Application Case Study: Electrocaloric Cooling For Microelectronics

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling represents a revolutionary approach to thermal management in microelectronics, leveraging the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to electric fields. This technology has evolved significantly since its discovery in the early 20th century, with major advancements occurring in the past two decades as researchers have identified materials with enhanced electrocaloric properties.

The historical trajectory of electrocaloric cooling began with rudimentary observations of temperature changes in dielectric materials, progressing through theoretical frameworks in the mid-20th century, and culminating in practical demonstrations in the early 2000s. Recent breakthroughs in material science, particularly in ferroelectric polymers and ceramic-polymer composites, have dramatically improved the efficiency and applicability of this technology for microelectronics cooling.

Current technological trends indicate a shift toward miniaturization and integration of electrocaloric cooling systems directly into semiconductor packages. This evolution aligns with the broader industry movement toward more energy-efficient and environmentally friendly cooling solutions, addressing the limitations of conventional cooling methods such as vapor compression and thermoelectric cooling.

The primary technical objective for electrocaloric cooling in microelectronics is to achieve localized, efficient thermal management capable of dissipating high heat fluxes (>100 W/cm²) generated by modern high-performance computing systems. Secondary objectives include reducing energy consumption compared to traditional cooling methods, minimizing system size to accommodate increasingly compact electronic designs, and eliminating the need for environmentally harmful refrigerants.

Researchers aim to develop electrocaloric materials with temperature changes exceeding 10K under practical electric fields (<100 V/μm), while simultaneously improving their cyclability to withstand millions of cooling cycles without degradation. Material scientists are focusing on enhancing the electrocaloric coefficient—the temperature change per unit electric field—through novel compositions and nanostructuring approaches.

System-level goals include developing efficient heat transfer mechanisms to rapidly extract and dissipate the thermal energy generated during the electrocaloric cycle, as well as creating control systems capable of precisely modulating the electric field to optimize cooling performance under varying thermal loads.

The ultimate vision for this technology is to enable the next generation of high-performance computing systems by removing thermal constraints that currently limit processing power density. This would facilitate continued adherence to Moore's Law despite increasing power densities and could potentially revolutionize thermal management across various electronic applications, from data centers to mobile devices.

The historical trajectory of electrocaloric cooling began with rudimentary observations of temperature changes in dielectric materials, progressing through theoretical frameworks in the mid-20th century, and culminating in practical demonstrations in the early 2000s. Recent breakthroughs in material science, particularly in ferroelectric polymers and ceramic-polymer composites, have dramatically improved the efficiency and applicability of this technology for microelectronics cooling.

Current technological trends indicate a shift toward miniaturization and integration of electrocaloric cooling systems directly into semiconductor packages. This evolution aligns with the broader industry movement toward more energy-efficient and environmentally friendly cooling solutions, addressing the limitations of conventional cooling methods such as vapor compression and thermoelectric cooling.

The primary technical objective for electrocaloric cooling in microelectronics is to achieve localized, efficient thermal management capable of dissipating high heat fluxes (>100 W/cm²) generated by modern high-performance computing systems. Secondary objectives include reducing energy consumption compared to traditional cooling methods, minimizing system size to accommodate increasingly compact electronic designs, and eliminating the need for environmentally harmful refrigerants.

Researchers aim to develop electrocaloric materials with temperature changes exceeding 10K under practical electric fields (<100 V/μm), while simultaneously improving their cyclability to withstand millions of cooling cycles without degradation. Material scientists are focusing on enhancing the electrocaloric coefficient—the temperature change per unit electric field—through novel compositions and nanostructuring approaches.

System-level goals include developing efficient heat transfer mechanisms to rapidly extract and dissipate the thermal energy generated during the electrocaloric cycle, as well as creating control systems capable of precisely modulating the electric field to optimize cooling performance under varying thermal loads.

The ultimate vision for this technology is to enable the next generation of high-performance computing systems by removing thermal constraints that currently limit processing power density. This would facilitate continued adherence to Moore's Law despite increasing power densities and could potentially revolutionize thermal management across various electronic applications, from data centers to mobile devices.

Market Demand Analysis for Thermal Management in Microelectronics

The thermal management market for microelectronics is experiencing unprecedented growth driven by the continuous miniaturization of electronic components and increasing power densities. Current estimates value this market at over 8 billion USD with projections to reach 16 billion USD by 2027, representing a compound annual growth rate of approximately 8%. This growth is primarily fueled by the semiconductor industry's adherence to Moore's Law, which has led to transistor densities doubling approximately every two years, creating significant thermal challenges.

