Optimizing Dielectric Breakdown Strength For Higher Field Operation In Electrocaloric Cooling

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

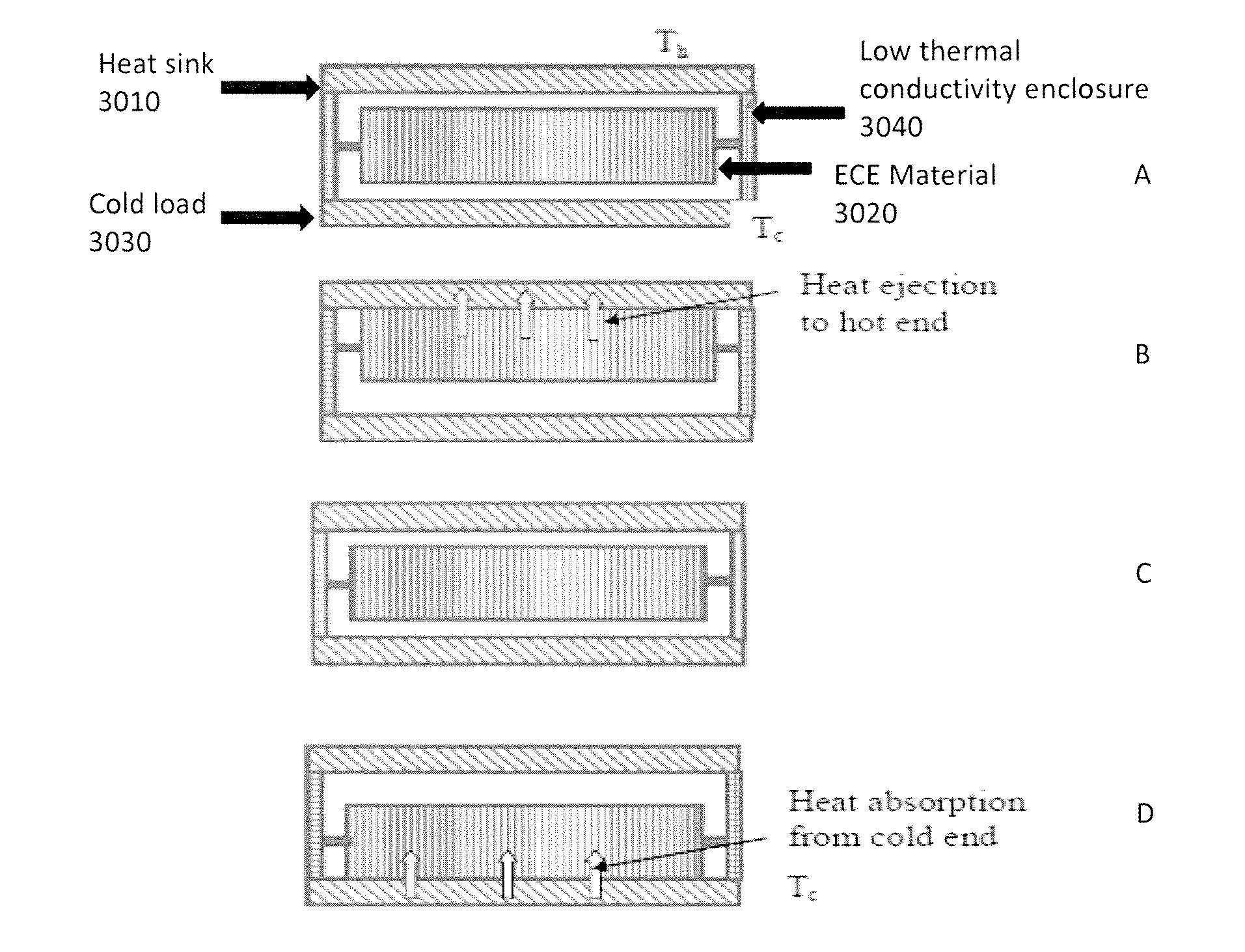

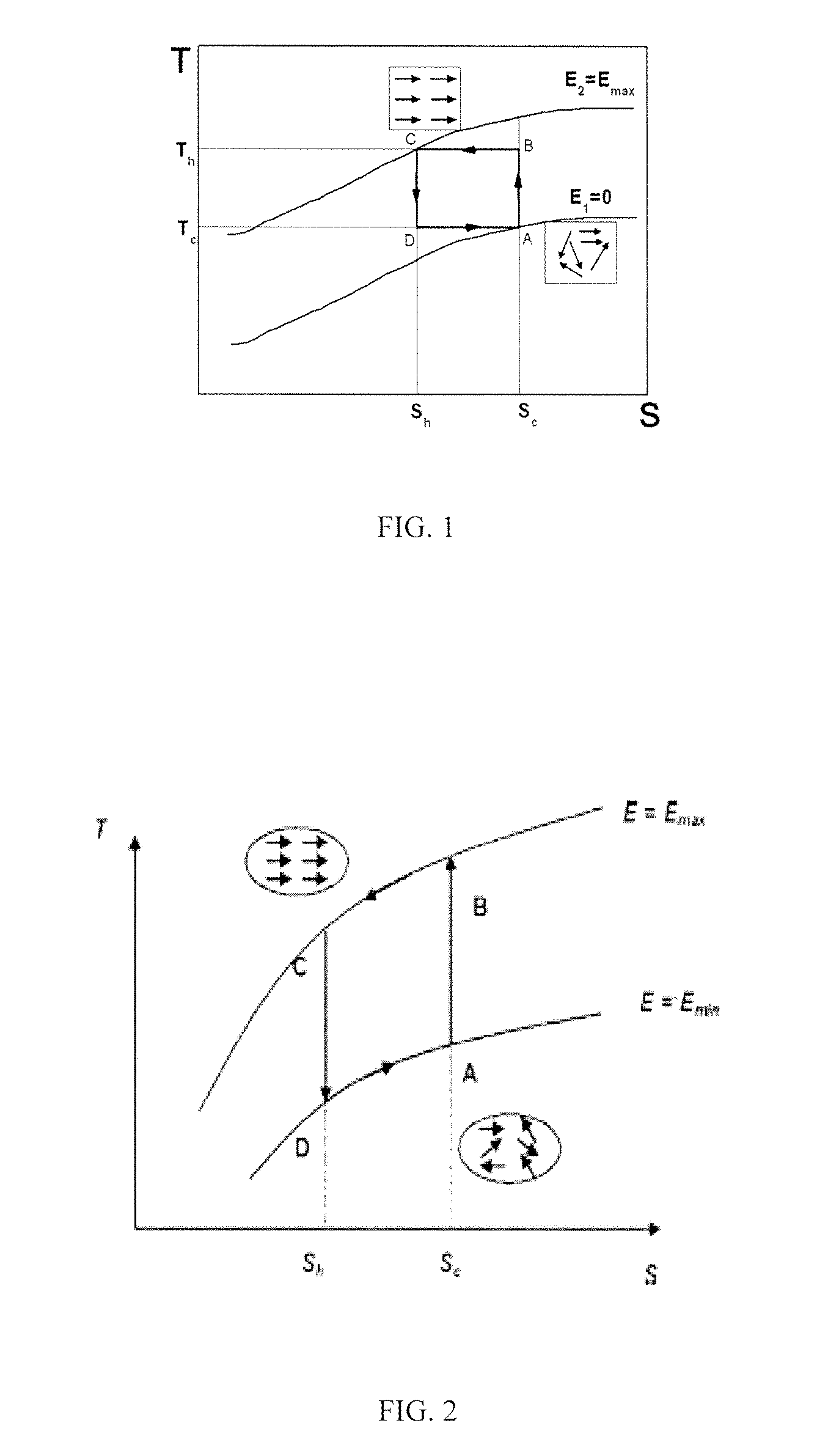

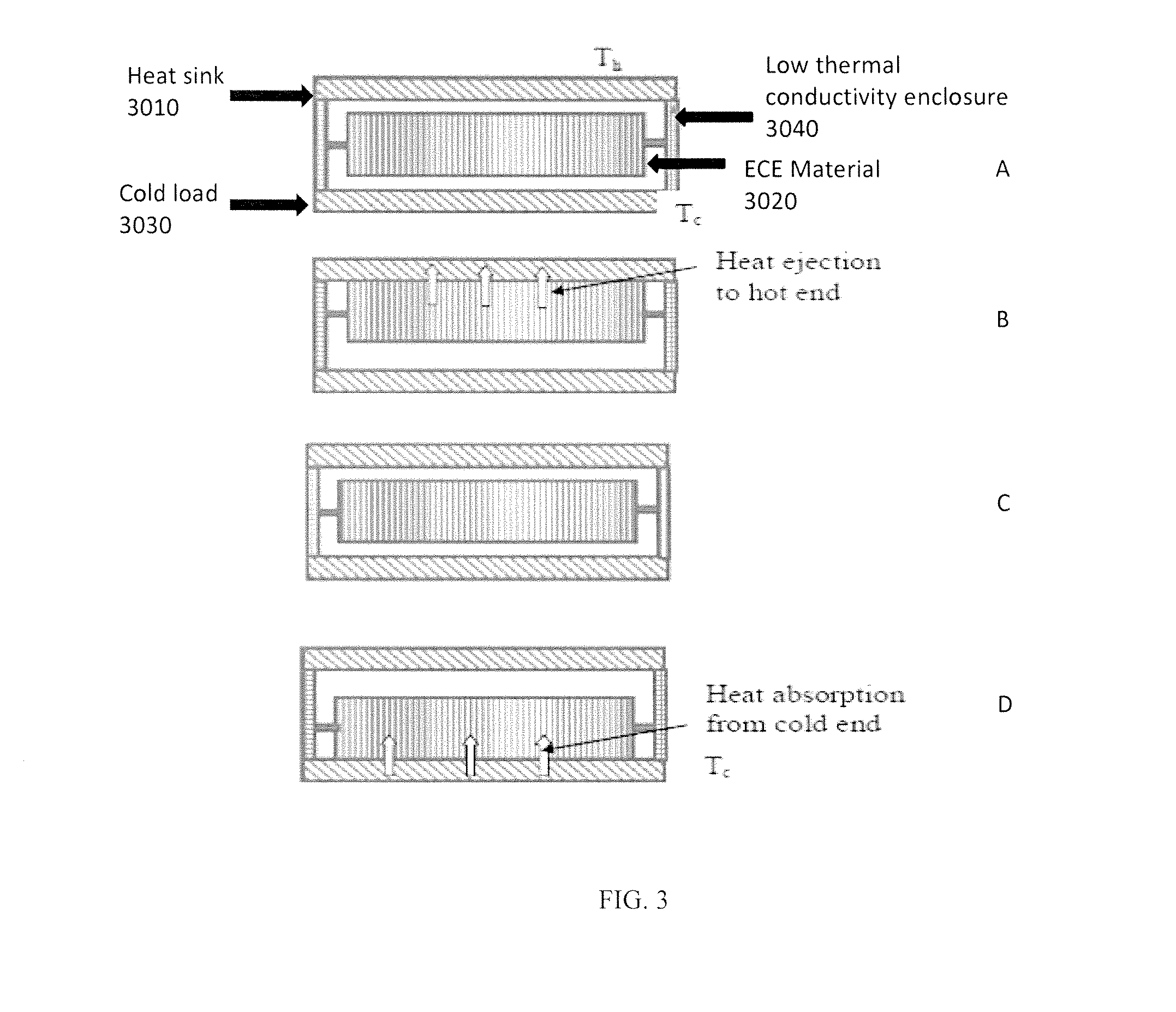

Electrocaloric cooling represents a revolutionary approach to thermal management, leveraging the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to electric fields. This technology has evolved significantly since its discovery in the early 20th century, with major advancements occurring in the past two decades as researchers have identified materials with enhanced electrocaloric properties and developed more sophisticated device architectures.

The evolution of electrocaloric cooling technology has been driven by increasing demands for energy-efficient, environmentally friendly cooling solutions that can replace conventional vapor-compression systems reliant on harmful refrigerants. Initial research focused primarily on ferroelectric ceramics, but has expanded to include relaxor ferroelectrics, polymers, and composite materials that demonstrate promising electrocaloric responses.

A critical limitation in current electrocaloric systems is their operational electric field threshold, constrained by the dielectric breakdown strength of materials. This parameter defines the maximum electric field a material can withstand before electrical failure occurs, directly impacting the achievable temperature change and cooling capacity of electrocaloric devices.

Recent technological trends indicate a shift toward multilayer configurations, thin-film geometries, and nanostructured materials designed to enhance dielectric breakdown strength while maintaining strong electrocaloric responses. Parallel developments in high-voltage power electronics and advanced manufacturing techniques have further accelerated progress in this field.

