Integration Of Electrocaloric Cooling With Building HVAC: Use Cases And Control Strategies

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling represents a revolutionary approach to thermal management that has gained significant attention in recent decades. This technology leverages the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. The historical development of electrocaloric cooling can be traced back to the 1930s when the effect was first discovered, but meaningful research acceleration only occurred in the early 2000s with the discovery of giant electrocaloric effects in thin films.

The evolution of this technology has been marked by several breakthrough moments, particularly the development of new electrocaloric materials with enhanced temperature change capabilities and improved energy efficiency. From initial ceramic-based materials to polymer-based electrocaloric materials, the field has witnessed continuous innovation aimed at increasing cooling capacity while reducing energy consumption.

Current technological trends indicate a shift toward integration solutions, where electrocaloric cooling systems are being designed to complement or replace conventional vapor-compression HVAC systems in buildings. This integration represents a significant opportunity for energy conservation in the building sector, which accounts for approximately 40% of global energy consumption, with HVAC systems responsible for nearly half of this usage.

The primary objective of electrocaloric cooling integration with building HVAC systems is to achieve substantial energy efficiency improvements while maintaining or enhancing thermal comfort for occupants. Specific technical goals include developing scalable electrocaloric modules capable of handling building-level cooling loads, creating intelligent control systems that optimize the operation of hybrid cooling solutions, and designing integration frameworks that allow for retrofitting existing HVAC infrastructure.

Additionally, this technology aims to address environmental concerns by eliminating the need for refrigerants with high global warming potential, thus aligning with global sustainability initiatives and increasingly stringent environmental regulations. The reduction of greenhouse gas emissions associated with building cooling represents a critical objective in the context of climate change mitigation efforts.

Research objectives also extend to cost optimization, as current electrocaloric materials and manufacturing processes remain prohibitively expensive for widespread commercial adoption. Achieving cost parity with conventional cooling technologies through material innovations and manufacturing scale economies constitutes a fundamental goal for market viability.

The integration of electrocaloric cooling with building HVAC systems ultimately seeks to establish a new paradigm in building thermal management—one characterized by higher energy efficiency, reduced environmental impact, and enhanced system control capabilities through digital integration and smart building technologies.

The evolution of this technology has been marked by several breakthrough moments, particularly the development of new electrocaloric materials with enhanced temperature change capabilities and improved energy efficiency. From initial ceramic-based materials to polymer-based electrocaloric materials, the field has witnessed continuous innovation aimed at increasing cooling capacity while reducing energy consumption.

Current technological trends indicate a shift toward integration solutions, where electrocaloric cooling systems are being designed to complement or replace conventional vapor-compression HVAC systems in buildings. This integration represents a significant opportunity for energy conservation in the building sector, which accounts for approximately 40% of global energy consumption, with HVAC systems responsible for nearly half of this usage.

The primary objective of electrocaloric cooling integration with building HVAC systems is to achieve substantial energy efficiency improvements while maintaining or enhancing thermal comfort for occupants. Specific technical goals include developing scalable electrocaloric modules capable of handling building-level cooling loads, creating intelligent control systems that optimize the operation of hybrid cooling solutions, and designing integration frameworks that allow for retrofitting existing HVAC infrastructure.

Additionally, this technology aims to address environmental concerns by eliminating the need for refrigerants with high global warming potential, thus aligning with global sustainability initiatives and increasingly stringent environmental regulations. The reduction of greenhouse gas emissions associated with building cooling represents a critical objective in the context of climate change mitigation efforts.

Research objectives also extend to cost optimization, as current electrocaloric materials and manufacturing processes remain prohibitively expensive for widespread commercial adoption. Achieving cost parity with conventional cooling technologies through material innovations and manufacturing scale economies constitutes a fundamental goal for market viability.

The integration of electrocaloric cooling with building HVAC systems ultimately seeks to establish a new paradigm in building thermal management—one characterized by higher energy efficiency, reduced environmental impact, and enhanced system control capabilities through digital integration and smart building technologies.