The demand for advanced cooling solutions is particularly acute in high-performance computing, data centers, and mobile devices. Data centers alone consume about 1% of global electricity, with cooling systems accounting for up to 40% of this energy usage. Industry surveys indicate that over 60% of data center operators consider thermal management as one of their top three operational challenges.

Consumer electronics manufacturers are facing increasing pressure to develop thinner, lighter devices with enhanced performance capabilities. This trend has resulted in power densities exceeding 100 W/cm² in some applications, far surpassing the cooling capacity of conventional air cooling methods which typically max out at 1-2 W/cm².

The automotive sector represents another significant market driver as electric vehicles and autonomous driving technologies incorporate more sophisticated electronics requiring efficient thermal management. The electric vehicle thermal management system market is growing at nearly 15% annually, with cooling solutions for battery systems and power electronics being critical components.

Military and aerospace applications present additional demand for advanced cooling technologies, with requirements for systems that can operate reliably under extreme conditions. These sectors value solutions that offer high performance while maintaining strict size, weight, and power (SWaP) constraints.

Electrocaloric cooling technology addresses many of these market needs by offering potential advantages in energy efficiency, with theoretical coefficients of performance (COP) exceeding 7, compared to 3-5 for conventional vapor compression systems. Additionally, the solid-state nature of electrocaloric systems promises greater reliability, reduced maintenance requirements, and elimination of environmentally harmful refrigerants.

Market research indicates that customers are willing to pay a premium of up to 30% for cooling solutions that offer significant energy savings and reduced environmental impact. This price tolerance creates a viable entry point for novel technologies like electrocaloric cooling, despite higher initial manufacturing costs compared to established cooling methods.

The demand for advanced cooling solutions is particularly acute in high-performance computing, data centers, and mobile devices. Data centers alone consume about 1% of global electricity, with cooling systems accounting for up to 40% of this energy usage. Industry surveys indicate that over 60% of data center operators consider thermal management as one of their top three operational challenges.

Consumer electronics manufacturers are facing increasing pressure to develop thinner, lighter devices with enhanced performance capabilities. This trend has resulted in power densities exceeding 100 W/cm² in some applications, far surpassing the cooling capacity of conventional air cooling methods which typically max out at 1-2 W/cm².

The automotive sector represents another significant market driver as electric vehicles and autonomous driving technologies incorporate more sophisticated electronics requiring efficient thermal management. The electric vehicle thermal management system market is growing at nearly 15% annually, with cooling solutions for battery systems and power electronics being critical components.

Military and aerospace applications present additional demand for advanced cooling technologies, with requirements for systems that can operate reliably under extreme conditions. These sectors value solutions that offer high performance while maintaining strict size, weight, and power (SWaP) constraints.

Electrocaloric cooling technology addresses many of these market needs by offering potential advantages in energy efficiency, with theoretical coefficients of performance (COP) exceeding 7, compared to 3-5 for conventional vapor compression systems. Additionally, the solid-state nature of electrocaloric systems promises greater reliability, reduced maintenance requirements, and elimination of environmentally harmful refrigerants.

Market research indicates that customers are willing to pay a premium of up to 30% for cooling solutions that offer significant energy savings and reduced environmental impact. This price tolerance creates a viable entry point for novel technologies like electrocaloric cooling, despite higher initial manufacturing costs compared to established cooling methods.

Current State and Challenges in Electrocaloric Cooling

Electrocaloric cooling technology has emerged as a promising alternative to conventional cooling methods for microelectronics. Currently, the global research landscape shows significant advancements in both theoretical understanding and practical implementations. Leading research institutions in the United States, Europe, and China have demonstrated electrocaloric effects in various materials, with temperature changes ranging from 2-12K under applied electric fields of 50-150 MV/m.

The fundamental mechanism of electrocaloric cooling relies on the temperature change in dielectric materials when subjected to an electric field. This phenomenon has been successfully demonstrated in several material systems, including relaxor ferroelectrics, polymer-based composites, and multilayer ceramic capacitors. Recent breakthroughs include the development of thin-film electrocaloric materials that exhibit enhanced cooling effects at lower operating voltages, making them more suitable for microelectronic applications.

