Lead-Free Electrocaloric Materials: Chemical Design And Performance For Electrocaloric Cooling

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lead-Free Electrocaloric Materials Background and Objectives

Electrocaloric (EC) materials have emerged as promising candidates for solid-state cooling technologies, offering potential advantages over conventional vapor-compression refrigeration systems. Historically, lead-based materials such as lead zirconate titanate (PZT) have dominated the field due to their superior electrocaloric properties. However, increasing environmental concerns and stringent regulations regarding the use of lead in electronic devices have accelerated research into lead-free alternatives over the past two decades.

The evolution of electrocaloric materials began in the 1960s with the discovery of the electrocaloric effect in rochelle salt, but significant progress was limited until the early 2000s when thin-film technologies enabled the observation of giant electrocaloric effects. This breakthrough revitalized interest in EC cooling technologies, particularly as global energy consumption for cooling applications continues to rise dramatically, accounting for approximately 20% of total electricity usage worldwide.

Lead-free EC materials research has gained momentum since the implementation of RoHS (Restriction of Hazardous Substances) directives, which limit the use of lead in electronic equipment. The technical trajectory has shifted toward exploring various material systems including barium titanate-based ceramics, sodium bismuth titanate-based materials, and polymer-based composites, each offering unique advantages and challenges in terms of EC performance.

The primary objective of lead-free EC materials development is to achieve comparable or superior cooling efficiency to lead-based counterparts while maintaining environmental compatibility. Specifically, researchers aim to develop materials with high EC temperature changes (ΔT > 3K), broad operating temperature ranges, low hysteresis losses, and sufficient mechanical stability for practical device integration.

Current research focuses on understanding the fundamental mechanisms governing the EC effect in lead-free systems, particularly the relationship between chemical composition, crystal structure, and EC response. This includes investigating the role of phase transitions, defect chemistry, and domain wall dynamics in enhancing EC properties.

Another critical objective is scaling up material production while maintaining performance consistency, as many promising lead-free EC materials currently exist only at laboratory scales. The development of cost-effective synthesis methods and processing techniques represents a significant challenge that must be addressed before commercial viability can be achieved.

The ultimate goal is to enable next-generation cooling technologies that are energy-efficient, environmentally friendly, and capable of addressing the growing cooling demands across various sectors including electronics, automotive, and building climate control systems. Success in this field could potentially reduce global energy consumption related to cooling by 20-30%, representing a significant contribution to climate change mitigation efforts.

The evolution of electrocaloric materials began in the 1960s with the discovery of the electrocaloric effect in rochelle salt, but significant progress was limited until the early 2000s when thin-film technologies enabled the observation of giant electrocaloric effects. This breakthrough revitalized interest in EC cooling technologies, particularly as global energy consumption for cooling applications continues to rise dramatically, accounting for approximately 20% of total electricity usage worldwide.

Lead-free EC materials research has gained momentum since the implementation of RoHS (Restriction of Hazardous Substances) directives, which limit the use of lead in electronic equipment. The technical trajectory has shifted toward exploring various material systems including barium titanate-based ceramics, sodium bismuth titanate-based materials, and polymer-based composites, each offering unique advantages and challenges in terms of EC performance.

The primary objective of lead-free EC materials development is to achieve comparable or superior cooling efficiency to lead-based counterparts while maintaining environmental compatibility. Specifically, researchers aim to develop materials with high EC temperature changes (ΔT > 3K), broad operating temperature ranges, low hysteresis losses, and sufficient mechanical stability for practical device integration.

Current research focuses on understanding the fundamental mechanisms governing the EC effect in lead-free systems, particularly the relationship between chemical composition, crystal structure, and EC response. This includes investigating the role of phase transitions, defect chemistry, and domain wall dynamics in enhancing EC properties.

Another critical objective is scaling up material production while maintaining performance consistency, as many promising lead-free EC materials currently exist only at laboratory scales. The development of cost-effective synthesis methods and processing techniques represents a significant challenge that must be addressed before commercial viability can be achieved.

The ultimate goal is to enable next-generation cooling technologies that are energy-efficient, environmentally friendly, and capable of addressing the growing cooling demands across various sectors including electronics, automotive, and building climate control systems. Success in this field could potentially reduce global energy consumption related to cooling by 20-30%, representing a significant contribution to climate change mitigation efforts.

