Electrocaloric Device Scaling: From Lab Chip To Commercial Rack For Electrocaloric Cooling

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling technology represents a promising alternative to conventional vapor-compression refrigeration systems, offering potential advantages in energy efficiency, environmental impact, and form factor flexibility. The technology leverages the electrocaloric effect, a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. This effect was first observed in the 1930s but remained largely academic until recent decades when advances in materials science and engineering revitalized interest in its practical applications.

The evolution of electrocaloric cooling technology has accelerated significantly since the early 2000s, marked by breakthrough discoveries of giant electrocaloric effects in ferroelectric thin films and relaxor ferroelectrics. These discoveries demonstrated temperature changes of several degrees Kelvin, substantially higher than previously observed, igniting renewed research interest globally. The subsequent development trajectory has focused on enhancing material properties, optimizing device architectures, and addressing heat transfer challenges.

Current research trends indicate a shift from fundamental materials exploration to practical device implementation and scaling challenges. The scientific community has established the theoretical viability of electrocaloric cooling, with laboratory demonstrations achieving cooling powers in the milliwatt to watt range. However, the transition from laboratory prototypes to commercially viable systems requires significant technological advancement in several key areas.

The primary technical objective in this field is to scale electrocaloric devices from laboratory chip-level demonstrations to commercial rack-scale cooling systems capable of competing with conventional technologies. This scaling challenge encompasses multiple dimensions: physical size expansion, cooling power enhancement, efficiency improvement, reliability assurance, and cost reduction. Achieving these objectives requires interdisciplinary approaches combining materials science, thermal engineering, electrical engineering, and manufacturing innovation.

Material development remains central to progress, with research focusing on enhancing electrocaloric coefficients, reducing hysteresis losses, improving cycling stability, and developing lead-free alternatives to address environmental concerns. Simultaneously, device architecture innovation aims to optimize heat transfer mechanisms, reduce parasitic thermal losses, and develop effective regenerative cycles that maximize the cooling effect.

The ultimate goal is to develop electrocaloric cooling systems that offer compelling advantages over conventional technologies, particularly in applications where energy efficiency, environmental sustainability, compact form factors, or quiet operation are prioritized. These could include electronics cooling, refrigeration in transportation, building climate control, and specialized industrial applications.

Success in this technological trajectory would represent not only a significant scientific achievement but also a potential paradigm shift in cooling technology with far-reaching implications for energy consumption patterns and environmental impact in multiple sectors of the global economy.

The evolution of electrocaloric cooling technology has accelerated significantly since the early 2000s, marked by breakthrough discoveries of giant electrocaloric effects in ferroelectric thin films and relaxor ferroelectrics. These discoveries demonstrated temperature changes of several degrees Kelvin, substantially higher than previously observed, igniting renewed research interest globally. The subsequent development trajectory has focused on enhancing material properties, optimizing device architectures, and addressing heat transfer challenges.

Current research trends indicate a shift from fundamental materials exploration to practical device implementation and scaling challenges. The scientific community has established the theoretical viability of electrocaloric cooling, with laboratory demonstrations achieving cooling powers in the milliwatt to watt range. However, the transition from laboratory prototypes to commercially viable systems requires significant technological advancement in several key areas.

The primary technical objective in this field is to scale electrocaloric devices from laboratory chip-level demonstrations to commercial rack-scale cooling systems capable of competing with conventional technologies. This scaling challenge encompasses multiple dimensions: physical size expansion, cooling power enhancement, efficiency improvement, reliability assurance, and cost reduction. Achieving these objectives requires interdisciplinary approaches combining materials science, thermal engineering, electrical engineering, and manufacturing innovation.

Material development remains central to progress, with research focusing on enhancing electrocaloric coefficients, reducing hysteresis losses, improving cycling stability, and developing lead-free alternatives to address environmental concerns. Simultaneously, device architecture innovation aims to optimize heat transfer mechanisms, reduce parasitic thermal losses, and develop effective regenerative cycles that maximize the cooling effect.

The ultimate goal is to develop electrocaloric cooling systems that offer compelling advantages over conventional technologies, particularly in applications where energy efficiency, environmental sustainability, compact form factors, or quiet operation are prioritized. These could include electronics cooling, refrigeration in transportation, building climate control, and specialized industrial applications.

Success in this technological trajectory would represent not only a significant scientific achievement but also a potential paradigm shift in cooling technology with far-reaching implications for energy consumption patterns and environmental impact in multiple sectors of the global economy.

Market Analysis for Solid-State Cooling Solutions

The solid-state cooling market is experiencing significant growth, driven by increasing demand for energy-efficient, environmentally friendly cooling solutions across multiple industries. The global market for solid-state cooling technologies was valued at approximately $500 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate (CAGR) of 15.7%. This growth trajectory is substantially higher than the conventional cooling market, which grows at 3-5% annually.

Electrocaloric cooling technology, as a subset of solid-state cooling solutions, is positioned to capture a significant portion of this expanding market. While currently representing less than 10% of the solid-state cooling market, electrocaloric technology is expected to grow at an accelerated rate of 22% annually through 2030 due to its superior energy efficiency and scaling potential.

