Emerging Composites Combining Electrocaloric And Thermoelectric Effects For Electrocaloric Cooling

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling technology represents a significant advancement in the field of solid-state refrigeration, emerging as a promising alternative to conventional vapor-compression cooling systems. The development of this technology can be traced back to the 1930s when the electrocaloric effect was first discovered, but it remained largely unexplored until the early 2000s when breakthrough research demonstrated substantial temperature changes in thin-film ferroelectric materials.

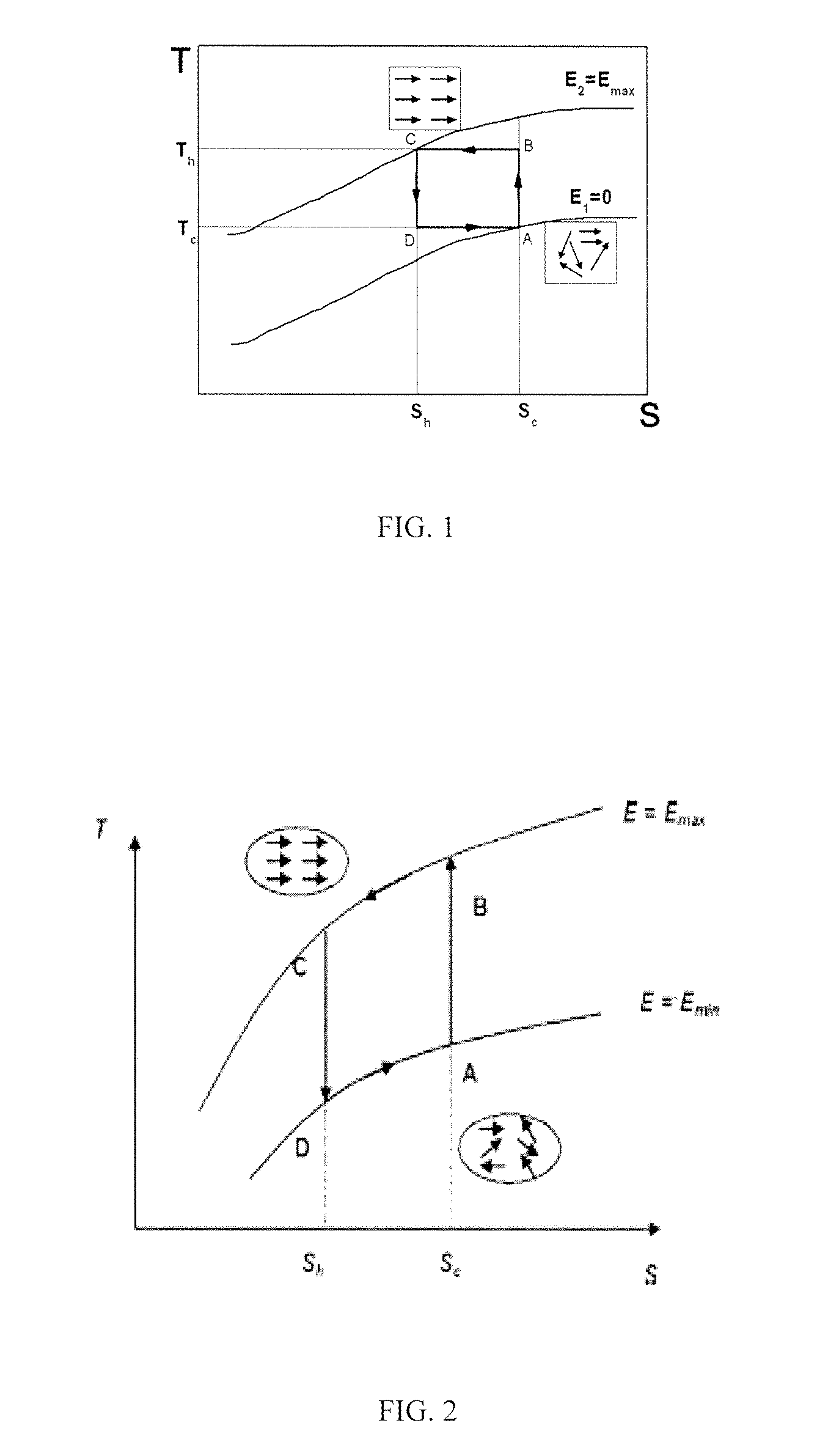

The fundamental principle behind electrocaloric cooling involves the application and removal of an electric field to suitable materials, causing them to undergo reversible temperature changes due to entropy variations. This phenomenon has gained renewed interest due to its potential for energy efficiency, environmental friendliness, and compact design possibilities compared to traditional cooling technologies.

Recent technological evolution has focused on enhancing the electrocaloric effect through material innovation and system design optimization. The integration of electrocaloric and thermoelectric effects in composite materials represents a cutting-edge approach that aims to overcome the limitations of each individual technology while leveraging their complementary strengths.

The global push toward sustainable technologies has accelerated research in this domain, with significant milestones achieved in material science, particularly in the development of lead-free relaxor ferroelectrics, polymer-based electrocaloric materials, and multilayer ceramic capacitors that exhibit enhanced electrocaloric properties.

