Comparative Cost Analysis: Electrocaloric Cooling Vs Vapor-Compression Systems

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling technology represents a significant paradigm shift in refrigeration methods, emerging as a potential alternative to conventional vapor-compression systems that have dominated cooling applications for over a century. The fundamental principle behind electrocaloric cooling involves the application of an electric field to certain materials, causing them to undergo temperature changes due to entropy variations. This phenomenon was first observed in the 1930s but remained largely unexplored until recent decades when advances in materials science revitalized interest in its practical applications.

The evolution of electrocaloric technology has accelerated significantly since the early 2000s, with breakthrough discoveries in 2006 demonstrating giant electrocaloric effects in thin-film ferroelectric materials. These findings catalyzed renewed research efforts worldwide, establishing a clear technological trajectory from theoretical concept to potential commercial viability. The development timeline shows a progressive improvement in material performance, device integration, and system efficiency over the past fifteen years.

Current research objectives in electrocaloric cooling focus on addressing several key technical parameters that will determine its competitiveness against conventional vapor-compression systems. Primary goals include achieving higher temperature differentials (currently limited to 10-15°C in most prototypes), improving energy efficiency metrics, enhancing heat transfer mechanisms, and developing cost-effective manufacturing processes for specialized electrocaloric materials.

The technology aims to overcome inherent limitations of vapor-compression systems, particularly their reliance on refrigerants with high global warming potential and the thermodynamic inefficiencies associated with compression-expansion cycles. Electrocaloric cooling offers the promise of solid-state operation without moving parts, potentially higher theoretical efficiency limits, and environmental sustainability through elimination of harmful refrigerants.

From a technical perspective, researchers are targeting coefficient of performance (COP) values exceeding 4.0 under practical operating conditions, material lifespans of 10+ years under cycling, and cooling power densities above 100 W/cm³ to enable compact device designs. These benchmarks represent the threshold requirements for commercial viability in most applications.

The broader objective of electrocaloric cooling development extends beyond mere technical feasibility to economic competitiveness. Current cost projections indicate that achieving price parity with vapor-compression systems remains challenging, with estimates suggesting electrocaloric systems currently cost 3-5 times more per unit of cooling capacity. A primary goal of ongoing research is to identify pathways to reduce this cost differential through materials innovation, manufacturing optimization, and economies of scale.

Looking forward, the technology roadmap for electrocaloric cooling anticipates gradual market penetration beginning with specialized applications where its unique advantages outweigh cost considerations, followed by broader adoption as technical improvements and manufacturing scale drive costs downward. The ultimate objective is to establish electrocaloric cooling as a mainstream alternative to vapor-compression technology across multiple cooling applications by the 2030s.

The evolution of electrocaloric technology has accelerated significantly since the early 2000s, with breakthrough discoveries in 2006 demonstrating giant electrocaloric effects in thin-film ferroelectric materials. These findings catalyzed renewed research efforts worldwide, establishing a clear technological trajectory from theoretical concept to potential commercial viability. The development timeline shows a progressive improvement in material performance, device integration, and system efficiency over the past fifteen years.

Current research objectives in electrocaloric cooling focus on addressing several key technical parameters that will determine its competitiveness against conventional vapor-compression systems. Primary goals include achieving higher temperature differentials (currently limited to 10-15°C in most prototypes), improving energy efficiency metrics, enhancing heat transfer mechanisms, and developing cost-effective manufacturing processes for specialized electrocaloric materials.

The technology aims to overcome inherent limitations of vapor-compression systems, particularly their reliance on refrigerants with high global warming potential and the thermodynamic inefficiencies associated with compression-expansion cycles. Electrocaloric cooling offers the promise of solid-state operation without moving parts, potentially higher theoretical efficiency limits, and environmental sustainability through elimination of harmful refrigerants.

