVAC manufacturers expanding into energy-efficient technologies, specialized cooling technology startups, and research institutions commercializing advanced materials. Strategic partnerships between material developers and system integrators are becoming increasingly common to accelerate market penetration.

The market for energy-efficient cooling solutions is projected to grow at a compound annual growth rate (CAGR) of 8.2% from 2023 to 2030, reaching a market value of $38.3 billion by 2030. This growth is particularly pronounced in regions with hot climates and rapidly developing economies, including Southeast Asia, India, and parts of Africa and Latin America, where cooling demand is expected to triple by 2050.

Commercial and residential building sectors represent the largest market segments for energy-efficient cooling technologies, accounting for approximately 65% of the total market share. The industrial sector follows with 20%, while transportation and specialized applications make up the remaining 15%. Within these segments, there is increasing demand for compact, efficient cooling solutions that can be integrated into existing infrastructure with minimal modifications.

Electrocaloric cooling technology, particularly using high-performance electrocaloric materials, addresses several key market needs. These systems offer potential energy efficiency improvements of 20-30% compared to conventional technologies, significantly reducing operational costs and environmental impact. The compact nature of electrocaloric cooling systems also makes them ideal for space-constrained applications in urban environments and for integration into electronic devices.

Consumer willingness to pay for energy-efficient cooling solutions has shown positive trends, with surveys indicating that 58% of consumers are willing to pay a premium of 10-15% for cooling systems that offer substantial energy savings. This is reinforced by government incentives and rebate programs in many countries, which can offset 15-30% of the initial investment costs for energy-efficient cooling technologies.

Market barriers include high initial costs, with electrocaloric systems currently estimated to be 2-3 times more expensive than conventional systems, though this gap is expected to narrow with technological advancements and economies of scale. Additionally, there is limited awareness among potential end-users about the benefits of electrocaloric cooling technology, necessitating educational marketing approaches and demonstration projects.

The competitive landscape includes traditional HVAC manufacturers expanding into energy-efficient technologies, specialized cooling technology startups, and research institutions commercializing advanced materials. Strategic partnerships between material developers and system integrators are becoming increasingly common to accelerate market penetration.

Current Status and Challenges in Electrocaloric Materials

Electrocaloric (EC) materials have emerged as promising candidates for next-generation solid-state cooling technologies. Currently, the global research landscape shows significant advancements in both organic and inorganic EC materials. Polymer-based materials, particularly polyvinylidene fluoride (PVDF) and its copolymers, demonstrate impressive EC effects with temperature changes (ΔT) of 12-16K under electric fields of 150-200 MV/m. Meanwhile, ceramic-based materials such as lead zirconate titanate (PZT) and barium titanate (BaTiO3) exhibit moderate EC effects with ΔT values of 2-5K under lower electric fields.

The geographical distribution of EC research shows concentration in North America, Europe, and East Asia. The United States leads in polymer-based EC materials research, with significant contributions from Pennsylvania State University and UCLA. China dominates ceramic-based EC materials development, with substantial research output from Chinese Academy of Sciences and Tsinghua University. European research centers, particularly in Germany and the UK, focus on multilayer composite EC systems and device integration.

Despite promising developments, several critical challenges impede widespread implementation of EC cooling technologies. The primary technical barrier remains the limited cooling capacity of current materials, with most EC materials exhibiting insufficient temperature changes for practical cooling applications. This limitation stems from the inherent properties of ferroelectric materials and the breakdown threshold under high electric fields.

Material stability presents another significant challenge, as repeated electrothermal cycling leads to performance degradation over time. Polymer-based materials suffer from mechanical fatigue and crystalline structure changes, while ceramic materials experience microcrack formation and polarization fatigue. These reliability issues must be addressed for long-term commercial viability.