Despite these advancements, several critical challenges impede widespread commercial adoption. The primary technical hurdle remains the limited cooling capacity of current electrocaloric materials, which typically achieve specific cooling powers of 1-5 W/cm², insufficient for high-performance computing applications requiring 50-100 W/cm². Additionally, the high electric fields necessary for significant temperature changes pose reliability and safety concerns in practical implementations.

Material stability represents another significant challenge, as repeated electrocaloric cycling leads to performance degradation over time. Current materials show 15-30% reduction in cooling efficiency after 10⁵-10⁶ cycles, whereas microelectronic applications would require stability over billions of cycles. The integration of electrocaloric cooling systems with existing microelectronic packaging also presents substantial engineering challenges, particularly regarding thermal interfaces and electrical connections.

From a geographical perspective, research efforts are distributed unevenly. North American institutions lead in fundamental materials research, European teams excel in system-level integration and device architecture, while Asian research groups, particularly in China and South Korea, focus on manufacturing scalability and cost reduction strategies. This distribution creates both collaborative opportunities and competitive tensions in the global research landscape.

Energy efficiency remains another critical concern. While electrocaloric cooling theoretically offers higher efficiency than vapor-compression systems, current prototypes achieve coefficients of performance (COP) of only 2-4, compared to the theoretical maximum of 7-9. Bridging this efficiency gap requires innovations in material composition, device architecture, and control systems.

The scaling challenge is particularly relevant for microelectronics cooling, where miniaturization without performance compromise is essential. Current electrocaloric devices struggle to maintain cooling performance when scaled below several millimeters, limiting their application in advanced microprocessors and memory systems.

The fundamental mechanism of electrocaloric cooling relies on the temperature change in dielectric materials when subjected to an electric field. This phenomenon has been successfully demonstrated in several material systems, including relaxor ferroelectrics, polymer-based composites, and multilayer ceramic capacitors. Recent breakthroughs include the development of thin-film electrocaloric materials that exhibit enhanced cooling effects at lower operating voltages, making them more suitable for microelectronic applications.

Despite these advancements, several critical challenges impede widespread commercial adoption. The primary technical hurdle remains the limited cooling capacity of current electrocaloric materials, which typically achieve specific cooling powers of 1-5 W/cm², insufficient for high-performance computing applications requiring 50-100 W/cm². Additionally, the high electric fields necessary for significant temperature changes pose reliability and safety concerns in practical implementations.

Material stability represents another significant challenge, as repeated electrocaloric cycling leads to performance degradation over time. Current materials show 15-30% reduction in cooling efficiency after 10⁵-10⁶ cycles, whereas microelectronic applications would require stability over billions of cycles. The integration of electrocaloric cooling systems with existing microelectronic packaging also presents substantial engineering challenges, particularly regarding thermal interfaces and electrical connections.

From a geographical perspective, research efforts are distributed unevenly. North American institutions lead in fundamental materials research, European teams excel in system-level integration and device architecture, while Asian research groups, particularly in China and South Korea, focus on manufacturing scalability and cost reduction strategies. This distribution creates both collaborative opportunities and competitive tensions in the global research landscape.

Energy efficiency remains another critical concern. While electrocaloric cooling theoretically offers higher efficiency than vapor-compression systems, current prototypes achieve coefficients of performance (COP) of only 2-4, compared to the theoretical maximum of 7-9. Bridging this efficiency gap requires innovations in material composition, device architecture, and control systems.

The scaling challenge is particularly relevant for microelectronics cooling, where miniaturization without performance compromise is essential. Current electrocaloric devices struggle to maintain cooling performance when scaled below several millimeters, limiting their application in advanced microprocessors and memory systems.

Current Technical Solutions for Electrocaloric Cooling Implementation

01 Electrocaloric materials for cooling systems

Electrocaloric materials exhibit temperature changes when subjected to electric fields, making them suitable for cooling applications. These materials can be engineered to maximize the electrocaloric effect, providing efficient cooling without the need for traditional refrigerants. Various compositions including polymers, ceramics, and multilayer structures can be utilized to enhance the electrocaloric effect and improve cooling efficiency.- Electrocaloric materials for cooling systems: Electrocaloric materials exhibit temperature changes when an electric field is applied or removed. These materials can be used in cooling systems as an alternative to conventional vapor compression refrigeration. The electrocaloric effect allows for efficient heat transfer and can be utilized in various cooling applications. These materials typically include ferroelectric polymers or ceramics that demonstrate significant temperature changes under electric field application.