Key market segments showing strong demand for solid-state cooling include consumer electronics, medical devices, automotive, aerospace, and data centers. The data center cooling market alone is projected to reach $20 billion by 2025, with solid-state solutions potentially capturing 15% of this segment by 2030. Consumer electronics manufacturers are increasingly seeking compact cooling solutions with minimal moving parts, creating a $300 million opportunity for electrocaloric devices by 2027.

Market drivers for electrocaloric cooling adoption include stringent environmental regulations phasing out hydrofluorocarbon (HFC) refrigerants, rising energy costs, and increasing demand for silent, vibration-free cooling in premium applications. The European Union's F-Gas Regulation and similar policies worldwide are accelerating the transition away from conventional vapor-compression systems.

Customer pain points addressed by electrocaloric cooling include energy efficiency (potential 30-40% reduction in energy consumption compared to conventional systems), space constraints (40-60% reduction in physical footprint), noise reduction (completely silent operation), and reliability (fewer moving parts leading to extended service life of 15+ years).

Market barriers include high initial costs (currently 3-5 times higher than conventional systems), limited awareness among potential customers, and competition from other solid-state technologies such as thermoelectric and magnetocaloric cooling. The cost premium is expected to decrease to 1.5-2 times by 2028 as manufacturing scales and materials science advances.

Regional analysis shows North America leading adoption with 42% market share, followed by Europe (31%), Asia-Pacific (22%), and rest of world (5%). China and India represent the fastest-growing markets with annual growth rates exceeding 25%, driven by rapid industrialization and increasing environmental awareness.

Electrocaloric cooling technology, as a subset of solid-state cooling solutions, is positioned to capture a significant portion of this expanding market. While currently representing less than 10% of the solid-state cooling market, electrocaloric technology is expected to grow at an accelerated rate of 22% annually through 2030 due to its superior energy efficiency and scaling potential.

Key market segments showing strong demand for solid-state cooling include consumer electronics, medical devices, automotive, aerospace, and data centers. The data center cooling market alone is projected to reach $20 billion by 2025, with solid-state solutions potentially capturing 15% of this segment by 2030. Consumer electronics manufacturers are increasingly seeking compact cooling solutions with minimal moving parts, creating a $300 million opportunity for electrocaloric devices by 2027.

Market drivers for electrocaloric cooling adoption include stringent environmental regulations phasing out hydrofluorocarbon (HFC) refrigerants, rising energy costs, and increasing demand for silent, vibration-free cooling in premium applications. The European Union's F-Gas Regulation and similar policies worldwide are accelerating the transition away from conventional vapor-compression systems.

Customer pain points addressed by electrocaloric cooling include energy efficiency (potential 30-40% reduction in energy consumption compared to conventional systems), space constraints (40-60% reduction in physical footprint), noise reduction (completely silent operation), and reliability (fewer moving parts leading to extended service life of 15+ years).

Market barriers include high initial costs (currently 3-5 times higher than conventional systems), limited awareness among potential customers, and competition from other solid-state technologies such as thermoelectric and magnetocaloric cooling. The cost premium is expected to decrease to 1.5-2 times by 2028 as manufacturing scales and materials science advances.

Regional analysis shows North America leading adoption with 42% market share, followed by Europe (31%), Asia-Pacific (22%), and rest of world (5%). China and India represent the fastest-growing markets with annual growth rates exceeding 25%, driven by rapid industrialization and increasing environmental awareness.

Current Challenges in Electrocaloric Device Scaling

Despite significant advancements in electrocaloric (EC) cooling technology at laboratory scale, scaling these devices to commercially viable dimensions presents formidable challenges. The fundamental issue lies in the inherent trade-off between cooling power and temperature span when increasing device size. Laboratory prototypes typically operate with small active material volumes (often less than 1 cm³), which cannot satisfy commercial cooling requirements that demand orders of magnitude larger capacity.

Material limitations constitute a primary obstacle in scaling efforts. Current electrocaloric materials exhibit maximum temperature changes of only 2-5K under practical electric fields, necessitating complex cascading systems to achieve commercially relevant temperature spans. Additionally, the high-performance EC materials often contain lead or other environmentally problematic elements, creating regulatory hurdles for mass production and commercial deployment.

Heat transfer efficiency dramatically decreases with increased device dimensions. As EC devices scale up, the surface-to-volume ratio decreases, resulting in less efficient heat exchange and slower thermal cycling. This physical constraint fundamentally limits the cooling power density achievable in larger systems, requiring innovative thermal management solutions that have yet to be fully developed.

Power management presents another significant challenge. Commercial-scale EC cooling systems would require substantial electrical infrastructure to handle the high voltage (often >1000V) and current demands. The associated power electronics for efficiently driving large EC arrays remain underdeveloped, particularly regarding high-voltage switching at the frequencies required for optimal EC performance (typically 0.1-10 Hz).

Manufacturing scalability issues further complicate commercialization efforts. Current fabrication methods for high-performance EC materials and devices are predominantly laboratory-focused, utilizing techniques ill-suited for mass production. The precision required in multilayer fabrication and electrode deposition becomes increasingly difficult to maintain across larger surface areas.

