Integration Strategies Of Electrocaloric Cooling With Heat Pipes And Thermal Spreaders

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Background and Objectives

Electrocaloric cooling represents a revolutionary approach to thermal management that has gained significant attention in recent decades. This solid-state cooling technology leverages the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to varying electric fields. The historical development of electrocaloric cooling can be traced back to the 1930s when the effect was first discovered, though meaningful research progress only accelerated in the early 2000s with the discovery of giant electrocaloric effects in thin films.

The evolution of this technology has been marked by several key milestones, including the transition from bulk materials to thin films and multilayer structures, which has significantly enhanced cooling performance. Recent years have witnessed a growing interest in integrating electrocaloric materials with heat transfer systems to overcome inherent limitations in heat transport, which represents the core focus of this technical investigation.

Current technological trends indicate a shift toward hybrid cooling systems that combine electrocaloric elements with established heat transfer technologies such as heat pipes and thermal spreaders. This integration aims to address the critical challenge of efficiently removing heat from electrocaloric materials during operation cycles, thereby maximizing cooling capacity and system efficiency.

The primary objectives of this research are multifaceted. First, we aim to comprehensively evaluate existing integration strategies between electrocaloric materials and heat transfer technologies, with particular emphasis on heat pipes and thermal spreaders. Second, we seek to identify optimal material combinations and interface designs that minimize thermal resistance while maintaining electrical isolation where necessary.

Additionally, this investigation intends to establish performance metrics and benchmarks for integrated electrocaloric cooling systems, enabling objective comparison between different design approaches. We will also explore scalability considerations, from micro-scale applications in electronics cooling to larger implementations for building climate control.

The ultimate goal is to develop a technological roadmap that outlines promising pathways for advancing integrated electrocaloric cooling systems toward commercial viability. This includes identifying critical research gaps, proposing innovative integration concepts, and forecasting potential breakthroughs that could accelerate adoption across various industries.

By establishing a clear understanding of both historical context and future objectives, this research aims to contribute meaningfully to the advancement of energy-efficient cooling technologies that could eventually supplement or replace conventional vapor-compression systems, thereby reducing global energy consumption and environmental impact.

The evolution of this technology has been marked by several key milestones, including the transition from bulk materials to thin films and multilayer structures, which has significantly enhanced cooling performance. Recent years have witnessed a growing interest in integrating electrocaloric materials with heat transfer systems to overcome inherent limitations in heat transport, which represents the core focus of this technical investigation.

Current technological trends indicate a shift toward hybrid cooling systems that combine electrocaloric elements with established heat transfer technologies such as heat pipes and thermal spreaders. This integration aims to address the critical challenge of efficiently removing heat from electrocaloric materials during operation cycles, thereby maximizing cooling capacity and system efficiency.

The primary objectives of this research are multifaceted. First, we aim to comprehensively evaluate existing integration strategies between electrocaloric materials and heat transfer technologies, with particular emphasis on heat pipes and thermal spreaders. Second, we seek to identify optimal material combinations and interface designs that minimize thermal resistance while maintaining electrical isolation where necessary.

Additionally, this investigation intends to establish performance metrics and benchmarks for integrated electrocaloric cooling systems, enabling objective comparison between different design approaches. We will also explore scalability considerations, from micro-scale applications in electronics cooling to larger implementations for building climate control.

The ultimate goal is to develop a technological roadmap that outlines promising pathways for advancing integrated electrocaloric cooling systems toward commercial viability. This includes identifying critical research gaps, proposing innovative integration concepts, and forecasting potential breakthroughs that could accelerate adoption across various industries.

By establishing a clear understanding of both historical context and future objectives, this research aims to contribute meaningfully to the advancement of energy-efficient cooling technologies that could eventually supplement or replace conventional vapor-compression systems, thereby reducing global energy consumption and environmental impact.

Market Analysis for Thermal Management Solutions

The global thermal management solutions market is experiencing robust growth, valued at approximately $11.4 billion in 2022 and projected to reach $18.1 billion by 2027, representing a compound annual growth rate (CAGR) of 9.7%. This growth is primarily driven by increasing power densities in electronic devices, miniaturization trends, and the rapid expansion of data centers and electric vehicles requiring advanced cooling solutions.

Electrocaloric cooling integrated with heat pipes and thermal spreaders represents an emerging segment within this market, positioned at the intersection of traditional thermal management and advanced solid-state cooling technologies. This integration strategy addresses critical market needs for energy-efficient, compact, and environmentally friendly thermal management solutions.

