Tradeoffs Between Cooling Power Density And Device Lifetime In Electrocaloric Cooling

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Evolution and Objectives

Electrocaloric cooling technology represents a promising alternative to conventional vapor-compression refrigeration systems, offering potential advantages in energy efficiency, environmental friendliness, and miniaturization capabilities. The evolution of this technology can be traced back to the early 20th century when the electrocaloric effect was first discovered, though significant research momentum only began building in the early 2000s with the discovery of giant electrocaloric effects in thin films.

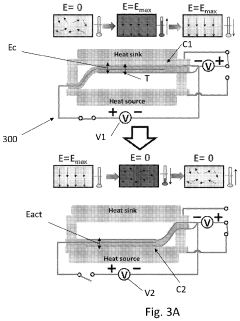

The fundamental principle behind electrocaloric cooling involves the temperature change in certain materials when subjected to an electric field. This phenomenon occurs due to the alignment of electric dipoles within the material, which affects the entropy of the system. When an electric field is applied, the dipoles align, reducing entropy and causing the material to heat up. When the field is removed, the dipoles randomize, increasing entropy and causing the material to cool down.

Over the past two decades, research has progressed from basic material discovery to device prototyping. Early work focused primarily on ferroelectric ceramics like lead zirconate titanate (PZT), while more recent efforts have expanded to include polymer-based materials such as polyvinylidene fluoride (PVDF) and its copolymers, as well as relaxor ferroelectrics that exhibit enhanced electrocaloric responses.

A critical evolution in the field has been the transition from bulk materials to thin films and multilayer structures, which allow for higher electric fields to be applied without breakdown, thereby enhancing the electrocaloric effect. This shift has enabled temperature changes of several degrees Kelvin, making practical applications more feasible.

The primary objective of current electrocaloric cooling research is to develop systems that can achieve high cooling power density while maintaining acceptable device lifetimes. This presents a fundamental tradeoff: higher electric fields generate stronger cooling effects but accelerate material degradation through mechanisms such as electrical fatigue, dielectric breakdown, and electrochemical degradation.

Secondary objectives include improving cycle efficiency, reducing hysteresis losses, enhancing heat transfer mechanisms, and developing cost-effective manufacturing processes for commercial viability. Researchers are also working to optimize operating frequencies, as faster cycling can increase cooling power but may exacerbate lifetime issues through mechanical and thermal stresses.

The long-term vision for electrocaloric technology encompasses applications ranging from microelectronics cooling to household refrigeration and air conditioning. For these applications to become reality, significant improvements in material properties, device architecture, and system integration are required to balance the fundamental tradeoff between cooling performance and operational longevity.

The fundamental principle behind electrocaloric cooling involves the temperature change in certain materials when subjected to an electric field. This phenomenon occurs due to the alignment of electric dipoles within the material, which affects the entropy of the system. When an electric field is applied, the dipoles align, reducing entropy and causing the material to heat up. When the field is removed, the dipoles randomize, increasing entropy and causing the material to cool down.

Over the past two decades, research has progressed from basic material discovery to device prototyping. Early work focused primarily on ferroelectric ceramics like lead zirconate titanate (PZT), while more recent efforts have expanded to include polymer-based materials such as polyvinylidene fluoride (PVDF) and its copolymers, as well as relaxor ferroelectrics that exhibit enhanced electrocaloric responses.

A critical evolution in the field has been the transition from bulk materials to thin films and multilayer structures, which allow for higher electric fields to be applied without breakdown, thereby enhancing the electrocaloric effect. This shift has enabled temperature changes of several degrees Kelvin, making practical applications more feasible.

The primary objective of current electrocaloric cooling research is to develop systems that can achieve high cooling power density while maintaining acceptable device lifetimes. This presents a fundamental tradeoff: higher electric fields generate stronger cooling effects but accelerate material degradation through mechanisms such as electrical fatigue, dielectric breakdown, and electrochemical degradation.

Secondary objectives include improving cycle efficiency, reducing hysteresis losses, enhancing heat transfer mechanisms, and developing cost-effective manufacturing processes for commercial viability. Researchers are also working to optimize operating frequencies, as faster cycling can increase cooling power but may exacerbate lifetime issues through mechanical and thermal stresses.

The long-term vision for electrocaloric technology encompasses applications ranging from microelectronics cooling to household refrigeration and air conditioning. For these applications to become reality, significant improvements in material properties, device architecture, and system integration are required to balance the fundamental tradeoff between cooling performance and operational longevity.

Market Analysis for High-Efficiency Cooling Solutions

The global cooling solutions market is experiencing significant growth, driven by increasing demand for energy-efficient technologies across residential, commercial, and industrial sectors. Currently valued at approximately $115 billion, this market is projected to reach $160 billion by 2027, with a compound annual growth rate of 6.8%. Within this broader market, advanced cooling technologies like electrocaloric cooling represent an emerging segment with substantial growth potential.

Electrocaloric cooling solutions specifically address the growing demand for environmentally friendly alternatives to conventional vapor-compression refrigeration systems. With global regulations increasingly restricting the use of hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential, the market for alternative cooling technologies is expanding rapidly. The Paris Agreement and Kigali Amendment to the Montreal Protocol have accelerated this transition, creating market opportunities for innovative cooling solutions.