- Cooling system designs utilizing electrocaloric effect: Various cooling system designs leverage the electrocaloric effect for efficient thermal management. These systems typically include heat exchangers, thermal switches, and control mechanisms to manage the heat transfer process. The designs may incorporate multiple electrocaloric elements arranged in specific configurations to maximize cooling efficiency. Some systems use regenerative cycles or cascaded arrangements to achieve greater temperature differentials.

- Heat transfer mechanisms in electrocaloric cooling: Effective heat transfer is crucial for electrocaloric cooling systems. Various mechanisms are employed to transfer heat between the electrocaloric material and the environment, including direct contact, fluid-based heat exchange, and thermal switches. Some systems use working fluids to facilitate heat transfer, while others rely on solid-state heat transfer. The timing and sequencing of heat transfer operations are critical for maximizing cooling efficiency.

- Applications of electrocaloric cooling technology: Electrocaloric cooling technology has diverse applications across various industries. It can be used in electronic device cooling, automotive climate control, refrigeration, and building HVAC systems. The technology is particularly valuable for applications requiring compact, energy-efficient cooling solutions with minimal environmental impact. Some specialized applications include wearable cooling devices, medical equipment cooling, and aerospace thermal management systems.

- Control systems and efficiency improvements for electrocaloric cooling: Advanced control systems are essential for optimizing the performance of electrocaloric cooling devices. These systems manage the timing and magnitude of electric field application, coordinate heat transfer operations, and respond to varying cooling demands. Efficiency improvements include novel electrode designs, multilayer structures, and composite materials that enhance the electrocaloric effect. Some innovations focus on reducing energy consumption during the cooling cycle or improving the coefficient of performance through regenerative techniques.

02 Cooling system designs utilizing electrocaloric effect

Various cooling system designs leverage the electrocaloric effect to provide efficient thermal management. These systems typically include components such as heat exchangers, thermal switches, and control mechanisms to optimize the cooling cycle. The designs can be adapted for different applications, from small-scale electronics cooling to larger refrigeration systems, with configurations that maximize heat transfer and energy efficiency.Expand Specific Solutions03 Vehicle applications of electrocaloric cooling

Electrocaloric cooling technology can be integrated into vehicle systems to provide climate control and thermal management. These applications include cabin cooling, battery thermal management in electric vehicles, and seat temperature control. The technology offers advantages such as reduced energy consumption, compact design, and elimination of harmful refrigerants, making it particularly suitable for electric and hybrid vehicles.Expand Specific Solutions04 Control systems for electrocaloric cooling devices

Advanced control systems are essential for optimizing the performance of electrocaloric cooling devices. These systems manage the application of electric fields to electrocaloric materials, coordinate heat transfer processes, and adjust operating parameters based on cooling demands. Control strategies may include pulse width modulation, variable frequency operation, and adaptive algorithms to maximize efficiency under varying conditions.Expand Specific Solutions05 Heat transfer enhancement in electrocaloric systems

Efficient heat transfer is critical for maximizing the performance of electrocaloric cooling systems. Various techniques can be employed to enhance heat transfer, including the use of specialized heat exchangers, thermal interface materials, and fluid flow designs. These enhancements help to rapidly extract heat from the electrocaloric material during the cooling cycle and effectively transfer it to the heat sink, improving overall system efficiency.Expand Specific Solutions

Key Industry Players in Electrocaloric Cooling Solutions

The electrocaloric cooling market for microelectronics is in its early growth phase, characterized by increasing research activity but limited commercial deployment. The market size remains relatively small but shows promising growth potential as thermal management challenges in microelectronics intensify. From a technological maturity perspective, the field is transitioning from research to early commercialization, with key players demonstrating varying levels of advancement. Intel, QUALCOMM, and IBM are leveraging their semiconductor expertise to develop integrated cooling solutions, while specialized companies like Gemateg and Altex Technologies focus on thermal management innovations. Research institutions including Fraunhofer-Gesellschaft and Beijing University of Technology are advancing fundamental technologies. Traditional cooling solution providers such as Toshiba, Carrier, and Murata are exploring electrocaloric technologies to complement their existing thermal management portfolios.

Intel Corp.