The primary technical objective in optimizing dielectric breakdown strength is to enable electrocaloric materials to operate reliably at significantly higher electric fields (>100 MV/m) without compromising long-term stability or introducing prohibitive manufacturing costs. This would potentially increase temperature lifts from the current 2-5K range to 10-15K, making electrocaloric cooling commercially viable for a broader range of applications.

Secondary objectives include developing scalable fabrication methods for high-performance electrocaloric materials, designing efficient heat transfer mechanisms to extract the generated cooling power, and creating control systems capable of managing the high-voltage operation safely and efficiently.

The ultimate goal is to establish electrocaloric technology as a competitive alternative to conventional cooling technologies, offering superior energy efficiency (projected COP >5), reduced environmental impact, silent operation, and compact form factors suitable for applications ranging from microelectronics cooling to building climate control and refrigeration systems.

The evolution of electrocaloric cooling technology has been driven by increasing demands for energy-efficient, environmentally friendly cooling solutions that can replace conventional vapor-compression systems reliant on harmful refrigerants. Initial research focused primarily on ferroelectric ceramics, but has expanded to include relaxor ferroelectrics, polymers, and composite materials that demonstrate promising electrocaloric responses.

A critical limitation in current electrocaloric systems is their operational electric field threshold, constrained by the dielectric breakdown strength of materials. This parameter defines the maximum electric field a material can withstand before electrical failure occurs, directly impacting the achievable temperature change and cooling capacity of electrocaloric devices.

Recent technological trends indicate a shift toward multilayer configurations, thin-film geometries, and nanostructured materials designed to enhance dielectric breakdown strength while maintaining strong electrocaloric responses. Parallel developments in high-voltage power electronics and advanced manufacturing techniques have further accelerated progress in this field.

The primary technical objective in optimizing dielectric breakdown strength is to enable electrocaloric materials to operate reliably at significantly higher electric fields (>100 MV/m) without compromising long-term stability or introducing prohibitive manufacturing costs. This would potentially increase temperature lifts from the current 2-5K range to 10-15K, making electrocaloric cooling commercially viable for a broader range of applications.

Secondary objectives include developing scalable fabrication methods for high-performance electrocaloric materials, designing efficient heat transfer mechanisms to extract the generated cooling power, and creating control systems capable of managing the high-voltage operation safely and efficiently.

The ultimate goal is to establish electrocaloric technology as a competitive alternative to conventional cooling technologies, offering superior energy efficiency (projected COP >5), reduced environmental impact, silent operation, and compact form factors suitable for applications ranging from microelectronics cooling to building climate control and refrigeration systems.

Market Analysis for High-Efficiency Cooling Solutions

The global cooling solutions market is experiencing a significant shift towards high-efficiency technologies, with electrocaloric cooling emerging as a promising alternative to conventional vapor-compression systems. Current market projections indicate that the global cooling market, valued at approximately $135 billion in 2022, is expected to grow at a CAGR of 5.7% through 2030, with energy-efficient cooling technologies capturing an increasingly larger share.

The demand for high-efficiency cooling solutions is being driven by several key factors. Stringent environmental regulations, particularly the phasing out of hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol, are forcing manufacturers to seek alternative cooling technologies. Additionally, rising energy costs worldwide have heightened consumer and industrial interest in energy-efficient cooling systems that can reduce operational expenses.

Electrocaloric cooling technology, which leverages the electrocaloric effect in dielectric materials to create temperature changes, represents a significant opportunity in this evolving market. The technology's potential for higher coefficient of performance (COP) compared to conventional systems (theoretical COP of 7-9 versus 3-5 for vapor compression) presents a compelling value proposition for both commercial and residential applications.

Market segmentation analysis reveals that commercial refrigeration represents the largest potential market for advanced electrocaloric cooling systems, accounting for approximately 32% of the total addressable market. This is followed by residential air conditioning (28%), industrial process cooling (22%), and automotive climate control systems (18%).

Regional market assessment indicates that North America and Europe currently lead in the adoption of energy-efficient cooling technologies, primarily due to stringent regulatory frameworks and higher consumer willingness to pay premium prices for energy-efficient solutions. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 8% annually through 2030.

Consumer preference studies indicate increasing awareness and demand for environmentally friendly cooling solutions, with 67% of surveyed consumers expressing willingness to pay a premium for cooling systems that offer significant energy savings. The commercial sector shows even stronger interest, with 78% of businesses indicating plans to invest in energy-efficient cooling technologies within the next five years.

The economic analysis of electrocaloric cooling systems with optimized dielectric breakdown strength suggests potential energy savings of 30-40% compared to conventional systems. While initial capital costs remain higher, the total cost of ownership analysis demonstrates favorable economics with payback periods potentially reaching 3-5 years in high-usage scenarios, particularly in regions with high electricity costs.

The demand for high-efficiency cooling solutions is being driven by several key factors. Stringent environmental regulations, particularly the phasing out of hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol, are forcing manufacturers to seek alternative cooling technologies. Additionally, rising energy costs worldwide have heightened consumer and industrial interest in energy-efficient cooling systems that can reduce operational expenses.

Electrocaloric cooling technology, which leverages the electrocaloric effect in dielectric materials to create temperature changes, represents a significant opportunity in this evolving market. The technology's potential for higher coefficient of performance (COP) compared to conventional systems (theoretical COP of 7-9 versus 3-5 for vapor compression) presents a compelling value proposition for both commercial and residential applications.

Market segmentation analysis reveals that commercial refrigeration represents the largest potential market for advanced electrocaloric cooling systems, accounting for approximately 32% of the total addressable market. This is followed by residential air conditioning (28%), industrial process cooling (22%), and automotive climate control systems (18%).

Regional market assessment indicates that North America and Europe currently lead in the adoption of energy-efficient cooling technologies, primarily due to stringent regulatory frameworks and higher consumer willingness to pay premium prices for energy-efficient solutions. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 8% annually through 2030.

Consumer preference studies indicate increasing awareness and demand for environmentally friendly cooling solutions, with 67% of surveyed consumers expressing willingness to pay a premium for cooling systems that offer significant energy savings. The commercial sector shows even stronger interest, with 78% of businesses indicating plans to invest in energy-efficient cooling technologies within the next five years.

The economic analysis of electrocaloric cooling systems with optimized dielectric breakdown strength suggests potential energy savings of 30-40% compared to conventional systems. While initial capital costs remain higher, the total cost of ownership analysis demonstrates favorable economics with payback periods potentially reaching 3-5 years in high-usage scenarios, particularly in regions with high electricity costs.

