Model-Based Design Optimization For Electrocaloric Cooling Systems

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling technology represents a promising alternative to conventional vapor-compression refrigeration systems, offering potential advantages in energy efficiency, environmental impact, and system design flexibility. The technology leverages the electrocaloric effect, a thermodynamic phenomenon where certain materials exhibit temperature changes when subjected to varying electric fields. This effect was first discovered in the 1930s but remained largely unexplored for practical cooling applications until recent decades.

The evolution of electrocaloric cooling technology has been marked by significant advancements in material science, particularly in the development of ferroelectric and antiferroelectric materials with enhanced electrocaloric properties. Early research focused primarily on lead-based ceramics, while recent efforts have expanded to include lead-free alternatives, polymer-based materials, and multilayer composites to address environmental concerns and improve performance characteristics.

Current technological trajectories indicate a growing interest in integrating electrocaloric materials into practical cooling devices through innovative system designs. The field has witnessed a transition from theoretical studies to experimental prototypes, with increasing emphasis on optimizing the thermal transfer mechanisms and electrical control systems necessary for efficient operation.

The primary technical objectives for electrocaloric cooling systems include achieving higher temperature differentials, improving energy efficiency metrics, enhancing material durability under cyclic operation, and developing scalable manufacturing processes. Researchers aim to demonstrate cooling capacities comparable to conventional technologies while maintaining the unique advantages of solid-state operation.

Model-based design optimization emerges as a critical approach to accelerate the development of electrocaloric cooling systems by enabling systematic exploration of complex design spaces. These computational models integrate multiphysics simulations spanning electrostatics, thermodynamics, fluid dynamics, and structural mechanics to predict system performance under various operating conditions.

The ultimate goal of current research efforts is to establish electrocaloric technology as a viable alternative to conventional cooling methods, particularly in applications where size constraints, noise limitations, or environmental considerations are paramount. This includes potential implementations in electronics cooling, domestic refrigeration, building climate control, and specialized medical or scientific equipment.

Achieving these objectives requires addressing fundamental challenges related to material properties, heat transfer efficiency, electrical power management, and system integration. The interdisciplinary nature of these challenges necessitates collaboration across materials science, thermal engineering, electronics, and computational modeling domains to realize the full potential of electrocaloric cooling technology.

The evolution of electrocaloric cooling technology has been marked by significant advancements in material science, particularly in the development of ferroelectric and antiferroelectric materials with enhanced electrocaloric properties. Early research focused primarily on lead-based ceramics, while recent efforts have expanded to include lead-free alternatives, polymer-based materials, and multilayer composites to address environmental concerns and improve performance characteristics.

Current technological trajectories indicate a growing interest in integrating electrocaloric materials into practical cooling devices through innovative system designs. The field has witnessed a transition from theoretical studies to experimental prototypes, with increasing emphasis on optimizing the thermal transfer mechanisms and electrical control systems necessary for efficient operation.

The primary technical objectives for electrocaloric cooling systems include achieving higher temperature differentials, improving energy efficiency metrics, enhancing material durability under cyclic operation, and developing scalable manufacturing processes. Researchers aim to demonstrate cooling capacities comparable to conventional technologies while maintaining the unique advantages of solid-state operation.

Model-based design optimization emerges as a critical approach to accelerate the development of electrocaloric cooling systems by enabling systematic exploration of complex design spaces. These computational models integrate multiphysics simulations spanning electrostatics, thermodynamics, fluid dynamics, and structural mechanics to predict system performance under various operating conditions.

The ultimate goal of current research efforts is to establish electrocaloric technology as a viable alternative to conventional cooling methods, particularly in applications where size constraints, noise limitations, or environmental considerations are paramount. This includes potential implementations in electronics cooling, domestic refrigeration, building climate control, and specialized medical or scientific equipment.

Achieving these objectives requires addressing fundamental challenges related to material properties, heat transfer efficiency, electrical power management, and system integration. The interdisciplinary nature of these challenges necessitates collaboration across materials science, thermal engineering, electronics, and computational modeling domains to realize the full potential of electrocaloric cooling technology.

Market Analysis for Sustainable Cooling Solutions

The global cooling market is experiencing a significant shift towards sustainable solutions, driven by increasing environmental concerns and stringent regulations on conventional cooling technologies. The electrocaloric cooling systems market, though nascent, is positioned to capture a substantial share of this evolving landscape due to its energy efficiency and reduced environmental impact compared to traditional vapor-compression systems.

Current market analysis indicates that the conventional cooling sector, valued at approximately $135 billion globally, is under pressure to transition to more sustainable alternatives. Electrocaloric cooling technology represents a promising segment within the broader sustainable cooling solutions market, which is growing at a compound annual rate of 8.2% and expected to reach $300 billion by 2030.

Consumer demand for environmentally friendly cooling solutions has surged, particularly in developed regions where environmental regulations are most stringent. Corporate sustainability initiatives and government incentives further accelerate this market transformation. The commercial building sector represents the largest potential market for electrocaloric cooling systems, followed by residential applications and specialized industrial cooling requirements.

Regional market analysis reveals varying adoption patterns. North America and Europe lead in early adoption due to stronger environmental regulations and higher consumer willingness to pay premium prices for sustainable technologies. The Asia-Pacific region, while currently dominated by conventional cooling systems, shows the highest growth potential due to rapid urbanization, increasing disposable incomes, and growing environmental awareness.

