Reliability Testing Protocols For Electrocaloric Cooling Modules

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Background and Objectives

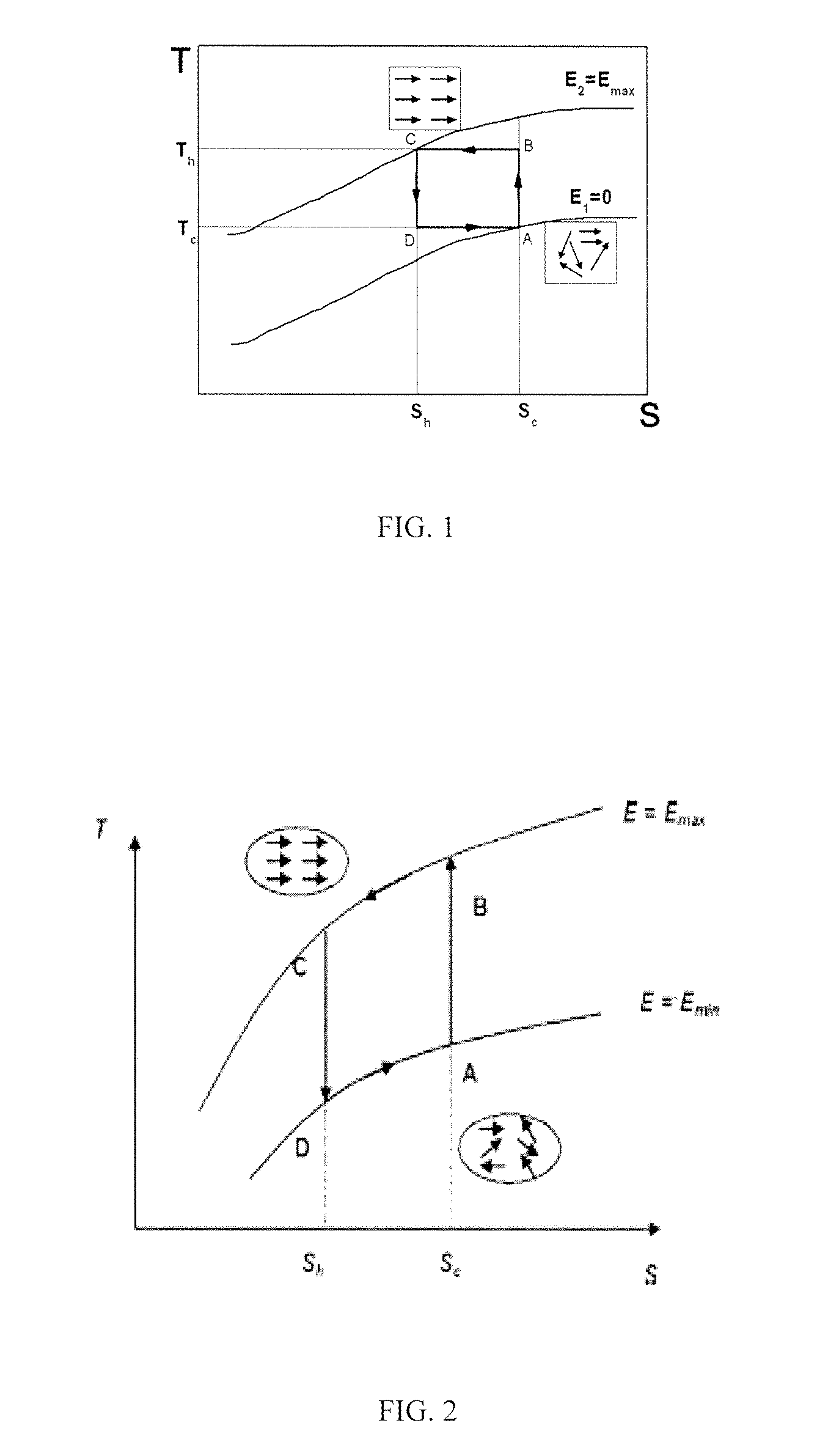

Electrocaloric cooling represents a revolutionary approach to thermal management that leverages the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. This technology has evolved significantly since its initial discovery in the 1930s, with major breakthroughs occurring in the early 2000s when thin-film electrocaloric materials demonstrated temperature changes exceeding 10K, reigniting interest in this field.

