Modeling Electrocaloric Device Efficiency For Electrocaloric Cooling Under Real-World Loads

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling technology represents a promising alternative to conventional vapor-compression refrigeration systems, offering potential advantages in energy efficiency, environmental friendliness, and system miniaturization. The technology leverages the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. This effect was first discovered in the 1930s but remained largely unexplored until recent decades due to limitations in material science and engineering capabilities.

The evolution of electrocaloric cooling technology has accelerated significantly since the early 2000s, marked by breakthrough discoveries of giant electrocaloric effects in ferroelectric thin films and relaxor ferroelectric materials. These advancements have sparked renewed interest in developing practical cooling applications based on this principle. The technology has progressed from theoretical concepts to laboratory prototypes, with increasing focus on improving efficiency, reliability, and scalability.

Current research trends indicate a shift toward developing composite materials with enhanced electrocaloric properties, optimizing device architectures for heat transfer, and creating more sophisticated control systems to manage the cooling cycles. The integration of advanced manufacturing techniques, such as 3D printing and nanofabrication, has further expanded the possibilities for creating efficient electrocaloric cooling devices.

The primary technical objective in modeling electrocaloric device efficiency under real-world loads is to bridge the gap between laboratory performance and practical application requirements. This involves developing comprehensive models that accurately predict system behavior under variable thermal loads, different operating conditions, and extended duty cycles. Such models must account for material fatigue, thermal hysteresis, electrical losses, and heat transfer limitations that may not be apparent in idealized laboratory settings.

Another critical objective is to establish standardized metrics and testing protocols for evaluating electrocaloric cooling performance. This standardization would facilitate meaningful comparisons between different technological approaches and accelerate the identification of the most promising pathways for further development.

The long-term goal of this technology is to achieve cooling efficiencies that surpass conventional vapor-compression systems while eliminating the use of environmentally harmful refrigerants. Additionally, researchers aim to develop compact, lightweight, and silent cooling solutions that can be integrated into various applications, from personal electronics to building climate control systems and even specialized medical devices.

As the global demand for energy-efficient cooling solutions continues to grow, electrocaloric technology stands at a pivotal juncture where theoretical understanding must be translated into practical engineering solutions capable of addressing real-world cooling challenges.

The evolution of electrocaloric cooling technology has accelerated significantly since the early 2000s, marked by breakthrough discoveries of giant electrocaloric effects in ferroelectric thin films and relaxor ferroelectric materials. These advancements have sparked renewed interest in developing practical cooling applications based on this principle. The technology has progressed from theoretical concepts to laboratory prototypes, with increasing focus on improving efficiency, reliability, and scalability.

Current research trends indicate a shift toward developing composite materials with enhanced electrocaloric properties, optimizing device architectures for heat transfer, and creating more sophisticated control systems to manage the cooling cycles. The integration of advanced manufacturing techniques, such as 3D printing and nanofabrication, has further expanded the possibilities for creating efficient electrocaloric cooling devices.

The primary technical objective in modeling electrocaloric device efficiency under real-world loads is to bridge the gap between laboratory performance and practical application requirements. This involves developing comprehensive models that accurately predict system behavior under variable thermal loads, different operating conditions, and extended duty cycles. Such models must account for material fatigue, thermal hysteresis, electrical losses, and heat transfer limitations that may not be apparent in idealized laboratory settings.

Another critical objective is to establish standardized metrics and testing protocols for evaluating electrocaloric cooling performance. This standardization would facilitate meaningful comparisons between different technological approaches and accelerate the identification of the most promising pathways for further development.

The long-term goal of this technology is to achieve cooling efficiencies that surpass conventional vapor-compression systems while eliminating the use of environmentally harmful refrigerants. Additionally, researchers aim to develop compact, lightweight, and silent cooling solutions that can be integrated into various applications, from personal electronics to building climate control systems and even specialized medical devices.

As the global demand for energy-efficient cooling solutions continues to grow, electrocaloric technology stands at a pivotal juncture where theoretical understanding must be translated into practical engineering solutions capable of addressing real-world cooling challenges.

Market Analysis for Electrocaloric Cooling Solutions

The global cooling market is experiencing a significant shift towards more energy-efficient and environmentally friendly technologies, creating a substantial opportunity for electrocaloric cooling solutions. The conventional cooling market, dominated by vapor-compression systems, is valued at approximately $135 billion globally and is projected to grow at a compound annual growth rate of 5.7% through 2028.

Electrocaloric cooling represents a disruptive technology within this space, offering potential advantages in energy efficiency, reduced environmental impact, and design flexibility. Market research indicates that the specialized advanced cooling technologies segment, which includes electrocaloric systems, is growing at nearly twice the rate of conventional cooling technologies, driven by stringent energy regulations and sustainability goals across major economies.

Commercial applications for electrocaloric cooling solutions span multiple sectors. The electronics cooling market presents immediate opportunities, particularly for high-performance computing, data centers, and telecommunications infrastructure where thermal management challenges are becoming increasingly critical. This segment alone represents a $15 billion addressable market with growth rates exceeding 8% annually.

