Safety And Insulation Requirements For High-Voltage Electrocaloric Cooling Devices

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Voltage Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling technology represents a significant advancement in the field of thermal management, offering a promising alternative to conventional vapor-compression refrigeration systems. This technology harnesses the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to electric fields. The development of electrocaloric cooling dates back to the 1930s when the effect was first discovered, but significant progress has only been made in the past two decades due to advancements in material science and electrical engineering.

The evolution of electrocaloric materials has progressed from early lead-based ceramics to more environmentally friendly options such as polymer-based composites and relaxor ferroelectrics. Recent breakthroughs in thin-film technology have enabled the creation of multilayer capacitor structures that maximize the cooling effect while minimizing the required voltage, though high-voltage requirements remain a significant challenge.

Current research trends focus on developing materials with enhanced electrocaloric coefficients, improving heat transfer mechanisms, and addressing the safety concerns associated with high-voltage operation. The field is witnessing a convergence of materials science, electrical engineering, and thermal management disciplines to overcome existing limitations.

The primary technical objective for high-voltage electrocaloric cooling devices is to achieve commercially viable cooling performance while ensuring operational safety and reliability. Specifically, this entails developing insulation systems capable of withstanding electric fields of 50-100 kV/mm without breakdown, while maintaining thermal conductivity sufficient for effective heat transfer.

Secondary objectives include reducing the operating voltage requirements through novel material formulations and device architectures, enhancing the energy efficiency to surpass conventional cooling technologies, and extending operational lifetimes to meet commercial standards of 10+ years of continuous operation.

Long-term goals for the technology include integration with renewable energy sources to create sustainable cooling solutions, miniaturization for application in electronic device thermal management, and scaling up for industrial and commercial refrigeration applications. The ultimate aim is to establish electrocaloric cooling as a viable, energy-efficient alternative to conventional refrigeration technologies, potentially reducing global energy consumption related to cooling by 20-30%.

The technology trajectory suggests that with continued research into advanced insulation materials and safety systems, high-voltage electrocaloric devices could reach commercial readiness within the next 5-7 years, initially in specialized applications before broader market adoption.

The evolution of electrocaloric materials has progressed from early lead-based ceramics to more environmentally friendly options such as polymer-based composites and relaxor ferroelectrics. Recent breakthroughs in thin-film technology have enabled the creation of multilayer capacitor structures that maximize the cooling effect while minimizing the required voltage, though high-voltage requirements remain a significant challenge.

Current research trends focus on developing materials with enhanced electrocaloric coefficients, improving heat transfer mechanisms, and addressing the safety concerns associated with high-voltage operation. The field is witnessing a convergence of materials science, electrical engineering, and thermal management disciplines to overcome existing limitations.

The primary technical objective for high-voltage electrocaloric cooling devices is to achieve commercially viable cooling performance while ensuring operational safety and reliability. Specifically, this entails developing insulation systems capable of withstanding electric fields of 50-100 kV/mm without breakdown, while maintaining thermal conductivity sufficient for effective heat transfer.

Secondary objectives include reducing the operating voltage requirements through novel material formulations and device architectures, enhancing the energy efficiency to surpass conventional cooling technologies, and extending operational lifetimes to meet commercial standards of 10+ years of continuous operation.

Long-term goals for the technology include integration with renewable energy sources to create sustainable cooling solutions, miniaturization for application in electronic device thermal management, and scaling up for industrial and commercial refrigeration applications. The ultimate aim is to establish electrocaloric cooling as a viable, energy-efficient alternative to conventional refrigeration technologies, potentially reducing global energy consumption related to cooling by 20-30%.

The technology trajectory suggests that with continued research into advanced insulation materials and safety systems, high-voltage electrocaloric devices could reach commercial readiness within the next 5-7 years, initially in specialized applications before broader market adoption.

Market Analysis for Electrocaloric Cooling Solutions

The global market for electrocaloric cooling solutions is experiencing significant growth, driven by increasing demand for energy-efficient and environmentally friendly cooling technologies. The market is projected to reach $2.3 billion by 2030, with a compound annual growth rate of 8.7% from 2023 to 2030. This growth trajectory is primarily fueled by stringent environmental regulations targeting conventional cooling systems that use harmful refrigerants.