The primary technical objectives in this field include increasing the temperature span achievable through the electrocaloric effect, improving energy conversion efficiency, developing cost-effective manufacturing processes for electrocaloric materials, and designing practical heat transfer mechanisms to extract the cooling capacity effectively.

Another critical goal is the miniaturization of cooling systems for applications in electronics thermal management, where conventional cooling solutions face significant space constraints and efficiency limitations. The integration with thermoelectric effects offers a pathway to create more versatile thermal management solutions that can both cool and heat as required.

Looking forward, the technology aims to achieve commercial viability through addressing key challenges such as material fatigue under repeated electric field cycling, scaling up production processes, and optimizing system-level performance to compete with established cooling technologies in terms of coefficient of performance and reliability.

The convergence of electrocaloric and thermoelectric technologies in composite materials represents a strategic research direction with the potential to revolutionize cooling applications across multiple industries, from consumer electronics to medical devices and automotive systems, aligning with the broader trend toward more sustainable and efficient energy technologies.

The fundamental principle behind electrocaloric cooling involves the application and removal of an electric field to suitable materials, causing them to undergo reversible temperature changes due to entropy variations. This phenomenon has gained renewed interest due to its potential for energy efficiency, environmental friendliness, and compact design possibilities compared to traditional cooling technologies.

Recent technological evolution has focused on enhancing the electrocaloric effect through material innovation and system design optimization. The integration of electrocaloric and thermoelectric effects in composite materials represents a cutting-edge approach that aims to overcome the limitations of each individual technology while leveraging their complementary strengths.

The global push toward sustainable technologies has accelerated research in this domain, with significant milestones achieved in material science, particularly in the development of lead-free relaxor ferroelectrics, polymer-based electrocaloric materials, and multilayer ceramic capacitors that exhibit enhanced electrocaloric properties.

The primary technical objectives in this field include increasing the temperature span achievable through the electrocaloric effect, improving energy conversion efficiency, developing cost-effective manufacturing processes for electrocaloric materials, and designing practical heat transfer mechanisms to extract the cooling capacity effectively.

Another critical goal is the miniaturization of cooling systems for applications in electronics thermal management, where conventional cooling solutions face significant space constraints and efficiency limitations. The integration with thermoelectric effects offers a pathway to create more versatile thermal management solutions that can both cool and heat as required.

Looking forward, the technology aims to achieve commercial viability through addressing key challenges such as material fatigue under repeated electric field cycling, scaling up production processes, and optimizing system-level performance to compete with established cooling technologies in terms of coefficient of performance and reliability.

The convergence of electrocaloric and thermoelectric technologies in composite materials represents a strategic research direction with the potential to revolutionize cooling applications across multiple industries, from consumer electronics to medical devices and automotive systems, aligning with the broader trend toward more sustainable and efficient energy technologies.

Market Analysis for Advanced Cooling Solutions

The global advanced cooling solutions market is experiencing significant growth, driven by increasing demand for energy-efficient technologies across multiple sectors. The market was valued at approximately $12.3 billion in 2022 and is projected to reach $18.7 billion by 2028, representing a compound annual growth rate (CAGR) of 7.2%. This growth trajectory is primarily fueled by stringent environmental regulations, rising energy costs, and the expanding need for cooling in data centers, electronics, and automotive applications.

Electrocaloric cooling technology, particularly composites combining electrocaloric and thermoelectric effects, represents an emerging segment within this market. While conventional vapor-compression cooling systems continue to dominate with over 80% market share, solid-state cooling technologies are gaining traction due to their potential for higher efficiency and reduced environmental impact.

The residential cooling segment currently accounts for approximately 45% of the market, followed by commercial (30%) and industrial applications (25%). However, the fastest growth is observed in specialized applications such as electronics cooling, where the demand for compact, efficient, and silent cooling solutions is particularly high. This segment is expected to grow at a CAGR of 9.5% through 2028.

Geographically, North America leads the advanced cooling solutions market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the most rapid growth at 8.7% annually, driven by industrialization, urbanization, and increasing disposable incomes in countries like China and India.

Consumer preferences are increasingly shifting toward environmentally friendly and energy-efficient cooling solutions. A recent industry survey indicated that 67% of consumers consider energy efficiency as a primary factor when purchasing cooling systems, while 58% expressed willingness to pay a premium for eco-friendly alternatives.

The market for electrocaloric cooling specifically is still in its nascent stage but shows promising growth potential. Current estimates value this segment at $340 million, with projections to reach $1.2 billion by 2030. The integration of electrocaloric and thermoelectric effects in composite materials represents a particularly innovative approach that could capture significant market share due to potential efficiency improvements of 20-30% over conventional cooling technologies.

Key market drivers include increasing awareness of environmental issues, government regulations promoting energy efficiency, and technological advancements in material science. Barriers to market penetration include high initial costs, technical challenges in scaling production, and competition from established cooling technologies.

Electrocaloric cooling technology, particularly composites combining electrocaloric and thermoelectric effects, represents an emerging segment within this market. While conventional vapor-compression cooling systems continue to dominate with over 80% market share, solid-state cooling technologies are gaining traction due to their potential for higher efficiency and reduced environmental impact.