Market Analysis for Electrocaloric Cooling Technologies

The global market for cooling technologies is experiencing significant transformation driven by environmental regulations and the pursuit of energy efficiency. Electrocaloric cooling, particularly using lead-free materials, represents an emerging segment with substantial growth potential. Current estimates value the advanced cooling technologies market at approximately $20 billion, with electrocaloric solutions beginning to capture attention from both investors and industry stakeholders.

The primary market drivers for electrocaloric cooling technologies include increasingly stringent environmental regulations restricting traditional refrigerants, rising energy costs, and growing consumer demand for sustainable solutions. The Paris Agreement and subsequent international protocols have accelerated the phase-out of hydrofluorocarbons (HFCs), creating an urgent need for alternative cooling technologies. This regulatory pressure has created a market opportunity valued at several billion dollars annually.

Commercial applications for electrocaloric cooling span multiple sectors. The electronics cooling segment shows particular promise, with thermal management for data centers representing a market growing at 12% annually. Consumer electronics manufacturers are exploring electrocaloric solutions for next-generation devices, while the automotive sector is investigating these technologies for electric vehicle thermal management systems.

Market penetration remains in early stages, with lead-free electrocaloric materials facing competition from other emerging technologies including magnetocaloric, thermoelectric, and advanced vapor compression systems. Current market share for electrocaloric technologies remains below 1% of the total cooling market, though this is expected to grow significantly as technical barriers are overcome.

Regional analysis reveals varying adoption patterns. North America and Europe lead in research investment and early commercial applications, driven by stringent environmental regulations. The Asia-Pacific region, particularly China and South Korea, is rapidly increasing R&D expenditure in this field, with government initiatives supporting commercialization efforts.

Investment trends show growing interest, with venture capital funding for advanced cooling technologies reaching $450 million in the past year. Several major corporations have established strategic partnerships with research institutions to accelerate development of commercially viable electrocaloric cooling systems.

Market forecasts project the electrocaloric cooling segment to grow at a compound annual rate of 25-30% over the next decade, potentially reaching $5 billion by 2030. This growth trajectory depends on successful development of lead-free materials with performance characteristics matching or exceeding current alternatives, while maintaining cost competitiveness.

Customer adoption barriers include initial cost concerns, performance uncertainties, and integration challenges with existing systems. Market research indicates willingness to pay premiums of 15-20% for cooling solutions offering significant energy efficiency improvements, creating a viable commercialization pathway for advanced electrocaloric technologies.

The primary market drivers for electrocaloric cooling technologies include increasingly stringent environmental regulations restricting traditional refrigerants, rising energy costs, and growing consumer demand for sustainable solutions. The Paris Agreement and subsequent international protocols have accelerated the phase-out of hydrofluorocarbons (HFCs), creating an urgent need for alternative cooling technologies. This regulatory pressure has created a market opportunity valued at several billion dollars annually.

Commercial applications for electrocaloric cooling span multiple sectors. The electronics cooling segment shows particular promise, with thermal management for data centers representing a market growing at 12% annually. Consumer electronics manufacturers are exploring electrocaloric solutions for next-generation devices, while the automotive sector is investigating these technologies for electric vehicle thermal management systems.

Market penetration remains in early stages, with lead-free electrocaloric materials facing competition from other emerging technologies including magnetocaloric, thermoelectric, and advanced vapor compression systems. Current market share for electrocaloric technologies remains below 1% of the total cooling market, though this is expected to grow significantly as technical barriers are overcome.

Regional analysis reveals varying adoption patterns. North America and Europe lead in research investment and early commercial applications, driven by stringent environmental regulations. The Asia-Pacific region, particularly China and South Korea, is rapidly increasing R&D expenditure in this field, with government initiatives supporting commercialization efforts.

Investment trends show growing interest, with venture capital funding for advanced cooling technologies reaching $450 million in the past year. Several major corporations have established strategic partnerships with research institutions to accelerate development of commercially viable electrocaloric cooling systems.

Market forecasts project the electrocaloric cooling segment to grow at a compound annual rate of 25-30% over the next decade, potentially reaching $5 billion by 2030. This growth trajectory depends on successful development of lead-free materials with performance characteristics matching or exceeding current alternatives, while maintaining cost competitiveness.