HVAC Market Demand Analysis for Electrocaloric Solutions

The global HVAC market is experiencing significant growth, projected to reach $367.5 billion by 2030, with a compound annual growth rate of 6.3% from 2023. This expansion is driven by increasing urbanization, rising global temperatures, and growing awareness of indoor air quality. Traditional HVAC systems, which account for approximately 40% of building energy consumption worldwide, face mounting pressure to improve efficiency and reduce environmental impact as energy costs continue to rise and climate regulations become more stringent.

Electrocaloric cooling technology represents a promising alternative to conventional vapor-compression systems, offering potential energy savings of 20-30% while eliminating environmentally harmful refrigerants. Market research indicates that building owners and facility managers are actively seeking HVAC solutions that can reduce operational costs, with 78% of commercial building decision-makers citing energy efficiency as their top priority when considering system upgrades.

The commercial building sector presents the most immediate opportunity for electrocaloric HVAC integration, particularly in data centers where cooling accounts for up to 40% of operational costs. These facilities require precise temperature control and have demonstrated willingness to adopt innovative cooling technologies that can reduce energy consumption while maintaining reliability. Office buildings represent another significant market segment, with demand for quieter, more efficient, and space-saving HVAC solutions that can be integrated into smart building management systems.

Residential applications for electrocaloric cooling show strong potential in premium housing markets, where consumers demonstrate increasing willingness to pay premium prices for energy-efficient and environmentally friendly home systems. Consumer surveys indicate that 65% of homeowners would consider paying more for HVAC systems that offer substantial long-term energy savings and reduced environmental impact.

Geographically, North America and Europe lead in demand for advanced HVAC technologies due to stringent energy regulations and higher consumer awareness. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with rapidly expanding construction sectors and increasing middle-class demand for air conditioning.

Market barriers include the higher initial cost of electrocaloric systems compared to conventional HVAC (currently estimated at 30-40% premium), limited awareness among contractors and installers, and the conservative nature of the building industry regarding new technologies. However, government incentives for energy-efficient building systems, including tax credits and rebates in many developed markets, are helping to accelerate adoption of innovative cooling technologies.

Electrocaloric cooling technology represents a promising alternative to conventional vapor-compression systems, offering potential energy savings of 20-30% while eliminating environmentally harmful refrigerants. Market research indicates that building owners and facility managers are actively seeking HVAC solutions that can reduce operational costs, with 78% of commercial building decision-makers citing energy efficiency as their top priority when considering system upgrades.

The commercial building sector presents the most immediate opportunity for electrocaloric HVAC integration, particularly in data centers where cooling accounts for up to 40% of operational costs. These facilities require precise temperature control and have demonstrated willingness to adopt innovative cooling technologies that can reduce energy consumption while maintaining reliability. Office buildings represent another significant market segment, with demand for quieter, more efficient, and space-saving HVAC solutions that can be integrated into smart building management systems.

Residential applications for electrocaloric cooling show strong potential in premium housing markets, where consumers demonstrate increasing willingness to pay premium prices for energy-efficient and environmentally friendly home systems. Consumer surveys indicate that 65% of homeowners would consider paying more for HVAC systems that offer substantial long-term energy savings and reduced environmental impact.

Geographically, North America and Europe lead in demand for advanced HVAC technologies due to stringent energy regulations and higher consumer awareness. However, the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with rapidly expanding construction sectors and increasing middle-class demand for air conditioning.

Market barriers include the higher initial cost of electrocaloric systems compared to conventional HVAC (currently estimated at 30-40% premium), limited awareness among contractors and installers, and the conservative nature of the building industry regarding new technologies. However, government incentives for energy-efficient building systems, including tax credits and rebates in many developed markets, are helping to accelerate adoption of innovative cooling technologies.