High-voltage electrocaloric cooling devices represent a promising segment within this market, offering potential advantages in energy efficiency and system compactness. Current market penetration remains limited, with most applications concentrated in specialized industrial and research settings. However, consumer electronics cooling and automotive climate control systems are emerging as high-potential application areas.

Regional analysis indicates North America and Europe lead in electrocaloric technology adoption, accounting for approximately 65% of the current market share. This dominance stems from robust research infrastructure and favorable regulatory environments promoting green technologies. Asia-Pacific, particularly China and South Korea, is witnessing the fastest growth rate at 12.3% annually, driven by expanding manufacturing capabilities and increasing investment in advanced cooling technologies.

Market segmentation reveals three primary application sectors: consumer electronics (31%), industrial cooling (42%), and automotive systems (18%), with other applications comprising the remaining 9%. The industrial cooling segment currently generates the highest revenue due to early adoption in high-value manufacturing processes where conventional cooling limitations are most pronounced.

Customer demand analysis indicates growing interest in cooling solutions that offer reduced energy consumption, smaller form factors, and elimination of greenhouse gas refrigerants. Safety considerations and insulation requirements for high-voltage operation represent significant market barriers, with surveys showing 73% of potential industrial adopters cite safety concerns as their primary hesitation.

Pricing trends suggest premium positioning for electrocaloric solutions, with current cost-per-watt-of-cooling approximately 3.5 times higher than conventional vapor-compression systems. This premium is expected to decrease to 1.8 times by 2027 as manufacturing scales and technology matures.

Market competition remains relatively concentrated, with established cooling technology companies and specialized startups competing for market share. Strategic partnerships between material science companies and cooling system manufacturers have increased by 45% over the past three years, indicating growing industry collaboration to overcome technical challenges related to high-voltage operation and insulation requirements.

High-voltage electrocaloric cooling devices represent a promising segment within this market, offering potential advantages in energy efficiency and system compactness. Current market penetration remains limited, with most applications concentrated in specialized industrial and research settings. However, consumer electronics cooling and automotive climate control systems are emerging as high-potential application areas.

Regional analysis indicates North America and Europe lead in electrocaloric technology adoption, accounting for approximately 65% of the current market share. This dominance stems from robust research infrastructure and favorable regulatory environments promoting green technologies. Asia-Pacific, particularly China and South Korea, is witnessing the fastest growth rate at 12.3% annually, driven by expanding manufacturing capabilities and increasing investment in advanced cooling technologies.

Market segmentation reveals three primary application sectors: consumer electronics (31%), industrial cooling (42%), and automotive systems (18%), with other applications comprising the remaining 9%. The industrial cooling segment currently generates the highest revenue due to early adoption in high-value manufacturing processes where conventional cooling limitations are most pronounced.

Customer demand analysis indicates growing interest in cooling solutions that offer reduced energy consumption, smaller form factors, and elimination of greenhouse gas refrigerants. Safety considerations and insulation requirements for high-voltage operation represent significant market barriers, with surveys showing 73% of potential industrial adopters cite safety concerns as their primary hesitation.

Pricing trends suggest premium positioning for electrocaloric solutions, with current cost-per-watt-of-cooling approximately 3.5 times higher than conventional vapor-compression systems. This premium is expected to decrease to 1.8 times by 2027 as manufacturing scales and technology matures.

Market competition remains relatively concentrated, with established cooling technology companies and specialized startups competing for market share. Strategic partnerships between material science companies and cooling system manufacturers have increased by 45% over the past three years, indicating growing industry collaboration to overcome technical challenges related to high-voltage operation and insulation requirements.

Technical Challenges in High-Voltage Insulation Systems

High-voltage electrocaloric cooling devices face significant technical challenges in their insulation systems, primarily due to the extreme electrical conditions under which they operate. These devices typically require electric fields exceeding 100 kV/cm to achieve meaningful cooling effects, creating substantial demands on insulation materials and design.

The fundamental challenge lies in preventing electrical breakdown while maintaining thermal efficiency. Traditional insulation materials like ceramics and polymers often fail to provide the necessary combination of high dielectric strength and low thermal resistance required for these applications. When electrical breakdown occurs, it not only compromises device functionality but also poses serious safety hazards including fire risks and potential release of harmful byproducts.