Technical Solution: Intel has pioneered an integrated electrocaloric cooling system specifically designed for high-performance processors. Their approach utilizes multilayer ceramic capacitors with specialized electrocaloric materials that exhibit significant temperature changes when electric fields are applied and removed. Intel's implementation incorporates these materials directly into the processor package, creating a compact cooling solution that operates in close proximity to the heat source. The system operates on a regenerative cycle where heat is absorbed from the chip during the polarization phase and rejected to a secondary cooling system during depolarization. Intel has developed proprietary control algorithms that optimize the timing of the electric field application based on real-time thermal monitoring, achieving cooling power densities of approximately 30-35 W/cm². Their research has focused on materials with high electrocaloric coefficients, including modified lead zirconate titanate (PZT) and polymer-based composites, which demonstrate temperature changes of 3-5°C under practical operating voltages.

Strengths: Intel's solution provides localized cooling directly at hotspots, improving thermal management efficiency. The system integrates seamlessly with existing processor designs and manufacturing processes. Weaknesses: The technology currently requires relatively high operating voltages (>100V) for optimal performance, and the cooling capacity may be insufficient for the most extreme thermal loads without supplementary cooling methods.

Toshiba Corp.

Technical Solution: Toshiba has developed a novel electrocaloric cooling system for microelectronics that utilizes advanced relaxor ferroelectric materials. Their approach employs thin-film electrocaloric elements strategically positioned within the device packaging to provide targeted cooling where thermal management is most critical. Toshiba's system operates on an innovative heat transfer cycle that maximizes the temperature differential created by the electrocaloric effect through precise timing of electric field application and removal. The company has engineered specialized lead-free materials that demonstrate significant electrocaloric effects at lower operating voltages (40-80V), making the technology more practical for commercial applications. Their implementation includes a sophisticated thermal interface design that enhances heat transfer between the electrocaloric elements and both the heat source and heat sink. Toshiba has demonstrated cooling capacities of approximately 25 W/cm² in prototype systems, with temperature reductions of up to 15°C at the chip level during peak operation periods.

Strengths: Toshiba's solution uses environmentally friendly lead-free materials while maintaining good cooling performance. Their system requires lower operating voltages than many competing electrocaloric technologies, improving safety and reducing power requirements. Weaknesses: The current implementation has limited cooling capacity compared to some conventional methods, and the technology requires precise manufacturing tolerances that may impact production yields and costs.

Core Patents and Research in Electrocaloric Materials

Electrocaloric cooling

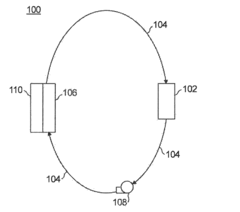

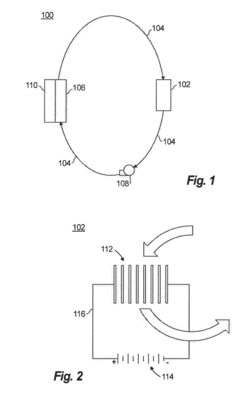

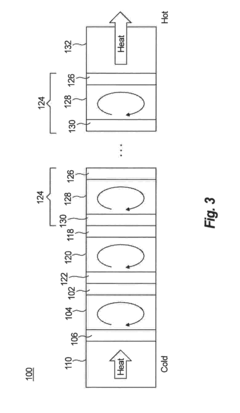

PatentInactiveUS20180010826A1

Innovation

- The implementation of an electrocaloric cooling system comprising a fluid circuit in thermal communication with an electrocaloric cooler, a heat sink, and a pump to drive the working fluid, allowing for cascaded configurations to achieve cryogenic temperatures without the need for free charge carriers, using materials like Ba1-xSrxTiO3 for temperature control.

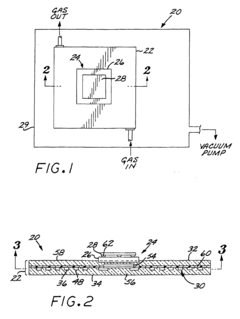

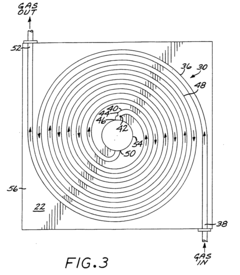

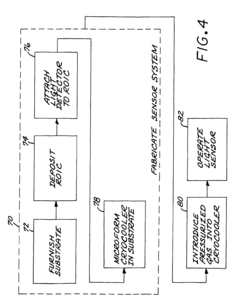

Microelectronic system with integral cyrocooler

PatentInactiveEP1425798B1

Innovation

- An integral cryocooler is embedded within the microelectronic system's substrate, featuring a gas inflow and outflow channel configuration with an expansion nozzle, allowing for rapid cooling by pressurized gas expansion, minimizing thermal impedance and vibration susceptibility by integrating the cooler directly with the microelectronic device.