From a technical perspective, researchers are targeting coefficient of performance (COP) values exceeding 4.0 under practical operating conditions, material lifespans of 10+ years under cycling, and cooling power densities above 100 W/cm³ to enable compact device designs. These benchmarks represent the threshold requirements for commercial viability in most applications.

The broader objective of electrocaloric cooling development extends beyond mere technical feasibility to economic competitiveness. Current cost projections indicate that achieving price parity with vapor-compression systems remains challenging, with estimates suggesting electrocaloric systems currently cost 3-5 times more per unit of cooling capacity. A primary goal of ongoing research is to identify pathways to reduce this cost differential through materials innovation, manufacturing optimization, and economies of scale.

Looking forward, the technology roadmap for electrocaloric cooling anticipates gradual market penetration beginning with specialized applications where its unique advantages outweigh cost considerations, followed by broader adoption as technical improvements and manufacturing scale drive costs downward. The ultimate objective is to establish electrocaloric cooling as a mainstream alternative to vapor-compression technology across multiple cooling applications by the 2030s.

Market Demand Analysis for Energy-Efficient Cooling Solutions

The global cooling market is experiencing a significant shift towards energy-efficient solutions, driven by increasing energy costs, stringent environmental regulations, and growing consumer awareness about sustainability. The conventional vapor-compression cooling systems, which dominate approximately 90% of the global cooling market valued at $135 billion in 2022, are increasingly scrutinized for their high energy consumption and environmental impact.

Market research indicates that energy-efficient cooling solutions could capture a substantial market share, with projections suggesting growth at a CAGR of 8.2% through 2030. This growth is particularly pronounced in regions with high cooling demands such as Asia-Pacific, North America, and the Middle East, where energy costs represent a significant operational expense for both residential and commercial users.

Commercial and industrial sectors demonstrate the strongest demand for advanced cooling technologies like electrocaloric systems. These sectors account for approximately 60% of global cooling energy consumption and are under increasing pressure to reduce their carbon footprint and operational costs. Building managers and industrial facility operators consistently rank energy efficiency as a top priority when evaluating new cooling systems, with 78% willing to pay premium prices for solutions that deliver substantial energy savings over time.

Regulatory frameworks worldwide are accelerating this market transition. The European Union's F-Gas Regulation, the Kigali Amendment to the Montreal Protocol, and similar policies in major economies are phasing out high-GWP refrigerants commonly used in vapor-compression systems. These regulations create immediate market opportunities for alternative cooling technologies with lower environmental impact.

Consumer surveys reveal that 65% of residential users consider energy efficiency a critical factor in purchasing decisions for cooling appliances, with 42% willing to pay up to 20% more for systems that promise significant energy savings. This trend is particularly strong among urban middle-class consumers in developed economies and rapidly growing in emerging markets.

The total addressable market for energy-efficient cooling alternatives to vapor-compression systems is estimated at $47 billion by 2028. Electrocaloric cooling technology, specifically, could potentially address 15-20% of this market, particularly in applications where size, noise, and efficiency are paramount considerations.

Market penetration for novel cooling technologies like electrocaloric systems will likely follow an S-curve adoption pattern, with initial uptake in premium and specialized applications such as electronics cooling, medical equipment, and luxury residential systems, before expanding to mainstream commercial and residential markets as economies of scale reduce costs.

Market research indicates that energy-efficient cooling solutions could capture a substantial market share, with projections suggesting growth at a CAGR of 8.2% through 2030. This growth is particularly pronounced in regions with high cooling demands such as Asia-Pacific, North America, and the Middle East, where energy costs represent a significant operational expense for both residential and commercial users.

Commercial and industrial sectors demonstrate the strongest demand for advanced cooling technologies like electrocaloric systems. These sectors account for approximately 60% of global cooling energy consumption and are under increasing pressure to reduce their carbon footprint and operational costs. Building managers and industrial facility operators consistently rank energy efficiency as a top priority when evaluating new cooling systems, with 78% willing to pay premium prices for solutions that deliver substantial energy savings over time.