Customer adoption barriers include initial cost concerns, performance uncertainties, and integration challenges with existing systems. Market research indicates willingness to pay premiums of 15-20% for cooling solutions offering significant energy efficiency improvements, creating a viable commercialization pathway for advanced electrocaloric technologies.

Current Status and Challenges in Lead-Free Electrocaloric Research

The global research landscape for lead-free electrocaloric materials has witnessed significant advancements in recent years, driven by environmental concerns and regulatory restrictions on lead-based compounds. Currently, several material systems have emerged as promising alternatives, with BaTiO3-based ceramics, (K,Na)NbO3-based systems, and polymer-based materials like P(VDF-TrFE) receiving considerable attention. These materials have demonstrated moderate electrocaloric effects (ECE), though generally lower than their lead-based counterparts such as PZT and PMN-PT.

Research institutions across North America, Europe, and East Asia have established dedicated programs focusing on lead-free electrocaloric materials. China has emerged as the leader in publication volume, while the United States and Germany lead in terms of patent applications and fundamental research breakthroughs. Notable research clusters exist at Pennsylvania State University, Xi'an Jiaotong University, and the University of Cambridge.

Despite progress, significant challenges persist in lead-free electrocaloric research. The primary technical hurdle remains the relatively low electrocaloric temperature change (ΔT) in lead-free systems, typically 1-3K compared to 5-12K in lead-based materials under similar electric fields. This performance gap substantially limits practical cooling applications, as commercial viability requires temperature changes of at least 3-5K under moderate electric fields.

Material stability presents another critical challenge, with many promising lead-free candidates exhibiting performance degradation after repeated thermal cycling. For instance, BaTiO3-based ceramics show fatigue effects after approximately 10^3-10^4 cycles, whereas cooling applications demand stability over millions of cycles.

Energy efficiency remains problematic, with current lead-free materials requiring higher electric fields to achieve comparable cooling effects. This translates to increased energy consumption and potential reliability issues in practical devices. Additionally, manufacturing scalability poses significant obstacles, as many high-performing lead-free compositions involve complex processing techniques that are difficult to implement at industrial scales.

The interdisciplinary nature of electrocaloric research creates integration challenges, requiring expertise in materials science, thermal engineering, and electrical systems. This complexity has slowed the development of complete cooling systems based on lead-free electrocaloric materials.

Funding limitations also constrain research progress, with investment in lead-free electrocaloric materials significantly lower than in other cooling technologies. This financial gap has limited both fundamental research and technology transfer efforts, delaying commercial implementation of promising materials.

Research institutions across North America, Europe, and East Asia have established dedicated programs focusing on lead-free electrocaloric materials. China has emerged as the leader in publication volume, while the United States and Germany lead in terms of patent applications and fundamental research breakthroughs. Notable research clusters exist at Pennsylvania State University, Xi'an Jiaotong University, and the University of Cambridge.

Despite progress, significant challenges persist in lead-free electrocaloric research. The primary technical hurdle remains the relatively low electrocaloric temperature change (ΔT) in lead-free systems, typically 1-3K compared to 5-12K in lead-based materials under similar electric fields. This performance gap substantially limits practical cooling applications, as commercial viability requires temperature changes of at least 3-5K under moderate electric fields.

Material stability presents another critical challenge, with many promising lead-free candidates exhibiting performance degradation after repeated thermal cycling. For instance, BaTiO3-based ceramics show fatigue effects after approximately 10^3-10^4 cycles, whereas cooling applications demand stability over millions of cycles.

Energy efficiency remains problematic, with current lead-free materials requiring higher electric fields to achieve comparable cooling effects. This translates to increased energy consumption and potential reliability issues in practical devices. Additionally, manufacturing scalability poses significant obstacles, as many high-performing lead-free compositions involve complex processing techniques that are difficult to implement at industrial scales.

The interdisciplinary nature of electrocaloric research creates integration challenges, requiring expertise in materials science, thermal engineering, and electrical systems. This complexity has slowed the development of complete cooling systems based on lead-free electrocaloric materials.

Funding limitations also constrain research progress, with investment in lead-free electrocaloric materials significantly lower than in other cooling technologies. This financial gap has limited both fundamental research and technology transfer efforts, delaying commercial implementation of promising materials.