Reliability and durability concerns intensify with scale. Larger EC systems face accelerated degradation due to increased mechanical stress during thermal cycling, dielectric breakdown risks across larger areas, and fatigue in electrical connections. Commercial applications would require operational lifetimes of 5-10 years, far exceeding what has been demonstrated in laboratory prototypes.

Cost considerations ultimately may present the most significant barrier. Current estimates suggest EC cooling systems would cost 5-10 times more than conventional vapor compression systems of equivalent capacity. This economic reality necessitates either dramatic cost reductions through materials innovation and manufacturing optimization or initial market entry through high-value niche applications where conventional cooling is inadequate.

Material limitations constitute a primary obstacle in scaling efforts. Current electrocaloric materials exhibit maximum temperature changes of only 2-5K under practical electric fields, necessitating complex cascading systems to achieve commercially relevant temperature spans. Additionally, the high-performance EC materials often contain lead or other environmentally problematic elements, creating regulatory hurdles for mass production and commercial deployment.

Heat transfer efficiency dramatically decreases with increased device dimensions. As EC devices scale up, the surface-to-volume ratio decreases, resulting in less efficient heat exchange and slower thermal cycling. This physical constraint fundamentally limits the cooling power density achievable in larger systems, requiring innovative thermal management solutions that have yet to be fully developed.

Power management presents another significant challenge. Commercial-scale EC cooling systems would require substantial electrical infrastructure to handle the high voltage (often >1000V) and current demands. The associated power electronics for efficiently driving large EC arrays remain underdeveloped, particularly regarding high-voltage switching at the frequencies required for optimal EC performance (typically 0.1-10 Hz).

Manufacturing scalability issues further complicate commercialization efforts. Current fabrication methods for high-performance EC materials and devices are predominantly laboratory-focused, utilizing techniques ill-suited for mass production. The precision required in multilayer fabrication and electrode deposition becomes increasingly difficult to maintain across larger surface areas.

Reliability and durability concerns intensify with scale. Larger EC systems face accelerated degradation due to increased mechanical stress during thermal cycling, dielectric breakdown risks across larger areas, and fatigue in electrical connections. Commercial applications would require operational lifetimes of 5-10 years, far exceeding what has been demonstrated in laboratory prototypes.

Cost considerations ultimately may present the most significant barrier. Current estimates suggest EC cooling systems would cost 5-10 times more than conventional vapor compression systems of equivalent capacity. This economic reality necessitates either dramatic cost reductions through materials innovation and manufacturing optimization or initial market entry through high-value niche applications where conventional cooling is inadequate.

Current Scaling Approaches for Electrocaloric Devices

01 Electrocaloric material selection and optimization

The selection and optimization of electrocaloric materials is crucial for device scaling. Materials with high electrocaloric effect, such as certain ferroelectric polymers and relaxor ferroelectrics, can significantly improve cooling efficiency. The composition, structure, and processing of these materials can be tailored to enhance their electrocaloric properties at different operating temperatures and electric field strengths, which is essential for scaling devices from laboratory prototypes to commercial applications.- Scaling of electrocaloric materials and device structures: Scaling of electrocaloric materials and device structures is crucial for optimizing cooling performance. This involves adjusting the dimensions and configurations of electrocaloric elements to maximize the temperature change and heat transfer efficiency. Proper scaling of material thickness, electrode spacing, and active area can significantly enhance the cooling capacity and energy efficiency of electrocaloric devices.

- Multilayer and cascade configurations for enhanced cooling: Electrocaloric devices can be scaled through multilayer and cascade configurations to amplify cooling effects. By stacking multiple electrocaloric layers or arranging them in series, the overall temperature differential can be increased. These configurations allow for more compact designs while maintaining or improving cooling capacity, making them suitable for applications with space constraints.

- Integration with heat transfer systems and thermal management: Scaling electrocaloric devices requires effective integration with heat transfer systems. This includes designing efficient heat exchangers, thermal switches, and fluid circulation systems that can transfer heat to and from the electrocaloric elements. Proper thermal management ensures that the cooling effect is effectively distributed throughout the system and prevents localized heating that could reduce efficiency.

- Manufacturing techniques for scaled production: Advanced manufacturing techniques are essential for scaling electrocaloric devices from laboratory prototypes to commercial products. These include thin-film deposition methods, roll-to-roll processing, and additive manufacturing approaches that enable cost-effective production of electrocaloric materials and devices at scale. Precision manufacturing ensures consistent performance across multiple units and reduces production costs.

- Control systems and power electronics for scaled operation: Scaling electrocaloric devices requires sophisticated control systems and power electronics to manage the electric field application and heat transfer timing. These systems optimize the electrocaloric cycle, adjust operating parameters based on cooling demand, and ensure efficient energy usage. Advanced control algorithms can compensate for material fatigue and performance variations, maintaining consistent cooling performance over the device lifetime.

