Noise And Vibration Advantages Of Solid-State Electrocaloric Cooling Systems

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Background and Objectives

Electrocaloric cooling represents a revolutionary approach to thermal management that has gained significant attention in recent decades. This technology leverages the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. The historical development of electrocaloric cooling can be traced back to the 1930s when the effect was first discovered, though meaningful research progress remained limited until the early 2000s when significant breakthroughs in material science revitalized interest in this field.

The evolution of cooling technologies has traditionally been dominated by vapor-compression systems, which despite their efficiency, present numerous environmental challenges including the use of harmful refrigerants and significant energy consumption. This has created an urgent need for alternative cooling solutions that are both environmentally friendly and energy-efficient, positioning electrocaloric cooling as a promising candidate for next-generation thermal management.

Solid-state electrocaloric cooling systems represent a particularly innovative branch within this technology domain. Unlike conventional cooling methods that rely on moving parts and fluid refrigerants, these systems operate through electric field-induced phase transitions in solid materials, eliminating the need for mechanical components that generate noise and vibration. This fundamental difference in operational mechanism constitutes the primary advantage of electrocaloric systems in terms of acoustic and vibrational performance.

The technical objectives for advancing electrocaloric cooling technology are multifaceted. Primary goals include enhancing the temperature differential achievable through the electrocaloric effect, improving energy efficiency metrics to surpass conventional cooling technologies, and developing materials with stronger electrocaloric responses at practical operating temperatures. Additionally, there is a focused effort to design system architectures that maximize the inherent noise and vibration advantages of solid-state operation.

Current research trends indicate a growing emphasis on novel material compositions, particularly relaxor ferroelectrics and polymer-based electrocaloric materials, which show promising temperature change capabilities under applied electric fields. Simultaneously, there is increasing attention to system-level design considerations that optimize heat transfer mechanisms while maintaining the solid-state advantages of these systems.

The anticipated trajectory for electrocaloric cooling technology suggests potential commercialization within specialized applications in the next 5-10 years, with broader market penetration dependent on overcoming current limitations in material performance and manufacturing scalability. The noise and vibration advantages of these systems position them particularly well for applications where acoustic performance is critical, such as in residential settings, healthcare environments, and precision laboratory equipment.

The evolution of cooling technologies has traditionally been dominated by vapor-compression systems, which despite their efficiency, present numerous environmental challenges including the use of harmful refrigerants and significant energy consumption. This has created an urgent need for alternative cooling solutions that are both environmentally friendly and energy-efficient, positioning electrocaloric cooling as a promising candidate for next-generation thermal management.

Solid-state electrocaloric cooling systems represent a particularly innovative branch within this technology domain. Unlike conventional cooling methods that rely on moving parts and fluid refrigerants, these systems operate through electric field-induced phase transitions in solid materials, eliminating the need for mechanical components that generate noise and vibration. This fundamental difference in operational mechanism constitutes the primary advantage of electrocaloric systems in terms of acoustic and vibrational performance.

The technical objectives for advancing electrocaloric cooling technology are multifaceted. Primary goals include enhancing the temperature differential achievable through the electrocaloric effect, improving energy efficiency metrics to surpass conventional cooling technologies, and developing materials with stronger electrocaloric responses at practical operating temperatures. Additionally, there is a focused effort to design system architectures that maximize the inherent noise and vibration advantages of solid-state operation.

Current research trends indicate a growing emphasis on novel material compositions, particularly relaxor ferroelectrics and polymer-based electrocaloric materials, which show promising temperature change capabilities under applied electric fields. Simultaneously, there is increasing attention to system-level design considerations that optimize heat transfer mechanisms while maintaining the solid-state advantages of these systems.

The anticipated trajectory for electrocaloric cooling technology suggests potential commercialization within specialized applications in the next 5-10 years, with broader market penetration dependent on overcoming current limitations in material performance and manufacturing scalability. The noise and vibration advantages of these systems position them particularly well for applications where acoustic performance is critical, such as in residential settings, healthcare environments, and precision laboratory equipment.

Market Analysis for Quiet Cooling Solutions

The global market for quiet cooling solutions is experiencing significant growth, driven by increasing consumer demand for noise-reduced living and working environments. Current market research indicates that the global HVAC market values noise reduction as a premium feature, with consumers willing to pay 15-30% more for systems that operate below 40 decibels compared to conventional systems. This trend is particularly pronounced in residential applications, high-end commercial spaces, and noise-sensitive environments such as hospitals, libraries, and recording studios.

Solid-state electrocaloric cooling systems represent an emerging segment within this market, offering substantial noise and vibration advantages over traditional vapor-compression technology. Unlike conventional cooling systems that rely on compressors and refrigerants, electrocaloric systems operate without moving parts, eliminating the primary sources of operational noise and vibration. This technological distinction positions electrocaloric cooling as a potentially disruptive force in the quiet cooling market.

Market segmentation analysis reveals several key sectors with high growth potential. The residential premium cooling segment shows strong demand for ultra-quiet systems, particularly in urban environments and luxury housing developments where noise pollution is a significant concern. Commercial applications in office buildings are increasingly prioritizing employee comfort, with studies linking reduced noise levels to improved productivity and satisfaction.