Market barriers for electrocaloric cooling systems include higher initial costs compared to conventional systems, limited awareness among potential end-users, and competition from other emerging sustainable cooling technologies such as magnetocaloric and thermoelectric systems. However, the superior energy efficiency of electrocaloric systems (potentially 30-40% more efficient than conventional systems) provides a compelling long-term value proposition.

Industry forecasts suggest that as manufacturing scales up and technology matures, production costs will decrease significantly, making electrocaloric cooling systems increasingly competitive. The market is expected to reach an inflection point around 2026-2027, after which adoption rates are projected to accelerate substantially.

Strategic partnerships between technology developers, manufacturing entities, and distribution channels will be crucial for market penetration. Early market entry strategies should focus on premium segments where energy efficiency and environmental benefits can command price premiums, gradually expanding to mass-market applications as economies of scale improve cost competitiveness.

Current market analysis indicates that the conventional cooling sector, valued at approximately $135 billion globally, is under pressure to transition to more sustainable alternatives. Electrocaloric cooling technology represents a promising segment within the broader sustainable cooling solutions market, which is growing at a compound annual rate of 8.2% and expected to reach $300 billion by 2030.

Consumer demand for environmentally friendly cooling solutions has surged, particularly in developed regions where environmental regulations are most stringent. Corporate sustainability initiatives and government incentives further accelerate this market transformation. The commercial building sector represents the largest potential market for electrocaloric cooling systems, followed by residential applications and specialized industrial cooling requirements.

Regional market analysis reveals varying adoption patterns. North America and Europe lead in early adoption due to stronger environmental regulations and higher consumer willingness to pay premium prices for sustainable technologies. The Asia-Pacific region, while currently dominated by conventional cooling systems, shows the highest growth potential due to rapid urbanization, increasing disposable incomes, and growing environmental awareness.

Market barriers for electrocaloric cooling systems include higher initial costs compared to conventional systems, limited awareness among potential end-users, and competition from other emerging sustainable cooling technologies such as magnetocaloric and thermoelectric systems. However, the superior energy efficiency of electrocaloric systems (potentially 30-40% more efficient than conventional systems) provides a compelling long-term value proposition.

Industry forecasts suggest that as manufacturing scales up and technology matures, production costs will decrease significantly, making electrocaloric cooling systems increasingly competitive. The market is expected to reach an inflection point around 2026-2027, after which adoption rates are projected to accelerate substantially.

Strategic partnerships between technology developers, manufacturing entities, and distribution channels will be crucial for market penetration. Early market entry strategies should focus on premium segments where energy efficiency and environmental benefits can command price premiums, gradually expanding to mass-market applications as economies of scale improve cost competitiveness.

Current State and Challenges in Electrocaloric System Design

Electrocaloric cooling systems represent a promising alternative to conventional vapor compression refrigeration technologies, offering potential advantages in energy efficiency, environmental impact, and form factor flexibility. Currently, the global research landscape shows significant advancements in material science and system design, though commercial viability remains elusive due to several technical challenges.

The state-of-the-art in electrocaloric materials has progressed substantially, with lead-based relaxor ferroelectrics demonstrating temperature changes of 2-12K under electric fields of 50-150 kV/cm. Polymer-based materials like P(VDF-TrFE) copolymers have shown comparable performance with better mechanical properties. However, these materials still fall short of the performance metrics required for competitive cooling systems, particularly in terms of temperature lift and cooling power density.

System design approaches have evolved from early proof-of-concept demonstrations to more sophisticated active regenerative cycles. Current designs predominantly utilize either fluid-based heat transfer mechanisms or solid-state thermal switches. The fluid-based systems offer higher heat transfer coefficients but face challenges in fluid containment and pumping efficiency. Solid-state designs eliminate moving parts but struggle with thermal contact resistance and cycle frequency limitations.

Computational modeling of electrocaloric systems has advanced significantly, with multi-physics models now capable of simulating coupled electro-thermal-mechanical phenomena. However, these models often rely on simplified material constitutive relationships that fail to capture the full complexity of electrocaloric effects, particularly near phase transitions or under cyclic loading conditions.

Key technical challenges include the limited temperature span achievable in single-stage systems, which typically ranges from 5-15K—insufficient for most practical applications. The cooling power density remains below 100 W/cm³, far from the 300-500 W/cm³ needed for competitive commercial systems. Additionally, the high driving voltages (>1000V) present safety concerns and complicate electronic control system design.

Material degradation under cyclic electric field application represents another significant hurdle, with performance decay observed after 10⁴-10⁶ cycles in many materials. This falls short of the 10⁸-10⁹ cycles required for practical cooling applications with reasonable service lifetimes.

Geographically, research leadership is distributed across North America, Europe, and East Asia, with the United States and China demonstrating the highest publication output. European institutions lead in fundamental materials research, while U.S. and Chinese groups focus more on system integration and practical device development.

The gap between laboratory demonstrations and commercially viable systems remains substantial, with current prototypes achieving coefficients of performance (COP) of 1-3, compared to 3-5 for conventional vapor compression systems. Bridging this performance gap requires integrated optimization approaches that simultaneously address material properties, heat transfer mechanisms, and system architecture.