02 Thermal management and heat transfer optimization

Effective thermal management is essential for scaling electrocaloric devices. This includes optimizing heat transfer between the electrocaloric material and heat exchangers, minimizing thermal resistance at interfaces, and designing efficient heat flow paths. Advanced thermal management techniques such as microchannel heat exchangers, thermal switches, and phase change materials can significantly improve the performance of scaled electrocaloric cooling systems by enhancing heat transfer rates and reducing thermal losses.Expand Specific Solutions03 Device architecture and system integration

The architecture of electrocaloric devices plays a critical role in their scalability. Various configurations, such as stacked multilayer structures, regenerative cycles, and cascaded systems, can be employed to enhance cooling capacity and efficiency. System integration considerations include the design of electrical circuits for applying and removing electric fields, mechanical systems for fluid flow or solid-state heat transfer, and control systems for optimizing operation under varying conditions. These architectural approaches enable scaling from small demonstration units to larger commercial cooling systems.Expand Specific Solutions04 Manufacturing processes and fabrication techniques

Scaling electrocaloric devices requires developing manufacturing processes suitable for mass production. This includes techniques for fabricating thin films or multilayer structures of electrocaloric materials, methods for electrode deposition and patterning, and assembly processes for complete devices. Advanced manufacturing approaches such as roll-to-roll processing, 3D printing, and microfabrication can enable cost-effective production of electrocaloric devices at scale while maintaining performance characteristics and reliability.Expand Specific Solutions05 Power electronics and control systems

Efficient power electronics and control systems are essential for scaling electrocaloric devices. This includes high-voltage power supplies capable of rapidly charging and discharging the electrocaloric elements, sophisticated control algorithms for optimizing the cooling cycle, and sensors for monitoring system performance. Advanced control strategies can adapt to varying cooling loads, ambient conditions, and power availability, improving the overall efficiency and reliability of scaled electrocaloric cooling systems while minimizing energy consumption.Expand Specific Solutions

Leading Companies and Research Institutions in Electrocaloric Cooling

The electrocaloric cooling technology market is currently transitioning from early-stage development to commercialization, with significant growth potential as energy-efficient cooling solutions gain importance. The global market for advanced cooling technologies is projected to expand rapidly, driven by data center cooling demands and sustainability initiatives. Major technology players like IBM, Intel, and NVIDIA are investing in electrocaloric research to address thermal management challenges in high-performance computing. Companies such as HP, Carrier, and Vertiv are exploring applications in commercial cooling systems. Academic institutions including National University of Singapore and Oregon State University are contributing fundamental research, while materials specialists like Murata Manufacturing and Oxford Instruments are developing critical components. The technology remains in early commercial maturity, with challenges in scaling from laboratory demonstrations to rack-level implementations requiring collaborative innovation across the ecosystem.

International Business Machines Corp.

Technical Solution: IBM has developed advanced electrocaloric cooling solutions focusing on scalability from chip to rack level. Their approach utilizes specialized ceramic materials with high electrocaloric effect coefficients that respond to applied electric fields by changing temperature. IBM's technology implements a regenerative heat exchange cycle where the electrocaloric material alternately absorbs heat from the cooling target and rejects it to a heat sink. For commercial rack scaling, IBM has designed modular electrocaloric cooling units that can be stacked and integrated into standard server racks, with each module capable of removing up to 180W of heat per U of rack space. Their system incorporates sophisticated control algorithms that optimize the electric field application timing and strength based on real-time cooling demands, achieving coefficient of performance (COP) values exceeding 3.5 in laboratory testing.

Strengths: Superior energy efficiency compared to conventional cooling methods, with potential for 30-40% energy savings. Highly scalable architecture allows seamless integration with existing data center infrastructure. Weaknesses: Requires specialized materials that may have limited commercial availability and higher initial costs compared to conventional cooling technologies.

Intel Corp.

Technical Solution: Intel has pioneered a multi-layered approach to electrocaloric cooling technology specifically designed for high-performance computing environments. Their solution employs thin-film electrocaloric materials deposited directly onto silicon substrates, creating an integrated cooling solution that addresses thermal management at the processor level. Intel's technology utilizes a proprietary blend of relaxor ferroelectric polymers that demonstrate enhanced electrocaloric effects at lower voltages (30-50V) compared to ceramic alternatives. The company has developed a micropump-based heat transfer system that circulates a specialized heat transfer fluid across the electrocaloric elements, efficiently moving heat from the chip to the rack-level cooling infrastructure. Intel's scaling approach involves hierarchical cooling zones that can be independently controlled based on localized thermal loads, allowing for precise thermal management across varied computing workloads. Their latest prototypes have demonstrated cooling capacities of up to 250W/cm² with response times under 10ms, making the technology particularly suitable for handling the transient thermal spikes common in AI and high-performance computing applications.

Strengths: Direct integration with semiconductor manufacturing processes enables highly efficient chip-level cooling. Rapid thermal response capabilities allow for dynamic thermal management during varying workloads. Weaknesses: Current implementations require specialized control electronics that add complexity to the overall system. The technology's performance degrades at extremely high ambient temperatures (>40°C).