Healthcare facilities represent another substantial market opportunity, where patient recovery rates have been correlated with quieter environments. Research institutions and laboratories requiring vibration-free environments for sensitive equipment constitute a specialized but high-value market segment. Additionally, the automotive industry is exploring electrocaloric technology for electric vehicle cooling systems, where energy efficiency and noise reduction are paramount concerns.

Regional market analysis indicates that North America and Europe currently lead in adoption of premium quiet cooling solutions, with Asia-Pacific showing the fastest growth rate as urbanization increases and middle-class consumers demand higher comfort standards. Japan specifically has established stringent noise regulations for residential cooling systems, creating a favorable market environment for electrocaloric technology.

Consumer behavior studies demonstrate that awareness of noise pollution impacts on health and wellbeing is rising globally, with 68% of surveyed consumers citing noise reduction as "important" or "very important" in purchasing decisions for home appliances. This awareness is expected to continue driving market growth for quiet cooling solutions at a compound annual growth rate exceeding the broader HVAC industry average.

Market forecasts suggest that as manufacturing scale increases and technology matures, the price premium for solid-state cooling systems will decrease, potentially expanding market penetration from current niche applications to mainstream adoption within the next decade.

Solid-state electrocaloric cooling systems represent an emerging segment within this market, offering substantial noise and vibration advantages over traditional vapor-compression technology. Unlike conventional cooling systems that rely on compressors and refrigerants, electrocaloric systems operate without moving parts, eliminating the primary sources of operational noise and vibration. This technological distinction positions electrocaloric cooling as a potentially disruptive force in the quiet cooling market.

Market segmentation analysis reveals several key sectors with high growth potential. The residential premium cooling segment shows strong demand for ultra-quiet systems, particularly in urban environments and luxury housing developments where noise pollution is a significant concern. Commercial applications in office buildings are increasingly prioritizing employee comfort, with studies linking reduced noise levels to improved productivity and satisfaction.

Healthcare facilities represent another substantial market opportunity, where patient recovery rates have been correlated with quieter environments. Research institutions and laboratories requiring vibration-free environments for sensitive equipment constitute a specialized but high-value market segment. Additionally, the automotive industry is exploring electrocaloric technology for electric vehicle cooling systems, where energy efficiency and noise reduction are paramount concerns.

Regional market analysis indicates that North America and Europe currently lead in adoption of premium quiet cooling solutions, with Asia-Pacific showing the fastest growth rate as urbanization increases and middle-class consumers demand higher comfort standards. Japan specifically has established stringent noise regulations for residential cooling systems, creating a favorable market environment for electrocaloric technology.

Consumer behavior studies demonstrate that awareness of noise pollution impacts on health and wellbeing is rising globally, with 68% of surveyed consumers citing noise reduction as "important" or "very important" in purchasing decisions for home appliances. This awareness is expected to continue driving market growth for quiet cooling solutions at a compound annual growth rate exceeding the broader HVAC industry average.

Market forecasts suggest that as manufacturing scale increases and technology matures, the price premium for solid-state cooling systems will decrease, potentially expanding market penetration from current niche applications to mainstream adoption within the next decade.

Current Challenges in Solid-State Cooling Technology

Despite the promising potential of solid-state electrocaloric cooling systems, several significant technical challenges currently impede their widespread commercial adoption. The primary obstacle remains the limited temperature span achievable in practical devices, with most laboratory demonstrations showing only 2-5°C temperature differentials—far below the 20-30°C required for mainstream applications like refrigeration or air conditioning. This limitation stems from the inherent properties of current electrocaloric materials, which exhibit maximum effects only within narrow temperature ranges.

Material performance presents another critical challenge. Current electrocaloric materials demonstrate electrocaloric effects that are too small for practical cooling capacity, typically showing temperature changes of only 2-8 K under applied electric fields. Additionally, these materials often require extremely high electric fields (>100 kV/cm) to produce meaningful cooling effects, creating significant electrical insulation and safety concerns for commercial products.

Scaling issues further complicate development efforts. Laboratory demonstrations have primarily focused on thin-film or small bulk samples, while practical applications require larger heat exchange areas and material volumes. The transition from microscale demonstrations to macroscale devices introduces thermal management complexities that significantly reduce system efficiency.

Cycle efficiency represents another substantial hurdle. Current electrocaloric cooling prototypes exhibit coefficients of performance (COP) significantly below conventional vapor-compression systems. This efficiency gap must be closed to make the technology economically viable, particularly given the higher initial manufacturing costs expected for solid-state systems.

Durability concerns also plague development efforts. Electrocaloric materials experience mechanical stress during repeated electric field cycling, leading to fatigue and potential failure. Many promising materials show performance degradation after only thousands of cycles, whereas commercial cooling systems require millions of cycles over their operational lifetime.

Manufacturing scalability presents additional complications. Current fabrication methods for high-performance electrocaloric materials often involve complex processes not readily adaptable to mass production. The precision required for multilayer capacitor structures and the specialized deposition techniques needed for thin films create significant barriers to cost-effective manufacturing.