Consumer and industrial sectors are showing increased willingness to adopt higher-priced cooling technologies that offer superior energy efficiency and reduced environmental impact. Market research indicates that energy consumption in cooling applications accounts for approximately 20% of global electricity usage, creating strong economic incentives for more efficient alternatives. Electrocaloric cooling systems, with their potential for higher coefficient of performance (COP) values, directly address this market need.

The commercial refrigeration segment represents a particularly promising market entry point for electrocaloric cooling technology. This segment values reliability and lifetime considerations alongside energy efficiency, making it receptive to innovations that balance cooling power density with device longevity. Market analysis shows that commercial users are willing to accept 15-25% higher initial costs for cooling systems that demonstrate 30% or greater energy savings over their operational lifetime.

Regional market analysis reveals varying adoption potential for advanced cooling technologies. North America and Europe lead in early adoption of premium cooling solutions, driven by stringent environmental regulations and higher energy costs. The Asia-Pacific region represents the fastest-growing market segment, with China and India investing heavily in energy-efficient infrastructure and showing increased demand for sustainable cooling technologies.

Market forecasts indicate that cooling solutions offering extended device lifetimes while maintaining competitive cooling power density could capture significant market share. Industry surveys show that 78% of commercial users rank system reliability and maintenance costs as top considerations in purchasing decisions, even above initial acquisition costs. This market preference aligns well with research focusing on optimizing the tradeoffs between cooling power density and device lifetime in electrocaloric systems.

Electrocaloric cooling solutions specifically address the growing demand for environmentally friendly alternatives to conventional vapor-compression refrigeration systems. With global regulations increasingly restricting the use of hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential, the market for alternative cooling technologies is expanding rapidly. The Paris Agreement and Kigali Amendment to the Montreal Protocol have accelerated this transition, creating market opportunities for innovative cooling solutions.

Consumer and industrial sectors are showing increased willingness to adopt higher-priced cooling technologies that offer superior energy efficiency and reduced environmental impact. Market research indicates that energy consumption in cooling applications accounts for approximately 20% of global electricity usage, creating strong economic incentives for more efficient alternatives. Electrocaloric cooling systems, with their potential for higher coefficient of performance (COP) values, directly address this market need.

The commercial refrigeration segment represents a particularly promising market entry point for electrocaloric cooling technology. This segment values reliability and lifetime considerations alongside energy efficiency, making it receptive to innovations that balance cooling power density with device longevity. Market analysis shows that commercial users are willing to accept 15-25% higher initial costs for cooling systems that demonstrate 30% or greater energy savings over their operational lifetime.

Regional market analysis reveals varying adoption potential for advanced cooling technologies. North America and Europe lead in early adoption of premium cooling solutions, driven by stringent environmental regulations and higher energy costs. The Asia-Pacific region represents the fastest-growing market segment, with China and India investing heavily in energy-efficient infrastructure and showing increased demand for sustainable cooling technologies.

Market forecasts indicate that cooling solutions offering extended device lifetimes while maintaining competitive cooling power density could capture significant market share. Industry surveys show that 78% of commercial users rank system reliability and maintenance costs as top considerations in purchasing decisions, even above initial acquisition costs. This market preference aligns well with research focusing on optimizing the tradeoffs between cooling power density and device lifetime in electrocaloric systems.

Current Limitations in Electrocaloric Material Performance

Electrocaloric (EC) materials have shown promising potential for solid-state cooling applications, but their performance is currently limited by several key factors. The most significant limitation is the trade-off between cooling power density and operational lifetime. High electric fields are required to achieve substantial temperature changes in EC materials, but these same fields accelerate material degradation and reduce device longevity.

Current EC materials exhibit relatively small temperature changes (typically 2-5K) under practical electric fields, necessitating cascaded designs or regenerative cycles to achieve useful cooling capacities. This complexity increases system size and reduces overall efficiency. The temperature change per unit electric field (EC coefficient) remains too low in most commercially viable materials, requiring fields approaching dielectric breakdown limits for meaningful cooling effects.

Material fatigue presents another critical limitation. Repeated electrocaloric cycling causes microstructural changes, domain wall motion, and eventual formation of microcracks that progressively degrade performance. Studies show that after 10^5-10^6 cycles, many EC materials experience 20-30% reduction in their cooling capacity, which is problematic for applications requiring millions of cycles over device lifetime.

Thermal hysteresis effects further constrain performance, as the temperature change during field application differs from that during field removal. This irreversibility reduces the net cooling effect and system efficiency. In multilayer capacitor configurations, which are promising for practical applications, interface effects between electrodes and EC materials create additional performance limitations through charge trapping and interfacial thermal resistance.

Leakage current represents another significant challenge, particularly at elevated temperatures and high electric fields. These currents not only waste energy but generate Joule heating that directly counteracts the desired cooling effect. As operating temperatures increase, leakage currents typically grow exponentially, severely limiting high-temperature applications.