The evolution of electrocaloric cooling technology has been characterized by progressive improvements in material properties, device architectures, and system integration approaches. Initially limited by modest temperature changes and high operating voltages, recent advancements in multilayer ceramic capacitors and polymer-based electrocaloric materials have substantially enhanced performance metrics while reducing energy requirements.

Current research trajectories focus on developing more efficient electrocaloric materials with higher temperature changes at lower applied electric fields, improving heat transfer mechanisms, and designing more effective thermal switching systems. These developments aim to overcome the limitations of conventional vapor-compression cooling technologies, which rely on environmentally harmful refrigerants and face efficiency plateaus.

The primary technical objectives for electrocaloric cooling modules center on achieving reliable, long-term operation under various environmental conditions. This includes developing standardized testing protocols that can accurately predict module lifespan, identify failure modes, and establish performance degradation patterns over extended operational periods. Such protocols must address the unique challenges posed by electrocaloric materials, including fatigue from repeated electric field cycling, thermal stress management, and electrical breakdown prevention.

Additionally, these testing protocols aim to establish industry benchmarks for reliability metrics such as mean time between failures (MTBF), temperature cycling endurance, and performance stability under varying humidity and temperature conditions. The ultimate goal is to develop electrocaloric cooling modules that can maintain consistent cooling performance for 10+ years of operation while withstanding at least 100 million operational cycles—requirements necessary for commercial viability in applications ranging from electronics cooling to refrigeration.

The technological trajectory suggests that electrocaloric cooling could potentially disrupt conventional cooling technologies by offering higher efficiency, reduced environmental impact, and enhanced form factor flexibility. However, realizing this potential requires overcoming significant reliability challenges through rigorous testing methodologies that can accurately predict long-term performance and identify optimization opportunities.

The evolution of electrocaloric cooling technology has been characterized by progressive improvements in material properties, device architectures, and system integration approaches. Initially limited by modest temperature changes and high operating voltages, recent advancements in multilayer ceramic capacitors and polymer-based electrocaloric materials have substantially enhanced performance metrics while reducing energy requirements.

Current research trajectories focus on developing more efficient electrocaloric materials with higher temperature changes at lower applied electric fields, improving heat transfer mechanisms, and designing more effective thermal switching systems. These developments aim to overcome the limitations of conventional vapor-compression cooling technologies, which rely on environmentally harmful refrigerants and face efficiency plateaus.

The primary technical objectives for electrocaloric cooling modules center on achieving reliable, long-term operation under various environmental conditions. This includes developing standardized testing protocols that can accurately predict module lifespan, identify failure modes, and establish performance degradation patterns over extended operational periods. Such protocols must address the unique challenges posed by electrocaloric materials, including fatigue from repeated electric field cycling, thermal stress management, and electrical breakdown prevention.

Additionally, these testing protocols aim to establish industry benchmarks for reliability metrics such as mean time between failures (MTBF), temperature cycling endurance, and performance stability under varying humidity and temperature conditions. The ultimate goal is to develop electrocaloric cooling modules that can maintain consistent cooling performance for 10+ years of operation while withstanding at least 100 million operational cycles—requirements necessary for commercial viability in applications ranging from electronics cooling to refrigeration.

The technological trajectory suggests that electrocaloric cooling could potentially disrupt conventional cooling technologies by offering higher efficiency, reduced environmental impact, and enhanced form factor flexibility. However, realizing this potential requires overcoming significant reliability challenges through rigorous testing methodologies that can accurately predict long-term performance and identify optimization opportunities.

Market Analysis for Electrocaloric Cooling Technologies

The global market for electrocaloric cooling technologies is experiencing significant growth, driven by increasing demand for energy-efficient and environmentally friendly cooling solutions. Current market valuations indicate that the electrocaloric cooling sector is positioned to reach substantial market share within the broader cooling technologies landscape by 2030, with particularly strong growth anticipated in regions with stringent environmental regulations.