Key Patents and Technical Breakthroughs in Electrocaloric Scaling

Electrocaloric cooling with electrostatic actuation

PatentActiveUS11397031B2

Innovation

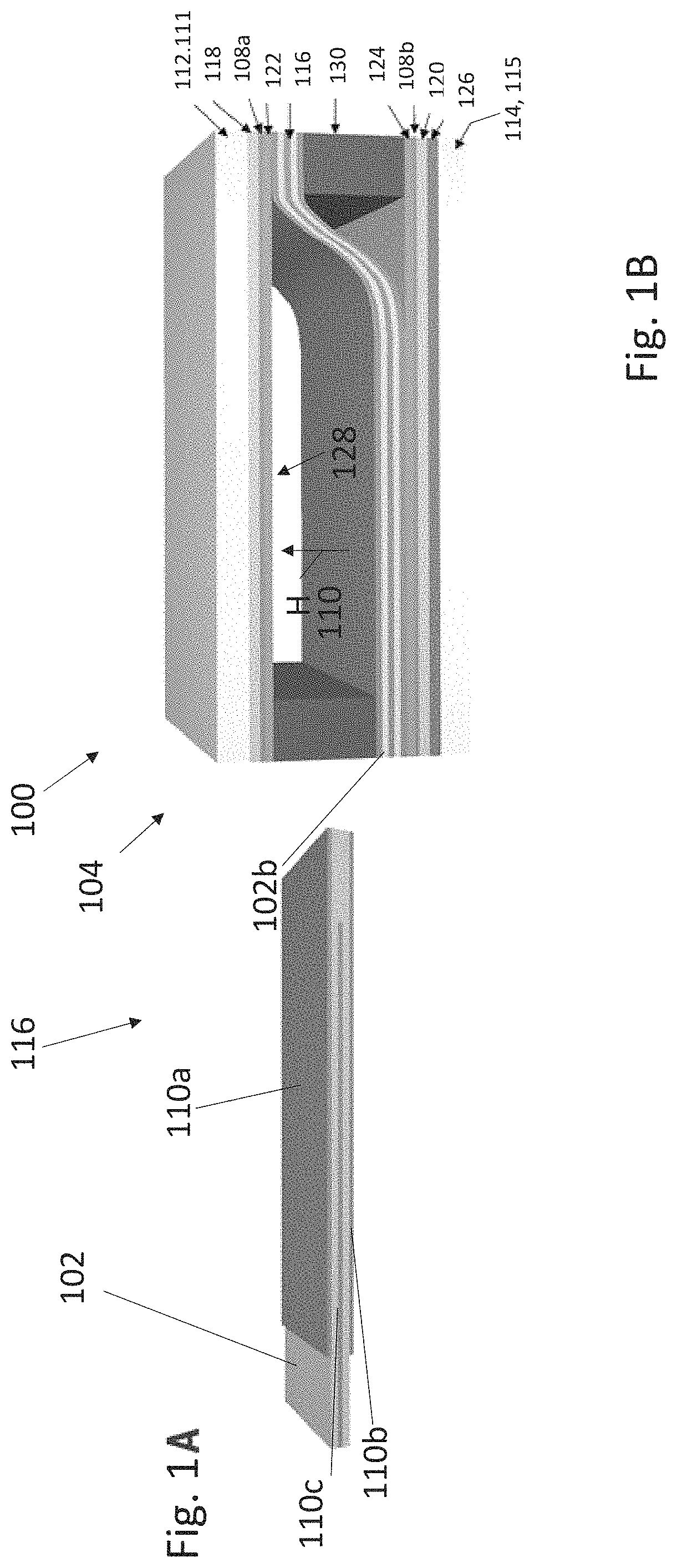

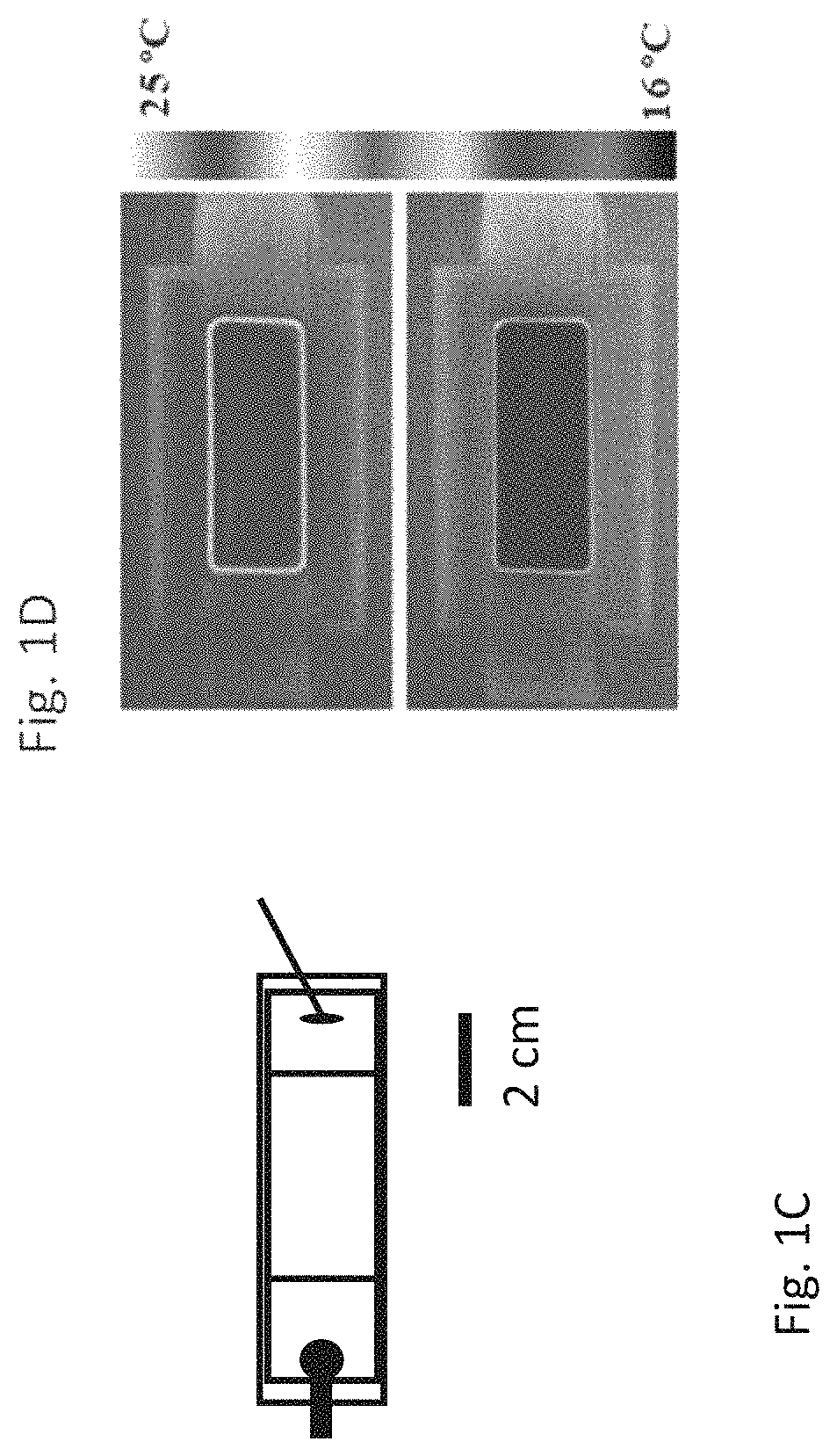

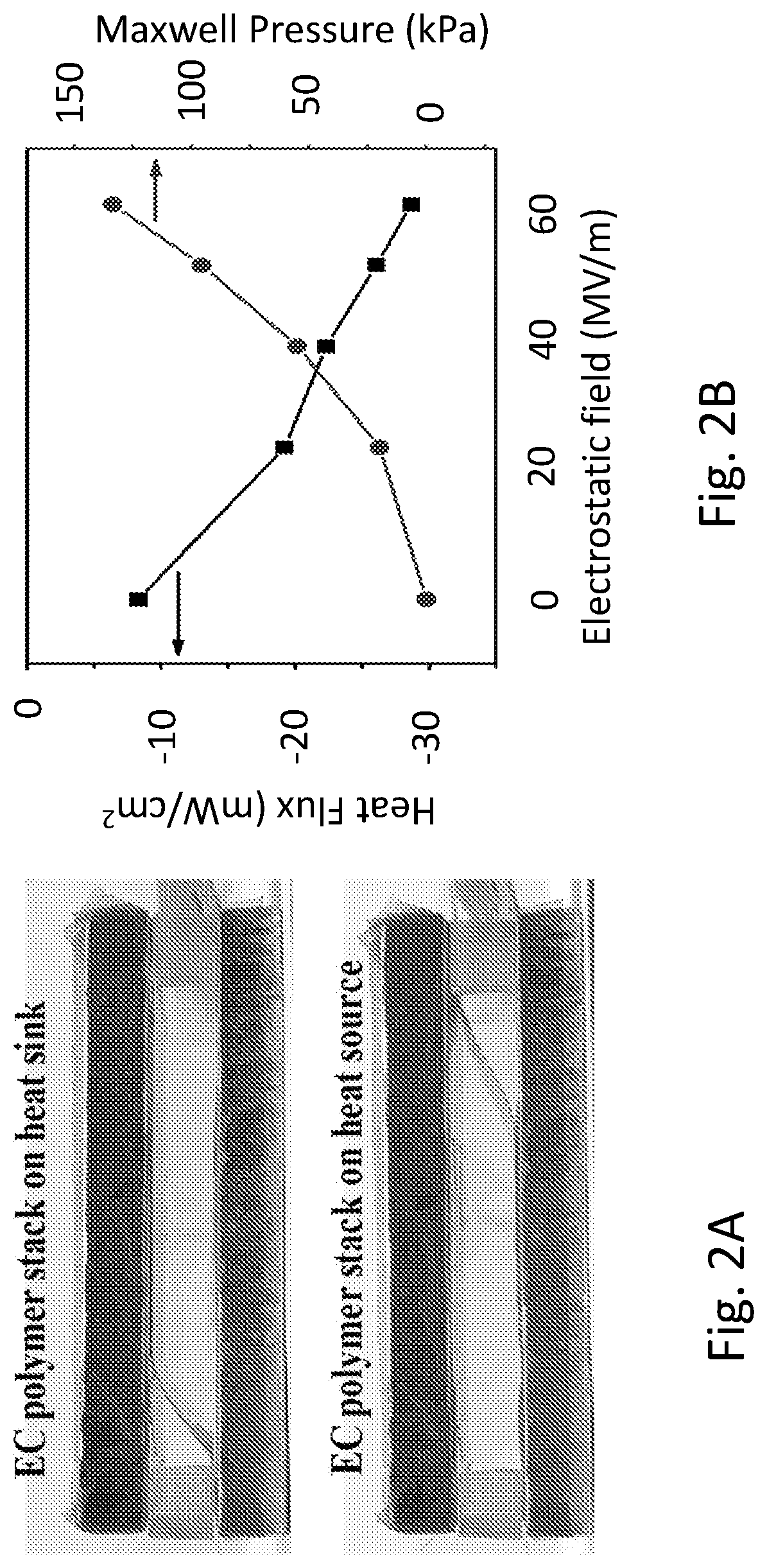

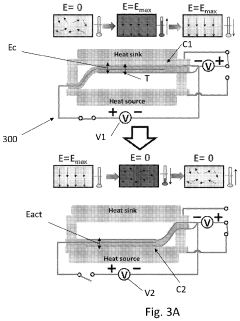

- A solid-state heat transporting device utilizing a flexible electrocaloric polymer film coupled with an electrostatic actuation mechanism, allowing for controlled heat transfer between heat sources and sinks by altering the shape or position of the film to enhance thermal contact and reduce parasitic power consumption.

Solid state electrocaloric cooling devices and methods

PatentWO2006056809A1

Innovation

- A solid-state electrocaloric cooling device with heat switches, comprising electrocaloric elements and thermoelectric or microelectromechanical heat switches, that controls heat transfer through a cascaded or parallel system, utilizing electrical connections to manage the electrocaloric effect for efficient heat management.

Materials Science Advancements for Enhanced Electrocaloric Effect

The advancement of materials science has been pivotal in enhancing the electrocaloric effect, which is fundamental to the development of efficient electrocaloric cooling systems. Recent breakthroughs in material composition and structure have significantly improved the temperature change capabilities of electrocaloric materials, making them more viable for commercial cooling applications.

Ferroelectric polymers, particularly polyvinylidene fluoride (PVDF) and its copolymers, have emerged as promising candidates due to their flexibility, low cost, and substantial electrocaloric response. Research has shown that incorporating nanofillers into these polymers can enhance their electrocaloric properties by increasing polarization and reducing hysteresis losses.