Manufacturing scalability remains problematic for high-performance EC materials. The best-performing materials often require complex processing techniques that are difficult to scale economically. Additionally, many high-performance EC materials contain lead or other environmentally problematic elements, creating regulatory hurdles for commercial deployment.

The temperature range of optimal EC performance is typically narrow, limiting application versatility. Most materials show peak EC effect near their phase transition temperature, with significantly reduced performance at temperatures even 10-20K away from this optimum. This necessitates careful material selection or complex multi-material systems for applications with wide operating temperature ranges.

Current EC materials exhibit relatively small temperature changes (typically 2-5K) under practical electric fields, necessitating cascaded designs or regenerative cycles to achieve useful cooling capacities. This complexity increases system size and reduces overall efficiency. The temperature change per unit electric field (EC coefficient) remains too low in most commercially viable materials, requiring fields approaching dielectric breakdown limits for meaningful cooling effects.

Material fatigue presents another critical limitation. Repeated electrocaloric cycling causes microstructural changes, domain wall motion, and eventual formation of microcracks that progressively degrade performance. Studies show that after 10^5-10^6 cycles, many EC materials experience 20-30% reduction in their cooling capacity, which is problematic for applications requiring millions of cycles over device lifetime.

Thermal hysteresis effects further constrain performance, as the temperature change during field application differs from that during field removal. This irreversibility reduces the net cooling effect and system efficiency. In multilayer capacitor configurations, which are promising for practical applications, interface effects between electrodes and EC materials create additional performance limitations through charge trapping and interfacial thermal resistance.

Leakage current represents another significant challenge, particularly at elevated temperatures and high electric fields. These currents not only waste energy but generate Joule heating that directly counteracts the desired cooling effect. As operating temperatures increase, leakage currents typically grow exponentially, severely limiting high-temperature applications.

Manufacturing scalability remains problematic for high-performance EC materials. The best-performing materials often require complex processing techniques that are difficult to scale economically. Additionally, many high-performance EC materials contain lead or other environmentally problematic elements, creating regulatory hurdles for commercial deployment.

The temperature range of optimal EC performance is typically narrow, limiting application versatility. Most materials show peak EC effect near their phase transition temperature, with significantly reduced performance at temperatures even 10-20K away from this optimum. This necessitates careful material selection or complex multi-material systems for applications with wide operating temperature ranges.

Power Density vs. Lifetime Optimization Approaches

01 Electrocaloric materials for enhanced cooling power density

Various electrocaloric materials can be used to achieve higher cooling power density in electrocaloric cooling systems. These materials exhibit a temperature change when an electric field is applied or removed. Materials such as relaxor ferroelectrics, polymer-based composites, and multilayer capacitors have shown promising results for achieving high cooling power density. The selection of appropriate electrocaloric materials with high electrocaloric coefficients is crucial for maximizing the cooling efficiency and power density of electrocaloric cooling devices.- Electrocaloric material selection for enhanced cooling power density: The selection of appropriate electrocaloric materials significantly impacts the cooling power density of electrocaloric cooling systems. Materials with high electrocaloric coefficients, such as certain ferroelectric polymers and relaxor ferroelectrics, can generate larger temperature changes when an electric field is applied. Multilayer structures and composite materials can further enhance the electrocaloric effect, leading to improved cooling power density. The development of materials with reduced hysteresis losses also contributes to more efficient cooling systems.

- Thermal cycling and heat transfer optimization techniques: Efficient heat transfer mechanisms are crucial for maximizing cooling power density in electrocaloric systems. Various designs incorporate specialized heat exchangers, thermal switches, and fluid-based heat transfer systems to optimize the thermal cycling process. Advanced thermal management techniques include synchronized application of electric fields with heat transfer cycles, minimizing dead thermal mass, and implementing regenerative heat recovery systems. These optimizations help to extract maximum cooling power from the electrocaloric effect while maintaining system efficiency.

- Device architecture and system integration for longevity: The physical configuration and integration of electrocaloric cooling devices significantly impact their lifetime. Designs that minimize mechanical stress on electrocaloric elements during thermal cycling help prevent material fatigue and degradation. Modular architectures allow for easier maintenance and component replacement, extending overall system life. Integration approaches that protect sensitive components from environmental factors such as moisture and contaminants further enhance device durability. Advanced manufacturing techniques and robust electrical connection methods also contribute to improved reliability and longevity.

- Electric field management and control strategies: Sophisticated control strategies for applying and managing electric fields are essential for both cooling power density and device lifetime. Precise timing and magnitude control of electric fields maximize the electrocaloric effect while preventing electrical breakdown of materials. Adaptive control systems that adjust field parameters based on cooling demand and material response help optimize performance while preventing excessive stress on components. Techniques for field cycling that minimize electrical fatigue and aging effects contribute significantly to extended device lifetime.

- Reliability enhancement and degradation mitigation: Specific design features and operational strategies focus on enhancing the reliability and mitigating degradation of electrocaloric cooling systems. These include protective circuits to prevent electrical overstress, thermal management systems to avoid temperature extremes that accelerate aging, and specialized coatings or encapsulation methods to protect electrocaloric materials. Accelerated life testing methodologies help identify failure modes and inform design improvements. Some systems incorporate self-diagnostic capabilities and predictive maintenance features to detect early signs of performance degradation and extend operational lifetime.