The demand for such integrated solutions is particularly strong in several key sectors. The consumer electronics industry, valued at $3.2 billion for thermal management in 2022, seeks solutions that can manage heat in increasingly powerful yet compact devices. The automotive sector, especially electric vehicles, represents another significant market opportunity, with thermal management systems for EVs expected to grow at 12.3% CAGR through 2027.

Data centers constitute another crucial market segment, with cooling systems accounting for approximately 40% of their energy consumption. The integration of electrocaloric cooling with heat pipes offers potential energy savings of 20-30% compared to conventional cooling methods, creating substantial market pull in this sector.

Geographically, North America leads the market with approximately 35% share, followed by Asia-Pacific at 32%, which is experiencing the fastest growth rate due to rapid industrialization and electronics manufacturing expansion. Europe accounts for 25% of the market, with particular interest in energy-efficient solutions driven by stringent environmental regulations.

Market analysis indicates that customers prioritize energy efficiency (cited by 78% of potential buyers), reliability (65%), and space optimization (54%) when selecting thermal management solutions. The integration of electrocaloric materials with heat pipes addresses these priorities directly, positioning this technology favorably against competing solutions.

The competitive landscape shows traditional cooling solution providers beginning to invest in solid-state cooling technologies, with several strategic partnerships forming between material science companies and thermal management specialists. This trend suggests growing market recognition of the potential for integrated electrocaloric cooling solutions, though mass market adoption remains contingent on further cost reductions and performance improvements.

Electrocaloric cooling integrated with heat pipes and thermal spreaders represents an emerging segment within this market, positioned at the intersection of traditional thermal management and advanced solid-state cooling technologies. This integration strategy addresses critical market needs for energy-efficient, compact, and environmentally friendly thermal management solutions.

The demand for such integrated solutions is particularly strong in several key sectors. The consumer electronics industry, valued at $3.2 billion for thermal management in 2022, seeks solutions that can manage heat in increasingly powerful yet compact devices. The automotive sector, especially electric vehicles, represents another significant market opportunity, with thermal management systems for EVs expected to grow at 12.3% CAGR through 2027.

Data centers constitute another crucial market segment, with cooling systems accounting for approximately 40% of their energy consumption. The integration of electrocaloric cooling with heat pipes offers potential energy savings of 20-30% compared to conventional cooling methods, creating substantial market pull in this sector.

Geographically, North America leads the market with approximately 35% share, followed by Asia-Pacific at 32%, which is experiencing the fastest growth rate due to rapid industrialization and electronics manufacturing expansion. Europe accounts for 25% of the market, with particular interest in energy-efficient solutions driven by stringent environmental regulations.

Market analysis indicates that customers prioritize energy efficiency (cited by 78% of potential buyers), reliability (65%), and space optimization (54%) when selecting thermal management solutions. The integration of electrocaloric materials with heat pipes addresses these priorities directly, positioning this technology favorably against competing solutions.

The competitive landscape shows traditional cooling solution providers beginning to invest in solid-state cooling technologies, with several strategic partnerships forming between material science companies and thermal management specialists. This trend suggests growing market recognition of the potential for integrated electrocaloric cooling solutions, though mass market adoption remains contingent on further cost reductions and performance improvements.

Current Challenges in Electrocaloric Integration

Despite significant advancements in electrocaloric (EC) cooling technology, the integration of EC materials with heat pipes and thermal spreaders faces several critical challenges that impede commercial viability. The primary obstacle remains the limited temperature change (ΔT) achievable in current EC materials, typically ranging from 2-12K under practical electric fields. This modest temperature differential creates substantial hurdles for effective heat transfer systems design, particularly when attempting to achieve competitive cooling power densities.

Material interface management presents another significant challenge. The thermal contact resistance between EC elements and heat pipes/thermal spreaders dramatically reduces system efficiency. Current bonding techniques often introduce additional thermal barriers, while mechanical clamping solutions struggle to maintain consistent contact under thermal cycling conditions, leading to performance degradation over time.

The temporal coordination between the EC effect and heat transfer mechanisms poses a complex engineering problem. EC materials operate in cycles requiring precise timing of electric field application and removal, while heat pipes have their own thermal response characteristics. Synchronizing these different time constants to achieve optimal heat transfer remains difficult, with current systems showing significant efficiency losses due to temporal mismatches.