System integration challenges further impede commercialization. Designing efficient heat transfer mechanisms between the electrocaloric material and heat source/sink remains problematic, with thermal contact resistance often limiting overall system performance. Additionally, the electronic control systems required to manage precise electric field application add complexity and cost to potential commercial products.

Material performance presents another critical challenge. Current electrocaloric materials demonstrate electrocaloric effects that are too small for practical cooling capacity, typically showing temperature changes of only 2-8 K under applied electric fields. Additionally, these materials often require extremely high electric fields (>100 kV/cm) to produce meaningful cooling effects, creating significant electrical insulation and safety concerns for commercial products.

Scaling issues further complicate development efforts. Laboratory demonstrations have primarily focused on thin-film or small bulk samples, while practical applications require larger heat exchange areas and material volumes. The transition from microscale demonstrations to macroscale devices introduces thermal management complexities that significantly reduce system efficiency.

Cycle efficiency represents another substantial hurdle. Current electrocaloric cooling prototypes exhibit coefficients of performance (COP) significantly below conventional vapor-compression systems. This efficiency gap must be closed to make the technology economically viable, particularly given the higher initial manufacturing costs expected for solid-state systems.

Durability concerns also plague development efforts. Electrocaloric materials experience mechanical stress during repeated electric field cycling, leading to fatigue and potential failure. Many promising materials show performance degradation after only thousands of cycles, whereas commercial cooling systems require millions of cycles over their operational lifetime.

Manufacturing scalability presents additional complications. Current fabrication methods for high-performance electrocaloric materials often involve complex processes not readily adaptable to mass production. The precision required for multilayer capacitor structures and the specialized deposition techniques needed for thin films create significant barriers to cost-effective manufacturing.

System integration challenges further impede commercialization. Designing efficient heat transfer mechanisms between the electrocaloric material and heat source/sink remains problematic, with thermal contact resistance often limiting overall system performance. Additionally, the electronic control systems required to manage precise electric field application add complexity and cost to potential commercial products.

Noise Reduction Approaches in Solid-State Cooling

01 Noise and vibration reduction in electrocaloric cooling systems

Solid-state electrocaloric cooling systems can generate noise and vibration during operation. Various techniques have been developed to reduce these issues, including vibration isolation mounts, damping materials, and acoustic insulation. These methods help minimize the transmission of vibrations to surrounding structures and reduce the overall noise level of the cooling system, making them more suitable for applications where noise is a concern.- Noise and vibration reduction mechanisms in electrocaloric cooling systems: Various mechanisms are employed to reduce noise and vibration in solid-state electrocaloric cooling systems. These include vibration isolation mounts, damping materials, and acoustic insulation to minimize the transmission of mechanical vibrations and noise. Advanced designs incorporate flexible connections between components and strategic placement of moving parts to reduce operational noise, enhancing user comfort while maintaining cooling efficiency.

- Solid-state cooling system design for inherent noise reduction: Innovative designs of solid-state electrocaloric cooling systems focus on inherent noise reduction through the elimination of conventional compressors and moving parts. These designs leverage the electrocaloric effect to create temperature differentials without mechanical compression, resulting in significantly quieter operation compared to traditional cooling systems. The solid-state nature of these systems contributes to reduced vibration and noise generation during operation.

- Active noise cancellation and electronic control systems: Advanced electrocaloric cooling systems incorporate active noise cancellation technologies and sophisticated electronic control systems to minimize operational noise. These systems use sensors to detect vibration patterns and generate counter-vibrations or adjust operational parameters to reduce noise. Microprocessor-controlled operation allows for real-time adjustments to minimize noise while optimizing cooling performance under varying conditions.

- Material selection and structural design for vibration dampening: Specific materials and structural designs are utilized in electrocaloric cooling systems to dampen vibrations and reduce noise transmission. High-density polymers, composite materials, and specialized alloys are selected for their vibration-absorbing properties. The structural design includes strategic component placement, vibration-isolating mounts, and acoustic barriers to minimize noise propagation throughout the system and to the surrounding environment.

- Thermal cycling and heat transfer optimization to reduce mechanical stress: Optimized thermal cycling and heat transfer mechanisms in electrocaloric cooling systems help reduce mechanical stress that can lead to vibration and noise. Advanced heat exchange designs, fluid flow patterns, and thermal interface materials minimize thermal expansion and contraction cycles. By reducing mechanical stress during operation, these systems experience less vibration and consequently generate less noise while maintaining efficient cooling performance.