Building HVAC systems constitute another substantial market opportunity, valued at over $90 billion globally. As energy efficiency standards become more stringent worldwide, technologies that can demonstrate significant efficiency improvements under variable real-world loads are positioned to capture market share. Electrocaloric cooling's potential for higher coefficient of performance under partial load conditions makes it particularly attractive in this application space.

The automotive sector represents a third significant market opportunity, especially with the rapid growth of electric vehicles. Thermal management systems for EVs require more sophisticated approaches than traditional internal combustion vehicles, creating a new market estimated at $4.3 billion with projected growth rates of 12-15% annually through 2030.

Consumer appliances, particularly refrigeration, represent a fourth major market segment with global value exceeding $40 billion. While price sensitivity in this market presents challenges for new technology adoption, premium segments focused on energy efficiency and environmental performance offer entry points for electrocaloric solutions.

Market adoption barriers include cost premiums associated with new technology implementation, integration challenges with existing systems, and limited awareness among potential end-users. However, regulatory drivers including phase-downs of hydrofluorocarbon refrigerants and increasingly stringent energy efficiency standards are creating favorable conditions for alternative cooling technologies like electrocaloric systems.

Electrocaloric cooling represents a disruptive technology within this space, offering potential advantages in energy efficiency, reduced environmental impact, and design flexibility. Market research indicates that the specialized advanced cooling technologies segment, which includes electrocaloric systems, is growing at nearly twice the rate of conventional cooling technologies, driven by stringent energy regulations and sustainability goals across major economies.

Commercial applications for electrocaloric cooling solutions span multiple sectors. The electronics cooling market presents immediate opportunities, particularly for high-performance computing, data centers, and telecommunications infrastructure where thermal management challenges are becoming increasingly critical. This segment alone represents a $15 billion addressable market with growth rates exceeding 8% annually.

Building HVAC systems constitute another substantial market opportunity, valued at over $90 billion globally. As energy efficiency standards become more stringent worldwide, technologies that can demonstrate significant efficiency improvements under variable real-world loads are positioned to capture market share. Electrocaloric cooling's potential for higher coefficient of performance under partial load conditions makes it particularly attractive in this application space.

The automotive sector represents a third significant market opportunity, especially with the rapid growth of electric vehicles. Thermal management systems for EVs require more sophisticated approaches than traditional internal combustion vehicles, creating a new market estimated at $4.3 billion with projected growth rates of 12-15% annually through 2030.

Consumer appliances, particularly refrigeration, represent a fourth major market segment with global value exceeding $40 billion. While price sensitivity in this market presents challenges for new technology adoption, premium segments focused on energy efficiency and environmental performance offer entry points for electrocaloric solutions.

Market adoption barriers include cost premiums associated with new technology implementation, integration challenges with existing systems, and limited awareness among potential end-users. However, regulatory drivers including phase-downs of hydrofluorocarbon refrigerants and increasingly stringent energy efficiency standards are creating favorable conditions for alternative cooling technologies like electrocaloric systems.

Technical Challenges in Electrocaloric Device Efficiency

Electrocaloric (EC) cooling technology faces significant technical challenges that impede its widespread adoption and commercialization. One of the primary obstacles is the limited temperature change (ΔT) achievable in current EC materials, typically ranging from 2-12K under practical electric fields. This constraint severely restricts the cooling capacity and efficiency of EC devices, particularly when operating under real-world thermal loads that demand greater temperature differentials.

Material limitations present another substantial hurdle. The most promising EC materials, such as lead-based relaxor ferroelectrics and polymer ferroelectrics, exhibit trade-offs between EC effect magnitude, operational temperature range, and material stability. Lead-based materials raise environmental and regulatory concerns, while polymer alternatives often suffer from lower EC coefficients, necessitating higher driving voltages that increase system complexity and energy consumption.

The development of accurate and comprehensive modeling frameworks represents a critical challenge. Current models often fail to account for the complex interplay between thermal, electrical, and mechanical properties under dynamic operating conditions. This modeling gap leads to significant discrepancies between theoretical predictions and experimental results, particularly when simulating device performance under variable thermal loads and cycling frequencies.

Heat transfer management within EC systems presents formidable engineering challenges. The rapid and efficient transfer of heat between the EC material and heat exchangers is essential for maximizing cooling power density. However, thermal contact resistance, thermal mass mismatch, and heat transfer fluid limitations often create bottlenecks that reduce overall system efficiency. These issues become particularly pronounced under transient operating conditions typical of real-world applications.

Energy efficiency optimization remains problematic, especially regarding the recovery of electrical energy during the EC cycle. While theoretical models suggest potential for high coefficient of performance (COP), practical implementations struggle to achieve these values due to electrical losses, parasitic heat flows, and inefficient energy recovery circuits. The development of advanced power electronics specifically tailored for EC applications lags behind material development.

Scaling challenges persist when transitioning from laboratory prototypes to commercially viable systems. As device dimensions increase, issues related to electric field uniformity, thermal gradients, and mechanical stress distribution become more pronounced. These scaling effects often lead to reduced performance and reliability in larger systems, limiting the practical cooling capacity achievable in commercial applications.

Reliability and durability concerns further complicate EC technology development. EC materials subjected to repeated electrical and thermal cycling often exhibit degradation in performance over time. Fatigue effects, electrical breakdown, and mechanical failure mechanisms are not well understood, particularly under the variable operating conditions encountered in real-world cooling applications.