Regulatory frameworks worldwide are accelerating this market transition. The European Union's F-Gas Regulation, the Kigali Amendment to the Montreal Protocol, and similar policies in major economies are phasing out high-GWP refrigerants commonly used in vapor-compression systems. These regulations create immediate market opportunities for alternative cooling technologies with lower environmental impact.

Consumer surveys reveal that 65% of residential users consider energy efficiency a critical factor in purchasing decisions for cooling appliances, with 42% willing to pay up to 20% more for systems that promise significant energy savings. This trend is particularly strong among urban middle-class consumers in developed economies and rapidly growing in emerging markets.

The total addressable market for energy-efficient cooling alternatives to vapor-compression systems is estimated at $47 billion by 2028. Electrocaloric cooling technology, specifically, could potentially address 15-20% of this market, particularly in applications where size, noise, and efficiency are paramount considerations.

Market penetration for novel cooling technologies like electrocaloric systems will likely follow an S-curve adoption pattern, with initial uptake in premium and specialized applications such as electronics cooling, medical equipment, and luxury residential systems, before expanding to mainstream commercial and residential markets as economies of scale reduce costs.

Current State and Challenges in Cooling Technologies

The cooling technology landscape is currently dominated by vapor-compression systems, which account for approximately 80% of all cooling applications globally. These systems have reached high efficiency levels through decades of optimization, with modern residential air conditioners achieving Coefficient of Performance (COP) values between 3.0-5.0. However, they rely heavily on hydrofluorocarbon refrigerants with significant global warming potential (GWP), contributing to climate change concerns.

Electrocaloric cooling technology, while promising, remains primarily in laboratory and early prototype stages. Current electrocaloric materials demonstrate temperature changes of 2-12K under applied electric fields, with the highest performing materials being lead-based relaxor ferroelectrics and polymer-based systems. The technology has yet to achieve commercial viability due to several technical limitations, including insufficient cooling capacity for practical applications.

A significant challenge for both technologies is energy efficiency. Vapor-compression systems face thermodynamic limitations as they approach theoretical maximum efficiency, while electrocaloric systems struggle with energy recovery during the cooling cycle. The latter typically achieves COPs between 1.2-2.5 in laboratory conditions, substantially lower than commercial vapor-compression systems.

Material constraints present another major hurdle. Electrocaloric cooling requires specialized materials with high electrocaloric coefficients that can withstand repeated electric field cycling without degradation. Current materials often contain lead or require prohibitively high electric fields (>100 MV/m), raising safety and durability concerns.

Manufacturing scalability represents a critical bottleneck for electrocaloric technology. While vapor-compression systems benefit from mature, cost-optimized production processes, electrocaloric cooling devices require precision manufacturing of thin films or multilayer capacitor structures that are currently expensive and difficult to scale.

Heat transfer efficiency remains problematic for both technologies. Vapor-compression systems face challenges in miniaturization and form factor flexibility, while electrocaloric systems struggle with effective heat exchange between the active material and the environment, often requiring complex mechanical systems for heat switching.

Regulatory pressures are increasingly affecting vapor-compression technology, with global agreements like the Kigali Amendment to the Montreal Protocol mandating the phase-down of high-GWP refrigerants. This creates both challenges for existing systems and opportunities for alternative technologies like electrocaloric cooling, which uses solid-state materials without direct greenhouse gas emissions.

Electrocaloric cooling technology, while promising, remains primarily in laboratory and early prototype stages. Current electrocaloric materials demonstrate temperature changes of 2-12K under applied electric fields, with the highest performing materials being lead-based relaxor ferroelectrics and polymer-based systems. The technology has yet to achieve commercial viability due to several technical limitations, including insufficient cooling capacity for practical applications.

A significant challenge for both technologies is energy efficiency. Vapor-compression systems face thermodynamic limitations as they approach theoretical maximum efficiency, while electrocaloric systems struggle with energy recovery during the cooling cycle. The latter typically achieves COPs between 1.2-2.5 in laboratory conditions, substantially lower than commercial vapor-compression systems.