The state-of-the-art in electrocaloric materials has progressed substantially, with lead-based relaxor ferroelectrics demonstrating temperature changes of 2-12K under electric fields of 50-150 kV/cm. Polymer-based materials like P(VDF-TrFE) copolymers have shown comparable performance with better mechanical properties. However, these materials still fall short of the performance metrics required for competitive cooling systems, particularly in terms of temperature lift and cooling power density.

System design approaches have evolved from early proof-of-concept demonstrations to more sophisticated active regenerative cycles. Current designs predominantly utilize either fluid-based heat transfer mechanisms or solid-state thermal switches. The fluid-based systems offer higher heat transfer coefficients but face challenges in fluid containment and pumping efficiency. Solid-state designs eliminate moving parts but struggle with thermal contact resistance and cycle frequency limitations.

Computational modeling of electrocaloric systems has advanced significantly, with multi-physics models now capable of simulating coupled electro-thermal-mechanical phenomena. However, these models often rely on simplified material constitutive relationships that fail to capture the full complexity of electrocaloric effects, particularly near phase transitions or under cyclic loading conditions.

Key technical challenges include the limited temperature span achievable in single-stage systems, which typically ranges from 5-15K—insufficient for most practical applications. The cooling power density remains below 100 W/cm³, far from the 300-500 W/cm³ needed for competitive commercial systems. Additionally, the high driving voltages (>1000V) present safety concerns and complicate electronic control system design.

Material degradation under cyclic electric field application represents another significant hurdle, with performance decay observed after 10⁴-10⁶ cycles in many materials. This falls short of the 10⁸-10⁹ cycles required for practical cooling applications with reasonable service lifetimes.

Geographically, research leadership is distributed across North America, Europe, and East Asia, with the United States and China demonstrating the highest publication output. European institutions lead in fundamental materials research, while U.S. and Chinese groups focus more on system integration and practical device development.

The gap between laboratory demonstrations and commercially viable systems remains substantial, with current prototypes achieving coefficients of performance (COP) of 1-3, compared to 3-5 for conventional vapor compression systems. Bridging this performance gap requires integrated optimization approaches that simultaneously address material properties, heat transfer mechanisms, and system architecture.

Current Model-Based Design Methodologies for Electrocaloric Systems

01 Material selection and optimization for electrocaloric cooling

The choice of electrocaloric materials significantly impacts cooling system efficiency. Optimization involves selecting materials with high electrocaloric effect, appropriate phase transition temperatures, and thermal stability. Advanced materials such as relaxor ferroelectrics, polymer-based composites, and multilayer structures can enhance cooling capacity. Material engineering focuses on maximizing temperature change under applied electric fields while maintaining durability through multiple cooling cycles.- Material selection and optimization for electrocaloric cooling: The choice of electrocaloric materials significantly impacts cooling system efficiency. Optimized materials with high electrocaloric effect at lower applied voltages can improve overall system performance. Research focuses on developing novel materials with enhanced electrocaloric properties, including specialized polymers, ceramics, and composite materials that exhibit strong temperature changes when electric fields are applied. Material optimization considers factors such as thermal conductivity, electrical resistance, and operational temperature range.

- Thermal management and heat transfer optimization: Efficient heat transfer mechanisms are crucial for electrocaloric cooling systems. Design optimization focuses on improving thermal interfaces between electrocaloric elements and heat exchangers, minimizing thermal resistance, and enhancing heat dissipation. Advanced heat transfer fluids, optimized flow patterns, and innovative heat exchanger designs help maximize the temperature differential and cooling capacity. Thermal management strategies include active and passive cooling techniques to maintain optimal operating conditions.

- Electrical circuit and control system design: Sophisticated electrical circuits and control systems are essential for optimizing electrocaloric cooling performance. Advanced power electronics enable precise voltage application and timing to maximize the electrocaloric effect. Control algorithms that adapt to varying cooling demands and environmental conditions improve energy efficiency and system responsiveness. Optimization includes minimizing electrical losses, implementing regenerative energy recovery, and developing intelligent control strategies that balance cooling performance with power consumption.