Material limitations present another substantial hurdle. The most promising EC materials, such as lead-based relaxor ferroelectrics and polymer ferroelectrics, exhibit trade-offs between EC effect magnitude, operational temperature range, and material stability. Lead-based materials raise environmental and regulatory concerns, while polymer alternatives often suffer from lower EC coefficients, necessitating higher driving voltages that increase system complexity and energy consumption.

The development of accurate and comprehensive modeling frameworks represents a critical challenge. Current models often fail to account for the complex interplay between thermal, electrical, and mechanical properties under dynamic operating conditions. This modeling gap leads to significant discrepancies between theoretical predictions and experimental results, particularly when simulating device performance under variable thermal loads and cycling frequencies.

Heat transfer management within EC systems presents formidable engineering challenges. The rapid and efficient transfer of heat between the EC material and heat exchangers is essential for maximizing cooling power density. However, thermal contact resistance, thermal mass mismatch, and heat transfer fluid limitations often create bottlenecks that reduce overall system efficiency. These issues become particularly pronounced under transient operating conditions typical of real-world applications.

Energy efficiency optimization remains problematic, especially regarding the recovery of electrical energy during the EC cycle. While theoretical models suggest potential for high coefficient of performance (COP), practical implementations struggle to achieve these values due to electrical losses, parasitic heat flows, and inefficient energy recovery circuits. The development of advanced power electronics specifically tailored for EC applications lags behind material development.

Scaling challenges persist when transitioning from laboratory prototypes to commercially viable systems. As device dimensions increase, issues related to electric field uniformity, thermal gradients, and mechanical stress distribution become more pronounced. These scaling effects often lead to reduced performance and reliability in larger systems, limiting the practical cooling capacity achievable in commercial applications.

Reliability and durability concerns further complicate EC technology development. EC materials subjected to repeated electrical and thermal cycling often exhibit degradation in performance over time. Fatigue effects, electrical breakdown, and mechanical failure mechanisms are not well understood, particularly under the variable operating conditions encountered in real-world cooling applications.

Current Modeling Approaches for Electrocaloric Device Efficiency

01 Material selection for electrocaloric efficiency

The choice of materials significantly impacts the efficiency of electrocaloric devices. Certain materials exhibit stronger electrocaloric effects, leading to better cooling performance. Advanced materials such as relaxor ferroelectrics, polymer-based composites, and multilayer structures can enhance the temperature change per applied voltage. Optimizing material composition and structure can lead to improved energy conversion efficiency and higher cooling capacity in electrocaloric cooling systems.- Electrocaloric material selection for improved efficiency: The choice of electrocaloric materials significantly impacts device efficiency. Materials with high electrocaloric coefficients, such as certain ferroelectric polymers and relaxor ferroelectrics, can generate larger temperature changes with smaller applied electric fields. Advanced composite materials and multilayer structures can enhance the electrocaloric effect while reducing energy losses. Optimizing material properties like polarization response, electrical resistance, and thermal conductivity is crucial for maximizing the efficiency of electrocaloric cooling devices.

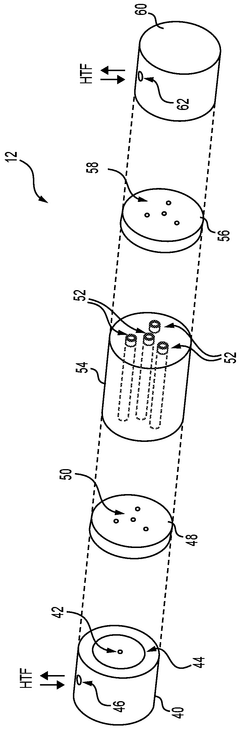

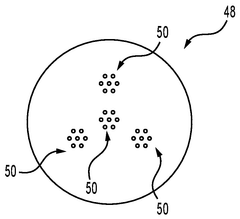

- Thermal management and heat transfer optimization: Efficient heat transfer mechanisms are essential for electrocaloric device performance. This includes optimizing thermal interfaces between the electrocaloric material and heat exchangers, implementing advanced heat sink designs, and creating effective thermal pathways. Reducing thermal resistance and minimizing parasitic heat loads improves the coefficient of performance. Innovative heat transfer fluids and thermal switching mechanisms can significantly enhance the overall system efficiency by enabling rapid cycling and effective heat extraction from the electrocaloric elements.

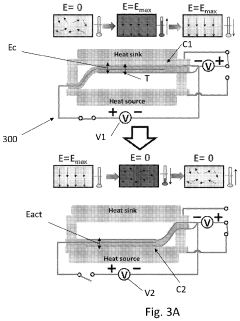

- Cycle design and operation optimization: The thermodynamic cycle design significantly affects electrocaloric device efficiency. Optimizing operational parameters such as electric field strength, cycling frequency, and duty cycles can maximize cooling power while minimizing energy consumption. Advanced cycle configurations, including regenerative cycles and cascaded systems, can improve performance. Implementing precise timing control for electric field application and removal, along with optimized heat transfer sequencing, enhances the coefficient of performance and reduces energy losses during operation.