Material degradation presents another critical challenge. High electric fields accelerate aging processes in insulation materials through mechanisms such as partial discharge, electrical treeing, and space charge accumulation. These phenomena progressively weaken the insulation system, reducing operational lifespan and reliability. The cyclical thermal stresses inherent to cooling applications further exacerbate this degradation through expansion and contraction cycles.

Interface management between different materials in the insulation system creates additional complexity. Electric field enhancement at material boundaries can lead to localized breakdown even when individual materials remain within their operational limits. This challenge is particularly pronounced in compact designs where space constraints necessitate sharp edges and transitions between components.

Environmental factors significantly impact insulation performance. Humidity, temperature fluctuations, and contaminants can dramatically reduce breakdown strength and accelerate aging. Designing systems that maintain insulation integrity across varying environmental conditions remains a substantial engineering challenge.

Miniaturization trends compound these difficulties as reducing device dimensions while maintaining voltage levels results in higher field gradients and reduced insulation distances. This scaling problem creates fundamental physical limits that conventional approaches struggle to overcome.

Heat dissipation within the insulation system itself presents a paradoxical challenge for cooling devices. Dielectric losses generate heat that must be managed without compromising the primary cooling function of the device. This requires sophisticated thermal management strategies integrated with the insulation design.

Testing and qualification methodologies for high-voltage insulation in electrocaloric applications remain underdeveloped. Standard test protocols from other industries often fail to adequately represent the unique combination of electrical, thermal, and mechanical stresses these systems experience, creating uncertainty in reliability predictions and safety margins.

The fundamental challenge lies in preventing electrical breakdown while maintaining thermal efficiency. Traditional insulation materials like ceramics and polymers often fail to provide the necessary combination of high dielectric strength and low thermal resistance required for these applications. When electrical breakdown occurs, it not only compromises device functionality but also poses serious safety hazards including fire risks and potential release of harmful byproducts.

Material degradation presents another critical challenge. High electric fields accelerate aging processes in insulation materials through mechanisms such as partial discharge, electrical treeing, and space charge accumulation. These phenomena progressively weaken the insulation system, reducing operational lifespan and reliability. The cyclical thermal stresses inherent to cooling applications further exacerbate this degradation through expansion and contraction cycles.

Interface management between different materials in the insulation system creates additional complexity. Electric field enhancement at material boundaries can lead to localized breakdown even when individual materials remain within their operational limits. This challenge is particularly pronounced in compact designs where space constraints necessitate sharp edges and transitions between components.

Environmental factors significantly impact insulation performance. Humidity, temperature fluctuations, and contaminants can dramatically reduce breakdown strength and accelerate aging. Designing systems that maintain insulation integrity across varying environmental conditions remains a substantial engineering challenge.

Miniaturization trends compound these difficulties as reducing device dimensions while maintaining voltage levels results in higher field gradients and reduced insulation distances. This scaling problem creates fundamental physical limits that conventional approaches struggle to overcome.

Heat dissipation within the insulation system itself presents a paradoxical challenge for cooling devices. Dielectric losses generate heat that must be managed without compromising the primary cooling function of the device. This requires sophisticated thermal management strategies integrated with the insulation design.

Testing and qualification methodologies for high-voltage insulation in electrocaloric applications remain underdeveloped. Standard test protocols from other industries often fail to adequately represent the unique combination of electrical, thermal, and mechanical stresses these systems experience, creating uncertainty in reliability predictions and safety margins.

Current Safety and Insulation Implementation Approaches

01 Electrical insulation and safety mechanisms

Electrocaloric cooling devices require robust electrical insulation to prevent electrical hazards during operation. These devices often operate with high voltages applied to electrocaloric materials, necessitating specialized insulation materials and designs. Safety mechanisms include electrical isolation layers, protective housings, and circuit protection components that prevent electrical leakage and ensure user safety. Advanced insulation techniques help maintain operational efficiency while minimizing electrical risks.- Electrical insulation materials for electrocaloric devices: Specialized electrical insulation materials are crucial for electrocaloric cooling devices to prevent electrical leakage and ensure safe operation. These materials must withstand high electric fields while maintaining thermal conductivity to allow efficient heat transfer. Common insulation approaches include polymer-based dielectrics, ceramic coatings, and composite materials that combine electrical insulation with thermal conductivity properties. Proper insulation design prevents electrical breakdown and protects users from potential electrical hazards.