Manufacturing scalability poses substantial difficulties, particularly for multilayer structures that require precise fabrication techniques. Current laboratory-scale production methods are difficult to translate to mass production while maintaining performance consistency and cost-effectiveness. The integration of EC materials into functional cooling devices also presents challenges in thermal management, electrical connection, and system miniaturization.

Energy efficiency remains suboptimal, with current EC cooling systems showing coefficients of performance (COP) below competitive alternatives. This efficiency gap stems from electrical losses, thermal transfer inefficiencies, and control system limitations. Additionally, many high-performance EC materials contain lead and other environmentally problematic elements, creating regulatory hurdles in many markets.

The cost-performance ratio of EC materials requires significant improvement, as current materials and fabrication techniques result in prohibitively expensive cooling solutions compared to conventional technologies. Bridging this economic gap will require both material innovations and manufacturing breakthroughs.

The geographical distribution of EC research shows concentration in North America, Europe, and East Asia. The United States leads in polymer-based EC materials research, with significant contributions from Pennsylvania State University and UCLA. China dominates ceramic-based EC materials development, with substantial research output from Chinese Academy of Sciences and Tsinghua University. European research centers, particularly in Germany and the UK, focus on multilayer composite EC systems and device integration.

Despite promising developments, several critical challenges impede widespread implementation of EC cooling technologies. The primary technical barrier remains the limited cooling capacity of current materials, with most EC materials exhibiting insufficient temperature changes for practical cooling applications. This limitation stems from the inherent properties of ferroelectric materials and the breakdown threshold under high electric fields.

Material stability presents another significant challenge, as repeated electrothermal cycling leads to performance degradation over time. Polymer-based materials suffer from mechanical fatigue and crystalline structure changes, while ceramic materials experience microcrack formation and polarization fatigue. These reliability issues must be addressed for long-term commercial viability.

Manufacturing scalability poses substantial difficulties, particularly for multilayer structures that require precise fabrication techniques. Current laboratory-scale production methods are difficult to translate to mass production while maintaining performance consistency and cost-effectiveness. The integration of EC materials into functional cooling devices also presents challenges in thermal management, electrical connection, and system miniaturization.

Energy efficiency remains suboptimal, with current EC cooling systems showing coefficients of performance (COP) below competitive alternatives. This efficiency gap stems from electrical losses, thermal transfer inefficiencies, and control system limitations. Additionally, many high-performance EC materials contain lead and other environmentally problematic elements, creating regulatory hurdles in many markets.

The cost-performance ratio of EC materials requires significant improvement, as current materials and fabrication techniques result in prohibitively expensive cooling solutions compared to conventional technologies. Bridging this economic gap will require both material innovations and manufacturing breakthroughs.

State-of-the-Art Electrocaloric Material Solutions

01 Material composition for enhanced electrocaloric effect

Various material compositions can enhance the electrocaloric effect, including relaxor ferroelectrics, polymers, and ceramic-polymer composites. These materials exhibit large temperature changes when an electric field is applied and removed. The performance of these materials depends on their chemical composition, crystal structure, and phase transitions. Optimizing these factors can lead to improved cooling efficiency and higher temperature changes in electrocaloric cooling systems.- Electrocaloric material compositions for enhanced performance: Various material compositions have been developed to enhance electrocaloric performance. These include relaxor ferroelectrics, polymer-based materials, and ceramic compositions that exhibit large temperature changes under applied electric fields. These materials are engineered at the molecular level to maximize the electrocaloric effect, with specific dopants and additives used to tune properties such as polarization, phase transition temperature, and hysteresis characteristics.

