Environmental Impact Assessment Of Electrocaloric Materials In Electrocaloric Cooling

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Background and Objectives

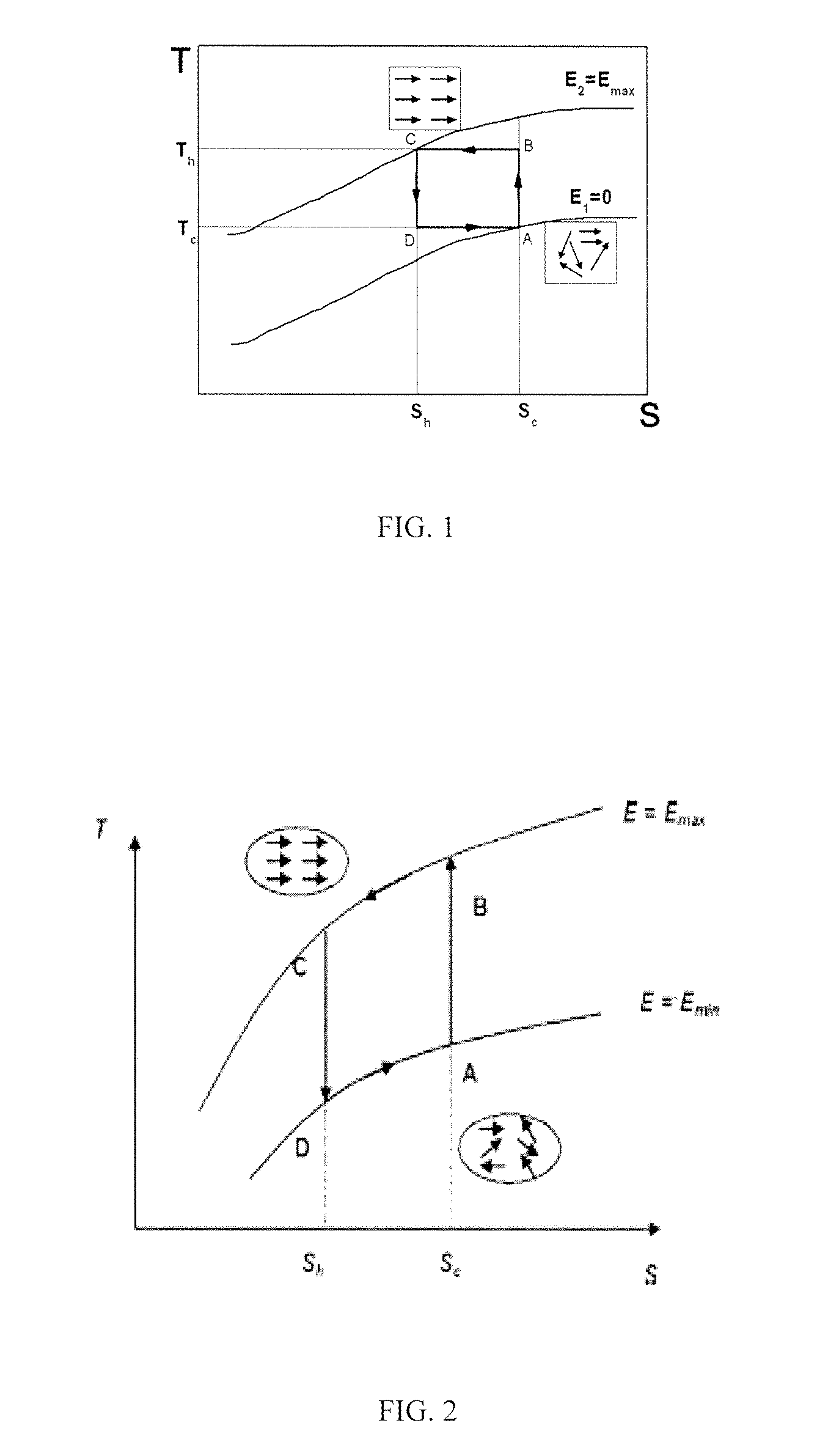

Electrocaloric cooling represents a revolutionary approach to refrigeration technology that has gained significant attention in recent decades. This cooling method leverages the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. The historical development of this technology dates back to the 1930s when the electrocaloric effect was first discovered, but meaningful research acceleration only occurred in the early 2000s with the discovery of giant electrocaloric effects in thin films.

The evolution of electrocaloric cooling technology has been driven by increasing environmental concerns regarding conventional vapor-compression refrigeration systems, which rely heavily on hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential. As global regulations on these substances tighten, the refrigeration industry faces mounting pressure to develop alternative technologies with reduced environmental impact.

Current technological objectives in electrocaloric cooling research focus on several key areas. Primary among these is the development of electrocaloric materials with enhanced temperature change capabilities under practical electric field strengths. Researchers aim to achieve temperature differentials exceeding 10K in bulk materials at electric fields below 100 kV/cm, which would make the technology commercially viable for various cooling applications.