- Thermal management and safety systems: Electrocaloric cooling devices require robust thermal management systems to handle heat transfer efficiently while maintaining safety. These systems include heat sinks, thermal interfaces, and temperature monitoring sensors that prevent overheating. Safety mechanisms such as automatic shutdown features, thermal fuses, and overcurrent protection are integrated to respond to abnormal operating conditions. Proper thermal management ensures device longevity and prevents safety hazards related to excessive heat generation during operation.

- Encapsulation and sealing techniques: Effective encapsulation and sealing are essential for electrocaloric cooling devices to protect internal components from environmental factors and prevent electrical hazards. Hermetic sealing techniques using specialized polymers, epoxy resins, or glass-to-metal seals help maintain internal conditions while providing electrical isolation. These methods also prevent moisture ingress that could compromise electrical safety. Advanced encapsulation designs incorporate pressure relief mechanisms to handle thermal expansion and contraction during operation cycles.

- High-voltage safety control systems: Electrocaloric devices often operate at high voltages, necessitating sophisticated safety control systems. These include voltage monitoring circuits, isolation transformers, and ground fault interrupters that detect abnormal electrical conditions. Multilayered protection schemes incorporate hardware and software safeguards that prevent user exposure to dangerous voltages. Advanced control algorithms monitor operating parameters in real-time and implement protective measures when unsafe conditions are detected, ensuring both operational reliability and user safety.

- Structural design for electrical isolation: The structural design of electrocaloric cooling devices incorporates specific features to maintain electrical isolation between high-voltage components and user-accessible parts. This includes the use of non-conductive housing materials, double insulation principles, and strategic component placement to maximize clearance and creepage distances. Modular designs separate high and low voltage sections, while protective barriers and shields prevent accidental contact with energized parts. These structural considerations are fundamental to meeting safety standards and preventing electrical accidents.

02 Thermal management and heat transfer safety

Effective thermal management is crucial for both safety and efficiency in electrocaloric cooling systems. These devices incorporate specialized heat transfer mechanisms to safely move heat between components while preventing overheating. Thermal insulation materials and designs are implemented to control heat flow paths, reduce thermal losses, and maintain temperature gradients. Safety features include thermal sensors, heat sinks, and thermal interface materials that prevent component damage from excessive temperatures during operation.Expand Specific Solutions03 Structural design for mechanical safety

The structural design of electrocaloric cooling devices incorporates mechanical safety features to ensure durability and reliability. These designs include robust housings, vibration dampening systems, and structural reinforcements that protect sensitive electrocaloric components. Mechanical safety considerations address issues such as thermal expansion, mechanical stress during cycling, and physical protection from environmental factors. Advanced materials and manufacturing techniques are employed to enhance mechanical integrity while maintaining cooling performance.Expand Specific Solutions04 Control systems and fail-safe mechanisms

Sophisticated control systems are integrated into electrocaloric cooling devices to monitor operating parameters and implement fail-safe mechanisms. These systems include sensors for temperature, voltage, current, and pressure monitoring, along with microcontrollers that can detect abnormal conditions. Fail-safe mechanisms automatically shut down the system or reduce power when unsafe conditions are detected. Advanced control algorithms optimize performance while maintaining operation within safe parameters, preventing damage to the device and ensuring user safety.Expand Specific Solutions05 Material selection for safety and insulation

The selection of materials for electrocaloric cooling devices is critical for both safety and insulation performance. High-performance dielectric materials with excellent electrical insulation properties are used for the electrocaloric elements. Specialized polymers, ceramics, and composite materials are employed for their combined thermal and electrical insulation characteristics. Materials must withstand repeated electrothermal cycling while maintaining their insulating properties. Safety considerations in material selection include low toxicity, fire resistance, and long-term stability under operational conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The high-voltage electrocaloric cooling technology market is currently in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market size is projected to expand as energy efficiency demands increase, particularly in automotive and industrial applications. Leading automotive manufacturers (BMW, Mercedes-Benz, Audi) are exploring this technology for electric vehicle thermal management, while industrial giants (Siemens, GE, TDK) focus on developing insulation materials and safety systems. Academic-industry partnerships are accelerating innovation, with institutions like University of Maryland collaborating with companies like Nascent Devices, which specializes in electrocaloric cooling systems. Technical challenges around high-voltage insulation and safety requirements remain significant barriers to widespread adoption, with companies like Hitachi Energy and State Grid developing specialized solutions for electrical isolation and thermal management.