Current Dielectric Breakdown Challenges in Electrocaloric Materials

Electrocaloric materials face significant dielectric breakdown challenges that limit their practical application in cooling systems. The dielectric breakdown strength (DBS) represents the maximum electric field a material can withstand before electrical failure occurs, and it directly impacts the cooling efficiency and operational range of electrocaloric devices. Currently, most promising electrocaloric materials exhibit breakdown at field strengths well below their theoretical performance thresholds.

A primary challenge is the presence of structural defects within electrocaloric materials. These include oxygen vacancies, grain boundaries, and microscopic voids that create localized field concentrations, initiating breakdown at lower than expected field strengths. In ferroelectric polymers like P(VDF-TrFE), chain entanglements and crystalline-amorphous interfaces serve as breakdown initiation sites, while ceramic materials suffer from porosity and compositional inhomogeneities.

Temperature dependence presents another significant obstacle. As electrocaloric materials operate through temperature cycling, their dielectric properties fluctuate substantially. Most materials show reduced breakdown strength at elevated temperatures—precisely when higher fields would be most beneficial for maximizing the electrocaloric effect. This inverse relationship between operating temperature and breakdown strength creates a fundamental design constraint.

Thickness effects further complicate material optimization. Thin films typically demonstrate higher breakdown strengths than bulk materials, but this advantage diminishes as thickness increases to levels practical for commercial cooling applications. The scaling relationship between thickness and breakdown strength follows non-linear patterns that vary by material class and processing method.

Processing-induced challenges also limit performance. Conventional fabrication methods introduce impurities and structural irregularities that serve as breakdown initiation sites. Solution-processed polymers contain residual solvents, while sintered ceramics develop microcracks during thermal cycling. These manufacturing artifacts significantly reduce practical breakdown strengths compared to theoretical limits.

Environmental factors introduce additional complications. Humidity, in particular, accelerates breakdown in many electrocaloric materials through moisture absorption and subsequent ionization pathways. Atmospheric contaminants can also penetrate material surfaces, creating conductive paths that trigger premature breakdown.

The measurement standardization problem further hinders progress. Different research groups employ varied testing protocols for determining breakdown strength, making direct comparisons between materials difficult. Factors such as electrode geometry, ramp rate, and environmental conditions significantly influence measured values, creating inconsistencies in reported performance metrics.

Finally, there exists a fundamental materials trade-off between electrocaloric performance and breakdown strength. Materials modifications that enhance electrocaloric effect (such as increasing dipole density) often simultaneously reduce breakdown strength by creating more potential failure sites. This inherent conflict necessitates careful optimization strategies that balance these competing properties.

A primary challenge is the presence of structural defects within electrocaloric materials. These include oxygen vacancies, grain boundaries, and microscopic voids that create localized field concentrations, initiating breakdown at lower than expected field strengths. In ferroelectric polymers like P(VDF-TrFE), chain entanglements and crystalline-amorphous interfaces serve as breakdown initiation sites, while ceramic materials suffer from porosity and compositional inhomogeneities.

Temperature dependence presents another significant obstacle. As electrocaloric materials operate through temperature cycling, their dielectric properties fluctuate substantially. Most materials show reduced breakdown strength at elevated temperatures—precisely when higher fields would be most beneficial for maximizing the electrocaloric effect. This inverse relationship between operating temperature and breakdown strength creates a fundamental design constraint.

Thickness effects further complicate material optimization. Thin films typically demonstrate higher breakdown strengths than bulk materials, but this advantage diminishes as thickness increases to levels practical for commercial cooling applications. The scaling relationship between thickness and breakdown strength follows non-linear patterns that vary by material class and processing method.

Processing-induced challenges also limit performance. Conventional fabrication methods introduce impurities and structural irregularities that serve as breakdown initiation sites. Solution-processed polymers contain residual solvents, while sintered ceramics develop microcracks during thermal cycling. These manufacturing artifacts significantly reduce practical breakdown strengths compared to theoretical limits.

Environmental factors introduce additional complications. Humidity, in particular, accelerates breakdown in many electrocaloric materials through moisture absorption and subsequent ionization pathways. Atmospheric contaminants can also penetrate material surfaces, creating conductive paths that trigger premature breakdown.

The measurement standardization problem further hinders progress. Different research groups employ varied testing protocols for determining breakdown strength, making direct comparisons between materials difficult. Factors such as electrode geometry, ramp rate, and environmental conditions significantly influence measured values, creating inconsistencies in reported performance metrics.

Finally, there exists a fundamental materials trade-off between electrocaloric performance and breakdown strength. Materials modifications that enhance electrocaloric effect (such as increasing dipole density) often simultaneously reduce breakdown strength by creating more potential failure sites. This inherent conflict necessitates careful optimization strategies that balance these competing properties.

Current Approaches to Enhance Dielectric Breakdown Strength

01 Composite dielectric materials for enhanced breakdown strength

Composite dielectric materials combining different components can significantly enhance breakdown strength. These composites often incorporate nanoparticles, polymer matrices, or ceramic fillers to create materials with superior dielectric properties. The synergistic effect between components helps to trap charge carriers, reduce defect concentration, and create tortuous paths for electrical breakdown, resulting in materials with higher breakdown strength suitable for high-voltage applications.- Composite dielectric materials for enhanced breakdown strength: Composite dielectric materials can significantly improve breakdown strength by combining different materials with complementary properties. These composites often incorporate nanoparticles or fillers within a polymer matrix to create interfaces that trap charges and inhibit electrical tree growth. The strategic combination of materials can lead to synergistic effects that enhance the overall dielectric performance beyond what individual components could achieve alone, making them suitable for high-voltage applications.

- Nanostructured dielectric materials: Nanostructured dielectric materials exhibit superior breakdown strength due to their unique structural characteristics at the nanoscale. By controlling the material structure at nanometer dimensions, these materials can effectively trap and distribute electrical charges, preventing localized field enhancement that typically leads to breakdown. Nanolaminates, nanocomposites, and materials with engineered nanoscale interfaces show significantly improved dielectric properties compared to their bulk counterparts.

- Polymer-based dielectric materials: Polymer-based dielectric materials offer excellent breakdown strength due to their inherent flexibility and processability. These materials can be chemically modified to enhance their dielectric properties through cross-linking, chain extension, or the addition of functional groups. Polymers such as polyimide, polypropylene, and fluoropolymers demonstrate superior breakdown strength and are widely used in capacitors, cables, and electronic devices where high voltage insulation is required.