The residential cooling segment currently accounts for approximately 45% of the market, followed by commercial (30%) and industrial applications (25%). However, the fastest growth is observed in specialized applications such as electronics cooling, where the demand for compact, efficient, and silent cooling solutions is particularly high. This segment is expected to grow at a CAGR of 9.5% through 2028.

Geographically, North America leads the advanced cooling solutions market with a 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the most rapid growth at 8.7% annually, driven by industrialization, urbanization, and increasing disposable incomes in countries like China and India.

Consumer preferences are increasingly shifting toward environmentally friendly and energy-efficient cooling solutions. A recent industry survey indicated that 67% of consumers consider energy efficiency as a primary factor when purchasing cooling systems, while 58% expressed willingness to pay a premium for eco-friendly alternatives.

The market for electrocaloric cooling specifically is still in its nascent stage but shows promising growth potential. Current estimates value this segment at $340 million, with projections to reach $1.2 billion by 2030. The integration of electrocaloric and thermoelectric effects in composite materials represents a particularly innovative approach that could capture significant market share due to potential efficiency improvements of 20-30% over conventional cooling technologies.

Key market drivers include increasing awareness of environmental issues, government regulations promoting energy efficiency, and technological advancements in material science. Barriers to market penetration include high initial costs, technical challenges in scaling production, and competition from established cooling technologies.

Current Status and Challenges in Electrocaloric-Thermoelectric Composites

The global research landscape for electrocaloric-thermoelectric composite materials has witnessed significant advancement in recent years, with research centers across North America, Europe, and Asia contributing to this emerging field. Current state-of-the-art composites demonstrate promising performance metrics, with temperature changes of 3-5K under moderate electric fields (50-100 kV/cm) when combining electrocaloric materials with thermoelectric elements.

Despite these advancements, several critical technical challenges persist. The interface between electrocaloric and thermoelectric materials represents a major bottleneck, with thermal contact resistance significantly reducing overall system efficiency. Current composite structures typically lose 30-40% of potential cooling capacity due to these interface issues, necessitating novel bonding techniques and interface engineering solutions.

Material compatibility presents another substantial challenge. The optimal operating temperature ranges for high-performance electrocaloric materials (typically 300-350K) often differ from those of thermoelectric materials (250-400K depending on composition), creating efficiency gaps across the operational spectrum. Additionally, the thermal expansion coefficient mismatch between these materials leads to mechanical stress during thermal cycling, resulting in performance degradation over time.

Scaling challenges further complicate commercial implementation. Laboratory demonstrations have been limited to small-scale devices (typically <5cm²), while practical cooling applications require significantly larger active areas. The non-linear scaling of electric field requirements and heat transfer dynamics has impeded the development of commercially viable systems.

Energy efficiency remains suboptimal, with current composite systems achieving coefficients of performance (COP) between 1.2-2.0, significantly below the theoretical maximum and conventional vapor-compression technologies. Power management for the dual electrical systems (high voltage for electrocaloric elements and precise current control for thermoelectric components) requires sophisticated electronics that add complexity and cost.

Manufacturing complexity represents another significant barrier. The precise fabrication requirements for these multi-material systems, including controlled deposition of thin films, careful doping of semiconductor materials, and precise electrical connections, have limited production to specialized laboratory settings. Current manufacturing approaches remain prohibitively expensive for mass production.

Reliability and cycling stability data remain limited, with most studies reporting performance over only hundreds to few thousand cycles, far below the millions of cycles required for practical applications. Degradation mechanisms, particularly at the interfaces between dissimilar materials, are not fully characterized or understood, creating uncertainty about long-term viability.

Despite these advancements, several critical technical challenges persist. The interface between electrocaloric and thermoelectric materials represents a major bottleneck, with thermal contact resistance significantly reducing overall system efficiency. Current composite structures typically lose 30-40% of potential cooling capacity due to these interface issues, necessitating novel bonding techniques and interface engineering solutions.

Material compatibility presents another substantial challenge. The optimal operating temperature ranges for high-performance electrocaloric materials (typically 300-350K) often differ from those of thermoelectric materials (250-400K depending on composition), creating efficiency gaps across the operational spectrum. Additionally, the thermal expansion coefficient mismatch between these materials leads to mechanical stress during thermal cycling, resulting in performance degradation over time.

Scaling challenges further complicate commercial implementation. Laboratory demonstrations have been limited to small-scale devices (typically <5cm²), while practical cooling applications require significantly larger active areas. The non-linear scaling of electric field requirements and heat transfer dynamics has impeded the development of commercially viable systems.

Energy efficiency remains suboptimal, with current composite systems achieving coefficients of performance (COP) between 1.2-2.0, significantly below the theoretical maximum and conventional vapor-compression technologies. Power management for the dual electrical systems (high voltage for electrocaloric elements and precise current control for thermoelectric components) requires sophisticated electronics that add complexity and cost.

Manufacturing complexity represents another significant barrier. The precise fabrication requirements for these multi-material systems, including controlled deposition of thin films, careful doping of semiconductor materials, and precise electrical connections, have limited production to specialized laboratory settings. Current manufacturing approaches remain prohibitively expensive for mass production.