Current State and Challenges in Electrocaloric-HVAC Integration

Electrocaloric (EC) cooling technology has emerged as a promising alternative to conventional vapor compression systems in building HVAC applications. Currently, the integration of EC cooling with building HVAC systems remains predominantly in the research and development phase, with limited commercial implementations. Laboratory-scale prototypes have demonstrated the feasibility of EC cooling, achieving temperature spans of 10-20°C and cooling capacities in the range of several watts to kilowatts.

The global landscape of EC-HVAC integration research shows concentration in North America, Europe, and East Asia, with the United States, Germany, China, and Japan leading in patent filings and academic publications. Research institutions and corporations in these regions have established collaborative networks to accelerate technology development, though significant regional variations exist in research focus and application priorities.

Several critical technical challenges currently impede widespread adoption of EC cooling in building HVAC systems. The primary limitation is the relatively low cooling capacity of existing EC materials, which restricts applications to small-scale or supplementary cooling scenarios. Most commercially viable EC materials exhibit temperature changes of only 2-5°C under practical electric field strengths, necessitating cascaded systems that increase complexity and cost.

Energy efficiency represents another significant hurdle. While theoretical analyses suggest EC systems could achieve coefficient of performance (COP) values exceeding 7, practical implementations typically achieve COPs between 2-4, comparable to but not substantially better than advanced vapor compression systems. This efficiency gap stems from parasitic losses in power electronics, thermal switching mechanisms, and heat transfer limitations.

System integration challenges further complicate implementation. EC cooling systems require sophisticated thermal management to handle cyclic operation, with thermal switching mechanisms often becoming performance bottlenecks. The high-voltage requirements (typically 1-5 kV) for effective EC effects necessitate specialized power electronics and safety considerations that are not standard in conventional HVAC infrastructure.

Scalability remains problematic, with most successful demonstrations limited to cooling capacities below 1 kW, whereas typical building HVAC applications require 3-10 kW for residential and significantly higher capacities for commercial buildings. Manufacturing challenges, including the production of high-quality EC materials at scale and the fabrication of reliable high-voltage components, contribute to high system costs that currently exceed $1,000 per kW of cooling capacity.

Regulatory frameworks and industry standards for EC-based HVAC systems are still evolving, creating uncertainty for manufacturers and potential adopters. The absence of standardized testing protocols and performance metrics specific to EC technology complicates fair comparisons with conventional cooling technologies.

The global landscape of EC-HVAC integration research shows concentration in North America, Europe, and East Asia, with the United States, Germany, China, and Japan leading in patent filings and academic publications. Research institutions and corporations in these regions have established collaborative networks to accelerate technology development, though significant regional variations exist in research focus and application priorities.

Several critical technical challenges currently impede widespread adoption of EC cooling in building HVAC systems. The primary limitation is the relatively low cooling capacity of existing EC materials, which restricts applications to small-scale or supplementary cooling scenarios. Most commercially viable EC materials exhibit temperature changes of only 2-5°C under practical electric field strengths, necessitating cascaded systems that increase complexity and cost.

Energy efficiency represents another significant hurdle. While theoretical analyses suggest EC systems could achieve coefficient of performance (COP) values exceeding 7, practical implementations typically achieve COPs between 2-4, comparable to but not substantially better than advanced vapor compression systems. This efficiency gap stems from parasitic losses in power electronics, thermal switching mechanisms, and heat transfer limitations.

System integration challenges further complicate implementation. EC cooling systems require sophisticated thermal management to handle cyclic operation, with thermal switching mechanisms often becoming performance bottlenecks. The high-voltage requirements (typically 1-5 kV) for effective EC effects necessitate specialized power electronics and safety considerations that are not standard in conventional HVAC infrastructure.

Scalability remains problematic, with most successful demonstrations limited to cooling capacities below 1 kW, whereas typical building HVAC applications require 3-10 kW for residential and significantly higher capacities for commercial buildings. Manufacturing challenges, including the production of high-quality EC materials at scale and the fabrication of reliable high-voltage components, contribute to high system costs that currently exceed $1,000 per kW of cooling capacity.