- Ceramic and glass dielectric materials: Ceramic and glass dielectric materials provide exceptional breakdown strength at high temperatures and in harsh environments. These materials, including aluminum oxide, silicon dioxide, and various specialized glass formulations, maintain their insulating properties under extreme conditions. Their rigid atomic structure and high bond strength contribute to their ability to withstand strong electric fields without breakdown, making them ideal for high-temperature electronics and power applications.

- Surface treatment and interface engineering: Surface treatment and interface engineering techniques can dramatically improve the breakdown strength of dielectric materials. By modifying the surface chemistry, creating gradient interfaces, or introducing controlled defects, the electric field distribution can be optimized to prevent localized field enhancement. These approaches include plasma treatment, chemical functionalization, and the creation of buffer layers between different materials, all of which contribute to enhanced dielectric performance and reliability.

02 Nanostructured dielectric materials

Nanostructured dielectric materials exhibit superior breakdown strength due to their unique structural properties. By engineering materials at the nanoscale, interfaces and boundaries can be precisely controlled to limit charge transport and inhibit breakdown mechanisms. These materials often feature reduced defect density, controlled grain boundaries, and engineered interfaces that effectively block the propagation of electrical treeing and partial discharges, leading to significantly improved breakdown strength.Expand Specific Solutions03 Processing techniques to improve dielectric breakdown strength

Various processing techniques can be employed to enhance the breakdown strength of dielectric materials. These include specialized heat treatment processes, controlled cooling rates, surface modification methods, and advanced deposition techniques. Such processing approaches can reduce structural defects, optimize crystallinity, eliminate voids and impurities, and create more homogeneous microstructures, all of which contribute to improved dielectric breakdown performance.Expand Specific Solutions04 Polymer-based dielectric materials with high breakdown strength

Polymer-based dielectric materials offer excellent breakdown strength characteristics for various applications. These materials can be engineered through molecular design, crosslinking, and addition of functional groups to enhance their electrical properties. Advanced polymer dielectrics often feature self-healing capabilities, controlled morphology, and optimized chain configurations that resist electrical breakdown under high field conditions, making them suitable for capacitors, insulation, and other high-voltage applications.Expand Specific Solutions05 Environmental and operational factors affecting breakdown strength

The breakdown strength of dielectric materials is significantly influenced by environmental and operational factors. Temperature fluctuations, humidity levels, mechanical stress, radiation exposure, and aging processes can all impact a material's ability to withstand electrical breakdown. Understanding these factors enables the development of dielectric materials with enhanced stability under various operating conditions, leading to more reliable performance in real-world applications.Expand Specific Solutions

Leading Companies and Research Institutions in Electrocaloric Technology

The electrocaloric cooling technology market is currently in an early growth phase, characterized by intensive R&D activities and limited commercial applications. The global market size remains relatively small but is projected to expand significantly as energy-efficient cooling solutions gain traction. Technologically, the field is still developing, with companies focusing on overcoming the dielectric breakdown strength challenge to enable higher field operation. Key players include materials specialists like Murata Manufacturing and ROHM, who bring expertise in dielectric materials; industrial giants such as Siemens, Mitsubishi Electric, and Infineon Technologies, who possess advanced manufacturing capabilities; and emerging specialists like Nascent Devices, which focuses specifically on electrocaloric cooling systems. Research institutions like Kyushu University and CEA are contributing fundamental breakthroughs, while automotive companies including Toyota and DENSO are exploring applications for vehicle thermal management.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed a comprehensive solution for enhancing dielectric breakdown strength in electrocaloric materials through their "Gradient-Engineered Dielectric" (GED) technology. This approach creates carefully controlled compositional gradients within the dielectric material, eliminating sharp interfaces where electric field concentrations typically lead to breakdown. Their process involves specialized co-firing techniques for multilayer ceramic capacitors adapted specifically for electrocaloric applications, with proprietary dopant profiles that optimize both breakdown strength and electrocaloric coefficient. Murata's research has demonstrated that controlling grain size distribution and orientation significantly impacts breakdown behavior, with their optimized structures showing up to 60% improvement in maximum operating field strength. Their technology incorporates specialized internal electrode designs that minimize field enhancement at edges, combined with surface passivation treatments that prevent environmental degradation. Recent developments include self-diagnostic capabilities where incipient breakdown events can be detected before catastrophic failure, enabling adaptive control of operating conditions to maximize cooling performance while ensuring reliability.

Strengths: Unparalleled expertise in multilayer ceramic capacitor manufacturing directly applicable to electrocaloric devices; extensive materials engineering capabilities; established high-volume production infrastructure. Weaknesses: Current focus primarily on ceramic-based systems rather than polymers; technology optimization may require compromises between maximum cooling performance and reliability; higher implementation complexity.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has pioneered a comprehensive approach to enhancing dielectric breakdown strength in electrocaloric materials through their proprietary "Field-Optimized Dielectric Architecture" (FODA). This technology employs a hierarchical structure design where nanoscale ferroelectric domains are precisely controlled to distribute electric fields more uniformly. Their solution incorporates specialized edge termination structures that reduce field enhancement at material boundaries - a common failure point in high-field applications. Mitsubishi's research has demonstrated that introducing controlled amounts of specific dopants (including lanthanum and manganese) into lead-free relaxor ferroelectrics significantly enhances breakdown strength while preserving electrocaloric performance. Their multilayer fabrication process includes proprietary electrode designs that minimize field concentrations and specialized heat treatment protocols that optimize grain structure. Recent testing has shown their materials can sustain fields up to 250 kV/mm with minimal degradation, representing approximately 40% improvement over conventional materials.

Strengths: Exceptional manufacturing precision and quality control; extensive experience with high-voltage power systems transferable to electrocaloric applications; strong integration with cooling system design expertise. Weaknesses: Higher production costs compared to conventional approaches; technology primarily optimized for their proprietary material systems; requires specialized manufacturing equipment.