Siemens AG

Technical Solution: Siemens has developed comprehensive safety and insulation solutions for high-voltage electrocaloric cooling devices through their advanced materials engineering approach. Their technology utilizes multi-layer ceramic insulation systems with specialized polymer composites that maintain dielectric strength at operating voltages exceeding 1000V while managing the thermal cycling inherent in electrocaloric applications. The system incorporates active monitoring through integrated temperature and leakage current sensors that provide real-time diagnostics and fault detection capabilities. Siemens' approach includes proprietary high-temperature resistant insulation materials that maintain performance integrity across the extreme temperature gradients (often exceeding 40°C) experienced in electrocaloric cooling cycles. Their safety architecture implements redundant isolation barriers with defined breakdown paths to ensure predictable failure modes that prioritize user safety in case of insulation compromise.

Strengths: Extensive experience in high-voltage systems integration and industrial safety standards compliance. Their solutions benefit from decades of expertise in power engineering and insulation technologies for extreme environments. Weaknesses: Their systems tend to be more costly than competitors and may be overengineered for smaller-scale electrocaloric applications, potentially limiting adoption in consumer markets.

Hitachi Energy Ltd.

Technical Solution: Hitachi Energy has pioneered advanced insulation systems specifically designed for high-voltage electrocaloric cooling applications, focusing on safety-critical environments. Their technology employs nano-enhanced composite insulation materials that maintain dielectric strength under the high electric fields (typically 50-100 kV/mm) required for effective electrocaloric effects while withstanding the mechanical stresses from thermal cycling. The company has developed a proprietary vacuum-pressure impregnation process that eliminates air voids in the insulation matrix, significantly reducing partial discharge risks that typically accelerate insulation aging. Their safety architecture incorporates multi-stage protection with fast-acting electronic disconnection systems that can detect insulation degradation before catastrophic failure occurs. Hitachi's cooling device insulation systems feature self-healing polymer technologies that can temporarily maintain integrity after minor electrical breakdown events, extending operational life while maintaining safety parameters.

Strengths: Exceptional material science capabilities and extensive experience with high-voltage insulation in demanding environments like power transmission systems. Their solutions demonstrate excellent long-term reliability under thermal cycling conditions. Weaknesses: Implementation complexity requires specialized manufacturing processes, potentially increasing production costs and limiting scalability for mass-market applications.

Key Patents in High-Voltage Electrocaloric Insulation

High-voltage device

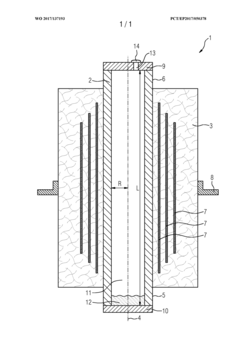

PatentWO2017137193A1

Innovation

- Determining the minimum volume of cooling liquid based on the waveguide's inner circumference and length (V = c*U*L) and optionally applying a safety factor to ensure sufficient evaporating vapor, while considering the inner surface profile and evacuating the interior to prevent contamination, with a preferred volume range that allows for efficient cooling without excessive weight or liquid overflow.

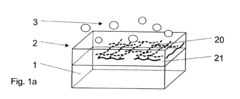

High-voltage insulation device

PatentInactiveEP1150313A2

Innovation

- A high-voltage insulation system utilizing cellulose fibers impregnated with polymer resin, combined with an electrically insulating coolant like liquid nitrogen, and press plates for mechanical support, allowing for improved thermal expansion matching and enhanced mechanical stability, along with a method that eliminates the need for drying and prevents resin layer formation between press plates.

Regulatory Compliance Framework for Cooling Technologies

The regulatory landscape for high-voltage electrocaloric cooling devices is complex and multifaceted, requiring compliance with various international, national, and industry-specific standards. At the international level, the International Electrotechnical Commission (IEC) provides overarching guidelines through standards such as IEC 60335 for household appliances and IEC 61010 for laboratory equipment, which establish baseline safety requirements for high-voltage applications.