Regulatory frameworks and industry standards for EC-based HVAC systems are still evolving, creating uncertainty for manufacturers and potential adopters. The absence of standardized testing protocols and performance metrics specific to EC technology complicates fair comparisons with conventional cooling technologies.

Current Integration Approaches for Electrocaloric-HVAC Systems

01 Electrocaloric materials for cooling systems

Electrocaloric materials exhibit temperature changes when an electric field is applied or removed. These materials can be used in cooling systems as an alternative to conventional vapor compression refrigeration. The electrocaloric effect occurs in certain dielectric materials, particularly ferroelectric materials, which show significant temperature changes under electric field application. These materials can be engineered into thin films or bulk structures to maximize the cooling effect and efficiency in various cooling applications.- Electrocaloric materials for cooling systems: Electrocaloric materials exhibit temperature changes when an electric field is applied or removed. These materials can be used in cooling systems as an alternative to conventional vapor-compression refrigeration. Various materials such as ferroelectric polymers, ceramics, and thin films demonstrate significant electrocaloric effects that can be harnessed for efficient cooling applications. The electrocaloric effect is reversible, allowing for sustainable cooling cycles with potentially higher efficiency than traditional methods.

- Cooling system designs utilizing electrocaloric effect: Various cooling system designs leverage the electrocaloric effect for refrigeration. These systems typically include electrocaloric elements arranged in specific configurations to maximize heat transfer. Designs may incorporate regenerative cycles, cascaded systems, or active regeneration to enhance cooling efficiency. Some systems utilize fluid circulation to transfer heat between hot and cold reservoirs, while others employ solid-state heat switches or thermal diodes to control heat flow direction.

- Control methods for electrocaloric cooling systems: Effective control strategies are essential for optimizing electrocaloric cooling performance. These methods include precise timing of electric field application and removal, temperature sensing feedback loops, and adaptive control algorithms. Advanced control systems can adjust operating parameters based on cooling demand, ambient conditions, and system efficiency metrics. Some approaches incorporate predictive models to anticipate cooling needs and optimize energy consumption while maintaining desired temperature ranges.

- Integration of electrocaloric cooling in specific applications: Electrocaloric cooling technology has been integrated into various applications including electronic device cooling, automotive climate control, medical equipment, and building HVAC systems. These implementations often require specialized designs to address application-specific constraints such as size limitations, power availability, and cooling capacity requirements. Some applications combine electrocaloric cooling with other technologies to create hybrid systems that maximize efficiency and performance under varying operating conditions.

- Manufacturing methods for electrocaloric devices: Advanced manufacturing techniques are employed to produce effective electrocaloric cooling devices. These methods include thin film deposition, multilayer fabrication, additive manufacturing, and specialized electrode application processes. Manufacturing approaches focus on maximizing the electrocaloric effect while ensuring durability, reliability, and cost-effectiveness. Some techniques involve creating composite structures or engineered interfaces to enhance performance characteristics such as heat transfer rates, electrical resistance, and thermal cycling stability.

02 Cooling system designs utilizing electrocaloric effect

Various cooling system designs leverage the electrocaloric effect for refrigeration and temperature control. These systems typically include electrocaloric elements arranged in specific configurations to facilitate heat transfer, along with heat exchangers, thermal switches, and control mechanisms. Some designs incorporate regenerative cycles, cascaded stages, or fluid-based heat transfer systems to enhance cooling efficiency. Advanced system architectures may integrate multiple electrocaloric modules operating in sequence to provide continuous cooling.Expand Specific Solutions03 Heat transfer mechanisms in electrocaloric cooling

Efficient heat transfer is crucial for electrocaloric cooling systems. Various mechanisms are employed to transfer heat to and from the electrocaloric material, including direct contact with heat sinks, fluid-based heat exchange systems, and thermal switches. Some designs use working fluids that flow across the electrocaloric elements to absorb or release heat. Advanced systems may incorporate phase-change materials or specialized heat transfer interfaces to improve thermal conductivity and overall system efficiency.Expand Specific Solutions04 Control systems and operational cycles for electrocaloric devices