02 Device architecture and design for improved lifetime

The architecture and design of electrocaloric cooling devices significantly impact their operational lifetime. Innovative designs incorporating heat exchangers, thermal switches, and optimized electrode configurations can reduce mechanical stress and electrical fatigue in the electrocaloric elements. Multilayer structures and advanced packaging techniques help distribute thermal and electrical stresses more evenly, preventing premature failure. Proper thermal management systems and reduced cycling frequency can also extend device lifetime while maintaining adequate cooling performance.Expand Specific Solutions03 Thermal cycling and fatigue management techniques

Managing thermal cycling and fatigue is essential for extending the lifetime of electrocaloric cooling devices. Techniques include controlled ramping of electric fields, optimized duty cycles, and temperature gradient management across the electrocaloric elements. Implementing gradual heating and cooling phases rather than abrupt changes can reduce thermal shock and mechanical stress. Advanced control algorithms that monitor device performance and adjust operating parameters can prevent excessive fatigue while maintaining cooling power density at optimal levels throughout the device's operational life.Expand Specific Solutions04 Heat transfer mechanisms for maximizing cooling efficiency

Efficient heat transfer mechanisms are critical for achieving high cooling power density in electrocaloric systems. Various approaches include direct contact heat exchange, fluid-based heat transfer systems, and advanced thermal interface materials. Optimizing the thermal contact between the electrocaloric elements and heat sinks reduces thermal resistance and improves heat flux. Implementing regenerative heat transfer cycles and cascaded cooling stages can further enhance the overall cooling power density while reducing the thermal load on individual components, thereby extending device lifetime.Expand Specific Solutions05 Control systems and operating strategies for balancing performance and longevity

Advanced control systems and operating strategies play a crucial role in balancing cooling power density with device lifetime. Adaptive control algorithms can optimize the applied electric field based on cooling demand, preventing unnecessary stress on the electrocaloric elements during periods of low cooling requirements. Implementing variable frequency operation, duty cycle management, and load-responsive cooling can significantly extend device lifetime while maintaining adequate cooling performance when needed. Monitoring systems that track performance degradation over time allow for predictive maintenance before catastrophic failure occurs.Expand Specific Solutions

Leading Companies and Research Institutions in Electrocaloric Field

Electrocaloric cooling technology is currently in the early development stage, with the market still emerging but showing significant growth potential due to increasing demand for energy-efficient cooling solutions. The global market size is estimated to reach $2-3 billion by 2030, driven by automotive, electronics, and industrial applications. Technologically, companies are at varying maturity levels: Hitachi, Toyota, and Mitsubishi Electric lead with advanced research programs and patent portfolios; DENSO, LG Chem, and Camfridge are developing commercial prototypes; while academic institutions like University of Maryland and Colorado School of Mines contribute fundamental research. The primary challenge remains balancing cooling power density with device longevity, as higher performance often compromises operational lifespan, requiring innovative material science solutions from industry players.

University of Maryland

Technical Solution: The University of Maryland has pioneered research in electrocaloric cooling with a focus on the fundamental trade-offs between cooling power density and material degradation. Their approach centers on developing novel polymer-based electrocaloric materials that demonstrate enhanced cyclability while maintaining significant temperature changes. The research team has created composite electrocaloric materials that incorporate nanostructured ferroelectric elements within a flexible polymer matrix, allowing for greater mechanical stability during thermal cycling. This design mitigates the mechanical stress that typically leads to device failure in ceramic-based systems. Their cooling system architecture employs a regenerative heat transfer mechanism with precisely timed electric field application and removal, optimizing the balance between maximum temperature change and material degradation[3]. The university's research has demonstrated that controlled electric field profiles with specific rise and fall times can reduce internal stress within the electrocaloric materials by up to 35%, significantly extending operational lifetime while sacrificing only 10-15% of maximum cooling power[4].

Strengths: Leading academic research in polymer-based electrocaloric materials with superior cycling stability and fundamental understanding of degradation mechanisms. Their regenerative heat transfer designs maximize efficiency. Weaknesses: As an academic institution, their technologies may be at lower technology readiness levels compared to commercial entities, and scaling to commercial production remains challenging.

The Iowa State University Research Foundation, Inc.

Technical Solution: The Iowa State University Research Foundation has developed innovative approaches to address the fundamental challenges in electrocaloric cooling, particularly focusing on the trade-off between cooling power density and operational lifetime. Their research centers on developing novel composite electrocaloric materials that combine ferroelectric ceramics with thermally conductive networks to enhance heat transfer while distributing mechanical stress during thermal cycling. A key innovation in their approach is the implementation of "staged cooling cycles" where the electric field is applied and removed in multiple steps rather than abruptly, significantly reducing the mechanical and electrical stress on the electrocaloric materials. Their cooling system architecture incorporates specialized thermal interfaces with gradient structures that accommodate the dimensional changes of electrocaloric materials during operation while maintaining efficient heat transfer. The research team has also developed advanced characterization techniques that allow for real-time monitoring of material degradation during operation, enabling the development of predictive models for lifetime estimation based on operating conditions[9]. Their studies have demonstrated that optimized electric field profiles can extend device lifetime by up to 250% while maintaining 80% of the maximum cooling power density compared to conventional operation[10].