Key Technical Innovations in High-Field Electrocaloric Materials

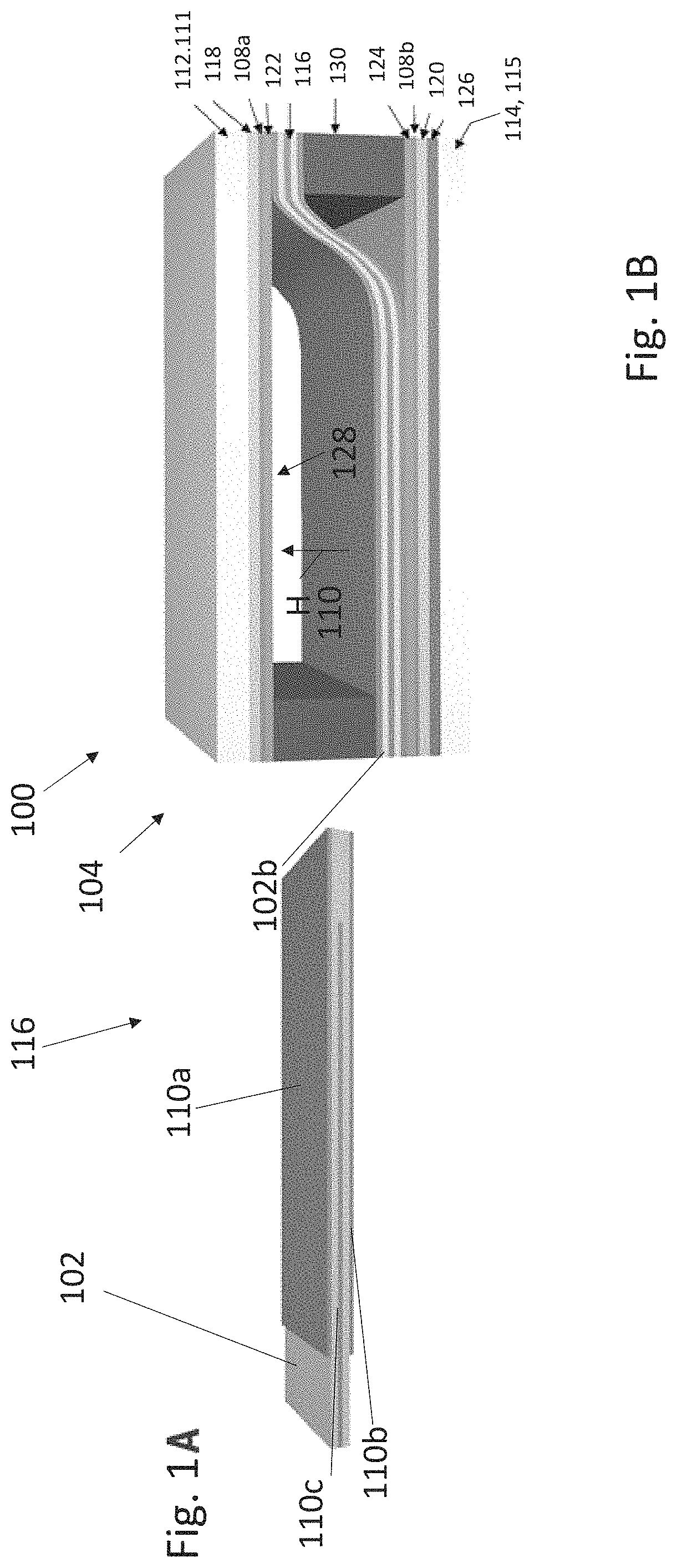

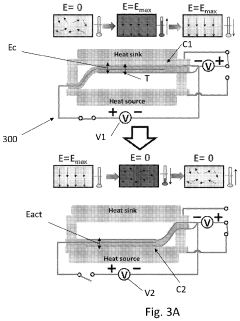

Electrocaloric cooling with electrostatic actuation

PatentActiveUS11397031B2

Innovation

- A solid-state heat transporting device utilizing a flexible electrocaloric polymer film coupled with an electrostatic actuation mechanism, allowing for controlled heat transfer between heat sources and sinks by altering the shape or position of the film to enhance thermal contact and reduce parasitic power consumption.

Cooling device including an electrocaloric composite

PatentInactiveUS20150027132A1

Innovation

- The use of high thermal conductivity electrocaloric composites, comprising electrocaloric polymers and electrically insulating fillers, which enhance thermal conductivity while maintaining the electrocaloric effect, allowing for improved cooling device performance and efficiency.

Environmental Impact and Sustainability of Electrocaloric Cooling

The environmental impact and sustainability of electrocaloric cooling systems are increasingly important considerations as the world seeks alternatives to conventional vapor-compression refrigeration technologies. Optimizing dielectric breakdown strength for higher field operation in electrocaloric cooling not only enhances performance but also offers significant environmental benefits compared to traditional cooling methods.

Electrocaloric cooling systems utilize solid-state materials rather than environmentally harmful refrigerants such as hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs) that contribute to ozone depletion and global warming. By improving dielectric breakdown strength, these systems can operate at higher electric fields without failure, increasing their cooling efficiency while maintaining their inherent environmental advantages.

The lifecycle assessment of electrocaloric cooling technologies reveals substantially lower greenhouse gas emissions compared to conventional refrigeration. When dielectric materials with enhanced breakdown strength are employed, the energy efficiency of these systems improves markedly, reducing electricity consumption and associated carbon emissions. Studies indicate potential energy savings of 20-30% when operating at optimized field strengths.

Material sustainability is another critical aspect of electrocaloric cooling systems. Current research focuses on developing lead-free dielectric materials with high breakdown strength, addressing concerns about toxic elements in electronic components. Promising alternatives include barium titanate-based ceramics and polymer-ceramic composites that combine high performance with reduced environmental impact.

The manufacturing processes for high-breakdown-strength dielectrics are becoming more sustainable through innovations in green chemistry and energy-efficient production methods. Techniques such as hydrothermal synthesis and sol-gel processing reduce solvent use and energy requirements compared to conventional ceramic processing, aligning with circular economy principles.

End-of-life considerations for electrocaloric cooling systems are favorable when compared to conventional refrigeration. The solid-state nature of these systems eliminates refrigerant leakage concerns during disposal. Additionally, many of the ceramic and polymer materials used in high-performance dielectrics can be recycled or repurposed, further reducing waste and resource consumption.

Policy frameworks worldwide are increasingly supporting the transition to more sustainable cooling technologies. The Kigali Amendment to the Montreal Protocol specifically targets the phase-down of HFCs, creating regulatory incentives for alternative technologies like electrocaloric cooling. Optimizing dielectric breakdown strength helps these systems meet performance standards necessary for widespread commercial adoption under these new regulatory regimes.

Electrocaloric cooling systems utilize solid-state materials rather than environmentally harmful refrigerants such as hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs) that contribute to ozone depletion and global warming. By improving dielectric breakdown strength, these systems can operate at higher electric fields without failure, increasing their cooling efficiency while maintaining their inherent environmental advantages.

The lifecycle assessment of electrocaloric cooling technologies reveals substantially lower greenhouse gas emissions compared to conventional refrigeration. When dielectric materials with enhanced breakdown strength are employed, the energy efficiency of these systems improves markedly, reducing electricity consumption and associated carbon emissions. Studies indicate potential energy savings of 20-30% when operating at optimized field strengths.