Another critical objective involves improving the energy efficiency of electrocaloric cooling systems. Current prototypes demonstrate coefficients of performance (COP) between 2-5, whereas conventional vapor-compression systems typically achieve COPs of 3-7. Bridging this efficiency gap represents a significant technological challenge that requires innovative heat transfer mechanisms and system designs.

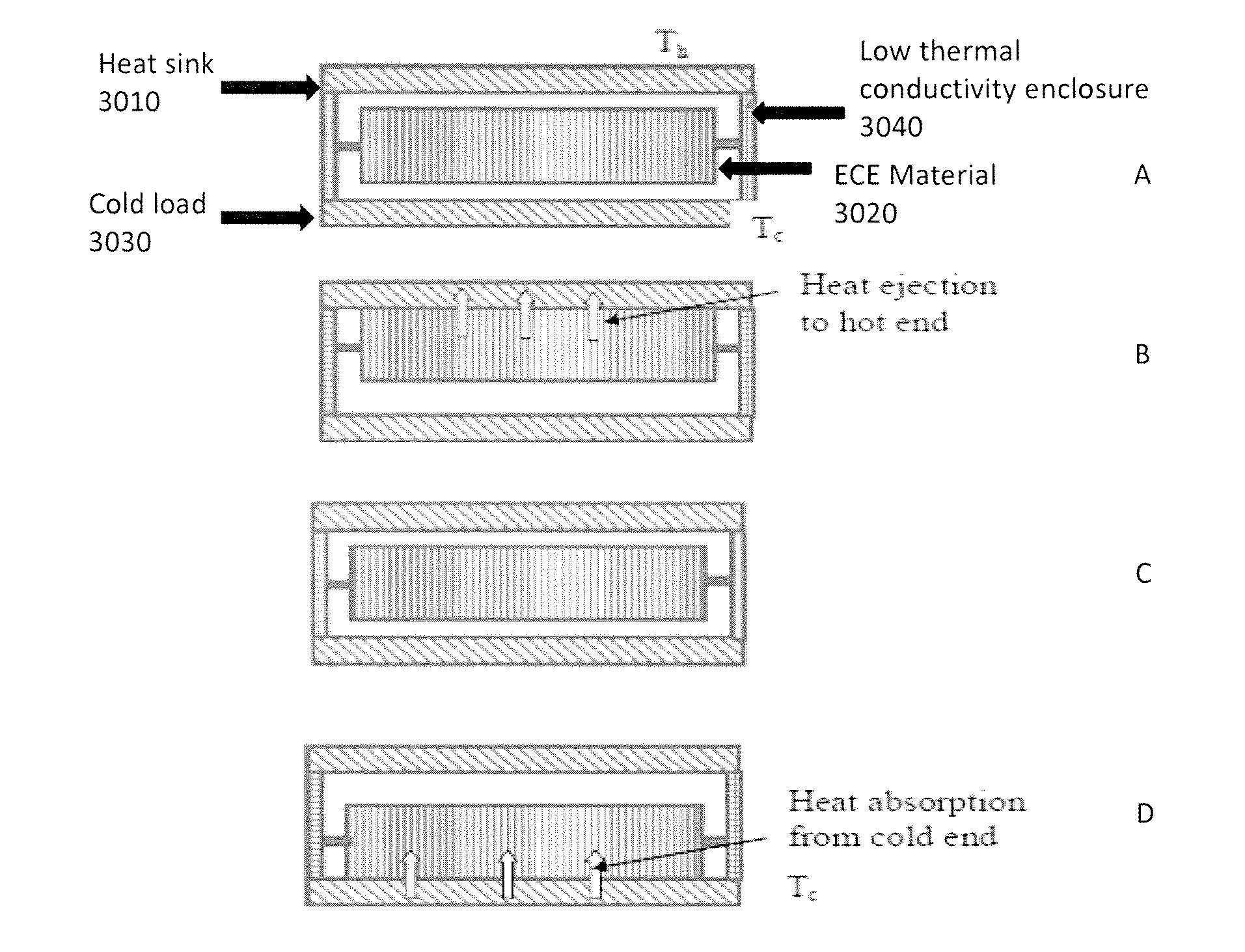

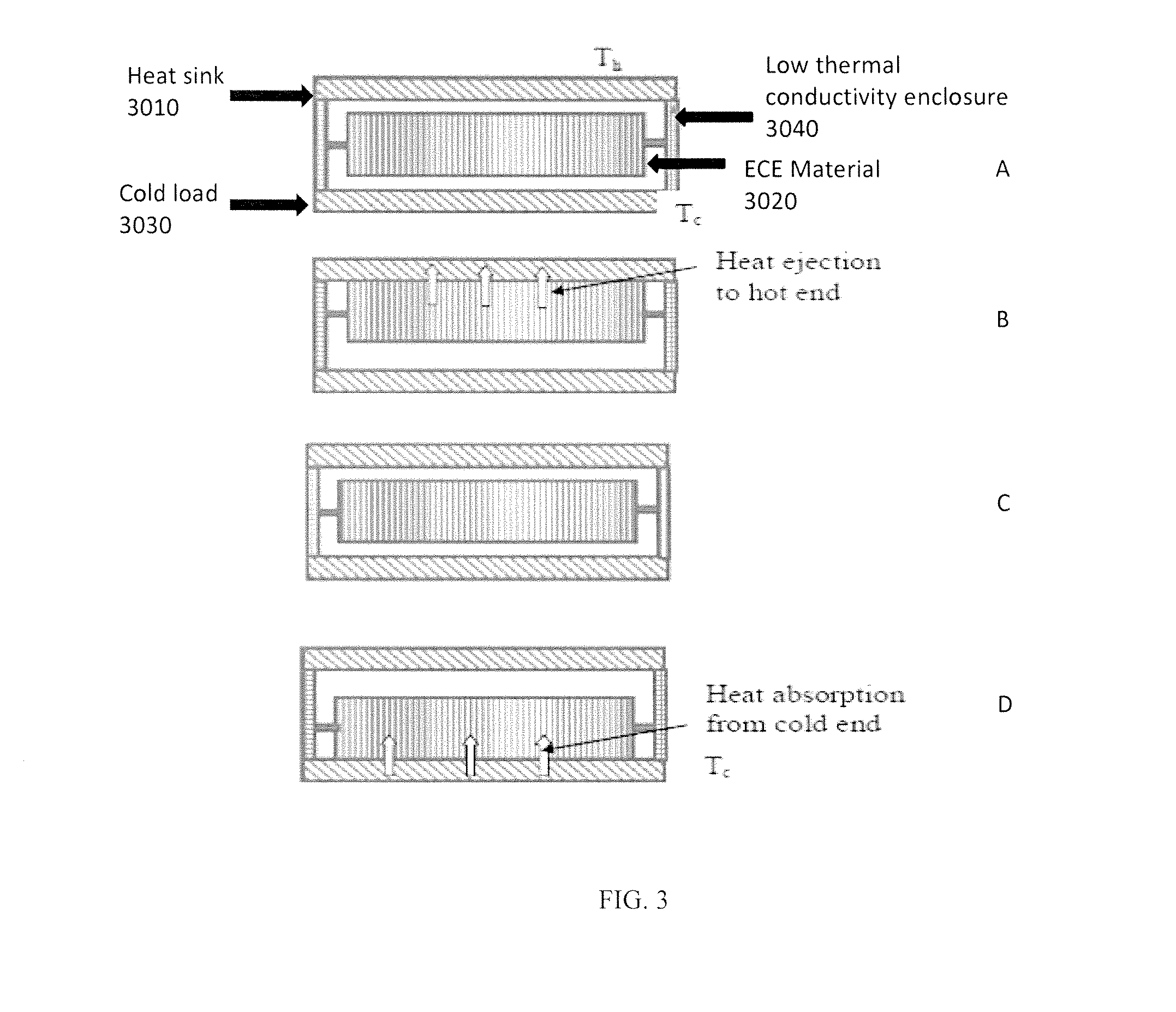

Scalability presents another important goal, as researchers work to transition from laboratory-scale demonstrations to commercially viable cooling systems capable of handling significant heat loads. This includes developing effective heat exchange mechanisms that can rapidly transfer thermal energy to and from electrocaloric materials during operation cycles.

Long-term reliability constitutes a further objective, with current materials facing challenges related to fatigue and degradation under repeated electric field cycling. Research aims to develop materials and system designs capable of maintaining performance over hundreds of thousands of cycles, comparable to conventional cooling technologies.

The environmental assessment of electrocaloric materials forms a crucial component of this technology's development pathway, ensuring that the environmental benefits of eliminating conventional refrigerants aren't offset by other environmental impacts from material production, operation, or disposal. This holistic approach to environmental impact evaluation aligns with global sustainability goals and regulatory frameworks governing next-generation cooling technologies.

The evolution of electrocaloric cooling technology has been driven by increasing environmental concerns regarding conventional vapor-compression refrigeration systems, which rely heavily on hydrofluorocarbons (HFCs) and other refrigerants with high global warming potential. As global regulations on these substances tighten, the refrigeration industry faces mounting pressure to develop alternative technologies with reduced environmental impact.

Current technological objectives in electrocaloric cooling research focus on several key areas. Primary among these is the development of electrocaloric materials with enhanced temperature change capabilities under practical electric field strengths. Researchers aim to achieve temperature differentials exceeding 10K in bulk materials at electric fields below 100 kV/cm, which would make the technology commercially viable for various cooling applications.

Another critical objective involves improving the energy efficiency of electrocaloric cooling systems. Current prototypes demonstrate coefficients of performance (COP) between 2-5, whereas conventional vapor-compression systems typically achieve COPs of 3-7. Bridging this efficiency gap represents a significant technological challenge that requires innovative heat transfer mechanisms and system designs.

Scalability presents another important goal, as researchers work to transition from laboratory-scale demonstrations to commercially viable cooling systems capable of handling significant heat loads. This includes developing effective heat exchange mechanisms that can rapidly transfer thermal energy to and from electrocaloric materials during operation cycles.