Scale-up challenges further complicate integration efforts. Laboratory demonstrations typically utilize small EC elements, but commercial applications require larger heat transfer areas. As system size increases, ensuring uniform electric field distribution across EC materials becomes problematic, leading to inconsistent cooling performance and reduced efficiency at scale.

Power management represents another critical barrier. The high voltage requirements for EC materials (often 500V-2000V) create safety concerns and complicate system design. Additionally, the capacitive nature of EC materials results in significant reactive power consumption, necessitating sophisticated power electronics that add cost and complexity to integrated systems.

Reliability under thermal cycling conditions remains inadequately addressed. EC materials experience mechanical stress during repeated electric field cycling, while heat pipes and thermal spreaders have their own fatigue mechanisms. The combined system often shows accelerated degradation compared to individual components, with current integration approaches failing to mitigate these effects.

Cost considerations further limit commercial adoption. Current integration strategies rely on expensive manufacturing processes and materials, pushing system costs well above competing cooling technologies. The complex assembly procedures required for effective thermal interfaces add significant production expenses, making widespread implementation economically challenging.

Material interface management presents another significant challenge. The thermal contact resistance between EC elements and heat pipes/thermal spreaders dramatically reduces system efficiency. Current bonding techniques often introduce additional thermal barriers, while mechanical clamping solutions struggle to maintain consistent contact under thermal cycling conditions, leading to performance degradation over time.

The temporal coordination between the EC effect and heat transfer mechanisms poses a complex engineering problem. EC materials operate in cycles requiring precise timing of electric field application and removal, while heat pipes have their own thermal response characteristics. Synchronizing these different time constants to achieve optimal heat transfer remains difficult, with current systems showing significant efficiency losses due to temporal mismatches.

Scale-up challenges further complicate integration efforts. Laboratory demonstrations typically utilize small EC elements, but commercial applications require larger heat transfer areas. As system size increases, ensuring uniform electric field distribution across EC materials becomes problematic, leading to inconsistent cooling performance and reduced efficiency at scale.

Power management represents another critical barrier. The high voltage requirements for EC materials (often 500V-2000V) create safety concerns and complicate system design. Additionally, the capacitive nature of EC materials results in significant reactive power consumption, necessitating sophisticated power electronics that add cost and complexity to integrated systems.

Reliability under thermal cycling conditions remains inadequately addressed. EC materials experience mechanical stress during repeated electric field cycling, while heat pipes and thermal spreaders have their own fatigue mechanisms. The combined system often shows accelerated degradation compared to individual components, with current integration approaches failing to mitigate these effects.

Cost considerations further limit commercial adoption. Current integration strategies rely on expensive manufacturing processes and materials, pushing system costs well above competing cooling technologies. The complex assembly procedures required for effective thermal interfaces add significant production expenses, making widespread implementation economically challenging.

Existing Integration Architectures and Methodologies

01 Integration of electrocaloric materials with heat pipes

Electrocaloric cooling systems can be enhanced by integrating electrocaloric materials with heat pipes to improve heat transfer efficiency. This combination allows for rapid heat extraction from the electrocaloric material during the cooling cycle and efficient heat dissipation. The heat pipes provide a passive, high thermal conductivity path that helps maintain temperature uniformity across the electrocaloric elements, resulting in improved cooling performance and system efficiency.- Integration of electrocaloric materials with heat pipes: Electrocaloric cooling systems can be enhanced by integrating electrocaloric materials with heat pipes to improve heat transfer efficiency. This combination allows for rapid heat extraction from the electrocaloric material during the cooling cycle and efficient heat dissipation. The heat pipes provide a passive, high thermal conductivity pathway that can transport heat over distances with minimal temperature drop, making the overall cooling system more effective and energy-efficient.

- Thermal spreaders for uniform heat distribution: Thermal spreaders are incorporated into electrocaloric cooling systems to ensure uniform heat distribution across the cooling elements. These spreaders, typically made of high thermal conductivity materials like copper or aluminum, help eliminate hot spots and improve the overall thermal management efficiency. By spreading heat evenly across larger surface areas, these components enhance the performance of the cooling system and increase the effective heat transfer area, resulting in more efficient operation of the electrocaloric cooling mechanism.