02 Design optimization for silent operation

The design of solid-state electrocaloric cooling systems can be optimized to minimize noise and vibration. This includes careful selection of component materials, geometric configurations, and operational parameters. Advanced designs incorporate features such as balanced mechanical structures, optimized fluid flow paths, and strategic placement of components to reduce resonance effects. These design considerations help achieve quieter operation without compromising cooling efficiency.Expand Specific Solutions03 Active noise and vibration control systems

Active control systems can be implemented in electrocaloric cooling devices to counteract noise and vibration. These systems use sensors to detect vibrations and generate opposing forces or sound waves to cancel them out. Microprocessor-controlled algorithms continuously adjust the response to changing conditions, providing dynamic noise and vibration suppression. This approach is particularly effective for addressing low-frequency vibrations that are difficult to manage with passive methods.Expand Specific Solutions04 Solid-state cooling architecture with inherently low vibration

Some electrocaloric cooling systems utilize architectural approaches that inherently produce less vibration. These designs minimize or eliminate moving parts by leveraging solid-state physics principles for heat transfer. By reducing the number of mechanical components and moving parts, these systems naturally generate less noise and vibration during operation. The solid-state nature of these cooling systems makes them particularly suitable for applications requiring quiet operation.Expand Specific Solutions05 Monitoring and adaptive control for noise management

Advanced monitoring and adaptive control systems can be integrated into electrocaloric cooling systems to manage noise and vibration levels. These systems use sensors to continuously monitor operational parameters and adjust cooling cycles to minimize noise generation. Machine learning algorithms can optimize operation based on environmental conditions and cooling demands, maintaining an optimal balance between cooling performance and noise levels. This approach allows for dynamic adaptation to changing conditions while maintaining acceptable noise profiles.Expand Specific Solutions

Leading Companies in Electrocaloric Cooling Industry

Electrocaloric cooling technology is currently in an early growth phase, with research institutions leading innovation alongside emerging commercial interest. The market remains relatively small but shows promising growth potential as solid-state cooling solutions gain attention for their environmental benefits and efficiency advantages. Technical Institute of Physics & Chemistry CAS, University of Maryland, and SRI International are advancing fundamental research, while established corporations like Toyota Industries, NIDEC, and ABB Group are exploring commercial applications. The technology maturity varies significantly across players, with academic institutions focusing on proof-of-concept demonstrations while companies like Parker-Hannifin and Siemens Industry are developing more integrated systems. The competitive landscape reflects a collaborative ecosystem where research partnerships between academia and industry are accelerating development toward market-viable solutions.