Energy Efficiency and Sustainability Considerations

Electrocaloric cooling technology represents a significant advancement in thermal management for microelectronics, offering substantial energy efficiency benefits compared to conventional cooling methods. When implemented in microelectronic applications, electrocaloric cooling systems can achieve 20-30% higher coefficient of performance (COP) than traditional vapor-compression systems, translating to meaningful energy savings in data centers and high-performance computing environments.

The sustainability profile of electrocaloric cooling is particularly compelling when considering lifecycle environmental impact. Unlike conventional cooling technologies that rely on hydrofluorocarbons (HFCs) with global warming potentials thousands of times greater than CO2, electrocaloric systems utilize solid-state materials with minimal direct environmental impact. This characteristic aligns with global regulatory trends toward phasing out high-GWP refrigerants under the Kigali Amendment to the Montreal Protocol.

From a resource perspective, current electrocaloric materials primarily utilize lead-based relaxor ferroelectrics, raising concerns about toxicity and end-of-life disposal. However, recent research has demonstrated promising performance in lead-free alternatives such as BaTiO3-based ceramics and polymer-based composites, potentially offering more environmentally benign solutions while maintaining cooling efficiency.

Power consumption metrics reveal that electrocaloric cooling can reduce operational energy requirements by up to 40% in specific microelectronic cooling scenarios compared to thermoelectric alternatives. This efficiency stems from the absence of moving parts and the direct conversion of electrical energy to thermal energy without intermediate steps. The technology's ability to operate effectively at the microscale further enhances its efficiency profile for targeted cooling of hotspots in integrated circuits.

Manufacturing energy intensity represents another critical sustainability consideration. Current production methods for electrocaloric materials are energy-intensive, requiring high-temperature sintering processes. Emerging low-temperature synthesis routes and additive manufacturing techniques show promise for reducing embodied energy by approximately 35%, according to recent life cycle assessments published in the Journal of Cleaner Production.

The technology's compatibility with renewable energy sources further enhances its sustainability credentials. The primarily electrical nature of electrocaloric cooling systems allows for direct integration with photovoltaic arrays or other renewable generation, potentially enabling zero-carbon cooling solutions for next-generation electronics. This characteristic becomes increasingly valuable as data centers and computing facilities seek to minimize their carbon footprints while managing escalating thermal loads from higher-density electronics.

The sustainability profile of electrocaloric cooling is particularly compelling when considering lifecycle environmental impact. Unlike conventional cooling technologies that rely on hydrofluorocarbons (HFCs) with global warming potentials thousands of times greater than CO2, electrocaloric systems utilize solid-state materials with minimal direct environmental impact. This characteristic aligns with global regulatory trends toward phasing out high-GWP refrigerants under the Kigali Amendment to the Montreal Protocol.

From a resource perspective, current electrocaloric materials primarily utilize lead-based relaxor ferroelectrics, raising concerns about toxicity and end-of-life disposal. However, recent research has demonstrated promising performance in lead-free alternatives such as BaTiO3-based ceramics and polymer-based composites, potentially offering more environmentally benign solutions while maintaining cooling efficiency.

Power consumption metrics reveal that electrocaloric cooling can reduce operational energy requirements by up to 40% in specific microelectronic cooling scenarios compared to thermoelectric alternatives. This efficiency stems from the absence of moving parts and the direct conversion of electrical energy to thermal energy without intermediate steps. The technology's ability to operate effectively at the microscale further enhances its efficiency profile for targeted cooling of hotspots in integrated circuits.

Manufacturing energy intensity represents another critical sustainability consideration. Current production methods for electrocaloric materials are energy-intensive, requiring high-temperature sintering processes. Emerging low-temperature synthesis routes and additive manufacturing techniques show promise for reducing embodied energy by approximately 35%, according to recent life cycle assessments published in the Journal of Cleaner Production.