- Electric field application and control strategies: Sophisticated electric field control strategies are crucial for electrocaloric device efficiency. This includes implementing variable field strengths, optimized waveforms, and precise timing to maximize the electrocaloric effect while minimizing electrical losses. Advanced power electronics with high efficiency and low parasitic losses improve overall system performance. Implementing feedback control systems that adjust field parameters based on operating conditions and load requirements can significantly enhance energy efficiency and system responsiveness.

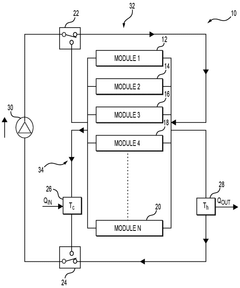

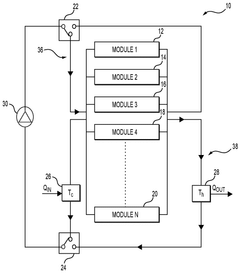

- Device architecture and system integration: The physical design and integration of electrocaloric devices significantly impact efficiency. Multilayer structures, miniaturization techniques, and advanced manufacturing methods can reduce thermal and electrical losses. Optimizing the geometry and arrangement of electrocaloric elements improves heat transfer and electric field distribution. Integrating complementary technologies such as regenerative heat exchangers, thermal diodes, and energy recovery systems enhances overall system efficiency. Modular designs that allow for scalability while maintaining high performance are particularly valuable for commercial applications.

02 Thermal management and heat transfer optimization

Efficient heat transfer mechanisms are crucial for maximizing the performance of electrocaloric devices. This includes optimizing heat exchange surfaces, implementing advanced thermal interfaces, and designing efficient heat sink structures. Proper thermal management ensures that the heat generated during the electrocaloric effect is effectively transferred away from the active elements, preventing performance degradation. Techniques such as fluid-based heat transfer systems and thermally conductive interfaces can significantly improve the overall efficiency of electrocaloric cooling devices.Expand Specific Solutions03 Cycle design and operation optimization

The efficiency of electrocaloric devices heavily depends on the design and optimization of their operating cycles. This includes parameters such as voltage application timing, cycle frequency, and duty cycles. Advanced control algorithms can dynamically adjust these parameters based on cooling demand and operating conditions. Regenerative cycles and cascaded systems can further enhance efficiency by recovering energy and maximizing temperature differentials. Proper cycle design minimizes energy losses and maximizes the cooling effect per unit of electrical input.Expand Specific Solutions04 System integration and device architecture

The overall architecture of electrocaloric devices plays a critical role in their efficiency. This includes the physical arrangement of electrocaloric elements, electrical connections, and supporting components. Multilayer designs, miniaturization techniques, and integrated cooling systems can significantly improve performance. Advanced manufacturing methods such as 3D printing and microfabrication enable more efficient device geometries. Proper system integration ensures that all components work together optimally, reducing energy losses at interfaces and maximizing overall system efficiency.Expand Specific Solutions05 Power electronics and control systems

Sophisticated power electronics and control systems are essential for maximizing the efficiency of electrocaloric devices. This includes high-efficiency voltage converters, precise timing circuits, and adaptive control algorithms. Minimizing electrical losses during voltage application and removal directly impacts overall system efficiency. Advanced sensing and feedback mechanisms allow for real-time optimization based on operating conditions and cooling demands. Smart control systems can balance performance and energy consumption, leading to more efficient operation across varying conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Electrocaloric Cooling

The electrocaloric cooling technology market is currently in an early growth phase, characterized by intensive research and development rather than widespread commercialization. The market size remains relatively modest but is projected to expand significantly as energy-efficient cooling solutions gain traction. Technologically, electrocaloric cooling is still maturing, with academic institutions like Nankai University, University of Maryland, and Harvard College leading fundamental research, while commercial entities including Hitachi, Toshiba, and Qingdao Haier are advancing practical applications. Research organizations such as Fraunhofer-Gesellschaft and SRI International are bridging the gap between theoretical advancements and commercial viability. The technology shows particular promise in specialized cooling applications where conventional methods face efficiency limitations, with major players focusing on improving device efficiency under real-world conditions.

The Regents of the University of California

Technical Solution: The University of California has developed comprehensive multiphysics modeling frameworks for electrocaloric cooling systems that integrate thermal, electrical, and mechanical domains. Their approach combines finite element analysis with thermodynamic modeling to simulate real-world cooling loads and transient responses. They've created advanced computational models that account for temperature-dependent material properties, heat transfer coefficients, and electrical field distributions across electrocaloric elements. Their research has demonstrated cycle-resolved simulations that predict coefficient of performance (COP) values exceeding 5 under variable cooling loads, representing significant improvements over conventional vapor compression systems. The university has also pioneered experimental validation techniques using custom-built test beds that measure actual device performance against model predictions with error margins below 10%.

Strengths: Strong interdisciplinary approach combining materials science, thermodynamics, and computational modeling; extensive experimental validation capabilities; access to advanced characterization facilities. Weaknesses: Academic research may face challenges in scaling to commercial applications; potential gaps between theoretical models and manufacturing realities.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed sophisticated electrocaloric cooling models that incorporate multiscale simulation techniques. Their approach integrates molecular dynamics at the material level with system-scale thermodynamic modeling to capture the full complexity of electrocaloric effects under varying load conditions. CEA's models uniquely account for the coupling between electrical polarization dynamics and thermal transport phenomena, enabling accurate prediction of cooling power density across different operating regimes. Their research has demonstrated the ability to model temperature lifts of 3-5K in multilayer ceramic capacitor (MLCC) based devices while accounting for Joule heating effects and electrical losses. The models incorporate advanced control algorithms that optimize switching frequencies and field strengths based on instantaneous cooling demand, significantly improving overall system efficiency.