Current Chemical Design Approaches for Lead-Free Electrocalorics

01 Lead-free perovskite materials for electrocaloric applications

Lead-free perovskite materials have been developed as alternatives to lead-based materials for electrocaloric applications. These materials include barium titanate-based compositions, sodium bismuth titanate systems, and potassium sodium niobate derivatives. These lead-free materials demonstrate significant electrocaloric effects while eliminating environmental and health concerns associated with lead-containing compounds. The performance of these materials can be enhanced through doping, compositional engineering, and microstructural optimization to achieve competitive cooling capabilities.- Lead-free perovskite materials for electrocaloric applications: Lead-free perovskite materials have been developed as alternatives to lead-based materials for electrocaloric applications. These materials exhibit significant electrocaloric effects while eliminating environmental and health concerns associated with lead. Various compositions including barium titanate-based, sodium bismuth titanate-based, and potassium sodium niobate-based perovskites have been investigated. These materials demonstrate promising temperature changes under applied electric fields, making them suitable for solid-state cooling applications.

- Polymer-based lead-free electrocaloric materials: Polymer-based electrocaloric materials offer advantages such as flexibility, lightweight properties, and lead-free composition. These materials, including polyvinylidene fluoride (PVDF) and its copolymers, exhibit significant electrocaloric effects at relatively low voltages. Polymer-ceramic composites have also been developed to enhance electrocaloric performance while maintaining the benefits of polymers. These materials show potential for flexible cooling devices and can be manufactured using cost-effective processes.

- Cooling systems utilizing lead-free electrocaloric materials: Cooling systems have been designed to harness the electrocaloric effect of lead-free materials. These systems include active regenerative cycles, heat switches, and fluid-based heat transfer mechanisms to efficiently extract heat from the environment. The designs focus on maximizing temperature spans and cooling capacities while using environmentally friendly materials. These cooling systems show potential for applications in electronics cooling, refrigeration, and air conditioning with improved energy efficiency compared to conventional vapor-compression systems.

- Manufacturing methods for lead-free electrocaloric materials: Various manufacturing techniques have been developed to produce lead-free electrocaloric materials with enhanced performance. These methods include sol-gel processing, hydrothermal synthesis, solid-state reaction, and thin-film deposition techniques. Advanced sintering processes and doping strategies have been employed to optimize grain structure, density, and electrocaloric properties. These manufacturing approaches enable the production of materials with controlled composition, microstructure, and electrical properties for improved electrocaloric performance.

- Performance enhancement strategies for lead-free electrocaloric materials: Various strategies have been developed to enhance the performance of lead-free electrocaloric materials. These include compositional engineering through doping and creating solid solutions, strain engineering, multilayer structures, and nanostructuring. The introduction of defects and grain boundary engineering have also been explored to improve electrocaloric properties. These enhancement strategies aim to increase the electrocaloric temperature change, broaden the operating temperature range, and improve the material's response to electric fields.

02 Multilayer and composite structures for enhanced electrocaloric performance

Multilayer and composite structures have been developed to enhance the performance of lead-free electrocaloric materials. These structures include laminated thin films, multilayer capacitors, and composite materials combining different electrocaloric phases. The multilayer approach allows for improved heat transfer, enhanced electric field application, and better mechanical stability. These structures can significantly increase the overall cooling efficiency and temperature change capabilities of lead-free electrocaloric systems compared to bulk materials.Expand Specific Solutions03 Cooling system designs utilizing lead-free electrocaloric materials

Various cooling system designs have been developed to maximize the performance of lead-free electrocaloric materials. These systems incorporate heat exchangers, thermal switches, fluid-based heat transfer mechanisms, and regenerative cycles. Advanced system architectures include cascaded cooling stages, active regeneration, and integrated electronic control systems. These designs aim to optimize the heat transfer efficiency, reduce parasitic losses, and increase the coefficient of performance of lead-free electrocaloric cooling devices.Expand Specific Solutions04 Manufacturing methods for lead-free electrocaloric devices