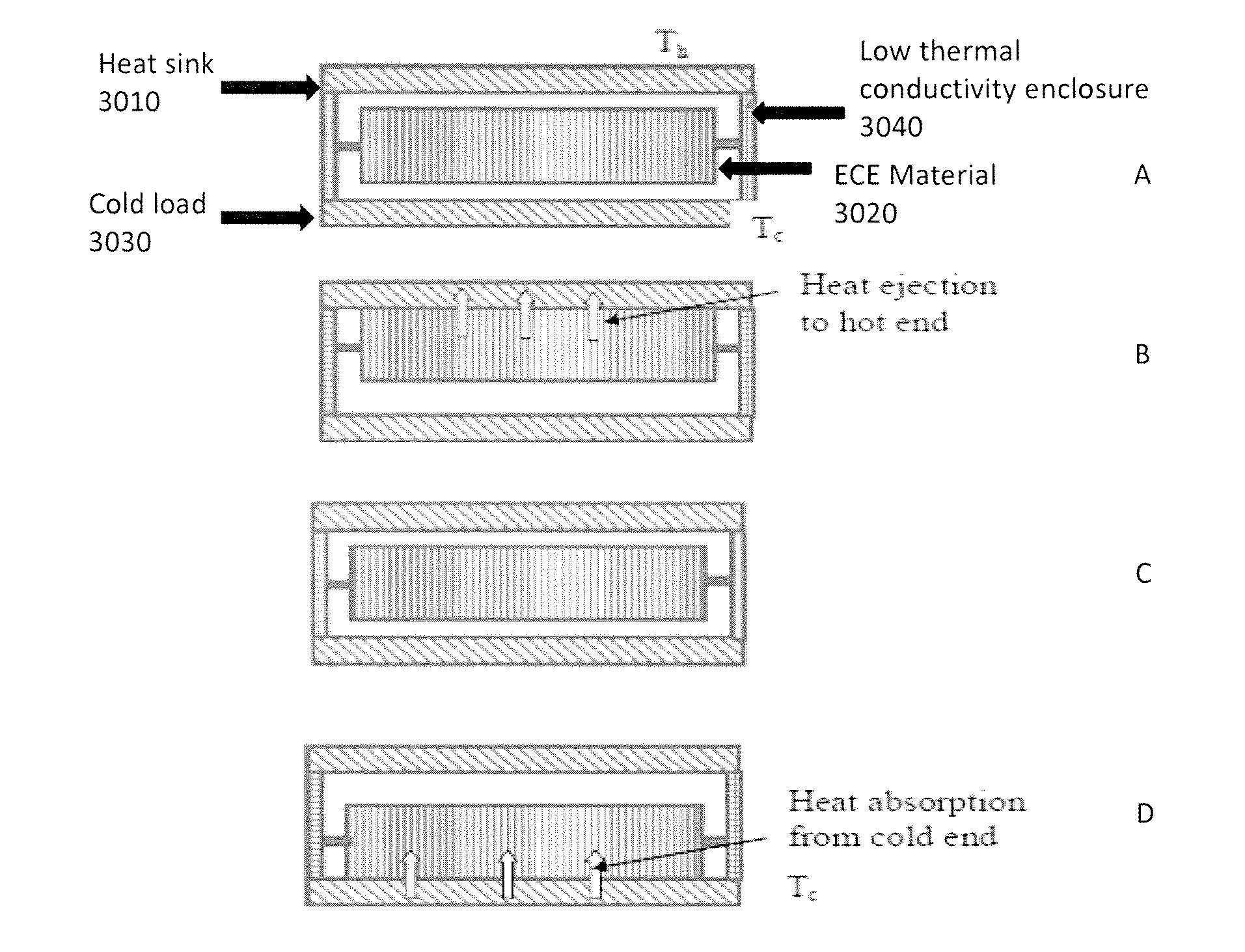

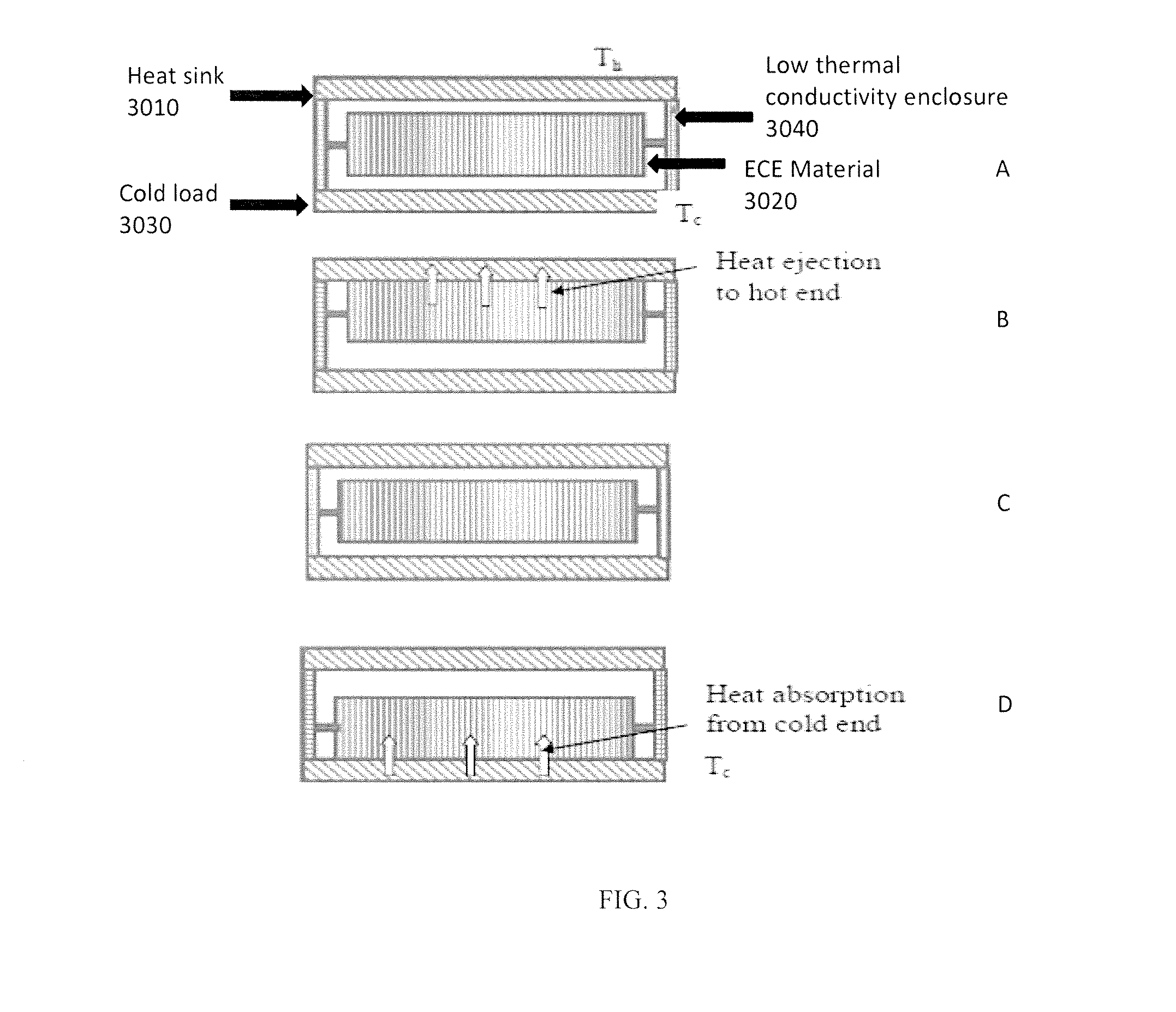

- Cooling system designs utilizing electrocaloric materials: Cooling systems incorporating electrocaloric materials have been designed to maximize thermal energy transfer and efficiency. These systems include heat exchangers, thermal switches, and fluid-based heat transfer mechanisms that work in conjunction with electrocaloric elements. The designs focus on optimizing the thermodynamic cycle, reducing thermal resistance between components, and implementing effective heat rejection strategies to achieve practical cooling applications.