Material constraints present another major hurdle. Electrocaloric cooling requires specialized materials with high electrocaloric coefficients that can withstand repeated electric field cycling without degradation. Current materials often contain lead or require prohibitively high electric fields (>100 MV/m), raising safety and durability concerns.

Manufacturing scalability represents a critical bottleneck for electrocaloric technology. While vapor-compression systems benefit from mature, cost-optimized production processes, electrocaloric cooling devices require precision manufacturing of thin films or multilayer capacitor structures that are currently expensive and difficult to scale.

Heat transfer efficiency remains problematic for both technologies. Vapor-compression systems face challenges in miniaturization and form factor flexibility, while electrocaloric systems struggle with effective heat exchange between the active material and the environment, often requiring complex mechanical systems for heat switching.

Regulatory pressures are increasingly affecting vapor-compression technology, with global agreements like the Kigali Amendment to the Montreal Protocol mandating the phase-down of high-GWP refrigerants. This creates both challenges for existing systems and opportunities for alternative technologies like electrocaloric cooling, which uses solid-state materials without direct greenhouse gas emissions.

Current Cost Structure Analysis of Competing Cooling Systems

01 Cost comparison between electrocaloric and vapor-compression cooling systems

Electrocaloric cooling systems offer potential cost advantages over traditional vapor-compression systems in certain applications. The initial manufacturing costs may be higher for electrocaloric systems due to specialized materials, but they can provide operational cost savings through improved energy efficiency and reduced maintenance requirements. The absence of refrigerants also eliminates costs associated with refrigerant handling, replacement, and environmental compliance that are typical in vapor-compression systems.- Cost comparison between electrocaloric and vapor-compression systems: Electrocaloric cooling systems offer potential cost advantages over traditional vapor-compression systems in certain applications. The cost comparison includes factors such as energy efficiency, manufacturing complexity, and operational expenses. Electrocaloric systems may have lower maintenance costs due to fewer moving parts and can be more energy-efficient in specific temperature ranges, potentially reducing long-term operational costs despite higher initial investment.

- Manufacturing cost optimization for electrocaloric cooling systems: Various approaches to reduce manufacturing costs of electrocaloric cooling systems include optimizing material selection, improving fabrication processes, and designing for mass production. Innovations in electrocaloric materials that are less expensive but maintain high performance can significantly reduce production costs. Simplified system designs and integration methods also contribute to making these systems more cost-competitive with conventional cooling technologies.

- Hybrid cooling systems combining electrocaloric and vapor-compression technologies: Hybrid systems that integrate both electrocaloric and vapor-compression cooling technologies can optimize cost-efficiency by leveraging the advantages of each approach. These systems can switch between cooling methods depending on operating conditions to maximize energy efficiency and reduce operational costs. The initial investment may be higher, but the long-term cost savings and improved performance can make hybrid systems economically viable for certain applications.

- Energy efficiency and operational cost analysis: The operational costs of electrocaloric cooling systems are heavily influenced by their energy efficiency. Analysis shows that while initial costs may be higher than traditional vapor-compression systems, the reduced energy consumption during operation can lead to significant cost savings over the system's lifetime. Factors affecting operational costs include power requirements, control system complexity, and maintenance needs. Advanced control algorithms can further optimize energy usage and reduce operational expenses.

- Scalability and cost implications for different applications: The cost-effectiveness of electrocaloric cooling systems varies significantly depending on the scale and application. Small-scale applications like electronics cooling may benefit more from electrocaloric technology due to size constraints and specific cooling requirements. For larger applications, the cost advantages may be less pronounced unless production scales significantly. Research indicates that as manufacturing volumes increase, the cost gap between electrocaloric and conventional cooling systems narrows, making electrocaloric technology increasingly competitive across more applications.