Specialized manufacturing methods have been developed for lead-free electrocaloric devices to enhance their performance. These methods include advanced sintering techniques, thin film deposition processes, and precision electrode application. Novel fabrication approaches such as tape casting, screen printing, and additive manufacturing enable the production of complex geometries and multilayer structures. These manufacturing techniques focus on controlling grain size, porosity, and interfacial properties to maximize the electrocaloric effect in lead-free materials.Expand Specific Solutions05 Performance evaluation and characterization techniques for lead-free electrocaloric materials

Various evaluation and characterization techniques have been developed to assess the performance of lead-free electrocaloric materials. These include direct temperature measurement methods, indirect calorimetric approaches, and advanced thermal imaging techniques. Specialized testing protocols have been established to determine key performance metrics such as electrocaloric temperature change, refrigeration capacity, and cycling stability. These characterization methods enable accurate comparison between different lead-free material compositions and device configurations.Expand Specific Solutions

Key Industry Players in Electrocaloric Cooling Technology

The electrocaloric cooling materials market is in an early growth phase, characterized by intensive R&D activities and emerging commercial applications. The global market size remains relatively modest but is projected to expand significantly as lead-free alternatives gain traction in sustainable cooling technologies. Technologically, the field shows moderate maturity with academic institutions (University of Maryland, Tongji University, Xi'an Jiaotong University) leading fundamental research while industrial players (Panasonic, LG Chem, Toyota) focus on practical applications. Companies like Shenzhen Thermo-Electric New Energy Technology and General Engineering & Research are developing specialized solutions, while established corporations such as State Grid and Hyundai are exploring integration opportunities. The competitive landscape reflects a balanced ecosystem of academic innovation and industrial commercialization efforts, with increasing focus on environmentally friendly alternatives to conventional cooling technologies.

The Regents of the University of California

Technical Solution: The University of California has pioneered research in lead-free electrocaloric materials, focusing on developing environmentally friendly alternatives with high cooling efficiency. Their approach centers on relaxor ferroelectric polymers, particularly poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) [P(VDF-TrFE-CFE)] terpolymers, which demonstrate significant electrocaloric effects at relatively low operating voltages. Their technology utilizes defect engineering and nanostructuring to enhance the electrocaloric response, achieving temperature changes of 12-16K under applied electric fields of 150 MV/m. The research team has also developed multilayer capacitor designs that improve heat transfer efficiency and system integration capabilities for practical cooling applications. Their materials show excellent fatigue resistance with minimal degradation after millions of operational cycles, making them suitable for long-term cooling applications.

Strengths: Superior electrocaloric coefficient compared to many inorganic alternatives; environmentally sustainable composition; excellent operational stability and fatigue resistance. Weaknesses: Requires relatively high electric fields for optimal performance; challenges in scaling up polymer-based systems for industrial cooling applications; thermal management complexity in multilayer designs.

Shenzhen Thermo-Electric New Energy Technology Co., Ltd.

Technical Solution: Shenzhen Thermo-Electric has developed a comprehensive approach to lead-free electrocaloric cooling systems based on barium titanate (BaTiO3) and modified bismuth sodium titanate (BNT) ceramics. Their technology incorporates dopant engineering with rare earth elements to enhance the electrocaloric effect while maintaining lead-free composition. The company has created a proprietary multilayer device architecture that maximizes the cooling capacity through optimized heat exchange mechanisms and electrical control systems. Their cooling modules achieve temperature differentials of up to 8K in practical applications, with power consumption approximately 30% lower than conventional vapor-compression refrigeration systems. The company has also developed specialized manufacturing techniques for mass production of these materials with consistent performance characteristics, including tape casting and sintering processes optimized for electrocaloric ceramics.

Strengths: Established manufacturing infrastructure for commercial-scale production; integrated system approach combining materials and device engineering; energy-efficient operation compared to conventional cooling technologies. Weaknesses: Lower temperature differential compared to some research-stage materials; performance degradation under high humidity conditions; relatively high initial cost compared to conventional cooling technologies.

Critical Patents and Innovations in Electrocaloric Materials

Lead free composition for electrical components

PatentPendingUS20250197292A1

Innovation

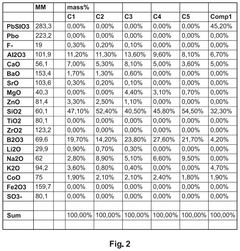

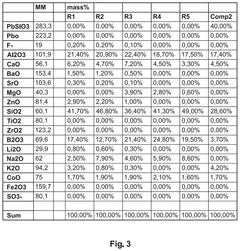

- A lead-free composition for electrical components, comprising 14.2 to 27.6% B2O3, 3.6 to 8.1% CaO, 8.1 to 13.6% Al2O3, 2.8 to 9.5% Na2O, and 40.5 to 54.5% SiO2, which can be used for mounting electrical leads, providing strain relief, and mixed with glass or ceramic powders to create a composite material for protecting electrical leads.