- Electric field application methods for electrocaloric devices: Methods for applying electric fields to electrocaloric materials significantly impact their performance. These include pulsed field techniques, variable frequency approaches, and multi-stage field application strategies. The timing, magnitude, and profile of the electric field application are optimized to maximize temperature change while minimizing energy input, improving the coefficient of performance of electrocaloric cooling systems.

- Fabrication techniques for electrocaloric devices: Advanced fabrication techniques have been developed to produce high-performance electrocaloric devices. These include thin-film deposition methods, multilayer structures, and composite material processing approaches. Techniques such as solution casting, spin coating, and controlled crystallization are employed to create materials with optimized microstructures, reduced defects, and enhanced electrocaloric properties, leading to improved overall device performance.

- Performance measurement and characterization methods: Specialized methods for measuring and characterizing electrocaloric material performance have been developed. These include direct temperature measurement techniques, indirect methods based on thermodynamic relationships, and high-throughput screening approaches. Advanced characterization tools such as infrared thermal imaging, calorimetry, and electrical property measurements are used to evaluate key performance metrics including temperature change, entropy change, and energy efficiency under various operating conditions.

02 Electrocaloric cooling system design and efficiency

The design of electrocaloric cooling systems significantly impacts their performance. Key design elements include heat transfer mechanisms, cycle timing, and system architecture. Advanced designs incorporate regenerative cycles, heat switches, and fluid-based heat transfer to maximize cooling capacity. Efficiency improvements can be achieved through optimized thermal management, reduced parasitic losses, and enhanced heat exchange between the electrocaloric material and the environment.Expand Specific Solutions03 Multilayer and thin film electrocaloric devices

Multilayer and thin film configurations offer significant advantages for electrocaloric devices, including faster heat transfer, reduced operating voltages, and improved integration capabilities. These structures allow for more efficient thermal cycling and better temperature control. The performance of such devices depends on layer thickness, electrode design, and interface quality. Advanced manufacturing techniques enable precise control of these parameters to optimize the electrocaloric response.Expand Specific Solutions04 Temperature range and stability of electrocaloric materials

The operating temperature range and stability of electrocaloric materials are critical performance factors. Materials that maintain strong electrocaloric effects across wide temperature ranges are particularly valuable for practical applications. Thermal cycling stability, fatigue resistance, and long-term performance retention are essential for commercial viability. Research focuses on developing materials with consistent performance near room temperature and reducing performance degradation over repeated thermal cycles.Expand Specific Solutions05 Integration of electrocaloric materials in cooling applications

Successful integration of electrocaloric materials into practical cooling applications requires addressing challenges related to system miniaturization, power consumption, and compatibility with existing technologies. Applications range from microelectronics cooling to refrigeration and air conditioning. The performance of integrated systems depends on the electrocaloric material properties, electrical driving circuits, and thermal management strategies. Advanced integration approaches include cascaded systems, hybrid cooling technologies, and smart control algorithms.Expand Specific Solutions

Leading Companies and Research Institutions in Electrocaloric Field

The electrocaloric cooling technology market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size remains relatively small but is projected to expand significantly as energy-efficient cooling solutions gain traction. From a technical maturity perspective, the field is transitioning from fundamental research to application development, with key players demonstrating varying levels of advancement. Established manufacturers like Murata, Carrier, and Robert Bosch are leveraging their thermal management expertise to develop practical applications, while research institutions including University of Maryland, Penn State, and Naval Research Laboratory are driving fundamental breakthroughs. Specialized companies such as Nascent Devices and Laird Thermal Systems are emerging as technology pioneers focused specifically on electrocaloric material development and system integration for next-generation cooling solutions.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed an integrated electrocaloric cooling system based on multilayer ceramic capacitors (MLCCs) using modified lead zirconate titanate (PZT) materials. Their approach focuses on system-level optimization, creating compact cooling modules with specialized heat exchangers that maximize thermal transfer from the electrocaloric elements. Their innovation includes a proprietary electrode design that reduces electrical resistance while maintaining mechanical integrity during thermal cycling. The Fraunhofer solution incorporates a microcontroller-based field application system that dynamically adjusts electric field parameters based on cooling demand, achieving energy efficiency improvements of approximately 30% compared to conventional fixed-field systems. Their latest prototypes demonstrate cooling capacities of 40-50 W with a form factor under 100 cm³, targeting applications in electronics cooling.