Market research reveals that the primary drivers for electrocaloric cooling adoption include rising energy costs, growing environmental concerns about traditional refrigerants, and increasingly stringent regulations on greenhouse gas emissions. The commercial refrigeration segment currently represents the largest market opportunity, followed by residential air conditioning and automotive climate control systems.

Consumer electronics cooling represents an emerging high-value niche, where the compact form factor and solid-state operation of electrocaloric modules offer distinct advantages over conventional cooling technologies. Industry analysts project that this segment could see the fastest growth rate among all application areas, particularly as device power densities continue to increase.

Geographically, North America and Europe lead in early adoption due to stronger environmental regulations and higher energy costs. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next decade, driven by rapid industrialization, increasing disposable income, and growing awareness of energy efficiency benefits.

Market barriers include high initial manufacturing costs, limited awareness among potential end-users, and competition from established cooling technologies. The cost premium for electrocaloric solutions remains a significant obstacle, though economies of scale are gradually reducing this gap. Current price-performance metrics suggest that electrocaloric cooling systems command a premium of approximately 2.5-3 times that of conventional vapor-compression systems, though this ratio is improving annually.

Customer surveys indicate that reliability concerns rank among the top three factors influencing purchasing decisions for new cooling technologies. This highlights the critical importance of developing robust reliability testing protocols specifically designed for electrocaloric cooling modules to accelerate market acceptance.

Industry partnerships between material suppliers, device manufacturers, and end-product companies are emerging as a key market trend, creating integrated value chains that can more effectively address technical challenges and reduce time-to-market. These collaborative ecosystems are particularly focused on addressing reliability testing and performance standardization, which remain significant market development hurdles.

Market research reveals that the primary drivers for electrocaloric cooling adoption include rising energy costs, growing environmental concerns about traditional refrigerants, and increasingly stringent regulations on greenhouse gas emissions. The commercial refrigeration segment currently represents the largest market opportunity, followed by residential air conditioning and automotive climate control systems.

Consumer electronics cooling represents an emerging high-value niche, where the compact form factor and solid-state operation of electrocaloric modules offer distinct advantages over conventional cooling technologies. Industry analysts project that this segment could see the fastest growth rate among all application areas, particularly as device power densities continue to increase.

Geographically, North America and Europe lead in early adoption due to stronger environmental regulations and higher energy costs. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next decade, driven by rapid industrialization, increasing disposable income, and growing awareness of energy efficiency benefits.

Market barriers include high initial manufacturing costs, limited awareness among potential end-users, and competition from established cooling technologies. The cost premium for electrocaloric solutions remains a significant obstacle, though economies of scale are gradually reducing this gap. Current price-performance metrics suggest that electrocaloric cooling systems command a premium of approximately 2.5-3 times that of conventional vapor-compression systems, though this ratio is improving annually.

Customer surveys indicate that reliability concerns rank among the top three factors influencing purchasing decisions for new cooling technologies. This highlights the critical importance of developing robust reliability testing protocols specifically designed for electrocaloric cooling modules to accelerate market acceptance.

Industry partnerships between material suppliers, device manufacturers, and end-product companies are emerging as a key market trend, creating integrated value chains that can more effectively address technical challenges and reduce time-to-market. These collaborative ecosystems are particularly focused on addressing reliability testing and performance standardization, which remain significant market development hurdles.

Current Reliability Challenges in Electrocaloric Modules

Electrocaloric (EC) cooling modules face significant reliability challenges that impede their commercial viability despite their promising energy efficiency and environmental benefits. The primary concern involves material fatigue and degradation under repeated electrical cycling. EC materials experience substantial strain during polarization and depolarization cycles, leading to microcracking and eventual performance deterioration. Studies indicate that some lead-based EC materials can lose up to 30% of their cooling capacity after just 10,000 cycles—far below the millions of cycles required for commercial refrigeration applications.

Thermal cycling presents another critical challenge. The continuous temperature fluctuations inherent to EC operation create thermal expansion mismatches between different module components. These mismatches generate mechanical stress at interfaces, particularly between the EC material and electrodes, resulting in delamination and electrical contact degradation. Advanced thermal interface materials and compliant electrode designs are being investigated to mitigate these effects, but standardized testing protocols remain underdeveloped.