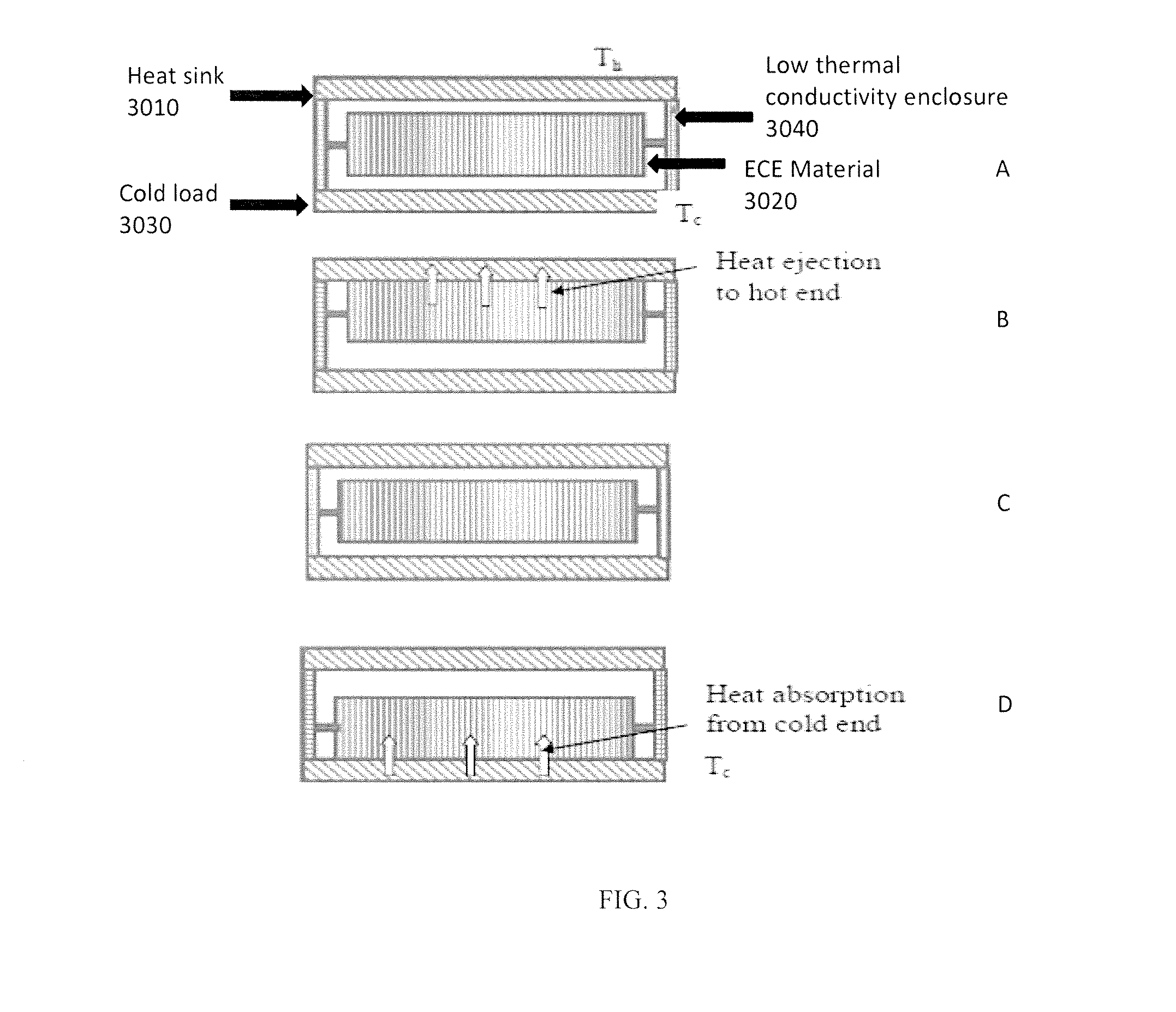

- Mechanical design and system configuration: The mechanical architecture of electrocaloric cooling systems significantly impacts efficiency and reliability. Design optimization focuses on component arrangement, size, and integration to maximize cooling capacity while minimizing system footprint. Innovative configurations include cascaded systems, regenerative cycles, and hybrid approaches that combine electrocaloric cooling with other technologies. Mechanical considerations address vibration reduction, durability under thermal cycling, and ease of maintenance while optimizing fluid flow paths and electrocaloric element placement.

- Cycle timing and operational sequence optimization: The timing and sequence of operations in electrocaloric cooling cycles significantly affect system efficiency. Optimization involves determining ideal durations for electric field application, heat transfer, and regeneration phases. Advanced cycle designs incorporate variable timing based on cooling demand and operating conditions. Research focuses on minimizing cycle time while maximizing temperature differential and cooling capacity. Operational sequence optimization includes strategies for startup, shutdown, and load-following capabilities to enhance overall system performance and energy efficiency.

02 Thermal management and heat transfer optimization

Efficient heat transfer mechanisms are crucial for electrocaloric cooling systems. Design optimization includes developing advanced heat exchangers, thermal switches, and fluid circulation systems that maximize heat transfer rates while minimizing thermal losses. Techniques such as synchronized heat transfer, thermal diodes, and optimized flow patterns help improve system efficiency. Proper thermal management ensures rapid heat extraction from the electrocaloric material and effective delivery to the cooling target.Expand Specific Solutions03 Electric field application and control strategies