Strengths: System-level integration expertise; optimized heat exchange mechanisms; advanced control systems for maximizing efficiency. Weaknesses: Reliance on lead-based materials presents regulatory challenges; higher manufacturing complexity increases production costs; current designs require specialized power electronics.

Penn State Research Foundation

Technical Solution: Penn State has pioneered advanced polymer-based electrocaloric materials, particularly focusing on relaxor ferroelectric polymers like P(VDF-TrFE-CFE) and P(VDF-TrFE-CTFE) that demonstrate giant electrocaloric effects. Their approach involves creating nanostructured polymer films with carefully engineered defect structures that enhance polarization responses under electric fields. Their materials achieve temperature changes of 12-20K under moderate electric fields (100-150 MV/m), significantly higher than conventional materials. Penn State has also developed multilayer capacitor configurations that maximize active cooling surface area while minimizing required voltage, enabling practical cooling devices with power densities exceeding 3 W/cm².

Strengths: Industry-leading temperature changes in polymer-based materials; scalable manufacturing potential; operates at lower voltages than ceramic alternatives. Weaknesses: Polymer materials face challenges with long-term stability under repeated electrical cycling; thermal conductivity limitations can reduce overall system efficiency.

Key Patents and Breakthroughs in High-Performance Electrocaloric Materials

Multi-layered electrocaloric heat pump systems and methods

PatentPendingUS20240019179A1

Innovation

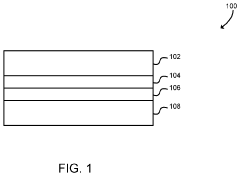

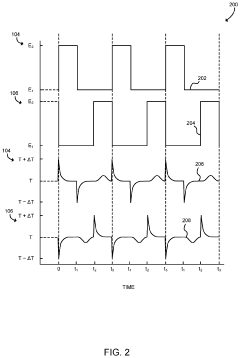

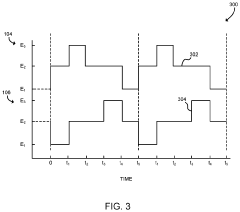

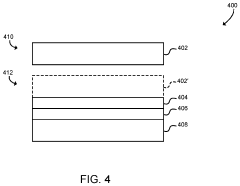

- A cooling system comprising independently controllable electrocaloric material layers separated by conductive or insulative materials, with a controller managing electric fields to move heat energy from a heat source to a heat sink during specific intervals and restore initial conditions, allowing for cyclic heat transfer without moving parts.

Cooling device including an electrocaloric composite

PatentInactiveUS20150027132A1

Innovation

- The use of high thermal conductivity electrocaloric composites, comprising electrocaloric polymers and electrically insulating fillers, which enhance thermal conductivity while maintaining the electrocaloric effect, allowing for improved cooling device performance and efficiency.

Environmental Impact and Sustainability Considerations

Electrocaloric cooling technology represents a significant advancement in thermal management systems, offering potential advantages over conventional vapor-compression refrigeration. However, its environmental impact and sustainability considerations must be thoroughly evaluated to ensure responsible development and implementation.

The primary environmental benefit of electrocaloric cooling systems stems from their elimination of harmful refrigerants. Traditional cooling technologies rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to global warming and ozone depletion. Electrocaloric materials, by contrast, operate without these environmentally damaging substances, potentially reducing direct greenhouse gas emissions from refrigerant leakage.