Sophisticated control systems are essential for optimizing the performance of electrocaloric cooling devices. These systems manage the timing and magnitude of electric field application, coordinate heat transfer processes, and regulate operational cycles. Various thermodynamic cycles can be implemented, including Brayton-like, Ericsson, and hybrid cycles, each offering different efficiency and cooling power characteristics. Advanced control algorithms may adapt to changing cooling demands or environmental conditions to maximize energy efficiency.Expand Specific Solutions05 Applications and integration of electrocaloric cooling technology

Electrocaloric cooling technology can be integrated into various applications, including electronic device cooling, automotive climate control, refrigeration, and building HVAC systems. The technology offers advantages such as compact size, reduced environmental impact, and potential for high efficiency. Some implementations focus on specific applications like cooling electronic components in confined spaces or providing temperature control in electric vehicles. Integration challenges include power supply requirements, system complexity, and ensuring reliable operation across varying conditions.Expand Specific Solutions

Key Industry Players in Electrocaloric and HVAC Sectors

The electrocaloric cooling integration with building HVAC systems is currently in an early growth phase, with the market expected to expand significantly as energy efficiency demands increase. Major HVAC industry leaders including Johnson Controls, Carrier, Honeywell, and Trane are actively developing solutions, while research institutions like Fraunhofer-Gesellschaft and Xi'an Jiaotong University are advancing the fundamental technology. The market is characterized by strategic partnerships between established HVAC manufacturers and technology innovators such as Phononic, which specializes in solid-state cooling. Technology maturity remains moderate, with commercial applications emerging but widespread implementation still developing. Companies like Siemens and Midea Group are integrating these systems into their smart building portfolios, focusing on energy optimization and sustainability compliance.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an integrated electrocaloric cooling system for building HVAC applications that utilizes solid-state cooling technology based on electrocaloric materials. Their approach incorporates advanced ceramic-based electrocaloric elements arranged in a regenerative cycle configuration to maximize cooling efficiency. The system employs proprietary heat transfer mechanisms that synchronize with building management systems through Honeywell's Forge platform, enabling dynamic response to varying thermal loads. Their solution includes intelligent control algorithms that optimize the electrocaloric cooling cycle based on real-time environmental conditions, occupancy patterns, and energy pricing. Honeywell's implementation features a modular design allowing for scalable integration with existing HVAC infrastructure, with demonstrated energy efficiency improvements of up to 35% compared to conventional vapor compression systems in commercial building applications.

Strengths: Seamless integration with existing building management systems; extensive HVAC control expertise; global service network for implementation support. Weaknesses: Higher initial capital costs compared to conventional systems; technology still in early commercial deployment phase with limited field performance data.

Carrier Corp.

Technical Solution: Carrier has developed an advanced electrocaloric cooling integration platform for commercial and residential HVAC applications. Their system utilizes proprietary electrocaloric materials with enhanced temperature change properties under applied electric fields, arranged in a regenerative cycle configuration. Carrier's implementation incorporates their i-Vu building automation system to provide comprehensive control and monitoring capabilities. The technology features a modular design that enables scalable deployment across different building sizes and types, with specialized configurations for both retrofit and new construction applications. Their control strategy employs a hierarchical approach that optimizes cooling at both the zone and system levels, with adaptive algorithms that continuously refine operation based on performance data. Carrier's solution includes intelligent load management capabilities that can prioritize cooling delivery based on occupancy and usage patterns. The system has demonstrated energy efficiency improvements of 20-30% in field trials compared to conventional vapor compression systems, with additional benefits in reduced maintenance requirements and extended system lifespan due to fewer moving parts.