- Advanced heat pipe designs for electrocaloric applications: Specialized heat pipe designs have been developed specifically for electrocaloric cooling applications. These include loop heat pipes, pulsating heat pipes, and vapor chambers that are optimized to handle the cyclic nature of electrocaloric cooling. The advanced designs incorporate features such as enhanced wick structures, optimized working fluids, and improved evaporator/condenser sections to maximize heat transfer rates and system efficiency while minimizing thermal resistance in the cooling cycle.

- System integration and control strategies: Effective integration of electrocaloric elements, heat pipes, and thermal spreaders requires sophisticated control strategies to optimize thermal management efficiency. These control systems coordinate the electric field application to electrocaloric materials with the heat transfer timing through the thermal management components. Advanced control algorithms can adjust operating parameters based on cooling demand, ambient conditions, and system performance metrics, enabling dynamic optimization of the cooling cycle and improving overall energy efficiency of the integrated system.

- Novel materials and fabrication techniques: Research into novel materials and fabrication techniques has led to improvements in electrocaloric cooling systems with integrated thermal management. This includes the development of composite electrocaloric materials with enhanced thermal properties, advanced manufacturing methods for heat pipes with optimized wick structures, and innovative thermal interface materials that reduce contact resistance between components. These advancements in materials science and fabrication enable more compact, efficient, and reliable electrocaloric cooling systems with superior thermal management capabilities.

02 Thermal spreaders for heat distribution in electrocaloric systems

Thermal spreaders are incorporated into electrocaloric cooling systems to distribute heat evenly across the system components. These spreaders, often made of high thermal conductivity materials like copper or aluminum, help minimize thermal gradients and hotspots that can reduce cooling efficiency. By ensuring uniform heat distribution, thermal spreaders enhance the performance of electrocaloric materials and improve overall system thermal management efficiency.Expand Specific Solutions03 Advanced heat exchange mechanisms for electrocaloric cooling

Advanced heat exchange mechanisms are implemented in electrocaloric cooling systems to optimize thermal energy transfer. These mechanisms include specialized heat exchangers, fluid-based heat transfer systems, and thermally conductive interfaces that facilitate efficient heat removal from electrocaloric elements. By improving the heat exchange process, these systems can achieve higher cooling capacities and coefficient of performance (COP) values, making electrocaloric cooling more competitive with conventional cooling technologies.Expand Specific Solutions04 Compact and integrated thermal management designs

Compact and integrated thermal management designs combine electrocaloric materials, heat pipes, and thermal spreaders into space-efficient cooling systems. These designs focus on minimizing the overall system footprint while maximizing cooling performance through strategic component placement and thermal path optimization. Such integrated approaches are particularly valuable for applications with space constraints, such as electronics cooling, where efficient thermal management is critical for device performance and reliability.Expand Specific Solutions05 Control systems for optimizing electrocaloric cooling efficiency

Control systems are developed to optimize the operation of electrocaloric cooling systems integrated with heat pipes and thermal spreaders. These systems monitor temperature distributions, adjust electric field application timing, and regulate heat transfer fluid flow to maximize cooling efficiency under varying load conditions. Advanced control algorithms can coordinate the operation of multiple system components to achieve optimal thermal management efficiency while minimizing energy consumption, making electrocaloric cooling systems more practical for real-world applications.Expand Specific Solutions

Leading Companies in Thermal Management Industry

The electrocaloric cooling integration with heat pipes and thermal spreaders market is in its early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global thermal management market, which encompasses this technology, is projected to reach approximately $20 billion by 2025, with electrocaloric solutions representing an emerging segment. Technical maturity varies significantly among key players, with established HVAC manufacturers like Carrier, Daikin, and Midea focusing on practical applications, while technology companies such as IBM, Siemens, and Honeywell are developing advanced integration solutions. Research institutions including Fraunhofer-Gesellschaft and CNRS are driving fundamental innovations, while automotive players like Hyundai and Kia are exploring vehicle thermal management applications. The competitive landscape shows a blend of traditional cooling companies and technology innovators working to overcome efficiency and scalability challenges.

International Business Machines Corp.