In the United States, regulatory oversight falls primarily under the jurisdiction of the Occupational Safety and Health Administration (OSHA) and the Consumer Product Safety Commission (CPSC). OSHA standard 1910.303 specifically addresses electrical safety requirements in workplaces, while the National Electrical Code (NEC/NFPA 70) provides comprehensive guidelines for electrical installations, including specific provisions for high-voltage systems exceeding 600V.

The European Union enforces compliance through the Low Voltage Directive (2014/35/EU) and the Machinery Directive (2006/42/EC), which mandate CE marking for products entering the European market. These directives are supplemented by harmonized standards such as EN 60204-1 for electrical equipment of machines and EN 60664 for insulation coordination.

For electrocaloric cooling technologies specifically, the emerging nature of this technology has created regulatory gaps that manufacturers must navigate carefully. The unique combination of high voltage requirements (often exceeding 1000V) and thermal management considerations necessitates compliance with both electrical safety and refrigeration standards, such as ISO 5149 and EN 378 for refrigerating systems and heat pumps.

Insulation requirements present particular challenges, as electrocaloric materials must maintain dielectric strength across varying temperature gradients. UL 1577 and IEC 60747-5 provide guidance on insulation testing methodologies, while IEC 60085 establishes thermal classification systems for electrical insulation materials that must be considered in design.

Environmental regulations also impact compliance frameworks, with the F-Gas Regulation in Europe and EPA regulations in the US restricting traditional refrigerants. This regulatory pressure creates opportunities for electrocaloric technologies as potentially more environmentally friendly alternatives, provided they can demonstrate compliance with electrical safety requirements.

Certification pathways for novel cooling technologies typically involve third-party testing laboratories such as UL, TÜV, and SGS, which can provide necessary safety certifications. However, the absence of specific standards for electrocaloric devices often requires manufacturers to demonstrate compliance through risk assessment methodologies outlined in ISO 12100 and IEC/ISO 31010.

In the United States, regulatory oversight falls primarily under the jurisdiction of the Occupational Safety and Health Administration (OSHA) and the Consumer Product Safety Commission (CPSC). OSHA standard 1910.303 specifically addresses electrical safety requirements in workplaces, while the National Electrical Code (NEC/NFPA 70) provides comprehensive guidelines for electrical installations, including specific provisions for high-voltage systems exceeding 600V.

The European Union enforces compliance through the Low Voltage Directive (2014/35/EU) and the Machinery Directive (2006/42/EC), which mandate CE marking for products entering the European market. These directives are supplemented by harmonized standards such as EN 60204-1 for electrical equipment of machines and EN 60664 for insulation coordination.

For electrocaloric cooling technologies specifically, the emerging nature of this technology has created regulatory gaps that manufacturers must navigate carefully. The unique combination of high voltage requirements (often exceeding 1000V) and thermal management considerations necessitates compliance with both electrical safety and refrigeration standards, such as ISO 5149 and EN 378 for refrigerating systems and heat pumps.

Insulation requirements present particular challenges, as electrocaloric materials must maintain dielectric strength across varying temperature gradients. UL 1577 and IEC 60747-5 provide guidance on insulation testing methodologies, while IEC 60085 establishes thermal classification systems for electrical insulation materials that must be considered in design.

Environmental regulations also impact compliance frameworks, with the F-Gas Regulation in Europe and EPA regulations in the US restricting traditional refrigerants. This regulatory pressure creates opportunities for electrocaloric technologies as potentially more environmentally friendly alternatives, provided they can demonstrate compliance with electrical safety requirements.

Certification pathways for novel cooling technologies typically involve third-party testing laboratories such as UL, TÜV, and SGS, which can provide necessary safety certifications. However, the absence of specific standards for electrocaloric devices often requires manufacturers to demonstrate compliance through risk assessment methodologies outlined in ISO 12100 and IEC/ISO 31010.

Risk Assessment Methodologies for High-Voltage Applications

Risk assessment for high-voltage electrocaloric cooling devices requires systematic methodologies to identify, evaluate, and mitigate potential hazards. Traditional risk assessment frameworks such as FMEA (Failure Mode and Effects Analysis), HAZOP (Hazard and Operability Study), and FTA (Fault Tree Analysis) provide foundational approaches that can be adapted specifically for electrocaloric applications operating at high voltages.