Material sustainability is another critical aspect of electrocaloric cooling systems. Current research focuses on developing lead-free dielectric materials with high breakdown strength, addressing concerns about toxic elements in electronic components. Promising alternatives include barium titanate-based ceramics and polymer-ceramic composites that combine high performance with reduced environmental impact.

The manufacturing processes for high-breakdown-strength dielectrics are becoming more sustainable through innovations in green chemistry and energy-efficient production methods. Techniques such as hydrothermal synthesis and sol-gel processing reduce solvent use and energy requirements compared to conventional ceramic processing, aligning with circular economy principles.

End-of-life considerations for electrocaloric cooling systems are favorable when compared to conventional refrigeration. The solid-state nature of these systems eliminates refrigerant leakage concerns during disposal. Additionally, many of the ceramic and polymer materials used in high-performance dielectrics can be recycled or repurposed, further reducing waste and resource consumption.

Policy frameworks worldwide are increasingly supporting the transition to more sustainable cooling technologies. The Kigali Amendment to the Montreal Protocol specifically targets the phase-down of HFCs, creating regulatory incentives for alternative technologies like electrocaloric cooling. Optimizing dielectric breakdown strength helps these systems meet performance standards necessary for widespread commercial adoption under these new regulatory regimes.

Thermal Performance Metrics and Testing Methodologies

Thermal performance metrics and testing methodologies are critical for evaluating the efficiency and effectiveness of electrocaloric cooling systems, particularly when optimizing dielectric breakdown strength for higher field operation. The primary metrics used in this field include the electrocaloric temperature change (ΔT), cooling power density, coefficient of performance (COP), and energy efficiency ratio (EER).