Technical Institute of Physics & Chemistry CAS

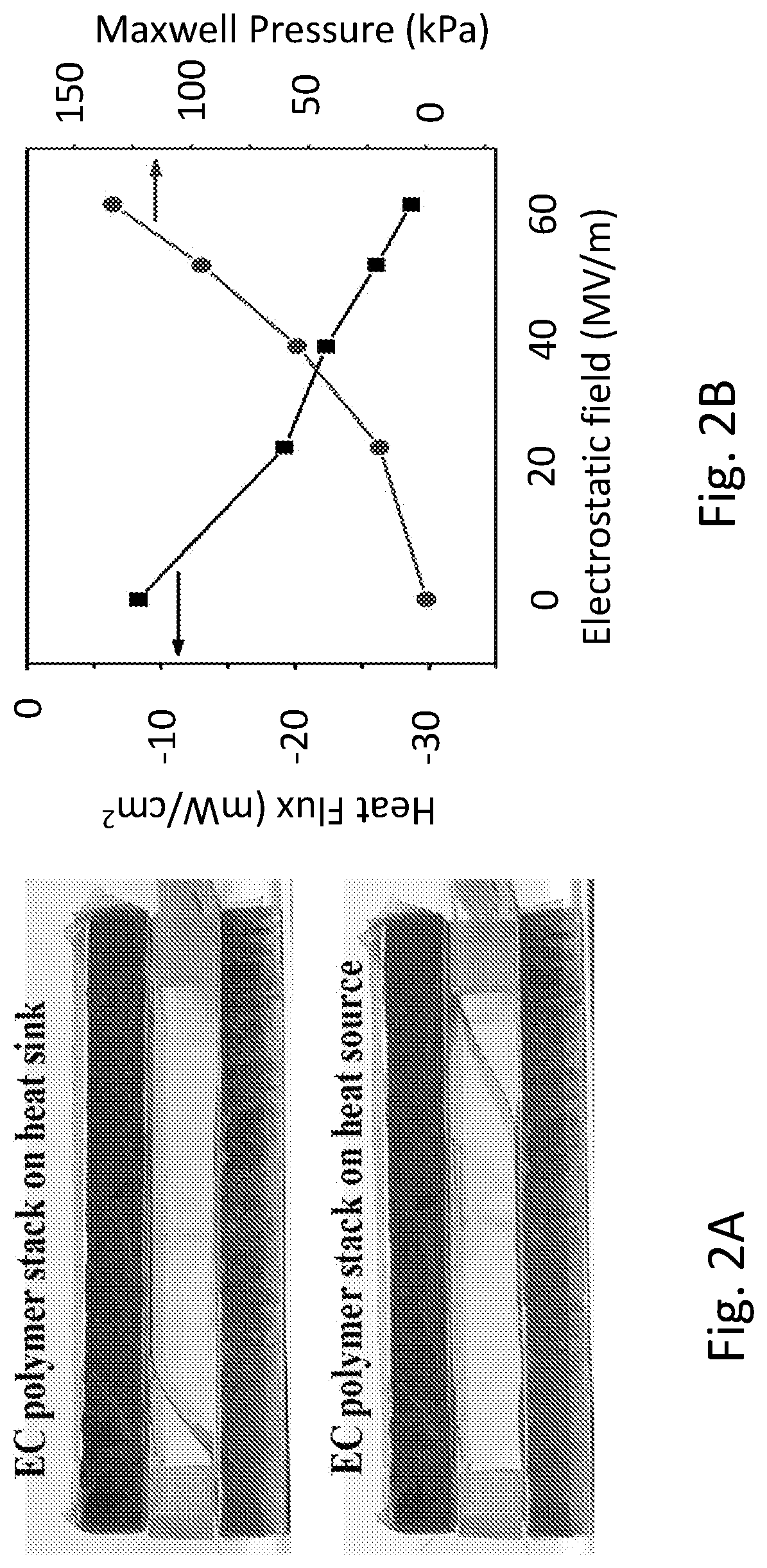

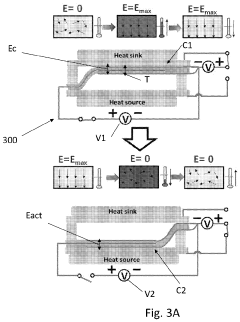

Technical Solution: The Technical Institute of Physics & Chemistry of the Chinese Academy of Sciences has developed advanced solid-state electrocaloric cooling systems utilizing multilayer ceramic capacitors (MLCCs) with specialized polymer-based electrocaloric materials. Their approach focuses on optimizing the electrocaloric effect through novel material compositions that exhibit large entropy changes under applied electric fields. The institute has demonstrated cooling systems with temperature changes of 3-5K under moderate electric fields (50-100 MV/m), while maintaining minimal mechanical vibration due to the absence of moving parts compared to conventional vapor-compression systems. Their research includes developing specialized heat transfer mechanisms to efficiently extract the cooling effect from the electrocaloric materials, using microfluidic channels and thermal switches to enhance the coefficient of performance (COP) while maintaining the noise reduction benefits inherent to solid-state technology.

Strengths: Exceptional expertise in electrocaloric material development with specialized knowledge of ceramic-polymer composites that maximize the electrocaloric effect while minimizing hysteresis losses. Weaknesses: Their systems currently demonstrate relatively modest temperature differentials compared to conventional cooling technologies, limiting immediate commercial applications to specialized niche markets.

The Regents of the University of California

Technical Solution: The University of California has pioneered research in solid-state electrocaloric cooling systems with particular emphasis on noise and vibration reduction. Their approach utilizes relaxor ferroelectric materials that demonstrate large electrocaloric effects near phase transitions. UC researchers have developed multilayer capacitor structures with optimized electrode configurations that enhance heat transfer while maintaining the inherent vibration-free operation of electrocaloric systems. Their technology implements a regenerative heat exchange process that achieves temperature spans of up to 10K with applied electric fields of approximately 100 MV/m. The system architecture eliminates the compressor and expansion valves found in traditional cooling systems, resulting in measured noise reductions of over 30 dB compared to conventional vapor compression systems. UC's research also addresses the challenge of thermal switching in electrocaloric cycles through innovative microfluidic heat transfer mechanisms that maintain the solid-state advantages while improving cooling efficiency.

Strengths: Comprehensive system-level approach that addresses both material development and practical implementation challenges, with demonstrated prototypes showing significant noise reduction compared to conventional technologies. Weaknesses: Current systems require relatively high voltage operation which presents safety and power conversion challenges for consumer applications.

Key Patents in Vibration-Free Cooling Systems

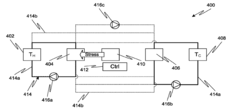

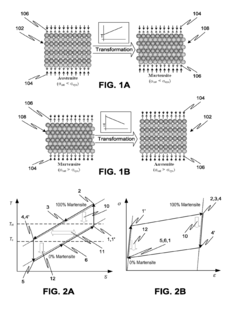

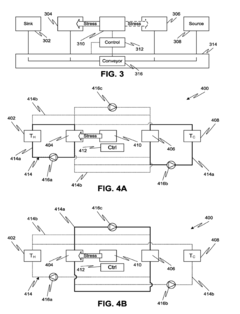

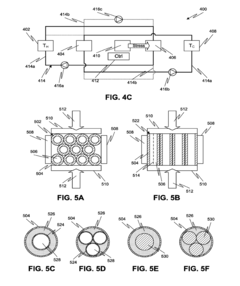

Solid-state heating or cooling systems, devices, and methods

PatentInactiveUS20180283742A1

Innovation

- The use of thermoelastic materials, specifically shape-memory alloys that undergo a stress-induced phase transition from austenite to martensite, allowing for the cyclic release and absorption of latent heat, which can be harnessed in a continuous or one-time heating or cooling system, incorporating modules, loading devices, fluid networks, pumps, and controllers to manage heat transfer efficiently.