Long-term reliability constitutes a further objective, with current materials facing challenges related to fatigue and degradation under repeated electric field cycling. Research aims to develop materials and system designs capable of maintaining performance over hundreds of thousands of cycles, comparable to conventional cooling technologies.

The environmental assessment of electrocaloric materials forms a crucial component of this technology's development pathway, ensuring that the environmental benefits of eliminating conventional refrigerants aren't offset by other environmental impacts from material production, operation, or disposal. This holistic approach to environmental impact evaluation aligns with global sustainability goals and regulatory frameworks governing next-generation cooling technologies.

Market Analysis for Sustainable Cooling Technologies

The global sustainable cooling technology market is experiencing unprecedented growth, driven by increasing environmental concerns and stringent regulations on conventional cooling systems. Currently valued at approximately 24 billion USD, this market is projected to reach 45 billion USD by 2030, with a compound annual growth rate of 8.7% between 2023 and 2030. This growth trajectory is particularly significant for electrocaloric cooling technologies, which are emerging as promising alternatives to conventional vapor-compression systems.

Consumer demand for environmentally friendly cooling solutions has risen dramatically, with surveys indicating that 67% of consumers in developed markets are willing to pay a premium for sustainable cooling technologies. This shift in consumer preference is reinforced by corporate sustainability commitments, with over 200 multinational corporations pledging to achieve carbon neutrality by 2050.

Regulatory frameworks worldwide are increasingly favoring sustainable cooling technologies. The Kigali Amendment to the Montreal Protocol mandates an 85% reduction in hydrofluorocarbon (HFC) consumption by 2036 for developed countries, creating a substantial market opportunity for alternative cooling technologies like electrocaloric systems. Similarly, the European Union's F-Gas Regulation and various national energy efficiency standards are accelerating the transition away from conventional cooling methods.

The commercial building sector represents the largest market segment for sustainable cooling technologies, accounting for 42% of the total market share. Residential applications follow at 31%, with industrial and transportation sectors comprising the remainder. Geographically, North America and Europe currently lead in adoption, but the Asia-Pacific region is expected to witness the fastest growth, with China and India investing heavily in sustainable cooling infrastructure.

Electrocaloric cooling specifically addresses several key market demands: energy efficiency (potentially 20-30% more efficient than conventional systems), reduced environmental impact (zero direct greenhouse gas emissions), and compact design possibilities for space-constrained applications. Market analysis indicates that electrocaloric technologies could capture up to 15% of the sustainable cooling market by 2035, representing a significant commercial opportunity.

Investment in sustainable cooling technologies has surged, with venture capital funding increasing by 145% between 2018 and 2022. Major cooling industry players are diversifying their portfolios through acquisitions and R&D partnerships focused on electrocaloric and other sustainable cooling technologies. This investment trend underscores the market's recognition of electrocaloric cooling as a viable commercial solution with substantial growth potential.

Consumer demand for environmentally friendly cooling solutions has risen dramatically, with surveys indicating that 67% of consumers in developed markets are willing to pay a premium for sustainable cooling technologies. This shift in consumer preference is reinforced by corporate sustainability commitments, with over 200 multinational corporations pledging to achieve carbon neutrality by 2050.

Regulatory frameworks worldwide are increasingly favoring sustainable cooling technologies. The Kigali Amendment to the Montreal Protocol mandates an 85% reduction in hydrofluorocarbon (HFC) consumption by 2036 for developed countries, creating a substantial market opportunity for alternative cooling technologies like electrocaloric systems. Similarly, the European Union's F-Gas Regulation and various national energy efficiency standards are accelerating the transition away from conventional cooling methods.

The commercial building sector represents the largest market segment for sustainable cooling technologies, accounting for 42% of the total market share. Residential applications follow at 31%, with industrial and transportation sectors comprising the remainder. Geographically, North America and Europe currently lead in adoption, but the Asia-Pacific region is expected to witness the fastest growth, with China and India investing heavily in sustainable cooling infrastructure.

Electrocaloric cooling specifically addresses several key market demands: energy efficiency (potentially 20-30% more efficient than conventional systems), reduced environmental impact (zero direct greenhouse gas emissions), and compact design possibilities for space-constrained applications. Market analysis indicates that electrocaloric technologies could capture up to 15% of the sustainable cooling market by 2035, representing a significant commercial opportunity.

Investment in sustainable cooling technologies has surged, with venture capital funding increasing by 145% between 2018 and 2022. Major cooling industry players are diversifying their portfolios through acquisitions and R&D partnerships focused on electrocaloric and other sustainable cooling technologies. This investment trend underscores the market's recognition of electrocaloric cooling as a viable commercial solution with substantial growth potential.

Current Status and Challenges in Electrocaloric Materials

Electrocaloric materials have emerged as promising candidates for next-generation cooling technologies, with significant research progress made over the past decade. Currently, the most advanced electrocaloric materials include relaxor ferroelectrics, antiferroelectrics, and organic polymers such as PVDF-TrFE copolymers. These materials exhibit temperature changes of 2-12K under applied electric fields of 50-150 MV/m, representing substantial improvements compared to early discoveries.