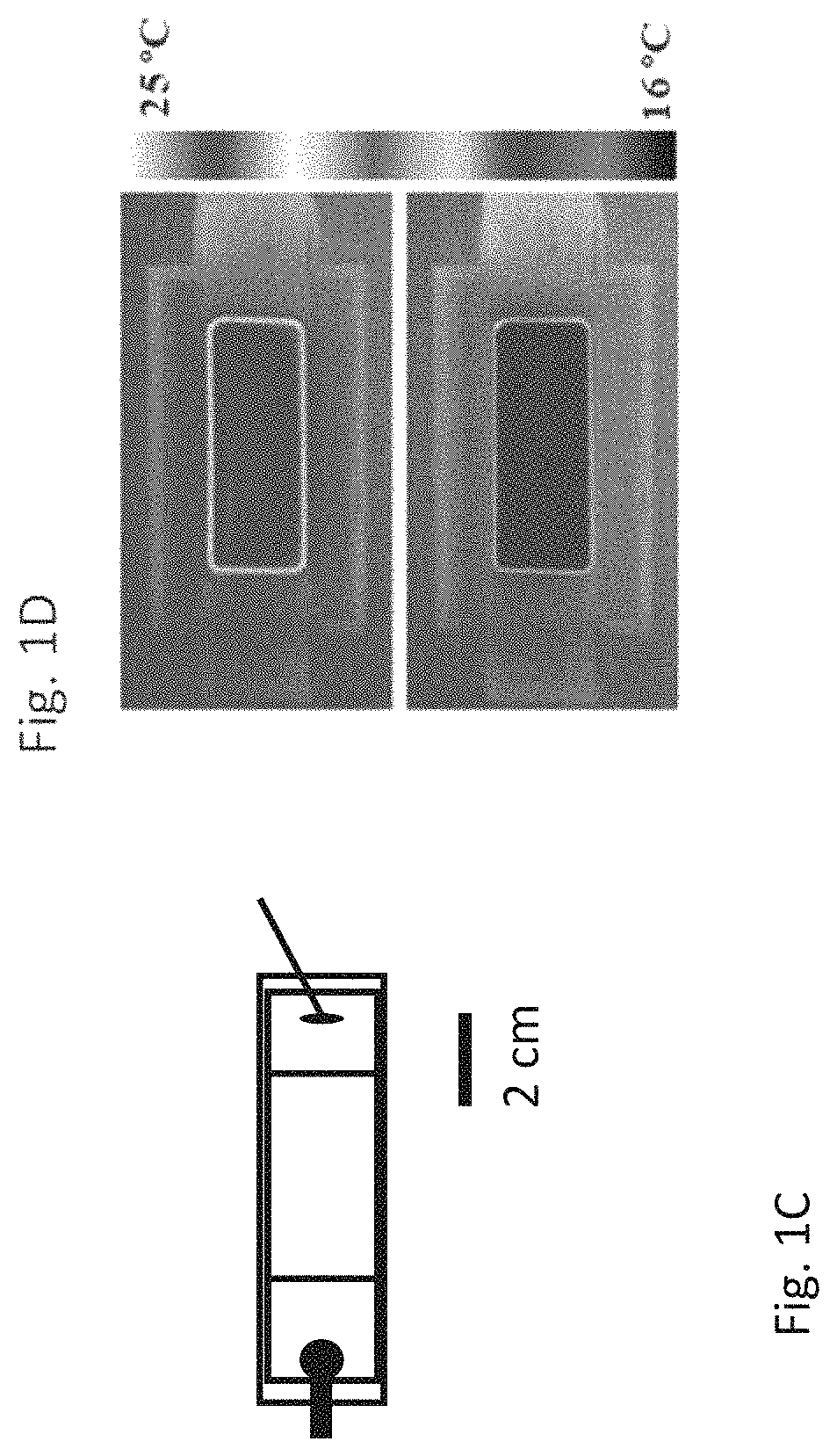

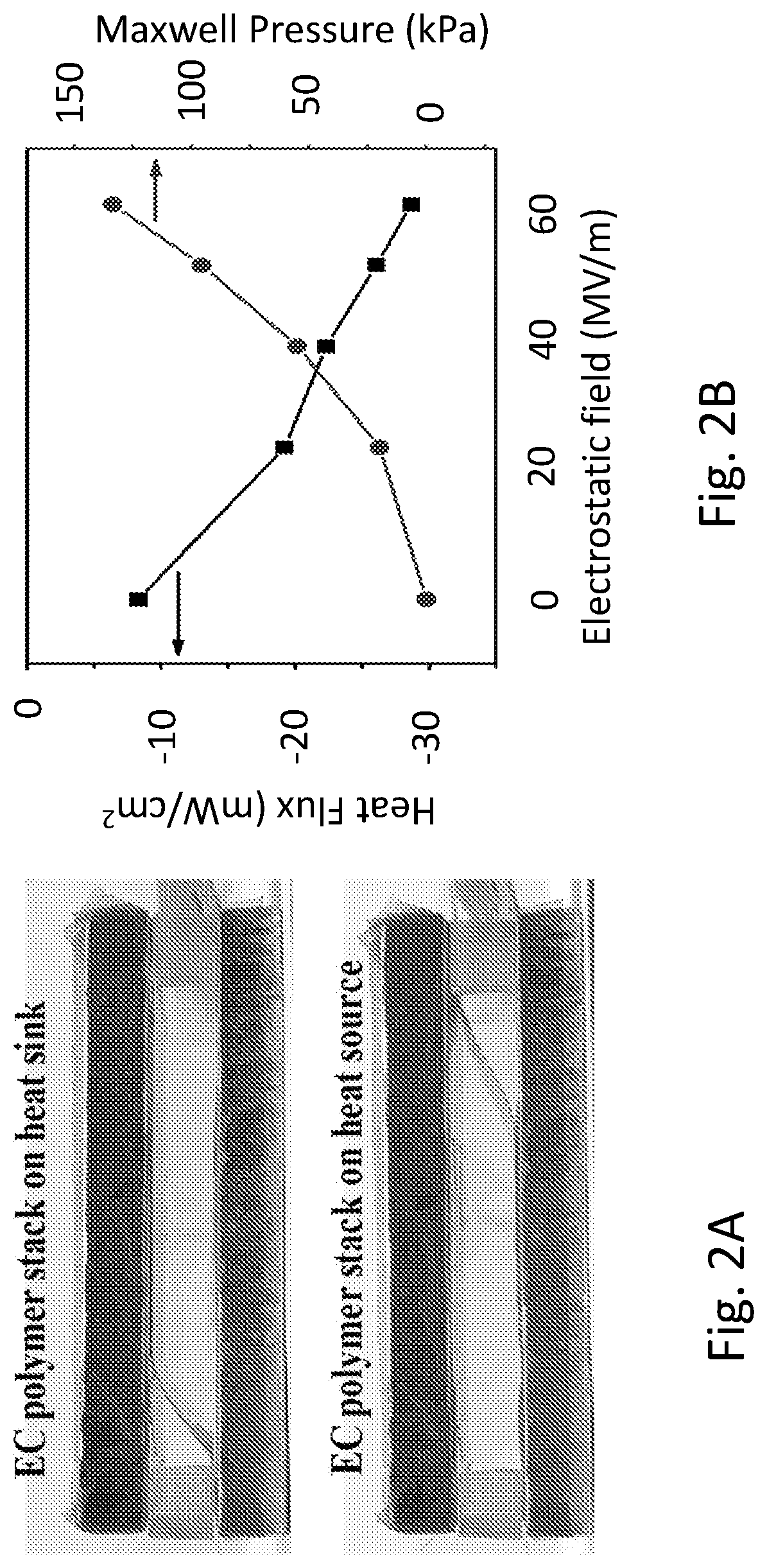

The electrocaloric temperature change represents the adiabatic temperature variation when an electric field is applied or removed from the electrocaloric material. This metric directly correlates with the dielectric breakdown strength, as higher electric fields generally produce larger temperature changes until breakdown occurs. Standard measurement techniques include direct methods using thermocouples or infrared cameras, and indirect methods based on Maxwell relations.

Cooling power density, measured in W/cm³, quantifies the heat transfer capability per unit volume of the electrocaloric material. This metric is particularly important for comparing different materials and device configurations when operating near their breakdown limits. Testing typically involves calorimetric measurements under various electric field strengths and cycling frequencies.

The coefficient of performance, defined as the ratio of cooling power to input power, serves as a key efficiency indicator. For electrocaloric systems operating at high electric fields, COP measurements must account for leakage currents that increase dramatically as the field approaches the breakdown threshold. Standardized testing protocols typically measure COP across a range of operating conditions to identify optimal performance regions.

Energy efficiency ratio provides a broader system-level performance metric that incorporates auxiliary components such as heat exchangers and control electronics. When optimizing for higher field operation, EER testing must evaluate the trade-offs between increased cooling capacity and potential reliability issues from operating near breakdown limits.

Testing methodologies for dielectric breakdown strength optimization involve specialized protocols including step-stress testing, where electric field strength is incrementally increased until breakdown occurs, and time-to-breakdown testing at constant field strengths. These tests are typically conducted under controlled temperature and humidity conditions to ensure reproducibility.

Advanced characterization techniques such as impedance spectroscopy and thermally stimulated current measurements provide insights into the mechanisms of dielectric breakdown, helping researchers develop strategies to enhance breakdown strength through material modifications or device architecture improvements. These techniques are essential for establishing correlations between material properties, processing conditions, and thermal performance metrics.

The electrocaloric temperature change represents the adiabatic temperature variation when an electric field is applied or removed from the electrocaloric material. This metric directly correlates with the dielectric breakdown strength, as higher electric fields generally produce larger temperature changes until breakdown occurs. Standard measurement techniques include direct methods using thermocouples or infrared cameras, and indirect methods based on Maxwell relations.

Cooling power density, measured in W/cm³, quantifies the heat transfer capability per unit volume of the electrocaloric material. This metric is particularly important for comparing different materials and device configurations when operating near their breakdown limits. Testing typically involves calorimetric measurements under various electric field strengths and cycling frequencies.

The coefficient of performance, defined as the ratio of cooling power to input power, serves as a key efficiency indicator. For electrocaloric systems operating at high electric fields, COP measurements must account for leakage currents that increase dramatically as the field approaches the breakdown threshold. Standardized testing protocols typically measure COP across a range of operating conditions to identify optimal performance regions.

Energy efficiency ratio provides a broader system-level performance metric that incorporates auxiliary components such as heat exchangers and control electronics. When optimizing for higher field operation, EER testing must evaluate the trade-offs between increased cooling capacity and potential reliability issues from operating near breakdown limits.

Testing methodologies for dielectric breakdown strength optimization involve specialized protocols including step-stress testing, where electric field strength is incrementally increased until breakdown occurs, and time-to-breakdown testing at constant field strengths. These tests are typically conducted under controlled temperature and humidity conditions to ensure reproducibility.

Advanced characterization techniques such as impedance spectroscopy and thermally stimulated current measurements provide insights into the mechanisms of dielectric breakdown, helping researchers develop strategies to enhance breakdown strength through material modifications or device architecture improvements. These techniques are essential for establishing correlations between material properties, processing conditions, and thermal performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!