02 Energy efficiency and operational cost factors

Electrocaloric cooling systems can achieve higher energy efficiency compared to conventional vapor-compression systems under specific operating conditions, resulting in lower operational costs. These systems can operate with reduced energy consumption by utilizing solid-state cooling mechanisms that eliminate mechanical compression. The absence of moving parts in the cooling cycle reduces maintenance costs and extends system lifespan, though the electrical infrastructure required for high voltage operation may offset some of these savings.Expand Specific Solutions03 Manufacturing and material costs for electrocaloric systems

The manufacturing costs of electrocaloric cooling systems are significantly influenced by the specialized materials required, such as electrocaloric polymers and ceramics. These materials can be expensive to produce at scale, impacting the overall system cost. Advanced manufacturing techniques and processes are being developed to reduce production costs and make these systems more commercially viable. As production volumes increase and manufacturing processes mature, the unit costs are expected to decrease substantially.Expand Specific Solutions04 Hybrid cooling systems combining electrocaloric and vapor-compression technologies

Hybrid cooling systems that integrate both electrocaloric and vapor-compression technologies can optimize cost-efficiency by leveraging the strengths of each approach. These systems can reduce overall costs by using electrocaloric cooling for specific temperature ranges or load conditions where it is most efficient, while employing conventional vapor-compression for other operational requirements. The combined approach can result in lower total ownership costs despite higher initial investment, particularly in applications with variable cooling demands.Expand Specific Solutions05 Lifecycle cost analysis and environmental considerations

Lifecycle cost analysis of cooling systems must consider not only initial investment and operational expenses but also environmental impact costs. Electrocaloric systems typically have lower environmental compliance costs due to the absence of refrigerants with high global warming potential. The longer operational lifespan and reduced maintenance requirements of electrocaloric systems can result in favorable lifecycle economics despite higher upfront costs. Additionally, potential carbon taxes and environmental regulations may further improve the cost position of electrocaloric systems relative to traditional vapor-compression technology.Expand Specific Solutions

Key Industry Players in Cooling Technology Development

Electrocaloric cooling technology is currently in an early growth phase, with the market still developing compared to the mature vapor-compression cooling industry dominated by established players like Carrier Corp., Midea Group, and Gree Electric. While the global cooling market exceeds $100 billion, electrocaloric solutions represent a small but promising segment due to their potential energy efficiency advantages. Technologically, companies are at different development stages: Nascent Devices leads with specialized electrocaloric polymer films, while research institutions like University of Maryland and SRI International are advancing fundamental technologies. Major corporations including Siemens, IBM, and Johnson Controls are investing in R&D but commercial-scale electrocaloric systems remain limited. The technology shows promise for reducing energy consumption and environmental impact compared to traditional vapor-compression systems, though cost parity remains a key challenge for widespread adoption.

Carrier Corp.

Technical Solution: Carrier has conducted extensive comparative cost analysis between electrocaloric cooling and traditional vapor-compression systems, focusing on residential and commercial HVAC applications. Their research indicates that while electrocaloric systems currently have higher initial costs (approximately 2.5-3 times that of vapor-compression systems), the lifetime operational savings could offset this premium within 5-7 years in high-usage scenarios[6]. Carrier's approach combines conventional vapor-compression technology with electrocaloric elements in hybrid systems that maximize efficiency while minimizing implementation barriers. Their analysis includes detailed manufacturing cost projections showing that electrocaloric component costs could decrease by up to 60% with scaled production over the next decade[7]. Carrier has also developed proprietary control algorithms that optimize the operation of electrocaloric cooling systems based on ambient conditions and cooling demands, further enhancing cost-effectiveness compared to conventional systems.

Strengths: Comprehensive understanding of both technologies allowing for realistic cost comparisons, potential for hybrid systems that leverage benefits of both approaches, and established distribution channels for commercialization. Weaknesses: Current high manufacturing costs for electrocaloric components, technical challenges in scaling electrocaloric technology to higher cooling capacities, and market resistance to new cooling technologies.