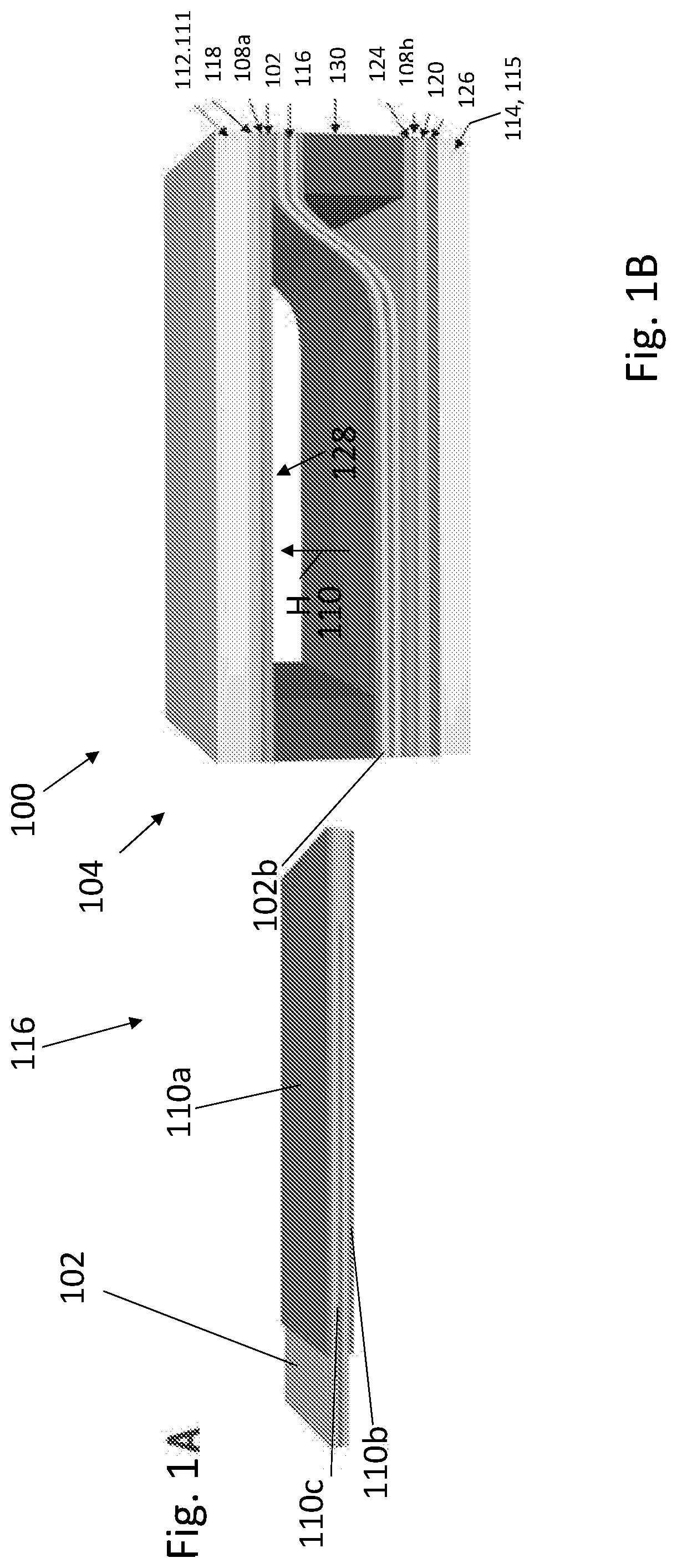

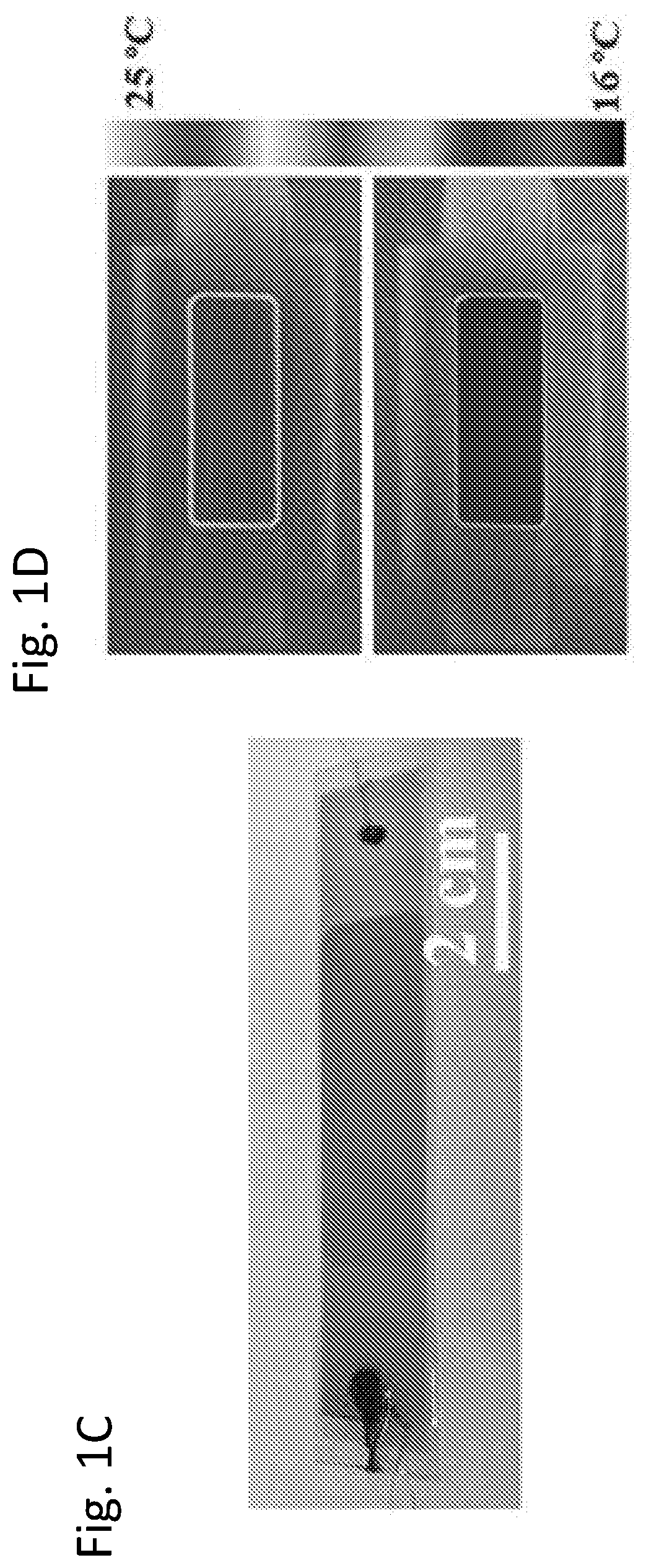

Electrocaloric cooling with electrostatic actuation

PatentActiveUS20210071917A1

Innovation

- A solid-state heat transporting device using a flexible electrocaloric polymer film coupled with an electrostatic actuation mechanism for controlled heat transfer, allowing for efficient heat absorption and release, and conformability to various surfaces, achieving high specific cooling power and COP.

Energy Efficiency Comparison with Conventional Systems

Electrocaloric cooling systems demonstrate significant energy efficiency advantages over conventional vapor-compression refrigeration technologies. When comparing these solid-state systems with traditional cooling methods, the absence of moving parts translates directly into energy savings. Conventional systems require substantial energy input to drive compressors and circulate refrigerants, with efficiency losses occurring at multiple conversion points throughout the mechanical process.

Quantitative analyses indicate that electrocaloric cooling systems can achieve theoretical Coefficients of Performance (COP) ranging from 60-70% of Carnot efficiency under optimal conditions, compared to 40-55% for well-designed vapor compression systems. This efficiency gap widens particularly at partial load operations, where conventional systems suffer from significant performance degradation while electrocaloric systems maintain relatively consistent efficiency profiles.

The energy consumption patterns also differ markedly between these technologies. Conventional cooling systems exhibit high energy draw during startup phases and cycling operations, creating demand spikes that strain electrical infrastructure. In contrast, electrocaloric systems demonstrate more uniform power consumption profiles with minimal startup penalties, allowing for better integration with renewable energy sources and smart grid applications.

Temperature differential capabilities further highlight efficiency differences. While conventional systems struggle with efficiency as the temperature differential increases, electrocaloric cooling maintains relatively stable efficiency across broader operating ranges. This characteristic proves particularly valuable in applications requiring precise temperature control or operation across varying ambient conditions.