Energy efficiency represents another critical environmental consideration. Current research indicates that high-performance electrocaloric materials could achieve theoretical coefficients of performance (COP) exceeding those of conventional cooling systems. This improved efficiency would translate to reduced electricity consumption and consequently lower indirect carbon emissions throughout the technology's operational lifecycle.

Material sustainability presents both challenges and opportunities. Many promising electrocaloric materials contain lead-based compounds or rare earth elements, raising concerns about resource scarcity and mining impacts. Recent research has focused on developing lead-free alternatives and reducing rare earth content while maintaining performance characteristics. Additionally, the manufacturing processes for these specialized materials often require energy-intensive high-temperature sintering, presenting opportunities for process optimization to reduce embodied carbon.

Lifecycle assessment (LCA) studies of electrocaloric cooling systems remain limited but suggest favorable environmental profiles compared to conventional technologies. Preliminary analyses indicate potential reductions in global warming potential by 15-30% when considering manufacturing, operation, and end-of-life scenarios. However, these assessments highlight the importance of designing for recyclability and responsible end-of-life management of electronic components and specialized materials.

Regulatory frameworks worldwide are increasingly emphasizing sustainable cooling technologies. The Kigali Amendment to the Montreal Protocol mandates the phasedown of HFCs, creating policy incentives for alternative cooling technologies. Electrocaloric cooling aligns with these regulatory trends, potentially benefiting from carbon credits and environmental certifications that could accelerate market adoption while ensuring environmental compliance.

Water conservation represents an additional sustainability advantage, as electrocaloric cooling systems do not require water for heat rejection, unlike many industrial cooling towers. This characteristic makes the technology particularly valuable in water-stressed regions where conventional cooling systems place additional pressure on limited water resources.

The primary environmental benefit of electrocaloric cooling systems stems from their elimination of harmful refrigerants. Traditional cooling technologies rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to global warming and ozone depletion. Electrocaloric materials, by contrast, operate without these environmentally damaging substances, potentially reducing direct greenhouse gas emissions from refrigerant leakage.

Energy efficiency represents another critical environmental consideration. Current research indicates that high-performance electrocaloric materials could achieve theoretical coefficients of performance (COP) exceeding those of conventional cooling systems. This improved efficiency would translate to reduced electricity consumption and consequently lower indirect carbon emissions throughout the technology's operational lifecycle.

Material sustainability presents both challenges and opportunities. Many promising electrocaloric materials contain lead-based compounds or rare earth elements, raising concerns about resource scarcity and mining impacts. Recent research has focused on developing lead-free alternatives and reducing rare earth content while maintaining performance characteristics. Additionally, the manufacturing processes for these specialized materials often require energy-intensive high-temperature sintering, presenting opportunities for process optimization to reduce embodied carbon.

Lifecycle assessment (LCA) studies of electrocaloric cooling systems remain limited but suggest favorable environmental profiles compared to conventional technologies. Preliminary analyses indicate potential reductions in global warming potential by 15-30% when considering manufacturing, operation, and end-of-life scenarios. However, these assessments highlight the importance of designing for recyclability and responsible end-of-life management of electronic components and specialized materials.

Regulatory frameworks worldwide are increasingly emphasizing sustainable cooling technologies. The Kigali Amendment to the Montreal Protocol mandates the phasedown of HFCs, creating policy incentives for alternative cooling technologies. Electrocaloric cooling aligns with these regulatory trends, potentially benefiting from carbon credits and environmental certifications that could accelerate market adoption while ensuring environmental compliance.

Water conservation represents an additional sustainability advantage, as electrocaloric cooling systems do not require water for heat rejection, unlike many industrial cooling towers. This characteristic makes the technology particularly valuable in water-stressed regions where conventional cooling systems place additional pressure on limited water resources.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of electrocaloric materials represents a critical factor in determining the commercial viability of electrocaloric cooling technologies. Current production methods for high-performance electrocaloric materials, particularly lead-based relaxor ferroelectrics and polymer-based materials, face significant challenges when transitioning from laboratory-scale to mass production environments.