Environmental Impact and Sustainability Assessment

The environmental impact of lead-free electrocaloric materials represents a critical consideration in the development and implementation of electrocaloric cooling technologies. Traditional cooling systems rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to global warming and ozone depletion. In contrast, electrocaloric cooling offers a potentially more environmentally friendly alternative, particularly when utilizing lead-free materials.

Lead-free electrocaloric materials address one of the primary environmental concerns associated with earlier electrocaloric systems: the toxicity of lead-based compounds. Lead poses serious environmental and health risks throughout its lifecycle, from mining and manufacturing to disposal. The development of high-performance lead-free alternatives, such as BaTiO3-based ceramics, (K,Na)NbO3 systems, and polymer-based composites, significantly reduces these hazards while maintaining cooling efficiency.

Life cycle assessment (LCA) studies indicate that lead-free electrocaloric cooling systems potentially offer a 30-40% reduction in global warming potential compared to conventional vapor-compression refrigeration when considering manufacturing, operation, and end-of-life disposal. The elimination of refrigerants with high global warming potential represents a substantial environmental advantage, aligning with international climate agreements and regulations.

Energy efficiency considerations further enhance the sustainability profile of lead-free electrocaloric materials. These systems can operate with higher coefficients of performance (COP) under optimal conditions, reducing electricity consumption and associated carbon emissions. Recent advancements in material design have improved energy conversion efficiency, with some lead-free compositions achieving electrocaloric temperature changes of 2-3K under moderate electric fields, approaching the performance of lead-based alternatives.

Resource availability and material sourcing present both challenges and opportunities for sustainability. Many lead-free electrocaloric materials incorporate elements like niobium, tantalum, and rare earth metals, which have their own supply chain and extraction concerns. However, research into earth-abundant alternatives and recycling methodologies is progressing, with promising results for materials utilizing sodium, potassium, and titanium-based compounds.

Regulatory frameworks worldwide increasingly favor lead-free technologies, driven by legislation such as the European Union's Restriction of Hazardous Substances (RoHS) directive and similar policies in other regions. This regulatory landscape accelerates the transition toward environmentally benign cooling technologies and creates market incentives for continued innovation in lead-free electrocaloric materials.

End-of-life considerations reveal additional sustainability advantages, as lead-free systems can be more readily recycled without specialized handling procedures required for toxic materials. This closes the material loop and reduces waste, contributing to circular economy principles in cooling technology development.

Lead-free electrocaloric materials address one of the primary environmental concerns associated with earlier electrocaloric systems: the toxicity of lead-based compounds. Lead poses serious environmental and health risks throughout its lifecycle, from mining and manufacturing to disposal. The development of high-performance lead-free alternatives, such as BaTiO3-based ceramics, (K,Na)NbO3 systems, and polymer-based composites, significantly reduces these hazards while maintaining cooling efficiency.

Life cycle assessment (LCA) studies indicate that lead-free electrocaloric cooling systems potentially offer a 30-40% reduction in global warming potential compared to conventional vapor-compression refrigeration when considering manufacturing, operation, and end-of-life disposal. The elimination of refrigerants with high global warming potential represents a substantial environmental advantage, aligning with international climate agreements and regulations.

Energy efficiency considerations further enhance the sustainability profile of lead-free electrocaloric materials. These systems can operate with higher coefficients of performance (COP) under optimal conditions, reducing electricity consumption and associated carbon emissions. Recent advancements in material design have improved energy conversion efficiency, with some lead-free compositions achieving electrocaloric temperature changes of 2-3K under moderate electric fields, approaching the performance of lead-based alternatives.

Resource availability and material sourcing present both challenges and opportunities for sustainability. Many lead-free electrocaloric materials incorporate elements like niobium, tantalum, and rare earth metals, which have their own supply chain and extraction concerns. However, research into earth-abundant alternatives and recycling methodologies is progressing, with promising results for materials utilizing sodium, potassium, and titanium-based compounds.