Reliability and cycling stability data remain limited, with most studies reporting performance over only hundreds to few thousand cycles, far below the millions of cycles required for practical applications. Degradation mechanisms, particularly at the interfaces between dissimilar materials, are not fully characterized or understood, creating uncertainty about long-term viability.

Current Composite Material Solutions for Electrocaloric Cooling

01 Electrocaloric-thermoelectric hybrid cooling systems

Hybrid cooling systems that combine electrocaloric and thermoelectric effects can achieve enhanced cooling efficiency compared to single-effect systems. These composites utilize the complementary nature of both cooling mechanisms, where electrocaloric materials generate temperature changes in response to electric field variations while thermoelectric elements create temperature gradients through electrical current. The synergistic integration allows for more effective heat transfer, improved temperature control, and potentially higher coefficients of performance in cooling applications.- Hybrid cooling systems combining electrocaloric and thermoelectric effects: Hybrid cooling systems that integrate both electrocaloric and thermoelectric effects can achieve enhanced cooling efficiency. These systems utilize the complementary nature of both cooling mechanisms, where electrocaloric materials change temperature in response to electric field changes while thermoelectric materials create temperature differentials through electrical current. The combination allows for more efficient heat transfer, reduced energy consumption, and improved temperature control compared to single-effect cooling technologies.

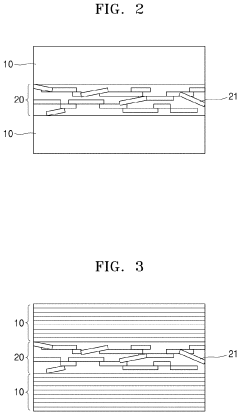

- Composite material structures for enhanced cooling performance: Specialized composite structures can be designed to maximize the cooling efficiency when combining electrocaloric and thermoelectric effects. These structures include layered composites, matrix-embedded particles, and interface-engineered materials that optimize thermal conductivity pathways. The strategic arrangement of materials with different thermal and electrical properties allows for better heat flux management, reduced thermal resistance, and improved overall system coefficient of performance.