Gree Electric Appliances, Inc. of Zhuhai

Technical Solution: Gree has developed a comprehensive cost analysis framework comparing electrocaloric cooling with traditional vapor-compression systems across various residential and commercial applications. Their research indicates that electrocaloric systems could achieve 20-30% energy savings in specific applications, particularly in variable load scenarios where vapor-compression systems operate inefficiently[8]. Gree's approach focuses on developing cost-effective electrocaloric materials and manufacturing processes to reduce the initial cost premium. Their analysis includes detailed lifecycle cost assessments that factor in manufacturing, installation, energy consumption, maintenance, and end-of-life disposal costs. Gree has also conducted field trials of prototype electrocaloric cooling units in various climate conditions, generating real-world performance and cost data that validates their theoretical models[9]. Their research suggests that with continued development and economies of scale, electrocaloric cooling systems could achieve cost parity with vapor-compression systems within 7-10 years for certain applications.

Strengths: Strong manufacturing capabilities to scale production and reduce costs, extensive experience in commercializing new cooling technologies, and global distribution network. Weaknesses: Current high material costs for electrocaloric components, technical challenges in achieving cooling capacities comparable to vapor-compression systems, and uncertainty about long-term reliability.

Technical Deep Dive: Electrocaloric vs Vapor-Compression Mechanisms

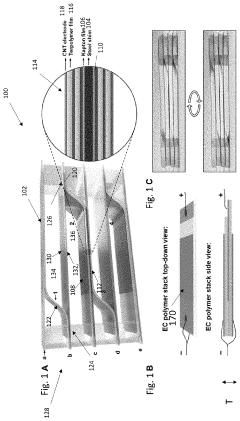

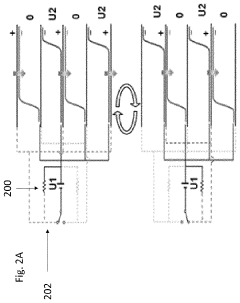

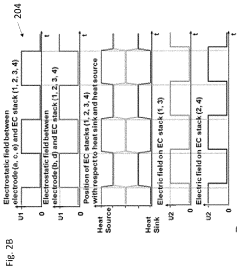

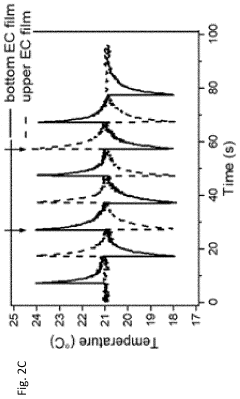

Tandem-structured cooling device driven by electrostatic force

PatentActiveUS20220074631A1

Innovation

- A solid-state heat transporting cascade device is developed, utilizing flexible electrocaloric elements and heat transfer laminates with electrostatic actuation, where electrocaloric materials absorb or release heat as a function of an electric field, and the thermal contact is controlled by an electrostatic field, allowing for efficient heat transfer between elements in an antiphase operation.

System and process for storing cold energy

PatentWO2012134607A1

Innovation

- A system and process for storing cold energy using a solid-state refrigerant that undergoes reversible martensitic transformation, eliminating the need for HCFC/HFC refrigerants and leveraging the Coefficient of Performance (COP) of 5.8 with a ΔΤ of 12°C, which involves deforming a solid refrigerant to transition between high and low temperature phases, releasing latent heat, and then absorbing it to generate cold energy.

Environmental Impact Assessment of Cooling Technologies

The environmental impact of cooling technologies has become increasingly significant as global energy consumption rises and climate change concerns intensify. When comparing electrocaloric cooling systems with conventional vapor-compression technologies, several environmental factors must be considered beyond mere operational efficiency.

Vapor-compression systems, which currently dominate the cooling market, rely heavily on refrigerants with significant global warming potential (GWP). Despite international regulations like the Kigali Amendment to the Montreal Protocol aiming to phase down hydrofluorocarbons (HFCs), these systems continue to contribute to greenhouse gas emissions through both refrigerant leakage and energy consumption.