Strengths: World-class expertise in materials physics and computational modeling; strong integration between fundamental research and application-oriented development; extensive experience with energy conversion systems. Weaknesses: Models may require significant computational resources; some approaches may be more theoretical than immediately implementable in commercial products.

Key Patents and Research in Electrocaloric Cooling Systems

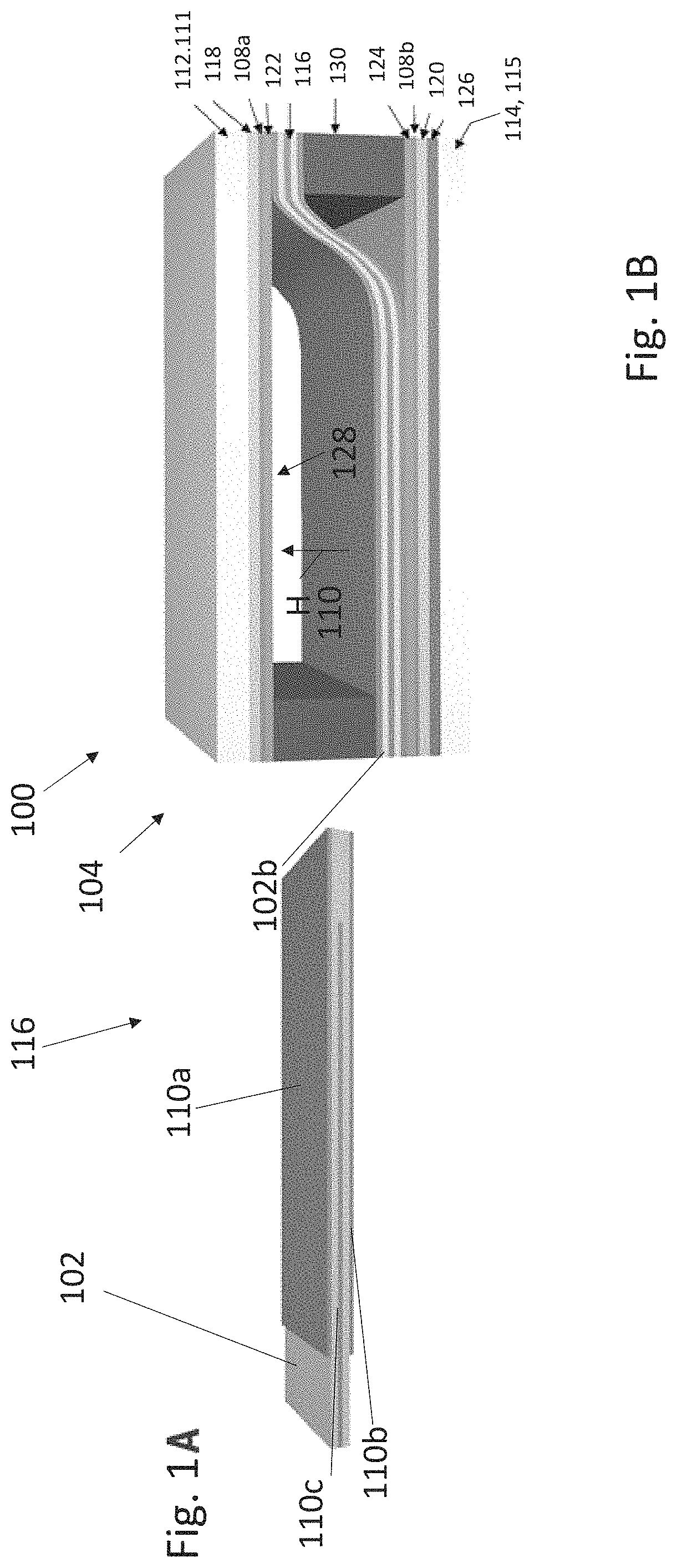

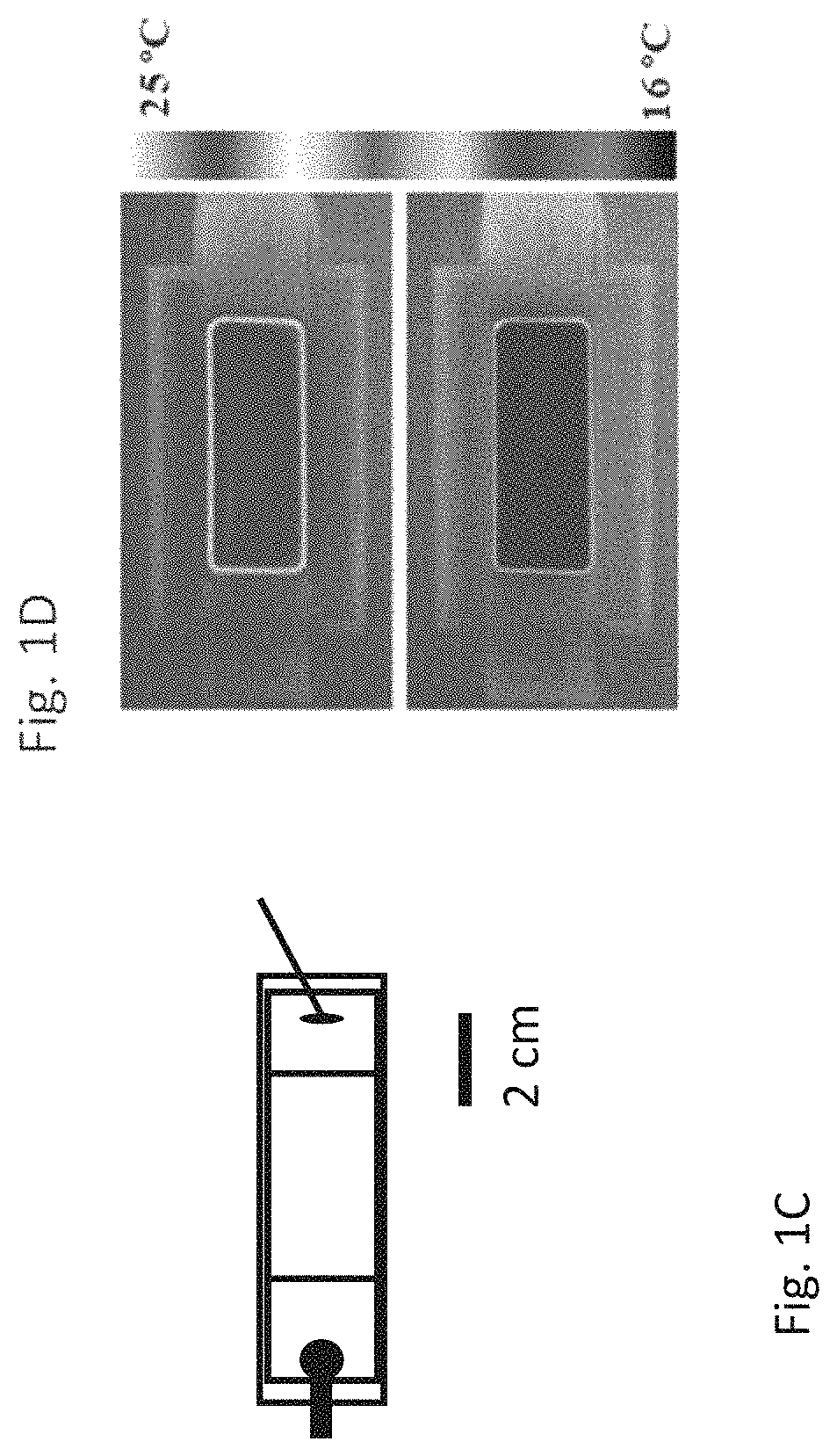

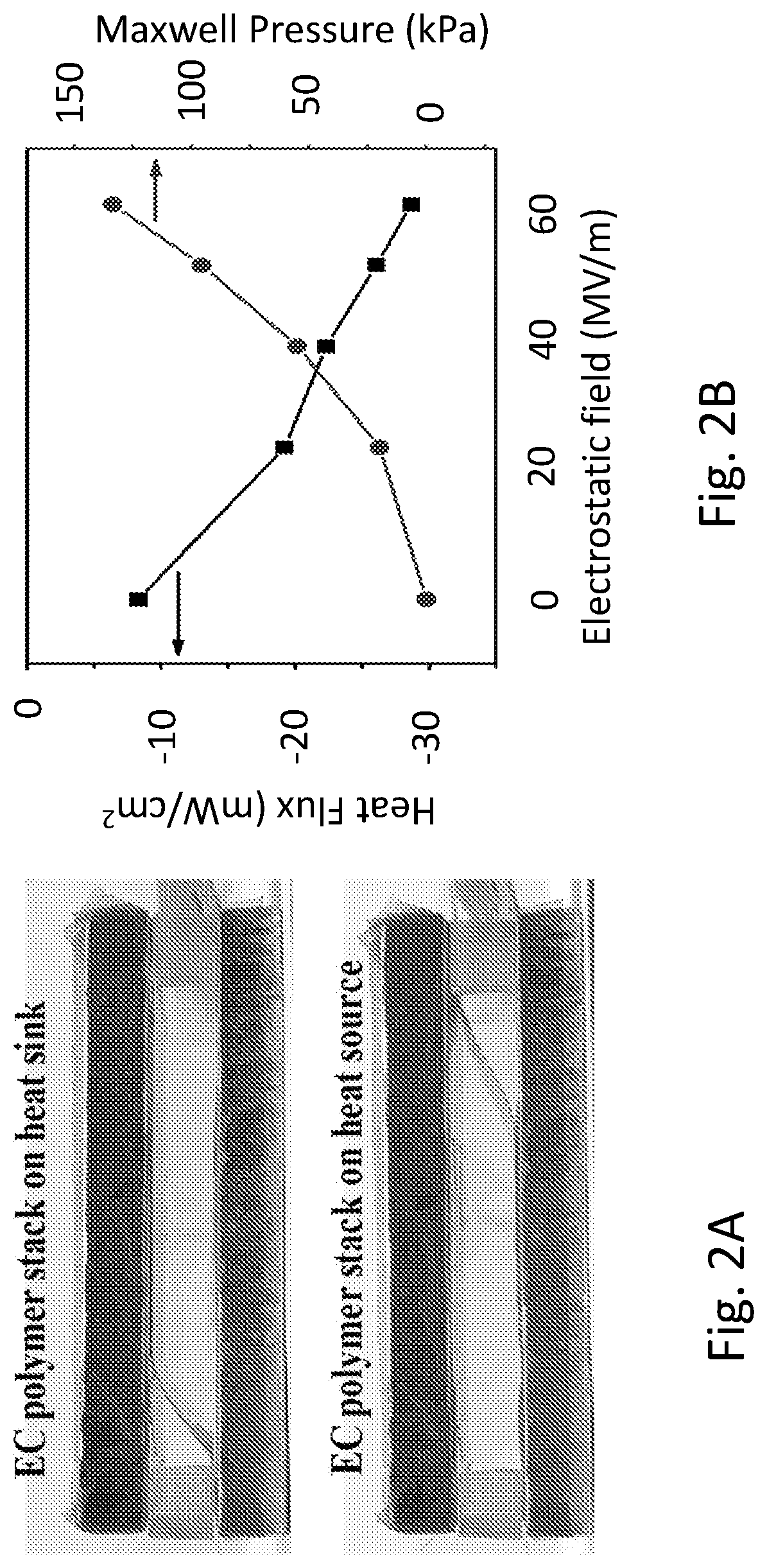

Electrocaloric cooling with electrostatic actuation

PatentActiveUS11397031B2

Innovation

- A solid-state heat transporting device utilizing a flexible electrocaloric polymer film coupled with an electrostatic actuation mechanism, allowing for controlled heat transfer between heat sources and sinks by altering the shape or position of the film to enhance thermal contact and reduce parasitic power consumption.

Elastocaloric cooling device

PatentWO2025152734A1

Innovation

- An elastocaloric cooling device utilizing shape memory alloy tubes embedded in a retainer, driven by a pump with a cyclic alternating fluid flow, connected in parallel to enhance thermal energy conversion.

Environmental Impact and Sustainability of Electrocaloric Cooling

Electrocaloric cooling technology represents a significant advancement in sustainable thermal management systems, offering potential environmental benefits compared to conventional vapor-compression refrigeration. The environmental impact assessment of electrocaloric cooling reveals several promising sustainability advantages that align with global efforts to reduce greenhouse gas emissions and minimize ecological footprints.