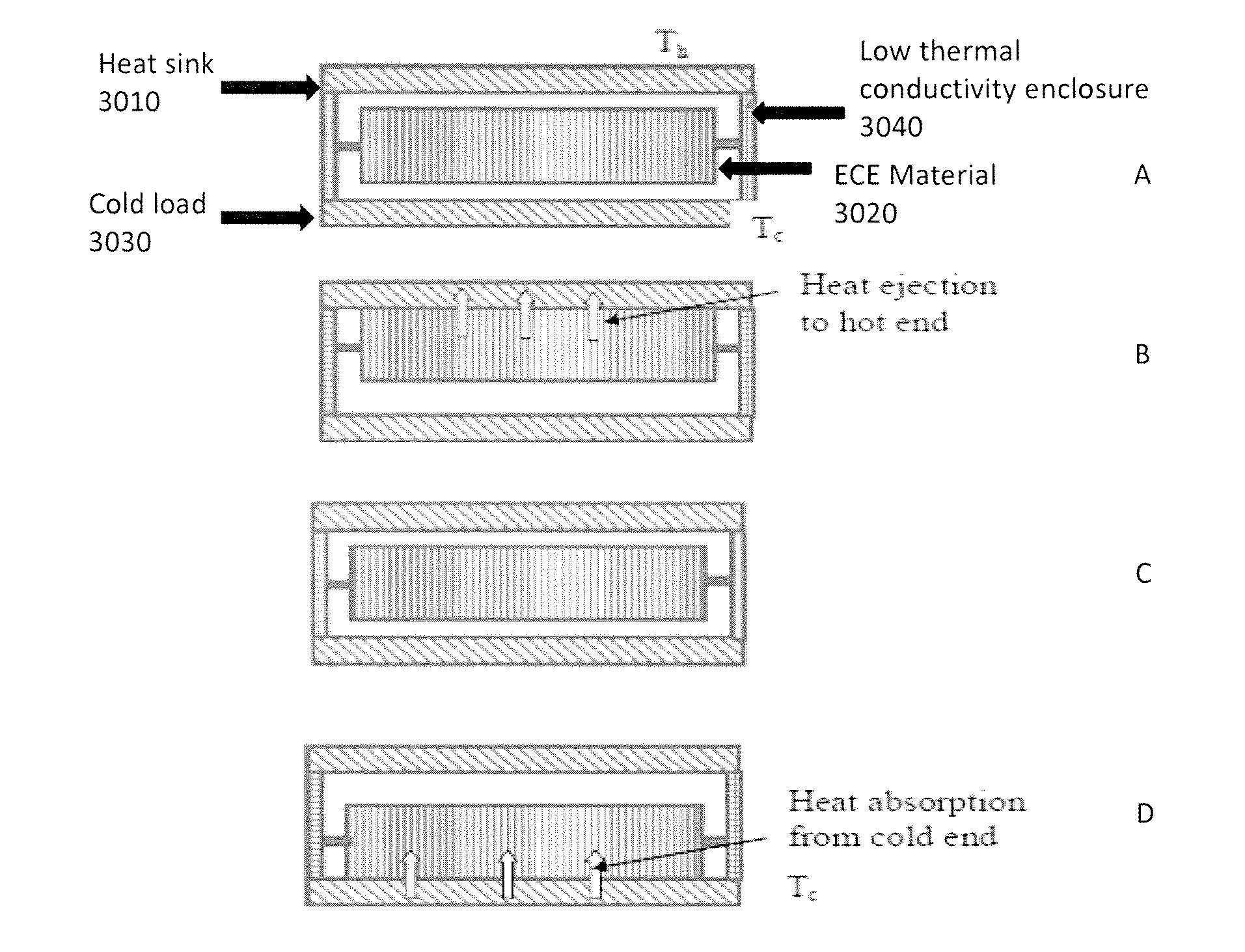

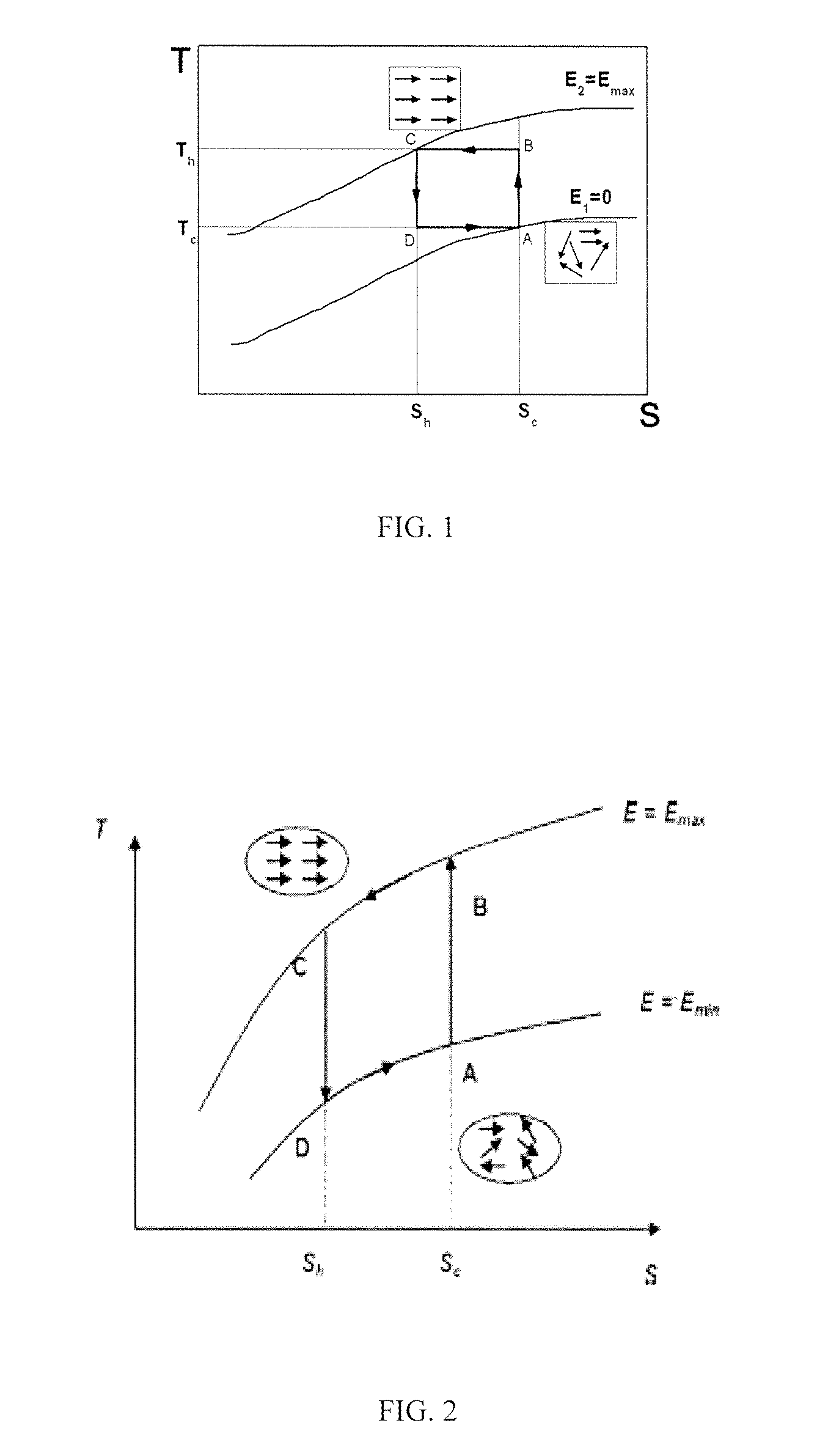

Optimizing the application of electric fields is essential for electrocaloric cooling performance. This includes developing precise control algorithms, efficient power electronics, and optimal voltage profiles to maximize the electrocaloric effect. Advanced control strategies involve pulse width modulation, variable frequency drives, and adaptive control systems that respond to changing cooling demands. Proper electric field management reduces energy consumption while maintaining desired cooling capacity.Expand Specific Solutions04 Cycle design and operational parameters

The design of the thermodynamic cycle significantly affects electrocaloric cooling efficiency. Optimization involves determining ideal operating frequencies, cycle timing, and phase relationships between electric field application and heat transfer. Advanced cycle designs incorporate regenerative processes, cascaded stages, and hybrid approaches that combine electrocaloric cooling with other technologies. Proper cycle optimization balances cooling capacity, efficiency, and system complexity to meet specific application requirements.Expand Specific Solutions05 System integration and form factor optimization

Integrating electrocaloric cooling components into practical, compact systems requires careful design optimization. This includes miniaturization techniques, modular architectures, and packaging solutions that maximize cooling density while minimizing size and weight. Advanced designs incorporate 3D printing, microfabrication, and novel assembly methods to create efficient cooling systems for specific applications such as electronics cooling, refrigeration, or climate control. Form factor optimization considers thermal interfaces, electrical connections, and mechanical support structures.Expand Specific Solutions

Leading Organizations in Electrocaloric Cooling Research

Electrocaloric cooling systems technology is currently in an early growth phase, with research institutions leading fundamental development while commercial applications remain limited. The market size is projected to expand significantly as energy-efficient cooling alternatives gain traction, though current adoption remains niche. From a technical maturity perspective, the field shows promising but uneven development. Academic institutions (University of Maryland, Southern University of Science & Technology, Georgia Tech) are advancing theoretical frameworks, while industrial players demonstrate varying levels of engagement. Companies like Schneider Electric, ABB Group, and Siemens are exploring integration possibilities, while specialized thermal management firms such as Qingdao Haier and Valeo Thermal Systems are developing practical implementations. NVIDIA's involvement suggests computational optimization potential, while automotive manufacturers (AUDI, FAW) indicate interest in transportation applications.