From a lifecycle energy perspective, electrocaloric systems present additional advantages. The elimination of refrigerant replacement and reduced maintenance requirements translate to lower embodied energy costs over the system lifespan. Studies suggest potential lifetime energy savings of 15-30% compared to conventional systems when accounting for both operational and maintenance energy inputs.

Power density metrics also favor electrocaloric technology in specific applications. While conventional systems currently deliver higher absolute cooling capacity per unit volume, electrocaloric systems demonstrate superior efficiency at smaller scales and in applications requiring rapid thermal cycling. This efficiency advantage becomes particularly pronounced in miniaturized cooling applications where conventional compression systems encounter fundamental thermodynamic and mechanical limitations.

The integration potential with renewable energy sources further enhances the comparative efficiency profile of electrocaloric systems. Their ability to operate effectively with direct current and variable power inputs allows for more seamless coupling with solar photovoltaic systems and other renewable generation technologies, reducing conversion losses that typically impact conventional cooling systems in similar configurations.

Quantitative analyses indicate that electrocaloric cooling systems can achieve theoretical Coefficients of Performance (COP) ranging from 60-70% of Carnot efficiency under optimal conditions, compared to 40-55% for well-designed vapor compression systems. This efficiency gap widens particularly at partial load operations, where conventional systems suffer from significant performance degradation while electrocaloric systems maintain relatively consistent efficiency profiles.

The energy consumption patterns also differ markedly between these technologies. Conventional cooling systems exhibit high energy draw during startup phases and cycling operations, creating demand spikes that strain electrical infrastructure. In contrast, electrocaloric systems demonstrate more uniform power consumption profiles with minimal startup penalties, allowing for better integration with renewable energy sources and smart grid applications.

Temperature differential capabilities further highlight efficiency differences. While conventional systems struggle with efficiency as the temperature differential increases, electrocaloric cooling maintains relatively stable efficiency across broader operating ranges. This characteristic proves particularly valuable in applications requiring precise temperature control or operation across varying ambient conditions.