Ceramic-based materials, such as lead zirconate titanate (PZT) and barium titanate (BaTiO3), have also demonstrated remarkable electrocaloric effects near their phase transition temperatures. The development of lead-free alternatives has gained momentum due to environmental concerns, with materials like sodium bismuth titanate showing promising results.

Multilayer composite structures represent another significant advancement, combining different materials to optimize the electrocaloric response while maintaining mechanical stability. These composites often utilize thin film technology to maximize the electric field applied while minimizing the required voltage, a crucial factor for practical device implementation.

Relaxor ferroelectrics have attracted considerable attention due to their broad phase transitions and enhanced electrocaloric response under moderate electric fields. Materials such as PMN-PT (lead magnesium niobate-lead titanate) have demonstrated temperature changes exceeding 12K, approaching the requirements for commercial cooling applications.

Nanoscale engineering of electrocaloric materials has opened new possibilities for performance enhancement. By controlling grain size, domain structure, and interfacial properties, researchers have achieved improved electrocaloric coefficients and reduced energy losses during cycling. This approach has been particularly effective in thin film configurations where surface effects play a dominant role.

The development of materials with reduced hysteresis has been crucial for improving the efficiency of electrocaloric cooling cycles. Novel processing techniques, including field-assisted sintering and epitaxial growth methods, have enabled better control over material microstructure, resulting in more reversible phase transitions and enhanced cooling capacity.