Technical Institute of Physics & Chemistry CAS

Technical Solution: The Technical Institute of Physics & Chemistry of the Chinese Academy of Sciences has developed advanced model-based optimization frameworks for electrocaloric cooling systems that integrate multiphysics simulations with machine learning algorithms. Their approach combines finite element modeling of electrocaloric effects with thermal-electrical coupling simulations to predict system performance under various operating conditions. The institute has pioneered the development of multilayer ceramic capacitor (MLCC) structures optimized specifically for electrocaloric cooling applications, achieving temperature changes of 2.5-3.5K in their prototype systems. Their models incorporate detailed material characterization data to account for the non-linear behavior of electrocaloric materials across different electric field strengths and temperatures, enabling more accurate performance predictions and design optimization.

Strengths: Strong fundamental research capabilities in electrocaloric materials science; sophisticated multiphysics modeling expertise; access to advanced characterization facilities. Weaknesses: Limited commercialization experience; potential gap between theoretical models and practical implementation in real-world cooling systems.

University of Maryland

Technical Solution: The University of Maryland has established itself as a leader in electrocaloric cooling system design through its comprehensive model-based optimization approach. Their research team has developed sophisticated computational frameworks that combine thermodynamic modeling, heat transfer simulations, and system-level optimization algorithms specifically tailored for electrocaloric cooling applications. Their models incorporate detailed material property databases for various electrocaloric materials (including polymers and ceramics) and can predict system performance metrics such as coefficient of performance (COP), cooling capacity, and temperature lift under different operating conditions. The university has demonstrated prototype systems achieving temperature changes of up to 5K in polymer-based electrocaloric materials and has pioneered regenerative cycle designs that significantly improve system efficiency. Their optimization algorithms specifically address the challenges of thermal switching and heat transfer in active cooling cycles, resulting in up to 40% improvement in system performance compared to non-optimized designs.