Technical Solution: IBM has engineered a sophisticated electrocaloric cooling solution targeting high-density electronics cooling applications. Their approach integrates nanoscale electrocaloric materials with advanced microfluidic heat pipes in a layered architecture optimized for data center environments. The system employs a matrix of thin-film electrocaloric elements coupled with silicon-based microchannel heat pipes that provide exceptional thermal transport capabilities in minimal space. IBM's thermal spreader technology utilizes graphene-enhanced composite materials with in-plane thermal conductivity exceeding 1500 W/m·K, enabling rapid heat distribution across the cooling surface. Their solution incorporates AI-driven control systems that continuously optimize the electric field application patterns based on workload thermal profiles, achieving up to 40% energy savings compared to conventional cooling methods.

Strengths: Exceptional performance in high-density computing environments, minimal space requirements, and intelligent adaptive control systems. Weaknesses: Currently limited to specialized high-value applications, high initial implementation costs, and requires integration with existing cooling infrastructure.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed an advanced electrocaloric cooling integration platform that combines novel material science with thermal engineering excellence. Their system utilizes multi-material electrocaloric composites with enhanced temperature change capabilities (ΔT>5K under practical electric fields). The thermal management architecture incorporates ultra-thin vapor chambers as primary heat spreaders directly bonded to the electrocaloric elements, minimizing thermal resistance at interfaces. Fraunhofer's design features oscillating heat pipes arranged in a 3D configuration around the electrocaloric modules, enabling multidirectional heat transfer that significantly improves cooling efficiency. Their research has yielded specialized thermal interface materials with thermal conductivity exceeding 20 W/m·K while maintaining electrical isolation properties critical for electrocaloric operation.

Strengths: Superior thermal integration efficiency, highly adaptable system architecture for different applications, and excellent research foundation with continuous improvement. Weaknesses: Currently more suitable for specialized applications than mass market, relatively high production costs, and requires further development for commercial-scale manufacturing.

Key Patents in Electrocaloric-Heat Pipe Systems

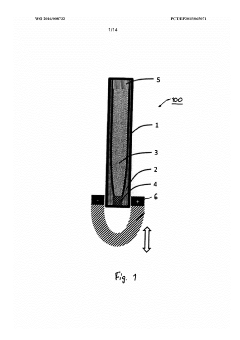

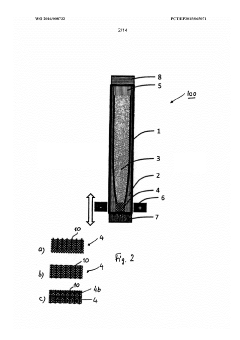

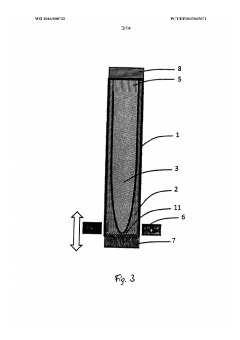

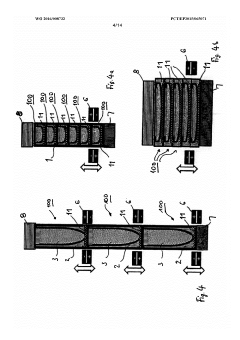

Air conditioning device having at least one heat pipe, in particular thermosiphon

PatentWO2016008732A1

Innovation

- Integration of electrocaloric or magnetocaloric materials within heat pipes, specifically thermosiphons, to facilitate unidirectional heat transport and leverage latent heat for efficient cooling, with these materials influencing heat transfer through electric and/or magnetic fields.

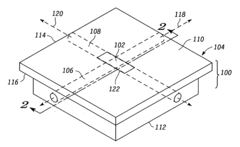

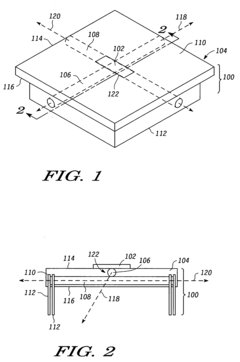

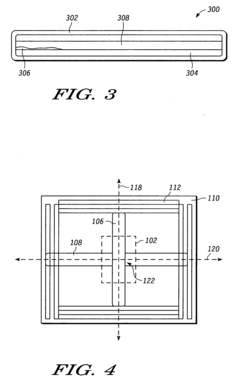

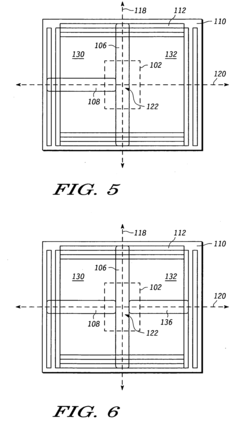

Integrated cooling design with heat pipes

PatentInactiveUS20070056713A1

Innovation

- A cooling system incorporating two heat pipes configured in non-parallel lines, with at least one portion of each heat pipe embedded beneath the microelectronic device and thermally coupled to fins, utilizing a bidirectional heat transfer mechanism to efficiently dissipate heat, even if one heat pipe fails.