Computational materials science has accelerated the discovery and optimization of electrocaloric materials through high-throughput screening and machine learning approaches. These methods have identified promising material compositions and structural configurations that would have been difficult to discover through traditional experimental methods alone.

Ferroelectric polymers, particularly polyvinylidene fluoride (PVDF) and its copolymers, have emerged as promising candidates due to their flexibility, low cost, and substantial electrocaloric response. Research has shown that incorporating nanofillers into these polymers can enhance their electrocaloric properties by increasing polarization and reducing hysteresis losses.

Ceramic-based materials, such as lead zirconate titanate (PZT) and barium titanate (BaTiO3), have also demonstrated remarkable electrocaloric effects near their phase transition temperatures. The development of lead-free alternatives has gained momentum due to environmental concerns, with materials like sodium bismuth titanate showing promising results.

Multilayer composite structures represent another significant advancement, combining different materials to optimize the electrocaloric response while maintaining mechanical stability. These composites often utilize thin film technology to maximize the electric field applied while minimizing the required voltage, a crucial factor for practical device implementation.

Relaxor ferroelectrics have attracted considerable attention due to their broad phase transitions and enhanced electrocaloric response under moderate electric fields. Materials such as PMN-PT (lead magnesium niobate-lead titanate) have demonstrated temperature changes exceeding 12K, approaching the requirements for commercial cooling applications.