Electrical breakdown represents a significant failure mode in EC modules. The high electric fields required for optimal EC performance (often exceeding 100 kV/cm) push materials close to their dielectric breakdown limits. Environmental factors such as humidity and temperature can further reduce breakdown thresholds, creating reliability concerns in real-world operating conditions. Current testing methodologies inadequately address accelerated aging under combined electrical and environmental stressors.

Heat transfer efficiency degradation over time constitutes another reliability challenge. The thermal interfaces between EC elements and heat exchangers gradually deteriorate due to thermal cycling and mechanical vibration, reducing overall system performance. This degradation is difficult to predict and model, complicating lifetime estimations for EC cooling systems.

Manufacturing consistency presents significant obstacles to reliability. Small variations in material composition, electrode application, or assembly processes can dramatically affect performance consistency and operational lifetime. The lack of standardized quality control metrics specifically designed for EC modules hampers progress in this area.

Sealing and environmental protection remain problematic for long-term reliability. EC materials, particularly polymer-based compositions, can be sensitive to moisture and oxidation. Current encapsulation technologies have not been thoroughly validated for the decade-plus lifetimes required in commercial applications. Accelerated environmental testing protocols specific to EC technology are needed to address this gap.

Thermal cycling presents another critical challenge. The continuous temperature fluctuations inherent to EC operation create thermal expansion mismatches between different module components. These mismatches generate mechanical stress at interfaces, particularly between the EC material and electrodes, resulting in delamination and electrical contact degradation. Advanced thermal interface materials and compliant electrode designs are being investigated to mitigate these effects, but standardized testing protocols remain underdeveloped.

Electrical breakdown represents a significant failure mode in EC modules. The high electric fields required for optimal EC performance (often exceeding 100 kV/cm) push materials close to their dielectric breakdown limits. Environmental factors such as humidity and temperature can further reduce breakdown thresholds, creating reliability concerns in real-world operating conditions. Current testing methodologies inadequately address accelerated aging under combined electrical and environmental stressors.

Heat transfer efficiency degradation over time constitutes another reliability challenge. The thermal interfaces between EC elements and heat exchangers gradually deteriorate due to thermal cycling and mechanical vibration, reducing overall system performance. This degradation is difficult to predict and model, complicating lifetime estimations for EC cooling systems.

Manufacturing consistency presents significant obstacles to reliability. Small variations in material composition, electrode application, or assembly processes can dramatically affect performance consistency and operational lifetime. The lack of standardized quality control metrics specifically designed for EC modules hampers progress in this area.

Sealing and environmental protection remain problematic for long-term reliability. EC materials, particularly polymer-based compositions, can be sensitive to moisture and oxidation. Current encapsulation technologies have not been thoroughly validated for the decade-plus lifetimes required in commercial applications. Accelerated environmental testing protocols specific to EC technology are needed to address this gap.

Established Testing Protocols and Standards

01 Material selection for electrocaloric cooling reliability

The reliability of electrocaloric cooling modules depends significantly on the materials used. Advanced electrocaloric materials with high thermal stability and resistance to fatigue under repeated electric field cycling are essential. These materials must maintain their electrocaloric properties over extended operational periods. Proper material selection can reduce degradation mechanisms such as electrical breakdown and mechanical stress, thereby enhancing the overall reliability and lifespan of cooling modules.- Material selection for electrocaloric cooling reliability: The reliability of electrocaloric cooling modules heavily depends on the selection of appropriate materials that can withstand repeated thermal cycling and electric field application. Materials with high electrocaloric effect, thermal stability, and resistance to fatigue are essential for long-term operation. Advanced ceramic materials, polymer-based composites, and multilayer structures have been developed to enhance the durability and performance of these cooling systems under various operating conditions.