The primary environmental benefit of electrocaloric cooling stems from its elimination of refrigerants with high global warming potential (GWP). Traditional cooling systems rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to climate change when leaked. Electrocaloric systems, operating on solid-state principles, require no such refrigerants, thereby eliminating direct emissions associated with refrigerant leakage throughout the device lifecycle.

Energy efficiency represents another critical environmental dimension of electrocaloric cooling technology. Current modeling of electrocaloric device efficiency under real-world loads suggests potential energy savings of 15-30% compared to conventional systems, particularly when operating under partial load conditions. This efficiency translates directly to reduced electricity consumption and lower indirect carbon emissions from power generation, especially significant considering that cooling accounts for approximately 10% of global electricity consumption.

Material sustainability considerations present both challenges and opportunities for electrocaloric cooling systems. The technology currently relies on specialized materials including lead-based ceramics and polymers containing fluorine. Life cycle assessments indicate that manufacturing processes for these materials can have significant environmental impacts. However, recent research directions focus on developing lead-free alternatives and environmentally benign polymer compositions that maintain high electrocaloric coefficients while reducing ecological footprints.

End-of-life management represents an emerging consideration in electrocaloric technology sustainability. Unlike conventional cooling systems with complex recovery requirements for refrigerants, electrocaloric devices potentially offer simpler recycling pathways. The solid-state nature of these systems facilitates material recovery, though specialized recycling infrastructure would need development to maximize resource recirculation and minimize waste.