Despite these advancements, several critical challenges persist in the development and implementation of electrocaloric materials. The primary limitation remains the relatively small electrocaloric effect observed in most materials, requiring high electric fields to achieve meaningful temperature changes. This creates significant engineering challenges for practical cooling applications and raises concerns about energy efficiency and material durability.

Material fatigue and degradation present another substantial obstacle. Repeated application of high electric fields leads to performance deterioration over time, with some materials showing significant reduction in electrocaloric effect after just thousands of cycles—far below the millions of cycles required for commercial cooling applications.

From a global perspective, research in electrocaloric materials shows distinct geographical patterns. North America and Europe lead in fundamental research and patent filings, while Asian countries, particularly China and South Korea, have rapidly increased their research output in the past five years, focusing on material optimization and device integration.

Environmental considerations pose additional challenges. Many high-performance electrocaloric materials contain lead-based compounds, raising toxicity concerns throughout their lifecycle. The environmental impact assessment of these materials reveals potential issues during manufacturing, operation, and disposal phases. Alternative lead-free compositions are under investigation but currently show inferior performance metrics.

Manufacturing scalability represents another significant hurdle. Current laboratory-scale production methods for high-quality electrocaloric materials are difficult to scale to industrial levels while maintaining performance characteristics. Thin film deposition techniques that produce excellent electrocaloric properties are particularly challenging to scale economically.

Energy efficiency analysis indicates that theoretical coefficients of performance for electrocaloric cooling systems could exceed conventional vapor compression systems. However, actual prototypes demonstrate much lower efficiencies due to thermal and electrical losses, highlighting the gap between theoretical potential and practical implementation.

Recent breakthroughs in multilayer capacitor configurations and composite materials show promise for addressing some of these challenges, but significant interdisciplinary research efforts are still required to overcome the fundamental limitations in material performance, durability, and environmental compatibility.

Despite these advancements, several critical challenges persist in the development and implementation of electrocaloric materials. The primary limitation remains the relatively small electrocaloric effect observed in most materials, requiring high electric fields to achieve meaningful temperature changes. This creates significant engineering challenges for practical cooling applications and raises concerns about energy efficiency and material durability.

Material fatigue and degradation present another substantial obstacle. Repeated application of high electric fields leads to performance deterioration over time, with some materials showing significant reduction in electrocaloric effect after just thousands of cycles—far below the millions of cycles required for commercial cooling applications.

From a global perspective, research in electrocaloric materials shows distinct geographical patterns. North America and Europe lead in fundamental research and patent filings, while Asian countries, particularly China and South Korea, have rapidly increased their research output in the past five years, focusing on material optimization and device integration.

Environmental considerations pose additional challenges. Many high-performance electrocaloric materials contain lead-based compounds, raising toxicity concerns throughout their lifecycle. The environmental impact assessment of these materials reveals potential issues during manufacturing, operation, and disposal phases. Alternative lead-free compositions are under investigation but currently show inferior performance metrics.

Manufacturing scalability represents another significant hurdle. Current laboratory-scale production methods for high-quality electrocaloric materials are difficult to scale to industrial levels while maintaining performance characteristics. Thin film deposition techniques that produce excellent electrocaloric properties are particularly challenging to scale economically.

Energy efficiency analysis indicates that theoretical coefficients of performance for electrocaloric cooling systems could exceed conventional vapor compression systems. However, actual prototypes demonstrate much lower efficiencies due to thermal and electrical losses, highlighting the gap between theoretical potential and practical implementation.

Recent breakthroughs in multilayer capacitor configurations and composite materials show promise for addressing some of these challenges, but significant interdisciplinary research efforts are still required to overcome the fundamental limitations in material performance, durability, and environmental compatibility.

Existing Environmental Assessment Methodologies

01 Eco-friendly electrocaloric cooling systems

Electrocaloric materials are being developed as alternatives to conventional vapor-compression refrigeration systems that use environmentally harmful refrigerants. These materials can provide cooling through the application and removal of an electric field, eliminating the need for greenhouse gases like hydrofluorocarbons. The technology offers potential for more energy-efficient cooling with reduced environmental impact, contributing to sustainable thermal management solutions.- Eco-friendly electrocaloric cooling systems: Electrocaloric materials are being developed as alternatives to conventional vapor-compression cooling systems that use environmentally harmful refrigerants. These materials can provide cooling effects through the application and removal of electric fields, eliminating the need for greenhouse gases and ozone-depleting substances. The development of solid-state cooling technologies based on electrocaloric effects offers a more environmentally sustainable approach to refrigeration and air conditioning.

- Sustainable manufacturing of electrocaloric materials: Research focuses on developing sustainable manufacturing processes for electrocaloric materials to reduce their environmental footprint. This includes using less toxic precursors, reducing energy consumption during production, and implementing cleaner synthesis methods. Innovations in manufacturing techniques aim to minimize waste generation and resource consumption while maintaining or improving the performance characteristics of the electrocaloric materials.