Strengths: Extensive HVAC industry experience and distribution network; comprehensive product integration capabilities; established service infrastructure. Weaknesses: Technology requires specialized installation expertise; higher initial cost compared to conventional systems; performance advantages may vary significantly based on climate conditions.

Core Patents and Research in Electrocaloric Cooling Applications

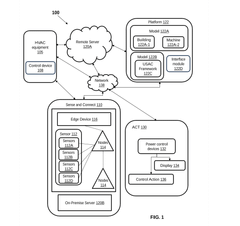

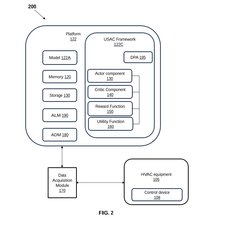

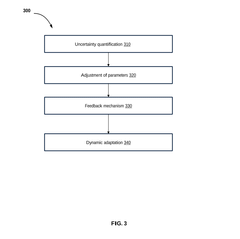

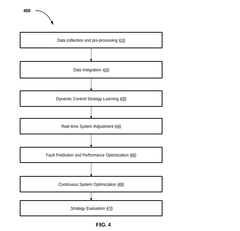

System and method for optimizing HVAC energy consumption using utility softactor-critic (USAC) framework

PatentPendingIN202441067587A

Innovation

- The implementation of a Utility Soft Actor-Critic (USAC) framework that dynamically balances exploration and exploitation based on real-time sensor data and uncertainty assessments, integrating hierarchical computing layers for unified control strategies and continuous learning.

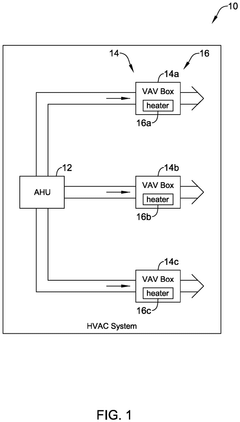

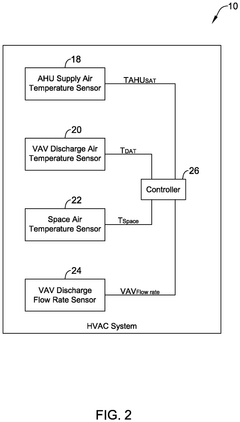

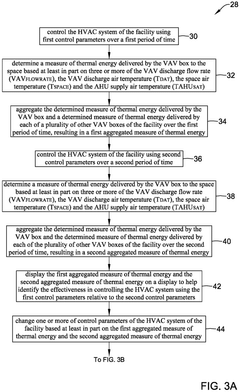

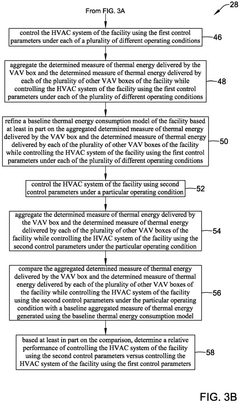

Methods and systems for controlling an HVAC system to identify energy usage under different control strategies

PatentPendingEP4513098A1

Innovation

- A method and system that calculate and aggregate the thermal energy delivered by Variable Air Volume (VAV) boxes in an HVAC system using sensors for air temperatures and flow rates, allowing for comparison of energy efficiency under different control parameters.

Energy Efficiency and Sustainability Implications

The integration of electrocaloric cooling technology with building HVAC systems presents significant opportunities for enhancing energy efficiency and sustainability in the built environment. Electrocaloric cooling systems operate with substantially higher theoretical efficiency compared to conventional vapor compression systems, potentially achieving coefficient of performance (COP) values of 5-7 under optimal conditions, versus 2-4 for traditional systems. This efficiency differential translates directly to reduced primary energy consumption, with preliminary studies indicating potential energy savings of 20-30% in moderate climates and up to 40% in regions with high cooling demands.