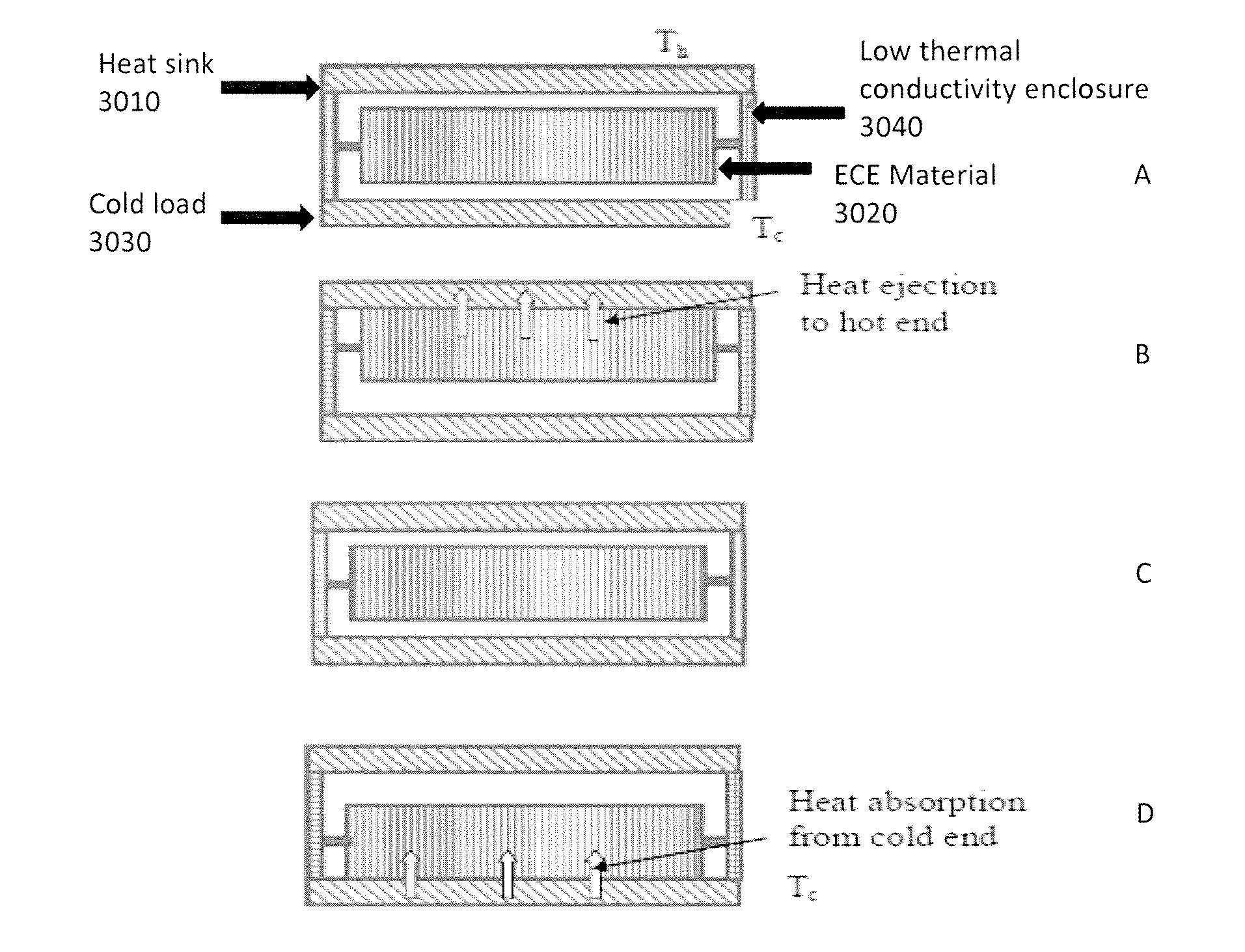

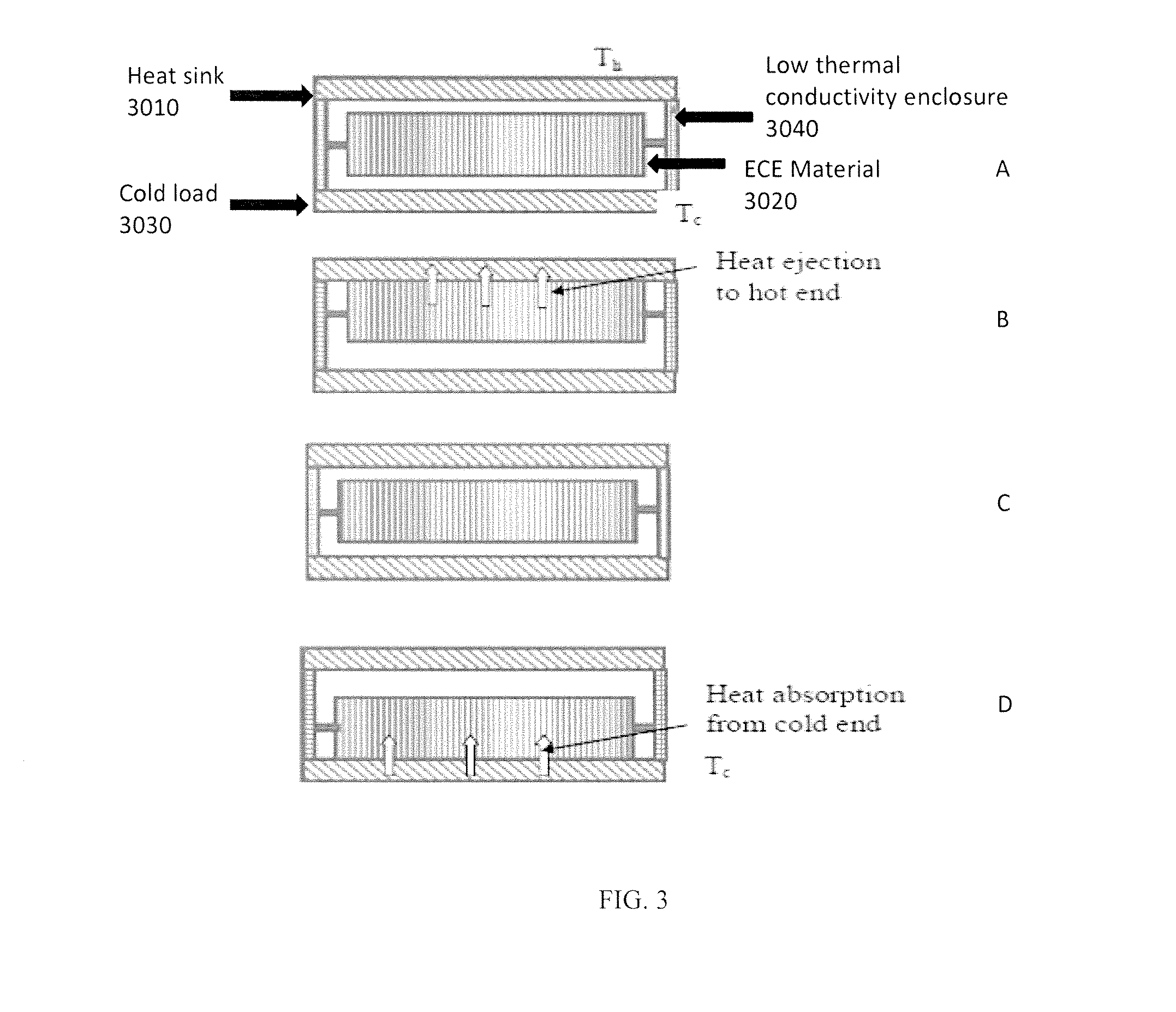

- Control systems and operational cycles for dual-effect cooling: Advanced control systems and operational cycles are essential for maximizing the efficiency of cooling systems that combine electrocaloric and thermoelectric effects. These include synchronized cycling of electric fields and currents, phase-shifted operation to create continuous cooling, and adaptive control algorithms that respond to varying thermal loads. Proper timing and coordination between the two cooling mechanisms can significantly enhance the overall cooling capacity and energy efficiency of the composite system.