Strengths: Innovative material design with composite structures that balance thermal performance and mechanical stability. Their staged cooling approach significantly extends device lifetime. Weaknesses: As a research foundation, commercialization pathways may be less developed, and their technologies may require further development for market readiness.

Critical Patents and Breakthroughs in Electrocaloric Materials

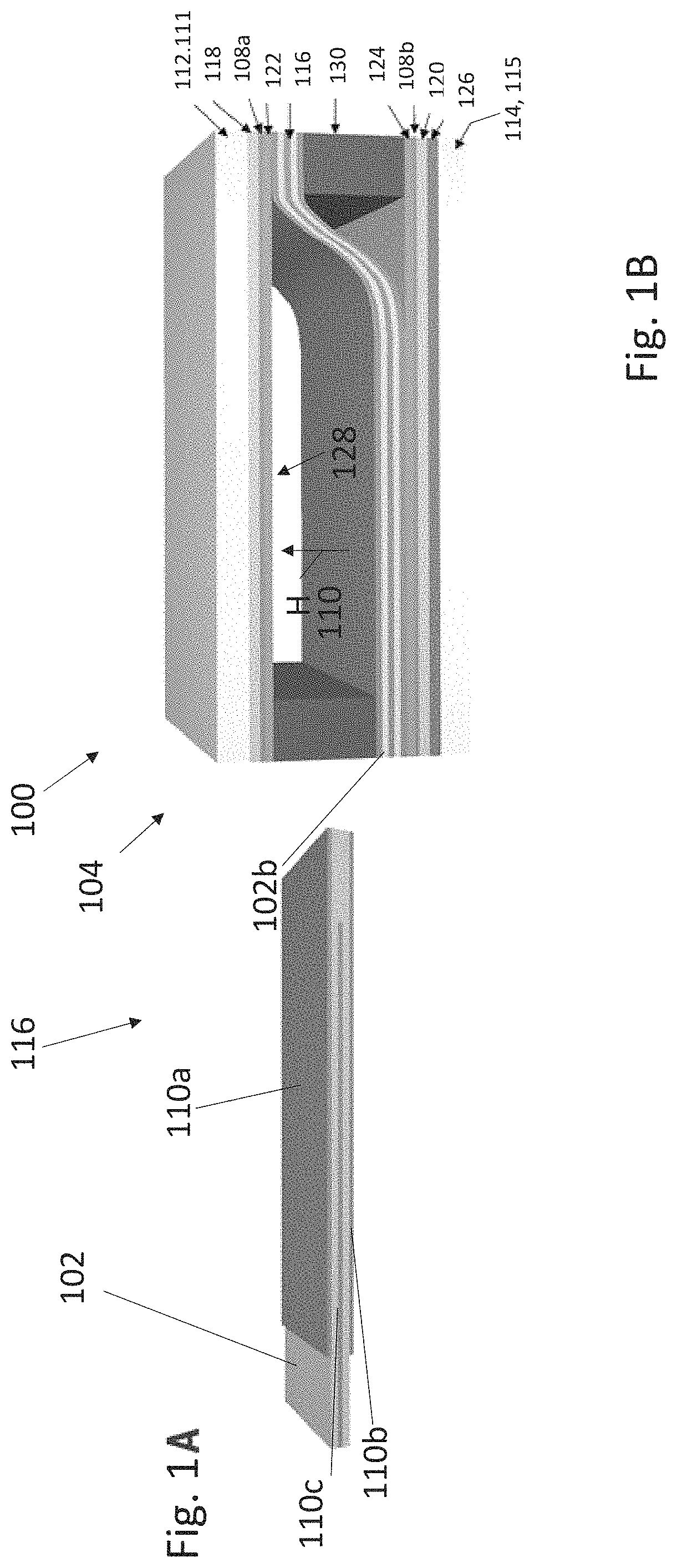

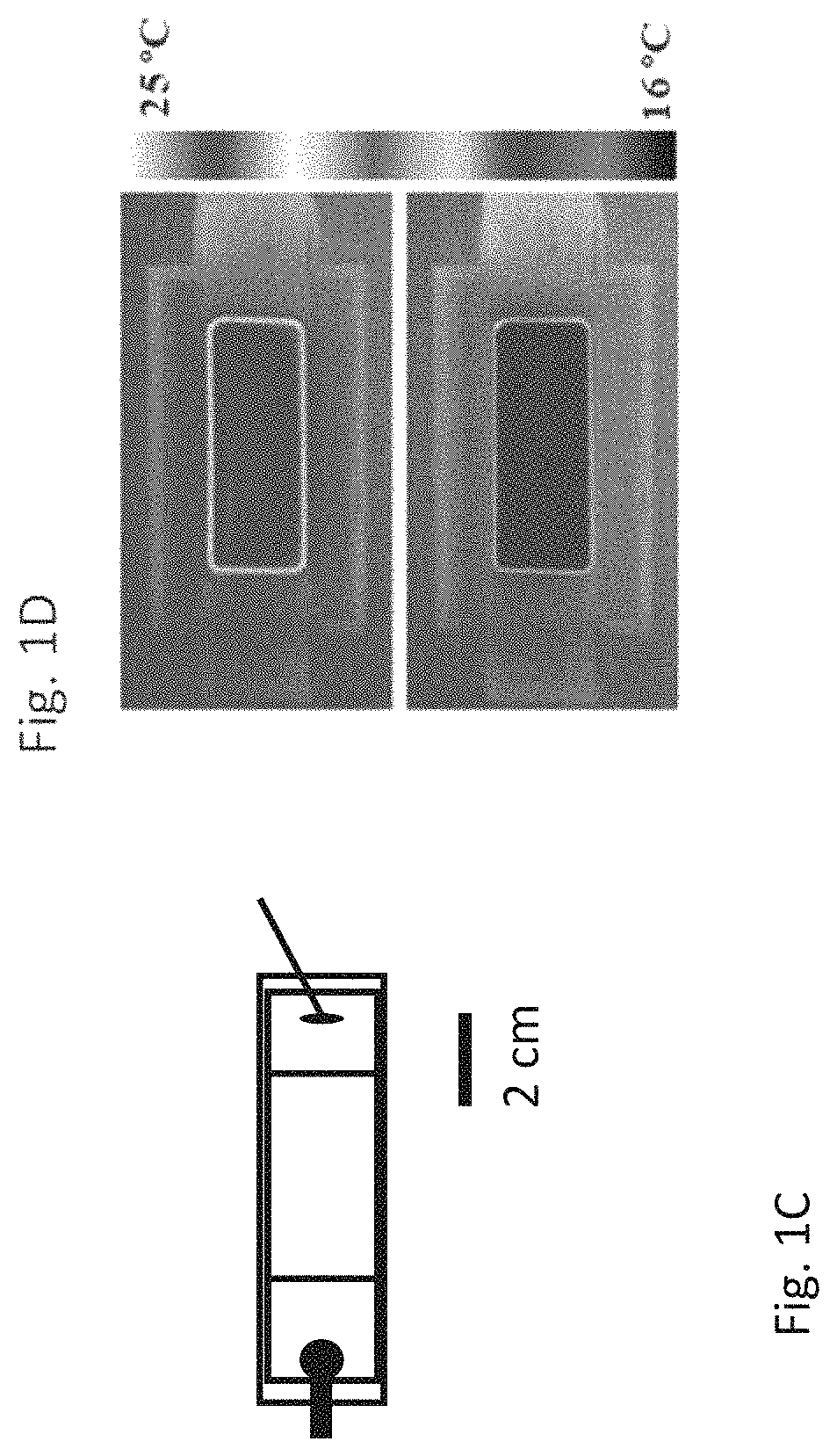

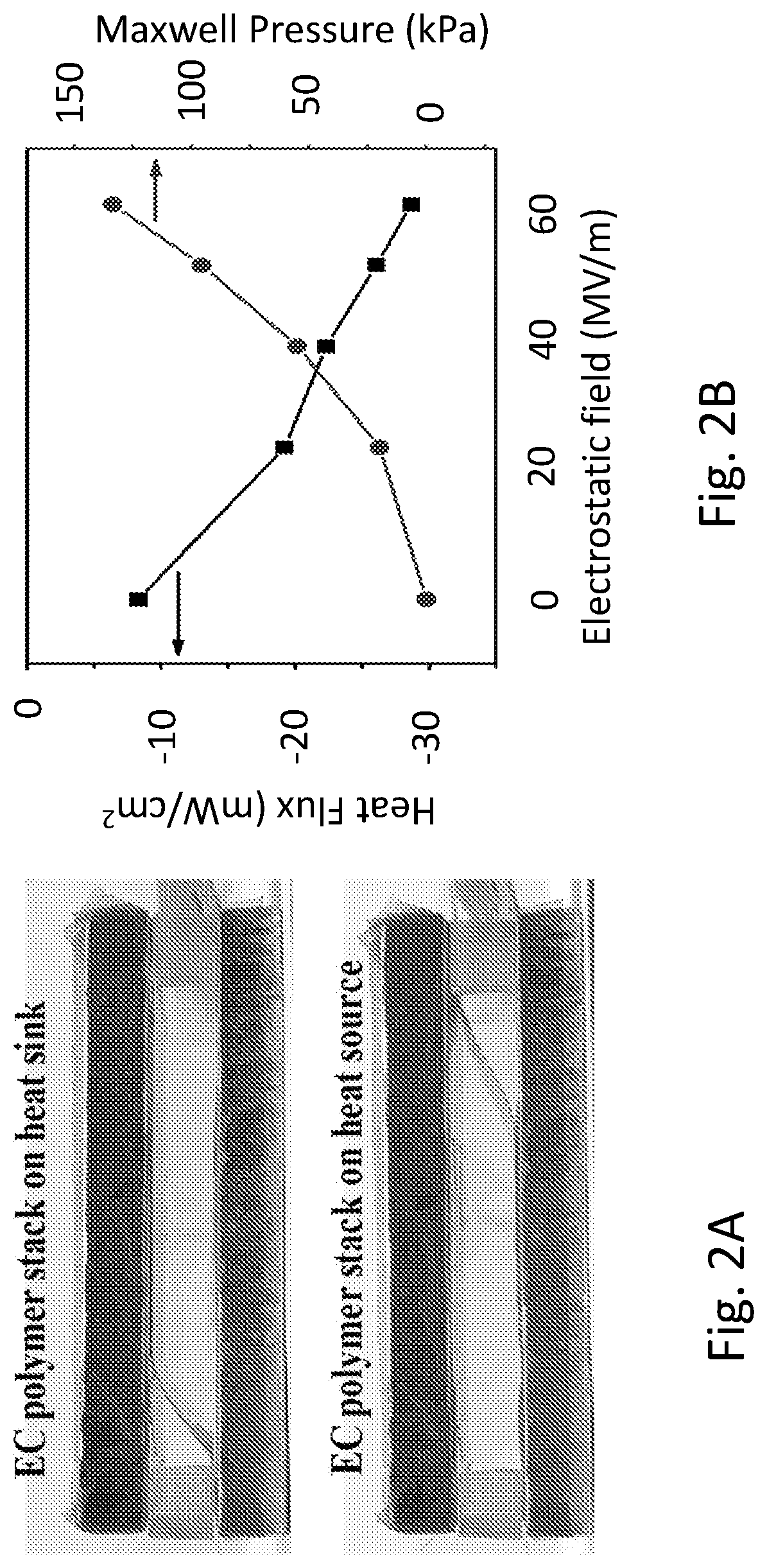

Electrocaloric cooling with electrostatic actuation

PatentActiveUS11397031B2

Innovation

- A solid-state heat transporting device utilizing a flexible electrocaloric polymer film coupled with an electrostatic actuation mechanism, allowing for controlled heat transfer between heat sources and sinks by altering the shape or position of the film to enhance thermal contact and reduce parasitic power consumption.

Determination of the lifetime of a component

PatentInactiveEP2031948A3

Innovation

- A real-time monitoring system within the power electronics appliance calculates the remaining service life of components based on component-specific data, including temperature, rotation speed, and operating hours, allowing for precise scheduling of replacements.

Thermal Cycling Fatigue Analysis and Mitigation Strategies

Thermal cycling is a critical factor affecting the lifetime of electrocaloric cooling devices. As these materials undergo repeated temperature changes during operation, they experience mechanical stresses that can lead to fatigue failure. The frequency and magnitude of thermal cycles directly correlate with cooling power density but inversely affect device longevity.