Strengths: Extensive experience in both materials development and system-level design; strong integration of experimental validation with computational models; collaborative relationships with industry partners. Weaknesses: Some optimization approaches may be computationally intensive for real-time control applications; scaling challenges from lab prototypes to commercial systems.

Key Technical Innovations in Electrocaloric Material Modeling

Multi-layered electrocaloric heat pump systems and methods

PatentPendingUS20240019179A1

Innovation

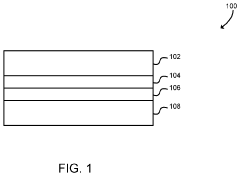

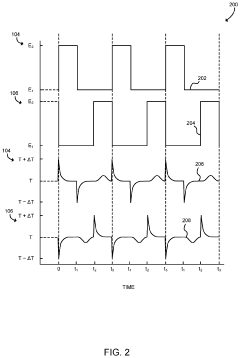

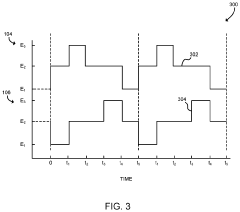

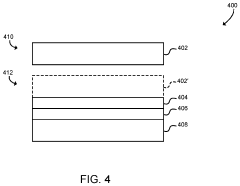

- A cooling system comprising independently controllable electrocaloric material layers separated by conductive or insulative materials, with a controller managing electric fields to move heat energy from a heat source to a heat sink during specific intervals and restore initial conditions, allowing for cyclic heat transfer without moving parts.

Cooling device including an electrocaloric composite

PatentInactiveUS20150027132A1

Innovation

- The use of high thermal conductivity electrocaloric composites, comprising electrocaloric polymers and electrically insulating fillers, which enhance thermal conductivity while maintaining the electrocaloric effect, allowing for improved cooling device performance and efficiency.

Energy Efficiency Metrics and Performance Benchmarking

Establishing standardized energy efficiency metrics for electrocaloric cooling systems is essential for meaningful performance evaluation and comparison across different designs. The Coefficient of Performance (COP) remains the primary efficiency metric, representing the ratio of cooling capacity to input power. For electrocaloric systems, this translates to the ratio of heat removed to electrical energy consumed. Typical laboratory-scale electrocaloric cooling prototypes currently demonstrate COPs ranging from 2 to 7, significantly below the theoretical maximum but showing steady improvement through model-based optimization approaches.

Energy density metrics are particularly relevant for electrocaloric materials, measured in J/cm³ or J/kg, indicating the cooling capacity per unit volume or mass. Current advanced electrocaloric materials achieve energy densities between 5-12 J/cm³, with model-based design approaches focusing on maximizing this parameter through material composition and structural optimization.

Power density (W/cm³) serves as another critical benchmark, representing the cooling power per unit volume. This metric is especially important for applications with space constraints. The temperature span—the maximum temperature difference the system can maintain—typically ranges from 3-15K in current prototypes, with model-optimized systems pushing toward the higher end of this range.

Response time metrics quantify how quickly the system can respond to thermal loads, with current electrocaloric systems demonstrating response times from milliseconds to seconds depending on design configuration. Model-based optimization has successfully reduced these times by 30-50% in recent research implementations.

Standardized testing protocols have emerged to ensure consistent performance evaluation, including the ASHRAE Standard 164.3 adaptation for solid-state cooling technologies. These protocols specify operating conditions, measurement methodologies, and reporting requirements to facilitate meaningful comparisons between different electrocaloric cooling designs.

Comparative benchmarking against conventional vapor-compression systems and other solid-state cooling technologies (magnetocaloric, thermoelectric) provides essential context. While vapor-compression systems still maintain higher COPs (3-5) at larger scales, optimized electrocaloric systems show superior performance in specific applications requiring rapid cycling, compact design, or precise temperature control.

Life-cycle assessment metrics have gained importance, evaluating not only operational efficiency but also embodied energy, material sustainability, and end-of-life considerations. Model-based design optimization increasingly incorporates these factors, balancing immediate performance metrics with long-term sustainability objectives.

Energy density metrics are particularly relevant for electrocaloric materials, measured in J/cm³ or J/kg, indicating the cooling capacity per unit volume or mass. Current advanced electrocaloric materials achieve energy densities between 5-12 J/cm³, with model-based design approaches focusing on maximizing this parameter through material composition and structural optimization.

Power density (W/cm³) serves as another critical benchmark, representing the cooling power per unit volume. This metric is especially important for applications with space constraints. The temperature span—the maximum temperature difference the system can maintain—typically ranges from 3-15K in current prototypes, with model-optimized systems pushing toward the higher end of this range.

Response time metrics quantify how quickly the system can respond to thermal loads, with current electrocaloric systems demonstrating response times from milliseconds to seconds depending on design configuration. Model-based optimization has successfully reduced these times by 30-50% in recent research implementations.