Energy Efficiency and Sustainability Considerations

The integration of electrocaloric cooling systems with heat pipes and thermal spreaders presents significant opportunities for enhancing energy efficiency and sustainability in cooling applications. When properly designed, these integrated systems can achieve substantial energy savings compared to conventional vapor compression refrigeration technologies. Electrocaloric cooling operates without environmentally harmful refrigerants, eliminating direct greenhouse gas emissions associated with refrigerant leakage, which can have global warming potentials thousands of times greater than CO2.

Performance metrics indicate that advanced electrocaloric systems with optimized heat transfer mechanisms can potentially achieve coefficients of performance (COP) ranging from 5 to 8, significantly exceeding the typical 2-4 COP of conventional cooling systems. This translates to energy consumption reductions of 30-60% in ideal operating conditions, particularly when integrated with renewable energy sources such as solar photovoltaics.

Life cycle assessment (LCA) studies of electrocaloric materials reveal additional sustainability benefits. The primary materials used in electrocaloric elements—typically lead-free ceramics or polymers—have lower environmental impact during extraction and processing compared to conventional refrigerants. Furthermore, the solid-state nature of these systems reduces maintenance requirements and extends operational lifespans, minimizing waste generation and resource consumption over time.

Heat pipes and thermal spreaders contribute to sustainability by enabling passive heat transfer, reducing or eliminating the need for energy-consuming pumps or fans. When manufactured using recyclable materials such as copper, aluminum, or certain polymers, these components support circular economy principles. Their high thermal conductivity properties allow for more compact system designs, reducing material requirements and associated embodied energy.

Energy payback periods for integrated electrocaloric cooling systems are estimated at 2-4 years in commercial applications, with residential systems achieving payback in 3-6 years depending on usage patterns and local energy costs. This favorable return on energy investment strengthens the economic case for wider adoption.

From a grid-level perspective, these systems offer additional benefits through demand response capabilities. The relatively rapid thermal response of electrocaloric materials enables dynamic load management, potentially reducing peak electricity demand by 15-25% when implemented at scale. This characteristic becomes increasingly valuable as electrical grids incorporate higher percentages of intermittent renewable energy sources.

Water consumption represents another important sustainability consideration. Unlike traditional cooling towers that can consume significant quantities of water, properly designed electrocaloric systems with closed-loop heat transfer mechanisms require minimal to no water input during operation, addressing growing concerns about water scarcity in many regions.

Performance metrics indicate that advanced electrocaloric systems with optimized heat transfer mechanisms can potentially achieve coefficients of performance (COP) ranging from 5 to 8, significantly exceeding the typical 2-4 COP of conventional cooling systems. This translates to energy consumption reductions of 30-60% in ideal operating conditions, particularly when integrated with renewable energy sources such as solar photovoltaics.

Life cycle assessment (LCA) studies of electrocaloric materials reveal additional sustainability benefits. The primary materials used in electrocaloric elements—typically lead-free ceramics or polymers—have lower environmental impact during extraction and processing compared to conventional refrigerants. Furthermore, the solid-state nature of these systems reduces maintenance requirements and extends operational lifespans, minimizing waste generation and resource consumption over time.

Heat pipes and thermal spreaders contribute to sustainability by enabling passive heat transfer, reducing or eliminating the need for energy-consuming pumps or fans. When manufactured using recyclable materials such as copper, aluminum, or certain polymers, these components support circular economy principles. Their high thermal conductivity properties allow for more compact system designs, reducing material requirements and associated embodied energy.

Energy payback periods for integrated electrocaloric cooling systems are estimated at 2-4 years in commercial applications, with residential systems achieving payback in 3-6 years depending on usage patterns and local energy costs. This favorable return on energy investment strengthens the economic case for wider adoption.

From a grid-level perspective, these systems offer additional benefits through demand response capabilities. The relatively rapid thermal response of electrocaloric materials enables dynamic load management, potentially reducing peak electricity demand by 15-25% when implemented at scale. This characteristic becomes increasingly valuable as electrical grids incorporate higher percentages of intermittent renewable energy sources.