Water conservation benefits also emerge from electrocaloric cooling implementations. Unlike traditional cooling towers that consume significant water resources through evaporation, electrocaloric systems operate as closed systems without water consumption. This characteristic becomes increasingly valuable in water-stressed regions where conventional cooling technologies place additional pressure on limited water resources.

The environmental sustainability profile of electrocaloric cooling aligns with global regulatory trends toward more stringent environmental standards for cooling technologies. As efficiency modeling continues to advance under real-world load conditions, the technology positions itself as a promising contributor to sustainable development goals related to climate action, responsible consumption, and energy efficiency.

The primary environmental benefit of electrocaloric cooling stems from its elimination of refrigerants with high global warming potential (GWP). Traditional cooling systems rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to climate change when leaked. Electrocaloric systems, operating on solid-state principles, require no such refrigerants, thereby eliminating direct emissions associated with refrigerant leakage throughout the device lifecycle.

Energy efficiency represents another critical environmental dimension of electrocaloric cooling technology. Current modeling of electrocaloric device efficiency under real-world loads suggests potential energy savings of 15-30% compared to conventional systems, particularly when operating under partial load conditions. This efficiency translates directly to reduced electricity consumption and lower indirect carbon emissions from power generation, especially significant considering that cooling accounts for approximately 10% of global electricity consumption.