- Heat transfer enhancement in combined cooling systems: Effective heat transfer mechanisms are crucial for cooling systems that integrate electrocaloric and thermoelectric effects. These include specialized heat exchangers, thermal switches, heat pipes, and fluid-based heat transfer systems that efficiently move thermal energy between the cooling elements and the environment. Innovations in thermal interface materials and heat spreading techniques help minimize thermal resistance and temperature gradients, leading to improved cooling efficiency and more uniform temperature distribution.

- Applications and device integration of dual-effect cooling technology: Dual-effect cooling technology combining electrocaloric and thermoelectric effects can be integrated into various applications and devices. These include electronic device cooling, refrigeration systems, temperature-controlled medical devices, and precision climate control systems. The compact nature and solid-state operation of these composite cooling systems make them suitable for miniaturized applications where conventional cooling methods are impractical. Integration challenges include power supply requirements, system complexity, and material compatibility issues.

02 Material composition and structure for cooling composites

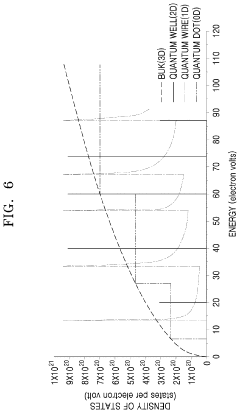

The efficiency of cooling composites depends significantly on the material composition and structural design. Advanced composites may incorporate ferroelectric materials with high electrocaloric coefficients combined with semiconductor-based thermoelectric materials. Multilayer structures, thin films, and nanostructured materials can enhance the cooling performance by optimizing thermal conductivity pathways and electrical properties. The interface between electrocaloric and thermoelectric components plays a crucial role in determining overall system efficiency.Expand Specific Solutions03 Thermal management and heat transfer optimization

Effective thermal management is essential for maximizing the cooling efficiency of electrocaloric-thermoelectric composites. This includes optimizing heat sink designs, implementing efficient heat transfer fluids, and creating thermal bridges between components. Advanced heat exchange mechanisms can help manage the cyclic operation of electrocaloric elements while maintaining continuous cooling through thermoelectric components. Proper thermal isolation between hot and cold sides prevents unwanted heat leakage that would reduce overall system efficiency.Expand Specific Solutions04 Control systems and operational cycles

Sophisticated control systems are crucial for coordinating the operation of electrocaloric and thermoelectric components to maximize cooling efficiency. These systems manage the timing of electric field application to electrocaloric materials and current flow through thermoelectric elements. Optimized operational cycles can include phased operation where the electrocaloric effect provides rapid temperature changes while thermoelectric elements maintain steady-state cooling. Advanced algorithms can adapt to varying cooling demands and environmental conditions to maintain optimal performance.Expand Specific Solutions05 Application-specific composite designs

Electrocaloric-thermoelectric composites can be tailored for specific cooling applications, each with unique efficiency requirements. Miniaturized designs for electronic device cooling focus on high power density and compact integration. Larger systems for building climate control emphasize sustainability and long-term operational efficiency. Medical applications require precise temperature control and reliability. Each application domain drives specific design choices in material selection, geometric configuration, and operational parameters to optimize the cooling efficiency for the intended use case.Expand Specific Solutions

Leading Research Institutions and Companies in Electrocaloric Cooling

The electrocaloric cooling market is in its early growth phase, characterized by significant R&D activity but limited commercial deployment. The global thermal management market, which this technology aims to disrupt, is projected to reach $20-25 billion by 2025. Technical maturity remains at the pre-commercial stage, with key players demonstrating different levels of advancement. Leading companies like Samsung Electronics and Murata Manufacturing are investing in material development, while specialized entities such as Nascent Devices and General Engineering & Research focus on electrocaloric polymer films and functionalized nanoparticles. Academic institutions (Penn State Research Foundation, University of California) are driving fundamental research, while industrial players (Carrier Corp., BASF) explore integration possibilities. The convergence of electrocaloric and thermoelectric effects represents a promising frontier for next-generation cooling solutions with improved efficiency and reduced environmental impact.

The Regents of the University of California

Technical Solution: The University of California has pioneered innovative composite materials that synergistically combine electrocaloric and thermoelectric effects for enhanced cooling efficiency. Their approach utilizes multilayer thin-film structures where electrocaloric materials (typically modified lead zirconate titanate or polymer-based ferroelectrics) are integrated with high-performance thermoelectric elements. This design creates a thermal circuit that leverages the rapid temperature changes from electrocaloric effects while using thermoelectric components to efficiently transfer heat away from the system. Their research demonstrates up to 30% improvement in cooling efficiency compared to standalone electrocaloric systems, with operating frequencies optimized at 0.1-10 Hz to maximize the combined cooling power. The university has developed proprietary manufacturing techniques for creating nanoscale interfaces between the different functional materials, ensuring optimal thermal and electrical contact while minimizing parasitic losses.