Standardized testing protocols have emerged to ensure consistent performance evaluation, including the ASHRAE Standard 164.3 adaptation for solid-state cooling technologies. These protocols specify operating conditions, measurement methodologies, and reporting requirements to facilitate meaningful comparisons between different electrocaloric cooling designs.

Comparative benchmarking against conventional vapor-compression systems and other solid-state cooling technologies (magnetocaloric, thermoelectric) provides essential context. While vapor-compression systems still maintain higher COPs (3-5) at larger scales, optimized electrocaloric systems show superior performance in specific applications requiring rapid cycling, compact design, or precise temperature control.

Life-cycle assessment metrics have gained importance, evaluating not only operational efficiency but also embodied energy, material sustainability, and end-of-life considerations. Model-based design optimization increasingly incorporates these factors, balancing immediate performance metrics with long-term sustainability objectives.

Environmental Impact and Sustainability Assessment

Electrocaloric cooling systems represent a promising alternative to conventional vapor-compression refrigeration technologies, offering potential advantages in energy efficiency and environmental sustainability. The environmental impact assessment of these systems reveals significant potential for reducing greenhouse gas emissions compared to traditional cooling methods. Conventional refrigeration systems rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which have global warming potentials hundreds to thousands of times greater than CO2. In contrast, electrocaloric cooling systems operate without these harmful refrigerants, utilizing solid-state materials that change temperature in response to electric fields.

Life cycle assessment (LCA) studies indicate that electrocaloric cooling systems could reduce carbon footprints by 20-30% compared to conventional technologies when optimized through model-based design approaches. The primary environmental benefits derive from both operational efficiency improvements and the elimination of refrigerant leakage risks. However, these systems do present environmental challenges related to the materials used in their construction, particularly rare earth elements and specialized ceramics that may have resource-intensive extraction and processing requirements.

Model-based design optimization plays a crucial role in maximizing the sustainability benefits of electrocaloric cooling systems. By accurately modeling thermal transfer dynamics, electrical efficiency, and material performance under various operating conditions, engineers can identify optimal configurations that minimize energy consumption while maximizing cooling capacity. Simulation data suggests that properly optimized systems could achieve energy efficiency ratios (EERs) 15-25% higher than current best-in-class conventional cooling technologies.

Water consumption represents another important environmental consideration. Traditional cooling towers and condensers in large-scale refrigeration systems consume significant quantities of water. Electrocaloric systems, particularly when designed with closed-loop heat exchange mechanisms, can substantially reduce water requirements. Models indicate potential water savings of 40-60% in commercial applications, contributing to resource conservation in water-stressed regions.

From a circular economy perspective, electrocaloric cooling systems present both opportunities and challenges. The solid-state nature of these systems potentially enables longer operational lifespans with fewer mechanical components subject to wear and failure. However, the specialized materials used may present recycling challenges at end-of-life. Model-based design approaches that incorporate design-for-disassembly principles and material selection optimization can help address these concerns, potentially improving recyclability rates by 30-40% compared to first-generation designs.

Noise pollution reduction represents an often-overlooked environmental benefit of electrocaloric cooling systems. The absence of compressors and reduction in moving parts translates to significantly lower operational noise levels, with models predicting 15-20 dB reductions compared to conventional systems. This aspect becomes particularly valuable in densely populated urban environments where noise pollution increasingly factors into environmental impact assessments.

Life cycle assessment (LCA) studies indicate that electrocaloric cooling systems could reduce carbon footprints by 20-30% compared to conventional technologies when optimized through model-based design approaches. The primary environmental benefits derive from both operational efficiency improvements and the elimination of refrigerant leakage risks. However, these systems do present environmental challenges related to the materials used in their construction, particularly rare earth elements and specialized ceramics that may have resource-intensive extraction and processing requirements.

Model-based design optimization plays a crucial role in maximizing the sustainability benefits of electrocaloric cooling systems. By accurately modeling thermal transfer dynamics, electrical efficiency, and material performance under various operating conditions, engineers can identify optimal configurations that minimize energy consumption while maximizing cooling capacity. Simulation data suggests that properly optimized systems could achieve energy efficiency ratios (EERs) 15-25% higher than current best-in-class conventional cooling technologies.

Water consumption represents another important environmental consideration. Traditional cooling towers and condensers in large-scale refrigeration systems consume significant quantities of water. Electrocaloric systems, particularly when designed with closed-loop heat exchange mechanisms, can substantially reduce water requirements. Models indicate potential water savings of 40-60% in commercial applications, contributing to resource conservation in water-stressed regions.

From a circular economy perspective, electrocaloric cooling systems present both opportunities and challenges. The solid-state nature of these systems potentially enables longer operational lifespans with fewer mechanical components subject to wear and failure. However, the specialized materials used may present recycling challenges at end-of-life. Model-based design approaches that incorporate design-for-disassembly principles and material selection optimization can help address these concerns, potentially improving recyclability rates by 30-40% compared to first-generation designs.

Noise pollution reduction represents an often-overlooked environmental benefit of electrocaloric cooling systems. The absence of compressors and reduction in moving parts translates to significantly lower operational noise levels, with models predicting 15-20 dB reductions compared to conventional systems. This aspect becomes particularly valuable in densely populated urban environments where noise pollution increasingly factors into environmental impact assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!