FMEA methodology proves particularly valuable for electrocaloric cooling systems by systematically identifying potential failure modes in components such as electrodes, dielectric materials, and insulation systems. This approach assigns risk priority numbers based on severity, occurrence probability, and detection difficulty, enabling prioritized risk management for these novel cooling technologies.

HAZOP studies focus on process deviations in electrocaloric systems, examining parameters like voltage fluctuations, thermal cycling effects, and dielectric breakdown scenarios. By analyzing deviation causes and consequences, this methodology helps establish robust safety protocols specific to the unique operational characteristics of electrocaloric cooling devices.

Quantitative risk assessment techniques incorporate probabilistic safety analysis (PSA) and event tree analysis to model complex failure scenarios in high-voltage electrocaloric applications. These methods calculate failure probabilities across different operational conditions, providing statistical foundations for safety margin determinations and insulation requirements.

Industry-specific standards adaptation represents another critical methodology component. IEC 60664 (insulation coordination), IEC 61010 (measurement equipment safety), and IEEE 1584 (arc flash hazard calculations) can be modified to address the unique challenges of electrocaloric cooling technologies, establishing appropriate clearance distances, creepage requirements, and insulation specifications.

Real-time monitoring methodologies complement traditional assessment approaches by implementing continuous diagnostic systems that detect insulation degradation, partial discharges, and thermal anomalies. These systems utilize machine learning algorithms to identify potential failure patterns before catastrophic events occur, particularly important for novel technologies with limited field experience.

Accelerated aging test protocols constitute another essential methodology component, subjecting electrocaloric materials and insulation systems to extreme conditions that simulate years of operational stress. These tests evaluate long-term reliability under combined electrical, thermal, and mechanical stresses, providing critical data for lifetime predictions and maintenance scheduling.

Human factors analysis methodologies assess operator interaction risks with high-voltage electrocaloric systems, examining interface design, emergency procedures, and maintenance protocols. This approach ensures that human error potential is minimized through appropriate training, clear documentation, and intuitive control systems designed specifically for these advanced cooling technologies.

FMEA methodology proves particularly valuable for electrocaloric cooling systems by systematically identifying potential failure modes in components such as electrodes, dielectric materials, and insulation systems. This approach assigns risk priority numbers based on severity, occurrence probability, and detection difficulty, enabling prioritized risk management for these novel cooling technologies.

HAZOP studies focus on process deviations in electrocaloric systems, examining parameters like voltage fluctuations, thermal cycling effects, and dielectric breakdown scenarios. By analyzing deviation causes and consequences, this methodology helps establish robust safety protocols specific to the unique operational characteristics of electrocaloric cooling devices.

Quantitative risk assessment techniques incorporate probabilistic safety analysis (PSA) and event tree analysis to model complex failure scenarios in high-voltage electrocaloric applications. These methods calculate failure probabilities across different operational conditions, providing statistical foundations for safety margin determinations and insulation requirements.

Industry-specific standards adaptation represents another critical methodology component. IEC 60664 (insulation coordination), IEC 61010 (measurement equipment safety), and IEEE 1584 (arc flash hazard calculations) can be modified to address the unique challenges of electrocaloric cooling technologies, establishing appropriate clearance distances, creepage requirements, and insulation specifications.

Real-time monitoring methodologies complement traditional assessment approaches by implementing continuous diagnostic systems that detect insulation degradation, partial discharges, and thermal anomalies. These systems utilize machine learning algorithms to identify potential failure patterns before catastrophic events occur, particularly important for novel technologies with limited field experience.

Accelerated aging test protocols constitute another essential methodology component, subjecting electrocaloric materials and insulation systems to extreme conditions that simulate years of operational stress. These tests evaluate long-term reliability under combined electrical, thermal, and mechanical stresses, providing critical data for lifetime predictions and maintenance scheduling.

Human factors analysis methodologies assess operator interaction risks with high-voltage electrocaloric systems, examining interface design, emergency procedures, and maintenance protocols. This approach ensures that human error potential is minimized through appropriate training, clear documentation, and intuitive control systems designed specifically for these advanced cooling technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!