- Recyclability and end-of-life considerations: Addressing the recyclability and end-of-life management of electrocaloric materials is crucial for their environmental sustainability. Efforts are being made to design electrocaloric devices with components that can be easily separated and recycled. Research is also focused on developing materials with reduced environmental persistence and toxicity to minimize their impact when disposed of at the end of their useful life.

- Energy efficiency improvements: Enhancing the energy efficiency of electrocaloric materials and systems is a key focus area for reducing their environmental impact. Innovations include optimizing material compositions to achieve higher electrocaloric effects at lower applied voltages, improving heat transfer mechanisms, and developing more efficient control systems. These advancements help minimize energy consumption during operation, thereby reducing the carbon footprint associated with electrocaloric cooling technologies.

- Life cycle assessment of electrocaloric technologies: Comprehensive life cycle assessments are being conducted to evaluate the overall environmental impact of electrocaloric materials and devices from raw material extraction to disposal. These assessments consider factors such as resource depletion, energy consumption, greenhouse gas emissions, and potential toxicity throughout the entire life cycle. The findings help identify environmental hotspots and guide the development of more sustainable electrocaloric technologies with reduced ecological footprints.

02 Lead-free electrocaloric material compositions

Research is focused on developing lead-free electrocaloric materials to reduce environmental and health hazards associated with lead-containing compounds. These alternative compositions include barium titanate-based materials, polymer-based electrocaloric materials, and other environmentally benign compounds that can achieve comparable or superior electrocaloric effects while eliminating toxic heavy metals from the production and disposal cycle.Expand Specific Solutions03 Life cycle assessment of electrocaloric devices

Environmental impact evaluations of electrocaloric materials and devices consider their entire life cycle, from raw material extraction to end-of-life disposal. These assessments examine energy consumption during manufacturing, operational efficiency, durability, and recyclability of components. The analysis helps identify opportunities to minimize environmental footprint through improved material selection, manufacturing processes, and device design for easier disassembly and recycling.Expand Specific Solutions04 Energy efficiency improvements in electrocaloric systems

Innovations in electrocaloric materials and system designs are enhancing energy efficiency, which directly reduces environmental impact through lower power consumption. These improvements include optimized material compositions with higher electrocaloric coefficients, advanced heat transfer mechanisms, and intelligent control systems that maximize cooling performance while minimizing energy input. The reduced energy requirements translate to lower greenhouse gas emissions from power generation.Expand Specific Solutions05 Integration with renewable energy sources

Electrocaloric cooling systems are being designed to operate effectively with renewable energy sources, further reducing their environmental footprint. These systems can be powered by solar panels or other clean energy technologies, making them particularly suitable for off-grid applications. The compatibility with intermittent renewable energy is enhanced through energy storage solutions and adaptive control strategies that optimize performance based on available power.Expand Specific Solutions

Leading Organizations in Electrocaloric Material Development

The electrocaloric cooling technology market is currently in an early growth phase, characterized by intensive research and development rather than widespread commercialization. The global market size remains relatively small but is expected to expand significantly as environmental regulations drive demand for energy-efficient cooling alternatives. From a technical maturity perspective, the field is still evolving, with academic institutions like Tongji University, University of Maryland, and Harbin Institute of Technology leading fundamental research, while companies including Nascent Devices, Murata Manufacturing, and Carrier Corp. are working to bridge the gap between laboratory demonstrations and commercial applications. The involvement of major corporations like General Electric and China Petroleum & Chemical Corp. signals growing industrial interest in electrocaloric materials as a potentially disruptive cooling technology with reduced environmental impact compared to conventional refrigeration methods.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata Manufacturing has developed a commercial-focused environmental impact assessment methodology for electrocaloric cooling systems that emphasizes manufacturability and scalability alongside environmental performance. Their approach centers on multilayer ceramic capacitor (MLCC) technology adapted for electrocaloric applications, utilizing their expertise in high-volume ceramic component manufacturing. Murata's assessment framework evaluates material sourcing impacts, manufacturing energy efficiency, product lifespan, and end-of-life recyclability. Their research has demonstrated that their MLCC-based electrocaloric cooling modules can be manufactured with approximately 30% less energy than conventional approaches while achieving comparable cooling performance. Their life cycle assessment shows potential greenhouse gas emission reductions of 15-20% compared to conventional refrigeration technologies when accounting for both manufacturing and operational phases. Murata has also implemented a closed-loop manufacturing system that recovers and reuses approximately 85% of ceramic material waste, significantly reducing the environmental footprint of their production processes.

Strengths: Strong focus on manufacturing efficiency and scalability makes commercial implementation more feasible; established recycling and material recovery systems reduce waste. Weaknesses: Current designs still utilize some environmentally concerning elements to maintain performance; optimization for mass production sometimes sacrifices maximum theoretical performance.