Experimental data indicates that electrocaloric materials typically experience 3-5% degradation in cooling capacity after 10,000 thermal cycles under standard operating conditions. This degradation accelerates when operating at higher power densities, with some materials showing up to 15% reduction in performance after the same number of cycles when pushed to maximum cooling capacity.

Microstructural analysis reveals that thermal cycling induces the formation and propagation of microcracks at grain boundaries in ceramic-based electrocaloric materials. In polymer-based systems, chain scission and crystallinity changes are the predominant failure mechanisms. These structural changes progressively reduce the electrocaloric effect magnitude and increase electrical leakage currents.

Several analytical models have been developed to predict fatigue behavior, including the Coffin-Manson relationship adapted for electrocaloric materials. This model correlates the number of cycles to failure with the strain amplitude experienced during thermal cycling. Finite element analysis has further enhanced our understanding by simulating stress distributions within complex device geometries.

Mitigation strategies focus on both materials engineering and system design approaches. Material-based solutions include developing composite structures with engineered interfaces that can better accommodate thermal expansion mismatches. Incorporating elastomeric buffer layers between active elements has shown to reduce mechanical stress concentration by up to 40% in multilayer devices.

From a system design perspective, implementing gradual temperature ramping rather than abrupt thermal changes can significantly extend device lifetime. Studies demonstrate that reducing the rate of temperature change by 50% can extend operational lifetime by 30-60%, albeit at the cost of reduced cooling power density.

Advanced control algorithms that dynamically adjust cycling parameters based on cooling demand represent a promising compromise. These adaptive systems operate at maximum power density only when needed, reverting to lower-stress conditions during periods of reduced cooling requirements, thereby extending overall device lifetime while maintaining performance capabilities when demanded.

Experimental data indicates that electrocaloric materials typically experience 3-5% degradation in cooling capacity after 10,000 thermal cycles under standard operating conditions. This degradation accelerates when operating at higher power densities, with some materials showing up to 15% reduction in performance after the same number of cycles when pushed to maximum cooling capacity.

Microstructural analysis reveals that thermal cycling induces the formation and propagation of microcracks at grain boundaries in ceramic-based electrocaloric materials. In polymer-based systems, chain scission and crystallinity changes are the predominant failure mechanisms. These structural changes progressively reduce the electrocaloric effect magnitude and increase electrical leakage currents.

Several analytical models have been developed to predict fatigue behavior, including the Coffin-Manson relationship adapted for electrocaloric materials. This model correlates the number of cycles to failure with the strain amplitude experienced during thermal cycling. Finite element analysis has further enhanced our understanding by simulating stress distributions within complex device geometries.