From a sustainability perspective, electrocaloric cooling eliminates the need for hydrofluorocarbon (HFC) refrigerants, which have global warming potentials thousands of times greater than CO2. The solid-state nature of electrocaloric materials means zero direct greenhouse gas emissions from refrigerant leakage, addressing a significant environmental concern in conventional HVAC systems where leakage rates average 10-15% annually across system lifespans.

Life cycle assessment (LCA) studies of prototype electrocaloric systems indicate reduced environmental impact across multiple categories. Carbon footprint analyses suggest a 30-45% reduction in lifecycle greenhouse gas emissions compared to conventional systems when accounting for manufacturing, operation, and end-of-life considerations. The materials used in electrocaloric devices, primarily specialized ceramics and polymers, present fewer end-of-life disposal challenges than conventional systems containing refrigerants, oils, and complex mechanical components.

Energy demand management capabilities represent another sustainability advantage. The rapid response characteristics of electrocaloric systems—capable of temperature changes within seconds rather than minutes—enable more precise load following and participation in demand response programs. This flexibility allows buildings to better integrate with variable renewable energy sources, potentially increasing renewable energy utilization by 15-25% compared to buildings with conventional HVAC systems.

Water conservation benefits also emerge as an important sustainability factor. Unlike traditional cooling towers that can consume thousands of gallons of water annually, electrocaloric systems require no water for heat rejection. In water-stressed regions, this characteristic could reduce building water consumption by 5-10%, addressing an increasingly critical sustainability concern.

The compact form factor of electrocaloric cooling units reduces material intensity and enables more efficient use of building space. Preliminary designs suggest a 30-40% reduction in physical footprint compared to conventional systems with equivalent cooling capacity, allowing for more efficient building designs or retrofits that maximize usable space while minimizing resource consumption.

From a sustainability perspective, electrocaloric cooling eliminates the need for hydrofluorocarbon (HFC) refrigerants, which have global warming potentials thousands of times greater than CO2. The solid-state nature of electrocaloric materials means zero direct greenhouse gas emissions from refrigerant leakage, addressing a significant environmental concern in conventional HVAC systems where leakage rates average 10-15% annually across system lifespans.

Life cycle assessment (LCA) studies of prototype electrocaloric systems indicate reduced environmental impact across multiple categories. Carbon footprint analyses suggest a 30-45% reduction in lifecycle greenhouse gas emissions compared to conventional systems when accounting for manufacturing, operation, and end-of-life considerations. The materials used in electrocaloric devices, primarily specialized ceramics and polymers, present fewer end-of-life disposal challenges than conventional systems containing refrigerants, oils, and complex mechanical components.

Energy demand management capabilities represent another sustainability advantage. The rapid response characteristics of electrocaloric systems—capable of temperature changes within seconds rather than minutes—enable more precise load following and participation in demand response programs. This flexibility allows buildings to better integrate with variable renewable energy sources, potentially increasing renewable energy utilization by 15-25% compared to buildings with conventional HVAC systems.

Water conservation benefits also emerge as an important sustainability factor. Unlike traditional cooling towers that can consume thousands of gallons of water annually, electrocaloric systems require no water for heat rejection. In water-stressed regions, this characteristic could reduce building water consumption by 5-10%, addressing an increasingly critical sustainability concern.

The compact form factor of electrocaloric cooling units reduces material intensity and enables more efficient use of building space. Preliminary designs suggest a 30-40% reduction in physical footprint compared to conventional systems with equivalent cooling capacity, allowing for more efficient building designs or retrofits that maximize usable space while minimizing resource consumption.

Building Code Compliance and Standardization Requirements

The integration of electrocaloric cooling systems with building HVAC must navigate a complex landscape of building codes and standardization requirements. Currently, most building codes do not specifically address electrocaloric technology, creating regulatory uncertainty for implementation. This gap necessitates careful consideration of how these innovative systems align with existing frameworks while anticipating future regulatory developments.