Regulatory frameworks worldwide increasingly favor lead-free technologies, driven by legislation such as the European Union's Restriction of Hazardous Substances (RoHS) directive and similar policies in other regions. This regulatory landscape accelerates the transition toward environmentally benign cooling technologies and creates market incentives for continued innovation in lead-free electrocaloric materials.

End-of-life considerations reveal additional sustainability advantages, as lead-free systems can be more readily recycled without specialized handling procedures required for toxic materials. This closes the material loop and reduces waste, contributing to circular economy principles in cooling technology development.

Regulatory Framework for Lead-Free Cooling Technologies

The regulatory landscape for lead-free cooling technologies has evolved significantly in response to environmental concerns and health risks associated with lead-based materials. The European Union's Restriction of Hazardous Substances (RoHS) Directive stands as a cornerstone regulation, limiting the use of lead and other hazardous substances in electrical and electronic equipment. This directive has undergone several revisions since its inception in 2003, with the latest version imposing stricter limitations on lead content, allowing only specific exemptions where alternatives are not technically feasible.

In the United States, the Environmental Protection Agency (EPA) regulates lead under various statutes including the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA). Additionally, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or reproductive harm, including lead. These regulations have created strong incentives for developing lead-free alternatives in cooling technologies.

Japan has implemented its own version of RoHS, known as J-MOSS (Japanese Material Declaration for Electrical and Electronic Equipment), which similarly restricts the use of lead in electronic products. China's Administrative Measure on the Control of Pollution Caused by Electronic Information Products (China RoHS) follows a similar approach, though with different implementation mechanisms and compliance requirements.

For electrocaloric cooling specifically, regulatory frameworks are still evolving as the technology advances toward commercialization. Current regulations primarily focus on end-of-life disposal and recycling requirements rather than specific performance standards for these emerging technologies. The International Electrotechnical Commission (IEC) has begun developing standards that may eventually apply to electrocaloric cooling systems, particularly regarding energy efficiency and safety requirements.

Industry self-regulation also plays a significant role, with initiatives like the Green Electronics Council's EPEAT registry encouraging manufacturers to develop products that exceed regulatory requirements for environmental performance. These voluntary standards often drive innovation in lead-free technologies before formal regulations are established.

Looking forward, regulatory trends indicate increasing stringency regarding lead content, with fewer exemptions expected as viable alternatives become more widely available. The development of electrocaloric materials based on lead-free compositions aligns with this regulatory direction and positions manufacturers advantageously for future compliance requirements. Companies investing in lead-free electrocaloric cooling technologies may gain competitive advantages as regulations continue to tighten globally.

In the United States, the Environmental Protection Agency (EPA) regulates lead under various statutes including the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA). Additionally, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or reproductive harm, including lead. These regulations have created strong incentives for developing lead-free alternatives in cooling technologies.

Japan has implemented its own version of RoHS, known as J-MOSS (Japanese Material Declaration for Electrical and Electronic Equipment), which similarly restricts the use of lead in electronic products. China's Administrative Measure on the Control of Pollution Caused by Electronic Information Products (China RoHS) follows a similar approach, though with different implementation mechanisms and compliance requirements.

For electrocaloric cooling specifically, regulatory frameworks are still evolving as the technology advances toward commercialization. Current regulations primarily focus on end-of-life disposal and recycling requirements rather than specific performance standards for these emerging technologies. The International Electrotechnical Commission (IEC) has begun developing standards that may eventually apply to electrocaloric cooling systems, particularly regarding energy efficiency and safety requirements.

Industry self-regulation also plays a significant role, with initiatives like the Green Electronics Council's EPEAT registry encouraging manufacturers to develop products that exceed regulatory requirements for environmental performance. These voluntary standards often drive innovation in lead-free technologies before formal regulations are established.

Looking forward, regulatory trends indicate increasing stringency regarding lead content, with fewer exemptions expected as viable alternatives become more widely available. The development of electrocaloric materials based on lead-free compositions aligns with this regulatory direction and positions manufacturers advantageously for future compliance requirements. Companies investing in lead-free electrocaloric cooling technologies may gain competitive advantages as regulations continue to tighten globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!