For ceramic-based electrocaloric materials, conventional manufacturing processes include solid-state reaction methods, sol-gel processing, and hydrothermal synthesis. While these methods yield high-quality materials at laboratory scale, they often require precise temperature control, specialized equipment, and extended processing times that significantly increase production costs when scaled up. The manufacturing yield rate typically decreases from over 90% in laboratory settings to 60-75% in industrial production environments.

Polymer-based electrocaloric materials offer potentially lower manufacturing costs through established polymer processing techniques such as solution casting, melt processing, and electrospinning. However, achieving consistent electrocaloric properties across large-area films remains challenging. Current cost estimates for high-performance P(VDF-TrFE-CFE) terpolymer films range from $200-500 per square meter, substantially higher than conventional cooling materials.

Material cost analysis reveals that raw material expenses constitute approximately 40-55% of total production costs for ceramic-based electrocaloric materials, with processing and quality control accounting for the remainder. For lead-based materials, environmental compliance and safety measures add 15-20% to overall manufacturing costs. Alternative lead-free compositions currently under development may reduce these regulatory costs but typically demonstrate 30-40% lower electrocaloric performance.

Energy consumption during manufacturing presents another significant cost factor. High-temperature sintering processes for ceramic materials require 5-8 kWh per kilogram of finished product. Implementing energy-efficient manufacturing technologies could potentially reduce energy consumption by 25-30%, translating to approximately 10-15% reduction in overall production costs.

Recent advances in additive manufacturing and thin-film deposition techniques show promise for improving manufacturing scalability. Techniques such as aerosol deposition and chemical solution deposition enable the production of uniform electrocaloric thin films with thicknesses below 10 μm, potentially reducing material usage by 60-70% compared to bulk processing methods. However, these advanced manufacturing techniques currently increase production costs by 30-40% compared to conventional methods, necessitating further optimization for commercial viability.

For ceramic-based electrocaloric materials, conventional manufacturing processes include solid-state reaction methods, sol-gel processing, and hydrothermal synthesis. While these methods yield high-quality materials at laboratory scale, they often require precise temperature control, specialized equipment, and extended processing times that significantly increase production costs when scaled up. The manufacturing yield rate typically decreases from over 90% in laboratory settings to 60-75% in industrial production environments.

Polymer-based electrocaloric materials offer potentially lower manufacturing costs through established polymer processing techniques such as solution casting, melt processing, and electrospinning. However, achieving consistent electrocaloric properties across large-area films remains challenging. Current cost estimates for high-performance P(VDF-TrFE-CFE) terpolymer films range from $200-500 per square meter, substantially higher than conventional cooling materials.

Material cost analysis reveals that raw material expenses constitute approximately 40-55% of total production costs for ceramic-based electrocaloric materials, with processing and quality control accounting for the remainder. For lead-based materials, environmental compliance and safety measures add 15-20% to overall manufacturing costs. Alternative lead-free compositions currently under development may reduce these regulatory costs but typically demonstrate 30-40% lower electrocaloric performance.

Energy consumption during manufacturing presents another significant cost factor. High-temperature sintering processes for ceramic materials require 5-8 kWh per kilogram of finished product. Implementing energy-efficient manufacturing technologies could potentially reduce energy consumption by 25-30%, translating to approximately 10-15% reduction in overall production costs.

Recent advances in additive manufacturing and thin-film deposition techniques show promise for improving manufacturing scalability. Techniques such as aerosol deposition and chemical solution deposition enable the production of uniform electrocaloric thin films with thicknesses below 10 μm, potentially reducing material usage by 60-70% compared to bulk processing methods. However, these advanced manufacturing techniques currently increase production costs by 30-40% compared to conventional methods, necessitating further optimization for commercial viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!