Material sustainability considerations present both challenges and opportunities for electrocaloric cooling systems. The technology currently relies on specialized materials including lead-based ceramics and polymers containing fluorine. Life cycle assessments indicate that manufacturing processes for these materials can have significant environmental impacts. However, recent research directions focus on developing lead-free alternatives and environmentally benign polymer compositions that maintain high electrocaloric coefficients while reducing ecological footprints.

End-of-life management represents an emerging consideration in electrocaloric technology sustainability. Unlike conventional cooling systems with complex recovery requirements for refrigerants, electrocaloric devices potentially offer simpler recycling pathways. The solid-state nature of these systems facilitates material recovery, though specialized recycling infrastructure would need development to maximize resource recirculation and minimize waste.

Water conservation benefits also emerge from electrocaloric cooling implementations. Unlike traditional cooling towers that consume significant water resources through evaporation, electrocaloric systems operate as closed systems without water consumption. This characteristic becomes increasingly valuable in water-stressed regions where conventional cooling technologies place additional pressure on limited water resources.

The environmental sustainability profile of electrocaloric cooling aligns with global regulatory trends toward more stringent environmental standards for cooling technologies. As efficiency modeling continues to advance under real-world load conditions, the technology positions itself as a promising contributor to sustainable development goals related to climate action, responsible consumption, and energy efficiency.

Real-World Application Scenarios and Performance Metrics

Electrocaloric cooling technology must be evaluated in diverse real-world application scenarios to determine its practical viability. In residential settings, electrocaloric cooling systems face variable thermal loads influenced by daily temperature fluctuations, occupancy patterns, and seasonal changes. These systems must maintain comfortable indoor temperatures (typically 20-25°C) while handling peak loads during extreme weather conditions, which can be 2-3 times higher than average loads.

Commercial applications present different challenges, with larger cooling capacities required for office buildings, retail spaces, and data centers. In these environments, electrocaloric systems must manage high-density heat loads (150-300 W/m² in data centers) and demonstrate reliability during extended operation periods. The ability to scale cooling capacity efficiently becomes a critical performance metric in these scenarios.

Automotive applications represent another significant market, where electrocaloric cooling must function under rapidly changing ambient conditions (-20°C to 50°C) and varying passenger loads. For electric vehicles, the technology must achieve a coefficient of performance (COP) exceeding 3.0 to minimize battery drain while maintaining cabin comfort and battery thermal management.

Performance metrics for evaluating electrocaloric cooling systems across these applications include energy efficiency ratio (EER), which should exceed 12 Btu/Wh to compete with conventional systems. System response time is equally important, with target values under 5 minutes for residential applications and under 2 minutes for automotive use cases. Cooling capacity density (W/cm³) serves as a key metric for space-constrained applications, with targets of 2-5 W/cm³ necessary for competitive implementation.

Reliability metrics include mean time between failures (MTBF), which should exceed 50,000 hours for residential and commercial applications. Operational lifetime expectations range from 10-15 years, requiring materials and components that maintain performance stability over thousands of thermal cycles. Temperature control precision (±0.5°C for residential, ±0.2°C for specialized applications) represents another critical performance parameter.

Cost-effectiveness metrics include initial system cost (target: $200-300 per kW cooling capacity), operational costs (target: 15-25% reduction compared to conventional systems), and maintenance requirements. These economic factors significantly influence market adoption potential across different application scenarios and must be carefully balanced against technical performance metrics.

Commercial applications present different challenges, with larger cooling capacities required for office buildings, retail spaces, and data centers. In these environments, electrocaloric systems must manage high-density heat loads (150-300 W/m² in data centers) and demonstrate reliability during extended operation periods. The ability to scale cooling capacity efficiently becomes a critical performance metric in these scenarios.

Automotive applications represent another significant market, where electrocaloric cooling must function under rapidly changing ambient conditions (-20°C to 50°C) and varying passenger loads. For electric vehicles, the technology must achieve a coefficient of performance (COP) exceeding 3.0 to minimize battery drain while maintaining cabin comfort and battery thermal management.

Performance metrics for evaluating electrocaloric cooling systems across these applications include energy efficiency ratio (EER), which should exceed 12 Btu/Wh to compete with conventional systems. System response time is equally important, with target values under 5 minutes for residential applications and under 2 minutes for automotive use cases. Cooling capacity density (W/cm³) serves as a key metric for space-constrained applications, with targets of 2-5 W/cm³ necessary for competitive implementation.

Reliability metrics include mean time between failures (MTBF), which should exceed 50,000 hours for residential and commercial applications. Operational lifetime expectations range from 10-15 years, requiring materials and components that maintain performance stability over thousands of thermal cycles. Temperature control precision (±0.5°C for residential, ±0.2°C for specialized applications) represents another critical performance parameter.

Cost-effectiveness metrics include initial system cost (target: $200-300 per kW cooling capacity), operational costs (target: 15-25% reduction compared to conventional systems), and maintenance requirements. These economic factors significantly influence market adoption potential across different application scenarios and must be carefully balanced against technical performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!