In the United States, compliance with ASHRAE Standard 90.1 for energy efficiency in buildings represents a primary consideration for any new HVAC technology. Electrocaloric cooling systems must demonstrate energy performance metrics comparable to or better than conventional systems to meet these requirements. Additionally, ASHRAE Standard 62.1 for ventilation and indoor air quality establishes parameters that integrated electrocaloric systems must satisfy to ensure occupant health and comfort.

The International Building Code (IBC) and International Mechanical Code (IMC) provide general requirements for mechanical systems that would apply to electrocaloric HVAC integration. These codes emphasize safety, reliability, and performance standards that novel cooling technologies must meet through appropriate testing and certification processes.

From an electrical safety perspective, compliance with the National Electrical Code (NEC) is essential, particularly regarding the power supply systems and control interfaces for electrocaloric components. The unique electrical characteristics of these systems may require specialized safety measures and circuit protection strategies to satisfy code requirements.

Refrigerant regulations present another critical compliance area. While electrocaloric cooling potentially reduces dependence on traditional refrigerants, any auxiliary refrigerants used must comply with EPA regulations under the Clean Air Act and international agreements like the Kigali Amendment to the Montreal Protocol, which mandate the phase-down of high-GWP refrigerants.

Standardization efforts specific to electrocaloric technology remain in nascent stages. Industry stakeholders should engage with standards development organizations such as ASTM International, UL, and ISO to establish testing methodologies and performance metrics tailored to electrocaloric cooling systems. This proactive approach would facilitate market acceptance and regulatory approval.

Energy efficiency certification programs like ENERGY STAR and building rating systems such as LEED represent voluntary but increasingly important compliance targets. Demonstrating how electrocaloric HVAC integration contributes to improved building energy performance under these frameworks could accelerate market adoption despite the absence of specific regulatory requirements.

Looking forward, manufacturers and developers should anticipate evolving requirements as building codes increasingly emphasize decarbonization and electrification. Establishing a technical foundation for compliance now will position electrocaloric cooling advantageously as these regulatory trends continue to develop.

In the United States, compliance with ASHRAE Standard 90.1 for energy efficiency in buildings represents a primary consideration for any new HVAC technology. Electrocaloric cooling systems must demonstrate energy performance metrics comparable to or better than conventional systems to meet these requirements. Additionally, ASHRAE Standard 62.1 for ventilation and indoor air quality establishes parameters that integrated electrocaloric systems must satisfy to ensure occupant health and comfort.

The International Building Code (IBC) and International Mechanical Code (IMC) provide general requirements for mechanical systems that would apply to electrocaloric HVAC integration. These codes emphasize safety, reliability, and performance standards that novel cooling technologies must meet through appropriate testing and certification processes.

From an electrical safety perspective, compliance with the National Electrical Code (NEC) is essential, particularly regarding the power supply systems and control interfaces for electrocaloric components. The unique electrical characteristics of these systems may require specialized safety measures and circuit protection strategies to satisfy code requirements.

Refrigerant regulations present another critical compliance area. While electrocaloric cooling potentially reduces dependence on traditional refrigerants, any auxiliary refrigerants used must comply with EPA regulations under the Clean Air Act and international agreements like the Kigali Amendment to the Montreal Protocol, which mandate the phase-down of high-GWP refrigerants.

Standardization efforts specific to electrocaloric technology remain in nascent stages. Industry stakeholders should engage with standards development organizations such as ASTM International, UL, and ISO to establish testing methodologies and performance metrics tailored to electrocaloric cooling systems. This proactive approach would facilitate market acceptance and regulatory approval.

Energy efficiency certification programs like ENERGY STAR and building rating systems such as LEED represent voluntary but increasingly important compliance targets. Demonstrating how electrocaloric HVAC integration contributes to improved building energy performance under these frameworks could accelerate market adoption despite the absence of specific regulatory requirements.

Looking forward, manufacturers and developers should anticipate evolving requirements as building codes increasingly emphasize decarbonization and electrification. Establishing a technical foundation for compliance now will position electrocaloric cooling advantageously as these regulatory trends continue to develop.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!