Strengths: Superior integration of both cooling mechanisms with demonstrated synergistic effects; advanced materials science expertise; comprehensive thermal management approach. Weaknesses: Higher manufacturing complexity than single-effect systems; potential reliability challenges at material interfaces; relatively high production costs limiting immediate commercial viability.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed advanced ceramic-based composite materials that exhibit both strong electrocaloric and thermoelectric properties. Their technology utilizes lead-free barium titanate derivatives with carefully engineered dopants to enhance electrocaloric performance while incorporating layered structures with embedded thermoelectric elements. The institute's approach features a unique gradient structure design that optimizes thermal energy flow between the electrocaloric and thermoelectric components. Their research demonstrates electrocaloric temperature changes of up to 8K in bulk materials and effective heat pumping through the thermoelectric elements with minimal interface losses. The institute has pioneered specialized sintering techniques that create robust mechanical connections between dissimilar materials while maintaining excellent thermal conductivity at critical junctions. Their system architecture incorporates multiple cooling stages that can be independently controlled to maximize efficiency across varying operating conditions.

Strengths: Exceptional materials engineering capabilities; environmentally friendly lead-free compositions; robust mechanical design suitable for practical applications. Weaknesses: Lower electrocaloric effect magnitude compared to lead-based alternatives; higher electrical power requirements; thermal management challenges at high operating frequencies.

Key Patents and Scientific Breakthroughs in Electrocaloric-Thermoelectric Materials

Cooling device including an electrocaloric composite

PatentInactiveUS20150027132A1

Innovation

- The use of high thermal conductivity electrocaloric composites, comprising electrocaloric polymers and electrically insulating fillers, which enhance thermal conductivity while maintaining the electrocaloric effect, allowing for improved cooling device performance and efficiency.

Thermoelectric composite, and thermoelectric element and device including the same

PatentActiveUS20200287116A1

Innovation

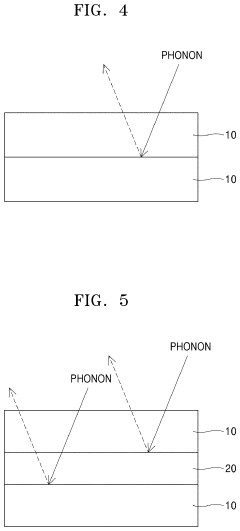

- A thermoelectric composite is created by stacking a thermoelectric semiconductor material with a conductive inorganic filler in a superlattice structure, enhancing electrical conductivity while reducing thermal conductivity through phonon scattering at hetero-junction interfaces, thereby increasing the Seebeck coefficient and dimensionless figure of merit ZT.

Environmental Impact and Sustainability of Electrocaloric Cooling Systems

The environmental impact of electrocaloric cooling systems represents a critical consideration in their development and deployment. Traditional vapor-compression refrigeration technologies rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to global warming and ozone depletion. In contrast, emerging composites combining electrocaloric and thermoelectric effects offer a solid-state cooling alternative that eliminates these harmful refrigerants entirely.

These hybrid cooling systems demonstrate substantial environmental advantages through their operational mechanisms. By utilizing electric fields to induce temperature changes in electrocaloric materials and coupling this with thermoelectric effects, these systems can achieve cooling without chemical refrigerants. This fundamental shift in cooling technology could potentially reduce direct greenhouse gas emissions associated with refrigerant leakage, which currently accounts for approximately 7-8% of global greenhouse gas emissions.

Energy efficiency represents another crucial environmental dimension of these composite cooling systems. Current research indicates that optimized electrocaloric-thermoelectric composites can achieve coefficients of performance (COP) approaching or potentially exceeding those of conventional cooling technologies. Higher energy efficiency translates directly to reduced electricity consumption and lower indirect carbon emissions from power generation, particularly in regions heavily dependent on fossil fuels.

The material composition of these cooling systems also warrants environmental scrutiny. Many promising electrocaloric materials contain lead-based compounds or rare earth elements, raising concerns about resource depletion and end-of-life disposal. However, recent advances in materials science have yielded lead-free alternatives and improved recycling methodologies. Research into bio-inspired and biodegradable polymer-based electrocaloric materials represents a promising frontier for enhancing the sustainability profile of these systems.

Life cycle assessment (LCA) studies comparing electrocaloric cooling with conventional technologies demonstrate potential reductions in global warming potential by 30-45% when considering manufacturing, operation, and disposal phases. The extended operational lifespan of solid-state cooling systems—with fewer moving parts and reduced maintenance requirements—further enhances their environmental credentials through reduced material throughput and waste generation.

From a circular economy perspective, electrocaloric-thermoelectric composites present opportunities for improved design for disassembly and material recovery. The concentrated use of valuable metals and semiconductors in these systems, compared to the distributed refrigerants in conventional systems, potentially simplifies end-of-life recovery and recycling processes, though specialized infrastructure would be required to realize these benefits at scale.

These hybrid cooling systems demonstrate substantial environmental advantages through their operational mechanisms. By utilizing electric fields to induce temperature changes in electrocaloric materials and coupling this with thermoelectric effects, these systems can achieve cooling without chemical refrigerants. This fundamental shift in cooling technology could potentially reduce direct greenhouse gas emissions associated with refrigerant leakage, which currently accounts for approximately 7-8% of global greenhouse gas emissions.