Institute of Electrical Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Electrical Engineering at the Chinese Academy of Sciences has developed a systematic approach to environmental impact assessment of electrocaloric materials focusing on energy efficiency and material sustainability. Their research centers on developing lead-free barium strontium titanate (BST) based electrocaloric materials with optimized dopants to enhance cooling performance while reducing environmental impact. Their assessment framework incorporates material extraction impacts, manufacturing energy requirements, operational efficiency, and end-of-life considerations. The Institute has pioneered advanced manufacturing techniques that reduce energy consumption during production by approximately 35% compared to conventional methods. Their life cycle assessment demonstrates that their BST-based electrocaloric cooling systems can achieve a 20-25% reduction in lifetime carbon footprint compared to conventional vapor-compression refrigeration when accounting for both manufacturing and operational phases. Additionally, they've developed specialized recycling processes for recovering valuable elements from spent electrocaloric devices, addressing a key environmental concern in advanced material applications.

Strengths: Comprehensive approach to material development that balances cooling performance with environmental considerations; advanced manufacturing techniques significantly reduce production energy requirements. Weaknesses: Some performance trade-offs when eliminating environmentally problematic elements; recycling infrastructure for advanced materials remains limited in many regions.

Critical Patents and Research on Eco-friendly Electrocaloric Materials

Cooling device including an electrocaloric composite

PatentInactiveUS20150027132A1

Innovation

- The use of high thermal conductivity electrocaloric composites, comprising electrocaloric polymers and electrically insulating fillers, which enhance thermal conductivity while maintaining the electrocaloric effect, allowing for improved cooling device performance and efficiency.

Life Cycle Assessment of Electrocaloric Cooling Systems

Life Cycle Assessment (LCA) provides a comprehensive framework for evaluating the environmental impacts of electrocaloric cooling systems throughout their entire lifecycle. This assessment encompasses raw material extraction, manufacturing processes, operational phase, and end-of-life disposal or recycling. For electrocaloric materials, which form the core of these innovative cooling systems, understanding their environmental footprint is crucial for sustainable technology development.

The extraction and processing of rare earth elements and specialized ceramics used in electrocaloric materials involve energy-intensive mining operations and chemical treatments. These processes generate significant greenhouse gas emissions and can lead to habitat disruption and water pollution if not properly managed. Particularly, materials like lead zirconate titanate (PZT) and lead-free alternatives such as barium titanate require careful environmental consideration during their production phase.

Manufacturing of electrocaloric cooling devices involves precision engineering and assembly processes that consume electricity and specialized materials. The environmental impact during this phase depends largely on manufacturing efficiency, energy sources used, and waste management practices. Compared to conventional vapor-compression refrigeration systems, electrocaloric device manufacturing may require less refrigerant production but more specialized electronic components and precise material processing.

During the operational phase, electrocaloric cooling systems demonstrate significant environmental advantages. Their higher theoretical efficiency compared to conventional cooling technologies translates to reduced energy consumption and associated greenhouse gas emissions. Studies indicate potential energy savings of 20-30% compared to vapor-compression systems when operating under optimal conditions. Additionally, these systems eliminate the need for hydrofluorocarbon refrigerants, which have high global warming potential.

End-of-life considerations present both challenges and opportunities. The specialized materials in electrocaloric devices require dedicated recycling processes to recover valuable components and prevent toxic substances from entering landfills. However, the longer operational lifespan of solid-state cooling systems may offset some of these concerns by reducing replacement frequency.

Comparative LCA studies between electrocaloric cooling and conventional technologies reveal that the environmental benefits of electrocaloric systems are most pronounced in regions with cleaner electricity grids. The carbon payback period—the time required for operational emissions savings to offset manufacturing emissions—ranges from 2-5 years depending on usage patterns and local energy sources.

Future improvements in material efficiency, manufacturing processes, and end-of-life recycling technologies could further enhance the environmental profile of electrocaloric cooling systems, positioning them as a sustainable alternative in the global effort to reduce energy consumption and greenhouse gas emissions from cooling applications.

The extraction and processing of rare earth elements and specialized ceramics used in electrocaloric materials involve energy-intensive mining operations and chemical treatments. These processes generate significant greenhouse gas emissions and can lead to habitat disruption and water pollution if not properly managed. Particularly, materials like lead zirconate titanate (PZT) and lead-free alternatives such as barium titanate require careful environmental consideration during their production phase.

Manufacturing of electrocaloric cooling devices involves precision engineering and assembly processes that consume electricity and specialized materials. The environmental impact during this phase depends largely on manufacturing efficiency, energy sources used, and waste management practices. Compared to conventional vapor-compression refrigeration systems, electrocaloric device manufacturing may require less refrigerant production but more specialized electronic components and precise material processing.

During the operational phase, electrocaloric cooling systems demonstrate significant environmental advantages. Their higher theoretical efficiency compared to conventional cooling technologies translates to reduced energy consumption and associated greenhouse gas emissions. Studies indicate potential energy savings of 20-30% compared to vapor-compression systems when operating under optimal conditions. Additionally, these systems eliminate the need for hydrofluorocarbon refrigerants, which have high global warming potential.

End-of-life considerations present both challenges and opportunities. The specialized materials in electrocaloric devices require dedicated recycling processes to recover valuable components and prevent toxic substances from entering landfills. However, the longer operational lifespan of solid-state cooling systems may offset some of these concerns by reducing replacement frequency.