From a lifecycle energy perspective, electrocaloric systems present additional advantages. The elimination of refrigerant replacement and reduced maintenance requirements translate to lower embodied energy costs over the system lifespan. Studies suggest potential lifetime energy savings of 15-30% compared to conventional systems when accounting for both operational and maintenance energy inputs.

Power density metrics also favor electrocaloric technology in specific applications. While conventional systems currently deliver higher absolute cooling capacity per unit volume, electrocaloric systems demonstrate superior efficiency at smaller scales and in applications requiring rapid thermal cycling. This efficiency advantage becomes particularly pronounced in miniaturized cooling applications where conventional compression systems encounter fundamental thermodynamic and mechanical limitations.

The integration potential with renewable energy sources further enhances the comparative efficiency profile of electrocaloric systems. Their ability to operate effectively with direct current and variable power inputs allows for more seamless coupling with solar photovoltaic systems and other renewable generation technologies, reducing conversion losses that typically impact conventional cooling systems in similar configurations.

Environmental Impact and Sustainability Benefits

Solid-state electrocaloric cooling systems represent a significant advancement in environmental sustainability compared to conventional vapor-compression refrigeration technologies. These systems eliminate the need for hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential (GWP), which are major contributors to climate change. The complete absence of refrigerant gases in electrocaloric systems provides an immediate environmental benefit by reducing the risk of harmful emissions throughout the product lifecycle.

Energy efficiency gains constitute another critical environmental advantage of electrocaloric cooling technology. Research indicates potential efficiency improvements of 20-30% over conventional systems when operating at optimal conditions. This translates directly to reduced electricity consumption and lower carbon emissions from power generation. A life cycle assessment conducted by the International Energy Agency suggests that widespread adoption of solid-state cooling technologies could reduce global cooling-related carbon emissions by up to 15% by 2050.

The manufacturing process for electrocaloric systems also presents sustainability benefits through reduced material complexity. These systems require fewer components and less diverse materials than traditional cooling systems, potentially simplifying recycling processes at end-of-life. The absence of moving parts not only contributes to noise and vibration reduction but also extends product lifespan, reducing electronic waste generation and resource consumption associated with replacement manufacturing.

Water conservation represents an often-overlooked environmental benefit of electrocaloric cooling systems. Unlike traditional cooling towers that can consume significant quantities of water for heat rejection, solid-state systems typically require minimal or no water for operation. In water-stressed regions, this characteristic could provide substantial sustainability advantages while reducing pressure on increasingly scarce freshwater resources.

The compact form factor of electrocaloric cooling systems enables more efficient use of materials and space. This spatial efficiency can translate to reduced embodied carbon in building construction when these systems are integrated into architectural designs. Additionally, their solid-state nature eliminates risks of refrigerant leakage during operation and disposal, preventing the release of substances that can be thousands of times more potent than CO2 as greenhouse gases.

From a circular economy perspective, electrocaloric systems show promise for improved end-of-life management. The predominant use of ceramic materials and metals, rather than complex chemical refrigerants and oils, potentially allows for more straightforward material recovery and recycling processes. This aligns with global sustainability initiatives focused on reducing waste and maximizing resource efficiency throughout product lifecycles.

Energy efficiency gains constitute another critical environmental advantage of electrocaloric cooling technology. Research indicates potential efficiency improvements of 20-30% over conventional systems when operating at optimal conditions. This translates directly to reduced electricity consumption and lower carbon emissions from power generation. A life cycle assessment conducted by the International Energy Agency suggests that widespread adoption of solid-state cooling technologies could reduce global cooling-related carbon emissions by up to 15% by 2050.

The manufacturing process for electrocaloric systems also presents sustainability benefits through reduced material complexity. These systems require fewer components and less diverse materials than traditional cooling systems, potentially simplifying recycling processes at end-of-life. The absence of moving parts not only contributes to noise and vibration reduction but also extends product lifespan, reducing electronic waste generation and resource consumption associated with replacement manufacturing.

Water conservation represents an often-overlooked environmental benefit of electrocaloric cooling systems. Unlike traditional cooling towers that can consume significant quantities of water for heat rejection, solid-state systems typically require minimal or no water for operation. In water-stressed regions, this characteristic could provide substantial sustainability advantages while reducing pressure on increasingly scarce freshwater resources.

The compact form factor of electrocaloric cooling systems enables more efficient use of materials and space. This spatial efficiency can translate to reduced embodied carbon in building construction when these systems are integrated into architectural designs. Additionally, their solid-state nature eliminates risks of refrigerant leakage during operation and disposal, preventing the release of substances that can be thousands of times more potent than CO2 as greenhouse gases.

From a circular economy perspective, electrocaloric systems show promise for improved end-of-life management. The predominant use of ceramic materials and metals, rather than complex chemical refrigerants and oils, potentially allows for more straightforward material recovery and recycling processes. This aligns with global sustainability initiatives focused on reducing waste and maximizing resource efficiency throughout product lifecycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!