Mitigation strategies focus on both materials engineering and system design approaches. Material-based solutions include developing composite structures with engineered interfaces that can better accommodate thermal expansion mismatches. Incorporating elastomeric buffer layers between active elements has shown to reduce mechanical stress concentration by up to 40% in multilayer devices.

From a system design perspective, implementing gradual temperature ramping rather than abrupt thermal changes can significantly extend device lifetime. Studies demonstrate that reducing the rate of temperature change by 50% can extend operational lifetime by 30-60%, albeit at the cost of reduced cooling power density.

Advanced control algorithms that dynamically adjust cycling parameters based on cooling demand represent a promising compromise. These adaptive systems operate at maximum power density only when needed, reverting to lower-stress conditions during periods of reduced cooling requirements, thereby extending overall device lifetime while maintaining performance capabilities when demanded.

Environmental Impact and Sustainability Considerations

Electrocaloric cooling technology presents significant environmental and sustainability implications that must be carefully considered alongside its technical performance metrics. The materials used in electrocaloric devices, particularly lead-based ferroelectrics and polymer-based materials, raise important environmental concerns. Lead-based compounds pose serious health and environmental risks throughout their lifecycle, from manufacturing to disposal, necessitating strict handling protocols and specialized recycling processes.

Alternative material development has focused on lead-free ceramics and environmentally benign polymers that maintain cooling efficiency while reducing ecological impact. These materials often require less energy-intensive production methods, though their performance characteristics may differ from traditional options, creating additional engineering challenges in device design.

Energy consumption patterns of electrocaloric cooling systems demonstrate promising sustainability advantages. When optimized for efficiency, these systems can achieve higher coefficients of performance than conventional vapor-compression refrigeration, potentially reducing overall energy demand. However, the relationship between cooling power density and device lifetime creates a sustainability paradox: higher power densities may accelerate material degradation, necessitating more frequent device replacement and increasing material consumption and waste generation.

Life cycle assessment studies indicate that the environmental footprint of electrocaloric cooling is heavily influenced by operational parameters. Devices operated at moderate power densities typically demonstrate extended lifetimes and better overall environmental performance than those pushed to maximum cooling capacity. This suggests that sustainability-optimized designs may need to accept modest reductions in peak performance to achieve better long-term environmental outcomes.

Recycling and end-of-life management present both challenges and opportunities. The composite nature of electrocaloric devices complicates material recovery, but emerging design-for-disassembly approaches show promise for improving recyclability. Advanced separation techniques can potentially recover valuable materials from end-of-life devices, reducing primary resource demand and minimizing waste.

Regulatory frameworks increasingly influence technology development in this field. Several jurisdictions have implemented restrictions on hazardous substances that impact material selection for electrocaloric devices. Forward-looking manufacturers are proactively adopting green chemistry principles and exploring bio-derived alternatives that can meet performance requirements while ensuring regulatory compliance across global markets.

The carbon footprint comparison between electrocaloric cooling and conventional technologies reveals potential climate benefits, particularly when powered by renewable energy sources. However, these advantages must be weighed against the embedded carbon in manufacturing and the greenhouse gas implications of any refrigerants used in hybrid cooling systems.

Alternative material development has focused on lead-free ceramics and environmentally benign polymers that maintain cooling efficiency while reducing ecological impact. These materials often require less energy-intensive production methods, though their performance characteristics may differ from traditional options, creating additional engineering challenges in device design.

Energy consumption patterns of electrocaloric cooling systems demonstrate promising sustainability advantages. When optimized for efficiency, these systems can achieve higher coefficients of performance than conventional vapor-compression refrigeration, potentially reducing overall energy demand. However, the relationship between cooling power density and device lifetime creates a sustainability paradox: higher power densities may accelerate material degradation, necessitating more frequent device replacement and increasing material consumption and waste generation.

Life cycle assessment studies indicate that the environmental footprint of electrocaloric cooling is heavily influenced by operational parameters. Devices operated at moderate power densities typically demonstrate extended lifetimes and better overall environmental performance than those pushed to maximum cooling capacity. This suggests that sustainability-optimized designs may need to accept modest reductions in peak performance to achieve better long-term environmental outcomes.

Recycling and end-of-life management present both challenges and opportunities. The composite nature of electrocaloric devices complicates material recovery, but emerging design-for-disassembly approaches show promise for improving recyclability. Advanced separation techniques can potentially recover valuable materials from end-of-life devices, reducing primary resource demand and minimizing waste.

Regulatory frameworks increasingly influence technology development in this field. Several jurisdictions have implemented restrictions on hazardous substances that impact material selection for electrocaloric devices. Forward-looking manufacturers are proactively adopting green chemistry principles and exploring bio-derived alternatives that can meet performance requirements while ensuring regulatory compliance across global markets.

The carbon footprint comparison between electrocaloric cooling and conventional technologies reveals potential climate benefits, particularly when powered by renewable energy sources. However, these advantages must be weighed against the embedded carbon in manufacturing and the greenhouse gas implications of any refrigerants used in hybrid cooling systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!