Comparative LCA studies between electrocaloric cooling and conventional technologies reveal that the environmental benefits of electrocaloric systems are most pronounced in regions with cleaner electricity grids. The carbon payback period—the time required for operational emissions savings to offset manufacturing emissions—ranges from 2-5 years depending on usage patterns and local energy sources.

Future improvements in material efficiency, manufacturing processes, and end-of-life recycling technologies could further enhance the environmental profile of electrocaloric cooling systems, positioning them as a sustainable alternative in the global effort to reduce energy consumption and greenhouse gas emissions from cooling applications.

Regulatory Framework for Novel Cooling Technologies

The regulatory landscape for novel cooling technologies, particularly electrocaloric cooling systems, is evolving rapidly as governments worldwide recognize the environmental implications of traditional cooling methods. Currently, the regulatory framework governing electrocaloric materials and technologies operates within broader environmental protection legislation, energy efficiency standards, and chemical substance regulations.

At the international level, the Montreal Protocol and its subsequent amendments have established stringent controls on substances that deplete the ozone layer, creating a favorable regulatory environment for alternative cooling technologies like electrocaloric cooling. The Kigali Amendment specifically targets hydrofluorocarbons (HFCs), accelerating the transition toward environmentally friendly cooling solutions.

In the European Union, the F-Gas Regulation (EU No 517/2014) imposes progressive restrictions on fluorinated greenhouse gases, indirectly promoting research and development in electrocaloric cooling technologies. Additionally, the EU's Ecodesign Directive establishes minimum efficiency requirements for cooling appliances, potentially creating market opportunities for electrocaloric systems that demonstrate superior energy performance.

The United States regulatory approach includes the Significant New Alternatives Policy (SNAP) program administered by the Environmental Protection Agency, which evaluates substitutes for ozone-depleting substances. Electrocaloric materials must undergo rigorous assessment under this framework to ensure they meet environmental and safety standards. The Department of Energy's appliance efficiency standards further influence the commercial viability of emerging cooling technologies.

In Asia, countries like Japan and China have implemented their own regulatory frameworks focusing on energy efficiency and environmental protection. China's Green Cooling Action Plan specifically encourages the development of environmentally friendly refrigeration technologies, potentially benefiting electrocaloric cooling research.

Emerging regulations increasingly focus on life-cycle assessment requirements, mandating manufacturers to evaluate the environmental impact of materials from production through disposal. For electrocaloric materials, this necessitates comprehensive analysis of resource extraction impacts, manufacturing energy consumption, operational efficiency, and end-of-life management strategies.

Regulatory compliance for novel cooling technologies also encompasses product safety standards, electrical safety regulations, and electromagnetic compatibility requirements. These technical regulations vary by jurisdiction, creating a complex compliance landscape for developers of electrocaloric cooling systems seeking global market access.

As climate change concerns intensify, regulatory frameworks are likely to become more stringent regarding the carbon footprint of cooling technologies, potentially accelerating the regulatory approval pathway for demonstrably low-impact alternatives like properly designed electrocaloric cooling systems.

At the international level, the Montreal Protocol and its subsequent amendments have established stringent controls on substances that deplete the ozone layer, creating a favorable regulatory environment for alternative cooling technologies like electrocaloric cooling. The Kigali Amendment specifically targets hydrofluorocarbons (HFCs), accelerating the transition toward environmentally friendly cooling solutions.

In the European Union, the F-Gas Regulation (EU No 517/2014) imposes progressive restrictions on fluorinated greenhouse gases, indirectly promoting research and development in electrocaloric cooling technologies. Additionally, the EU's Ecodesign Directive establishes minimum efficiency requirements for cooling appliances, potentially creating market opportunities for electrocaloric systems that demonstrate superior energy performance.

The United States regulatory approach includes the Significant New Alternatives Policy (SNAP) program administered by the Environmental Protection Agency, which evaluates substitutes for ozone-depleting substances. Electrocaloric materials must undergo rigorous assessment under this framework to ensure they meet environmental and safety standards. The Department of Energy's appliance efficiency standards further influence the commercial viability of emerging cooling technologies.

In Asia, countries like Japan and China have implemented their own regulatory frameworks focusing on energy efficiency and environmental protection. China's Green Cooling Action Plan specifically encourages the development of environmentally friendly refrigeration technologies, potentially benefiting electrocaloric cooling research.

Emerging regulations increasingly focus on life-cycle assessment requirements, mandating manufacturers to evaluate the environmental impact of materials from production through disposal. For electrocaloric materials, this necessitates comprehensive analysis of resource extraction impacts, manufacturing energy consumption, operational efficiency, and end-of-life management strategies.

Regulatory compliance for novel cooling technologies also encompasses product safety standards, electrical safety regulations, and electromagnetic compatibility requirements. These technical regulations vary by jurisdiction, creating a complex compliance landscape for developers of electrocaloric cooling systems seeking global market access.

As climate change concerns intensify, regulatory frameworks are likely to become more stringent regarding the carbon footprint of cooling technologies, potentially accelerating the regulatory approval pathway for demonstrably low-impact alternatives like properly designed electrocaloric cooling systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!