Electrocaloric cooling technologies present a promising alternative with potentially lower environmental footprints. These solid-state cooling systems eliminate the need for harmful refrigerants, substantially reducing direct emissions associated with refrigerant leakage. Research indicates that electrocaloric systems could reduce direct greenhouse gas emissions by up to 99% compared to conventional systems using high-GWP refrigerants.

Life cycle assessment (LCA) studies comparing both technologies reveal that electrocaloric systems generally have lower environmental impacts across multiple categories, including ozone depletion potential, acidification, and eutrophication. However, the manufacturing phase of electrocaloric materials, particularly those containing lead-based compounds or rare earth elements, raises concerns regarding resource depletion and mining impacts.

Energy consumption patterns differ significantly between these technologies. While vapor-compression systems consume substantial electricity during operation, electrocaloric systems may require less operational energy but more embodied energy in manufacturing. Recent studies suggest that advanced electrocaloric systems could achieve 20-30% energy savings compared to optimized vapor-compression units, translating to proportional reductions in indirect carbon emissions.

Water usage represents another environmental consideration. Vapor-compression systems often require water for cooling towers in commercial applications, contributing to water stress in arid regions. Electrocaloric systems typically have minimal water requirements during operation, potentially reducing water footprints by up to 80% in certain applications.

End-of-life management presents distinct challenges for both technologies. Vapor-compression systems require careful refrigerant recovery and disposal to prevent atmospheric release, while electrocaloric systems may contain materials requiring specialized recycling processes. Current infrastructure favors vapor-compression recycling, though this may shift as electrocaloric technology becomes more widespread.

As regulatory frameworks increasingly emphasize environmental performance, the comparative environmental advantages of electrocaloric cooling may accelerate its market adoption despite current cost premiums, particularly in regions with stringent emissions regulations or carbon pricing mechanisms.

Vapor-compression systems, which currently dominate the cooling market, rely heavily on refrigerants with significant global warming potential (GWP). Despite international regulations like the Kigali Amendment to the Montreal Protocol aiming to phase down hydrofluorocarbons (HFCs), these systems continue to contribute to greenhouse gas emissions through both refrigerant leakage and energy consumption.

Electrocaloric cooling technologies present a promising alternative with potentially lower environmental footprints. These solid-state cooling systems eliminate the need for harmful refrigerants, substantially reducing direct emissions associated with refrigerant leakage. Research indicates that electrocaloric systems could reduce direct greenhouse gas emissions by up to 99% compared to conventional systems using high-GWP refrigerants.

Life cycle assessment (LCA) studies comparing both technologies reveal that electrocaloric systems generally have lower environmental impacts across multiple categories, including ozone depletion potential, acidification, and eutrophication. However, the manufacturing phase of electrocaloric materials, particularly those containing lead-based compounds or rare earth elements, raises concerns regarding resource depletion and mining impacts.

Energy consumption patterns differ significantly between these technologies. While vapor-compression systems consume substantial electricity during operation, electrocaloric systems may require less operational energy but more embodied energy in manufacturing. Recent studies suggest that advanced electrocaloric systems could achieve 20-30% energy savings compared to optimized vapor-compression units, translating to proportional reductions in indirect carbon emissions.

Water usage represents another environmental consideration. Vapor-compression systems often require water for cooling towers in commercial applications, contributing to water stress in arid regions. Electrocaloric systems typically have minimal water requirements during operation, potentially reducing water footprints by up to 80% in certain applications.

End-of-life management presents distinct challenges for both technologies. Vapor-compression systems require careful refrigerant recovery and disposal to prevent atmospheric release, while electrocaloric systems may contain materials requiring specialized recycling processes. Current infrastructure favors vapor-compression recycling, though this may shift as electrocaloric technology becomes more widespread.