Nanoscale engineering of electrocaloric materials has opened new possibilities for performance enhancement. By controlling grain size, domain structure, and interfacial properties, researchers have achieved improved electrocaloric coefficients and reduced energy losses during cycling. This approach has been particularly effective in thin film configurations where surface effects play a dominant role.

The development of materials with reduced hysteresis has been crucial for improving the efficiency of electrocaloric cooling cycles. Novel processing techniques, including field-assisted sintering and epitaxial growth methods, have enabled better control over material microstructure, resulting in more reversible phase transitions and enhanced cooling capacity.

Computational materials science has accelerated the discovery and optimization of electrocaloric materials through high-throughput screening and machine learning approaches. These methods have identified promising material compositions and structural configurations that would have been difficult to discover through traditional experimental methods alone.

Energy Efficiency Comparison with Conventional Cooling Technologies

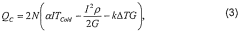

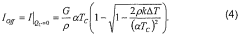

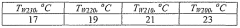

Electrocaloric cooling technology demonstrates significant potential for energy efficiency advantages over conventional cooling methods. When comparing the coefficient of performance (COP), laboratory-scale electrocaloric devices have achieved COPs ranging from 3 to 7, which compares favorably with traditional vapor compression systems that typically operate at COPs between 2 and 4 for similar temperature differentials.

The fundamental energy advantage stems from the direct conversion of electrical energy to thermal energy without intermediate mechanical processes. Conventional vapor compression systems require energy-intensive compressors that introduce significant mechanical losses. In contrast, electrocaloric systems primarily consume electricity for polarizing the electrocaloric material, with minimal mechanical components limited to fluid circulation pumps.

Theoretical analyses indicate that at commercial scale, electrocaloric cooling could reduce energy consumption by 20-30% compared to conventional refrigeration technologies. This efficiency advantage becomes particularly pronounced in applications requiring precise temperature control or rapid thermal cycling, where conventional systems suffer from significant inefficiencies due to thermal inertia.

Power density comparisons also favor electrocaloric technology. Laboratory prototypes have demonstrated cooling power densities exceeding 10 W/cm³, substantially higher than thermoelectric coolers (typically 0.1-1 W/cm³) and comparable to advanced vapor compression systems. This high power density enables more compact cooling solutions with reduced material requirements.

From a lifecycle perspective, electrocaloric systems offer additional efficiency benefits through reduced maintenance requirements. The absence of moving parts in the core cooling mechanism potentially extends operational lifetimes and decreases energy losses associated with component degradation over time. Preliminary lifecycle assessments suggest 15-25% lower total energy consumption over a 10-year operational period.

The scaling of electrocaloric devices from lab chips to commercial racks introduces new efficiency considerations. While smaller devices benefit from rapid heat transfer and minimal thermal gradients, larger commercial systems must address challenges in maintaining uniform electric fields across larger material volumes. Current research indicates that modular designs comprising multiple electrocaloric cells can maintain efficiency while scaling to commercial capacities.

When considering partial-load efficiency, electrocaloric systems demonstrate superior performance compared to conventional cooling technologies. Vapor compression systems typically experience significant efficiency drops at partial loads, while electrocaloric devices maintain near-optimal efficiency across a wider operating range due to their inherent scalability and rapid response characteristics.

The fundamental energy advantage stems from the direct conversion of electrical energy to thermal energy without intermediate mechanical processes. Conventional vapor compression systems require energy-intensive compressors that introduce significant mechanical losses. In contrast, electrocaloric systems primarily consume electricity for polarizing the electrocaloric material, with minimal mechanical components limited to fluid circulation pumps.

Theoretical analyses indicate that at commercial scale, electrocaloric cooling could reduce energy consumption by 20-30% compared to conventional refrigeration technologies. This efficiency advantage becomes particularly pronounced in applications requiring precise temperature control or rapid thermal cycling, where conventional systems suffer from significant inefficiencies due to thermal inertia.

Power density comparisons also favor electrocaloric technology. Laboratory prototypes have demonstrated cooling power densities exceeding 10 W/cm³, substantially higher than thermoelectric coolers (typically 0.1-1 W/cm³) and comparable to advanced vapor compression systems. This high power density enables more compact cooling solutions with reduced material requirements.

From a lifecycle perspective, electrocaloric systems offer additional efficiency benefits through reduced maintenance requirements. The absence of moving parts in the core cooling mechanism potentially extends operational lifetimes and decreases energy losses associated with component degradation over time. Preliminary lifecycle assessments suggest 15-25% lower total energy consumption over a 10-year operational period.

The scaling of electrocaloric devices from lab chips to commercial racks introduces new efficiency considerations. While smaller devices benefit from rapid heat transfer and minimal thermal gradients, larger commercial systems must address challenges in maintaining uniform electric fields across larger material volumes. Current research indicates that modular designs comprising multiple electrocaloric cells can maintain efficiency while scaling to commercial capacities.

When considering partial-load efficiency, electrocaloric systems demonstrate superior performance compared to conventional cooling technologies. Vapor compression systems typically experience significant efficiency drops at partial loads, while electrocaloric devices maintain near-optimal efficiency across a wider operating range due to their inherent scalability and rapid response characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!