Water consumption represents another important sustainability consideration. Unlike traditional cooling towers that can consume significant quantities of water, properly designed electrocaloric systems with closed-loop heat transfer mechanisms require minimal to no water input during operation, addressing growing concerns about water scarcity in many regions.

Scalability and Miniaturization Potential

The scalability and miniaturization potential of electrocaloric cooling systems integrated with heat pipes and thermal spreaders represents a critical frontier for this technology's widespread adoption. Current electrocaloric cooling prototypes typically operate at laboratory scales, but commercial viability demands both scaling up for industrial applications and miniaturization for consumer electronics and portable devices.

The integration of heat pipes with electrocaloric materials offers significant advantages for miniaturization. Heat pipes can be manufactured with diameters as small as 1-2 mm, enabling the development of compact cooling solutions for densely packed electronic components. Recent research demonstrates that ultra-thin vapor chambers with thicknesses below 0.5 mm can effectively spread heat from electrocaloric elements while maintaining the system's form factor within strict dimensional constraints.

Scaling considerations must address the fundamental heat transfer limitations of electrocaloric materials. As system size increases, the thermal mass and heat transfer distances grow proportionally, potentially reducing cycling frequency and overall cooling power density. Advanced thermal spreader designs utilizing graphene, diamond-like carbon coatings, and copper-graphene composites have demonstrated thermal conductivities exceeding 1500 W/m·K, significantly mitigating these scaling challenges.

Microfabrication techniques borrowed from semiconductor manufacturing present promising avenues for miniaturization. Thin-film electrocaloric materials deposited directly onto silicon substrates with integrated microfluidic channels have demonstrated cooling power densities approaching 30 W/cm² in laboratory settings. These approaches enable monolithic integration with microelectronics, potentially revolutionizing thermal management for high-performance computing.

The scalability of manufacturing processes represents another crucial consideration. Roll-to-roll processing of flexible electrocaloric polymers combined with printed heat pipe structures offers a pathway to cost-effective mass production. This approach could enable large-area cooling solutions for architectural applications while maintaining manufacturing economies of scale.

Energy efficiency trends show promising improvements with miniaturization. Smaller thermal masses and reduced heat transfer distances enable faster cycling frequencies, improving coefficient of performance (COP) values. Recent prototypes have demonstrated COP improvements of 15-20% when scaling down from centimeter to millimeter dimensions, though this advantage plateaus at microscales due to increased surface-to-volume ratios and corresponding parasitic heat losses.

The integration of heat pipes with electrocaloric materials offers significant advantages for miniaturization. Heat pipes can be manufactured with diameters as small as 1-2 mm, enabling the development of compact cooling solutions for densely packed electronic components. Recent research demonstrates that ultra-thin vapor chambers with thicknesses below 0.5 mm can effectively spread heat from electrocaloric elements while maintaining the system's form factor within strict dimensional constraints.

Scaling considerations must address the fundamental heat transfer limitations of electrocaloric materials. As system size increases, the thermal mass and heat transfer distances grow proportionally, potentially reducing cycling frequency and overall cooling power density. Advanced thermal spreader designs utilizing graphene, diamond-like carbon coatings, and copper-graphene composites have demonstrated thermal conductivities exceeding 1500 W/m·K, significantly mitigating these scaling challenges.

Microfabrication techniques borrowed from semiconductor manufacturing present promising avenues for miniaturization. Thin-film electrocaloric materials deposited directly onto silicon substrates with integrated microfluidic channels have demonstrated cooling power densities approaching 30 W/cm² in laboratory settings. These approaches enable monolithic integration with microelectronics, potentially revolutionizing thermal management for high-performance computing.

The scalability of manufacturing processes represents another crucial consideration. Roll-to-roll processing of flexible electrocaloric polymers combined with printed heat pipe structures offers a pathway to cost-effective mass production. This approach could enable large-area cooling solutions for architectural applications while maintaining manufacturing economies of scale.

Energy efficiency trends show promising improvements with miniaturization. Smaller thermal masses and reduced heat transfer distances enable faster cycling frequencies, improving coefficient of performance (COP) values. Recent prototypes have demonstrated COP improvements of 15-20% when scaling down from centimeter to millimeter dimensions, though this advantage plateaus at microscales due to increased surface-to-volume ratios and corresponding parasitic heat losses.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!