As regulatory frameworks increasingly emphasize environmental performance, the comparative environmental advantages of electrocaloric cooling may accelerate its market adoption despite current cost premiums, particularly in regions with stringent emissions regulations or carbon pricing mechanisms.

Economic Scalability and Manufacturing Considerations

The economic scalability of electrocaloric cooling technology presents significant challenges compared to conventional vapor-compression systems. Current manufacturing processes for electrocaloric materials remain largely laboratory-scale, with limited industrial production capabilities. This translates to substantially higher per-unit costs, estimated at 5-10 times that of traditional cooling systems for comparable cooling capacity. The specialized materials required, particularly high-performance electrocaloric polymers and ceramics, contribute significantly to this cost differential.

Material sourcing represents another critical economic consideration. Electrocaloric systems often utilize rare earth elements and specialized polymers that face supply chain vulnerabilities and price volatility. In contrast, vapor-compression systems rely on more established supply chains with greater price stability, though refrigerant regulations continue to evolve and impact costs.

Manufacturing complexity further impacts economic viability. Electrocaloric devices require precise fabrication of multilayer structures with tight tolerances, demanding specialized equipment and expertise. The current absence of standardized manufacturing protocols increases production variability and quality control costs. Vapor-compression systems benefit from decades of manufacturing optimization and economies of scale, with well-established production facilities worldwide.

Scale-up potential differs markedly between these technologies. Vapor-compression systems demonstrate proven scalability from small residential units to massive industrial installations. Electrocaloric technology, however, faces significant engineering challenges in scaling beyond small demonstration units. Current research indicates that performance efficiency often decreases as system size increases, presenting a fundamental obstacle to commercial viability at larger scales.

Investment requirements for manufacturing infrastructure present another economic hurdle. Establishing production facilities for electrocaloric systems would require substantial capital investment in specialized equipment and processes. Manufacturers of conventional cooling systems can leverage existing production infrastructure, significantly reducing capital requirements for capacity expansion or product evolution.

Long-term economic viability will depend on technological maturation and manufacturing innovation. Recent advances in materials science suggest potential pathways to more cost-effective electrocaloric materials, including polymer-based composites that could be manufactured using modified versions of existing production equipment. Additionally, emerging additive manufacturing techniques show promise for reducing fabrication complexity and enabling more efficient small-batch production as the technology transitions from research to commercial applications.

Material sourcing represents another critical economic consideration. Electrocaloric systems often utilize rare earth elements and specialized polymers that face supply chain vulnerabilities and price volatility. In contrast, vapor-compression systems rely on more established supply chains with greater price stability, though refrigerant regulations continue to evolve and impact costs.

Manufacturing complexity further impacts economic viability. Electrocaloric devices require precise fabrication of multilayer structures with tight tolerances, demanding specialized equipment and expertise. The current absence of standardized manufacturing protocols increases production variability and quality control costs. Vapor-compression systems benefit from decades of manufacturing optimization and economies of scale, with well-established production facilities worldwide.

Scale-up potential differs markedly between these technologies. Vapor-compression systems demonstrate proven scalability from small residential units to massive industrial installations. Electrocaloric technology, however, faces significant engineering challenges in scaling beyond small demonstration units. Current research indicates that performance efficiency often decreases as system size increases, presenting a fundamental obstacle to commercial viability at larger scales.

Investment requirements for manufacturing infrastructure present another economic hurdle. Establishing production facilities for electrocaloric systems would require substantial capital investment in specialized equipment and processes. Manufacturers of conventional cooling systems can leverage existing production infrastructure, significantly reducing capital requirements for capacity expansion or product evolution.

Long-term economic viability will depend on technological maturation and manufacturing innovation. Recent advances in materials science suggest potential pathways to more cost-effective electrocaloric materials, including polymer-based composites that could be manufactured using modified versions of existing production equipment. Additionally, emerging additive manufacturing techniques show promise for reducing fabrication complexity and enabling more efficient small-batch production as the technology transitions from research to commercial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!