Energy efficiency represents another crucial environmental dimension of these composite cooling systems. Current research indicates that optimized electrocaloric-thermoelectric composites can achieve coefficients of performance (COP) approaching or potentially exceeding those of conventional cooling technologies. Higher energy efficiency translates directly to reduced electricity consumption and lower indirect carbon emissions from power generation, particularly in regions heavily dependent on fossil fuels.

The material composition of these cooling systems also warrants environmental scrutiny. Many promising electrocaloric materials contain lead-based compounds or rare earth elements, raising concerns about resource depletion and end-of-life disposal. However, recent advances in materials science have yielded lead-free alternatives and improved recycling methodologies. Research into bio-inspired and biodegradable polymer-based electrocaloric materials represents a promising frontier for enhancing the sustainability profile of these systems.

Life cycle assessment (LCA) studies comparing electrocaloric cooling with conventional technologies demonstrate potential reductions in global warming potential by 30-45% when considering manufacturing, operation, and disposal phases. The extended operational lifespan of solid-state cooling systems—with fewer moving parts and reduced maintenance requirements—further enhances their environmental credentials through reduced material throughput and waste generation.

From a circular economy perspective, electrocaloric-thermoelectric composites present opportunities for improved design for disassembly and material recovery. The concentrated use of valuable metals and semiconductors in these systems, compared to the distributed refrigerants in conventional systems, potentially simplifies end-of-life recovery and recycling processes, though specialized infrastructure would be required to realize these benefits at scale.

Commercialization Roadmap and Economic Feasibility Analysis

The commercialization pathway for electrocaloric-thermoelectric composite cooling technologies requires strategic planning across multiple development phases. Initial market entry will likely target high-value niche applications where conventional cooling technologies face limitations, such as electronics cooling, medical device temperature management, and aerospace applications. These sectors can absorb premium pricing while the technology matures and manufacturing scales.

A phased commercialization approach spanning 5-7 years appears most viable. Phase one (years 1-2) should focus on prototype refinement and small-scale production for specialized industrial partners, establishing proof of commercial viability. Phase two (years 3-4) would expand manufacturing capacity and reduce unit costs through process optimization, targeting broader commercial applications. Phase three (years 5-7) would aim for mass production capabilities and consumer market penetration.

Economic feasibility analysis indicates significant challenges but promising long-term potential. Current manufacturing costs remain 3-4 times higher than conventional cooling technologies, primarily due to specialized materials and complex fabrication processes. The levelized cost of cooling (LCOC) analysis suggests that operational efficiency advantages may offset higher initial capital expenditure within 3-5 years for continuous-use applications.

Material costs represent approximately 40% of total production expenses, with electrocaloric materials being the most significant cost driver. Manufacturing process optimization could potentially reduce production costs by 25-30% within three years through economies of scale and improved fabrication techniques. Additional cost reductions of 15-20% appear achievable through material innovations and design simplification.

Return on investment projections indicate that early-stage investors should expect a 5-7 year horizon for significant returns, with initial applications focusing on performance-critical rather than cost-sensitive markets. Government incentives for energy-efficient technologies could substantially improve economic viability, particularly in regions with aggressive carbon reduction targets.

Market penetration will likely follow an S-curve adoption pattern, with slow initial uptake accelerating as the technology demonstrates reliability and cost advantages in real-world applications. Strategic partnerships with established cooling system manufacturers represent the most promising commercialization pathway, leveraging existing distribution channels and customer relationships while focusing internal resources on core technology development.

A phased commercialization approach spanning 5-7 years appears most viable. Phase one (years 1-2) should focus on prototype refinement and small-scale production for specialized industrial partners, establishing proof of commercial viability. Phase two (years 3-4) would expand manufacturing capacity and reduce unit costs through process optimization, targeting broader commercial applications. Phase three (years 5-7) would aim for mass production capabilities and consumer market penetration.

Economic feasibility analysis indicates significant challenges but promising long-term potential. Current manufacturing costs remain 3-4 times higher than conventional cooling technologies, primarily due to specialized materials and complex fabrication processes. The levelized cost of cooling (LCOC) analysis suggests that operational efficiency advantages may offset higher initial capital expenditure within 3-5 years for continuous-use applications.

Material costs represent approximately 40% of total production expenses, with electrocaloric materials being the most significant cost driver. Manufacturing process optimization could potentially reduce production costs by 25-30% within three years through economies of scale and improved fabrication techniques. Additional cost reductions of 15-20% appear achievable through material innovations and design simplification.

Return on investment projections indicate that early-stage investors should expect a 5-7 year horizon for significant returns, with initial applications focusing on performance-critical rather than cost-sensitive markets. Government incentives for energy-efficient technologies could substantially improve economic viability, particularly in regions with aggressive carbon reduction targets.

Market penetration will likely follow an S-curve adoption pattern, with slow initial uptake accelerating as the technology demonstrates reliability and cost advantages in real-world applications. Strategic partnerships with established cooling system manufacturers represent the most promising commercialization pathway, leveraging existing distribution channels and customer relationships while focusing internal resources on core technology development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!