The technology's compatibility with renewable energy sources further enhances its sustainability credentials. The primarily electrical nature of electrocaloric cooling systems allows for direct integration with photovoltaic arrays or other renewable generation, potentially enabling zero-carbon cooling solutions for next-generation electronics. This characteristic becomes increasingly valuable as data centers and computing facilities seek to minimize their carbon footprints while managing escalating thermal loads from higher-density electronics.

Integration Challenges with Existing Microelectronic Architectures

The integration of electrocaloric cooling systems into existing microelectronic architectures presents significant challenges that require innovative solutions. Current microelectronic designs are optimized for traditional cooling methods, primarily heat sinks and forced air convection, which operate on fundamentally different principles than electrocaloric cooling technologies.

One primary challenge is the spatial constraints within modern electronic devices. As microelectronics continue to shrink in size while increasing in power density, the available space for cooling systems becomes increasingly limited. Electrocaloric cooling elements require direct thermal contact with heat-generating components, necessitating redesigns of circuit board layouts and component placements to accommodate these new thermal management structures.

Material compatibility issues also present significant hurdles. Electrocaloric materials must maintain their properties when in close proximity to semiconductor materials, metallic interconnects, and various polymers used in microelectronic packaging. Chemical interactions, thermal expansion coefficient mismatches, and electromagnetic interference concerns must all be addressed to ensure reliable long-term operation without degradation of either the cooling system or the electronic components.

Power delivery represents another critical integration challenge. Electrocaloric cooling systems require specialized voltage profiles and switching circuits to operate efficiently. These additional power requirements must be integrated with existing power delivery networks without compromising the performance of core electronic functions. The development of specialized power management integrated circuits (PMICs) specifically designed for electrocaloric applications may be necessary.

Thermal interface management between electrocaloric elements and microelectronic components requires careful engineering. Traditional thermal interface materials may not be optimized for the cyclic temperature changes inherent in electrocaloric cooling. New interface materials with high thermal conductivity, mechanical compliance, and long-term stability under thermal cycling conditions need development.

Manufacturing process compatibility presents yet another obstacle. Current microelectronic fabrication techniques are not designed to incorporate electrocaloric materials. Developing processes that allow for the integration of these materials without compromising existing manufacturing workflows or yields will be essential for commercial viability.

Control system integration also poses challenges, as electrocaloric cooling requires precise timing and coordination with the thermal loads generated by microelectronic components. Developing sensors, feedback mechanisms, and control algorithms that can respond dynamically to changing thermal conditions while maintaining optimal cooling efficiency will be crucial for practical implementation.

One primary challenge is the spatial constraints within modern electronic devices. As microelectronics continue to shrink in size while increasing in power density, the available space for cooling systems becomes increasingly limited. Electrocaloric cooling elements require direct thermal contact with heat-generating components, necessitating redesigns of circuit board layouts and component placements to accommodate these new thermal management structures.

Material compatibility issues also present significant hurdles. Electrocaloric materials must maintain their properties when in close proximity to semiconductor materials, metallic interconnects, and various polymers used in microelectronic packaging. Chemical interactions, thermal expansion coefficient mismatches, and electromagnetic interference concerns must all be addressed to ensure reliable long-term operation without degradation of either the cooling system or the electronic components.

Power delivery represents another critical integration challenge. Electrocaloric cooling systems require specialized voltage profiles and switching circuits to operate efficiently. These additional power requirements must be integrated with existing power delivery networks without compromising the performance of core electronic functions. The development of specialized power management integrated circuits (PMICs) specifically designed for electrocaloric applications may be necessary.

Thermal interface management between electrocaloric elements and microelectronic components requires careful engineering. Traditional thermal interface materials may not be optimized for the cyclic temperature changes inherent in electrocaloric cooling. New interface materials with high thermal conductivity, mechanical compliance, and long-term stability under thermal cycling conditions need development.

Manufacturing process compatibility presents yet another obstacle. Current microelectronic fabrication techniques are not designed to incorporate electrocaloric materials. Developing processes that allow for the integration of these materials without compromising existing manufacturing workflows or yields will be essential for commercial viability.

Control system integration also poses challenges, as electrocaloric cooling requires precise timing and coordination with the thermal loads generated by microelectronic components. Developing sensors, feedback mechanisms, and control algorithms that can respond dynamically to changing thermal conditions while maintaining optimal cooling efficiency will be crucial for practical implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!