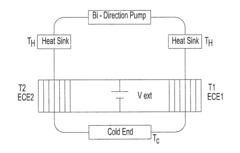

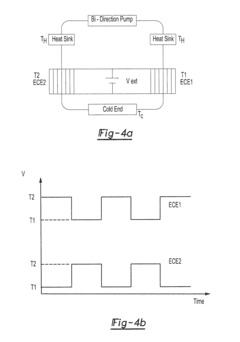

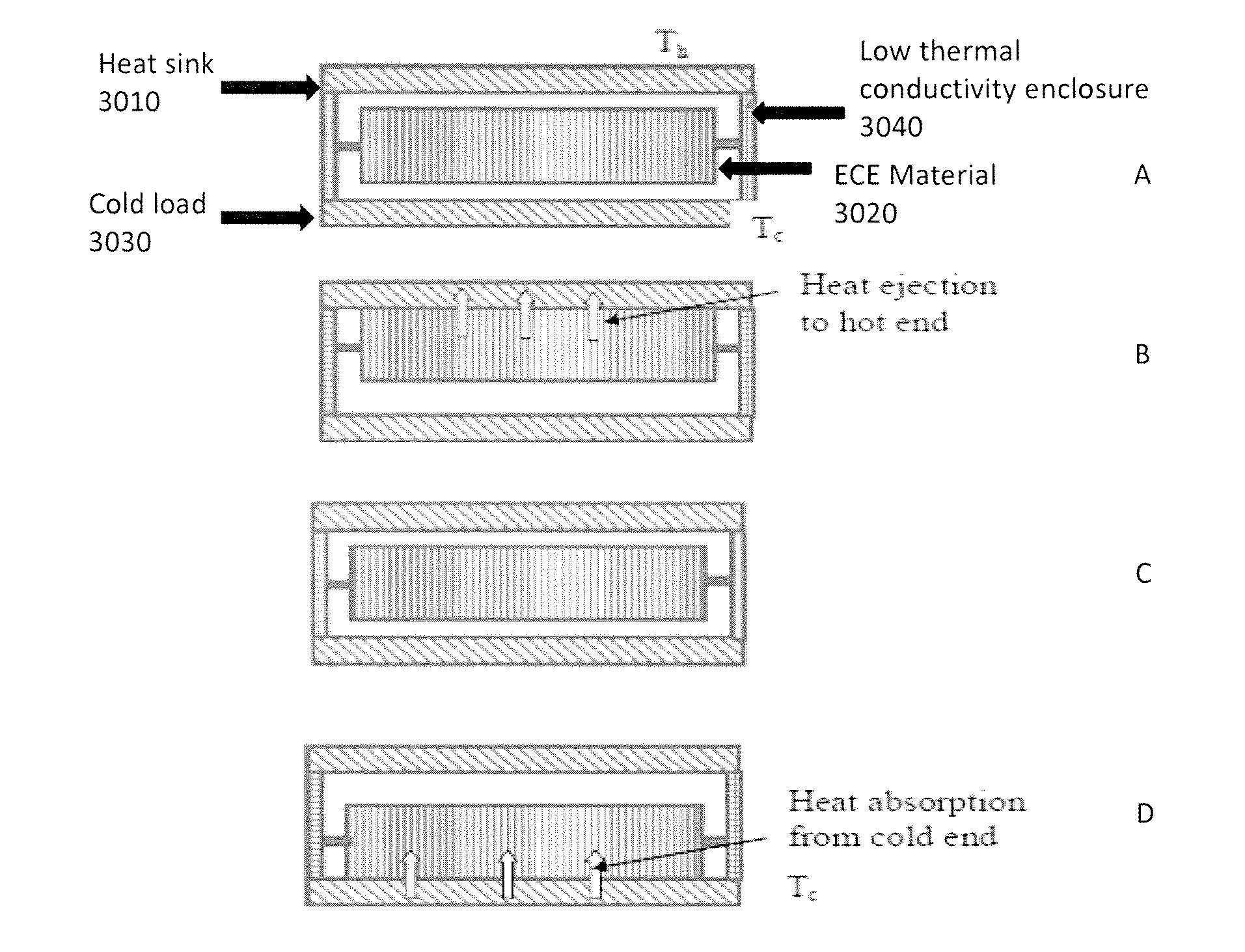

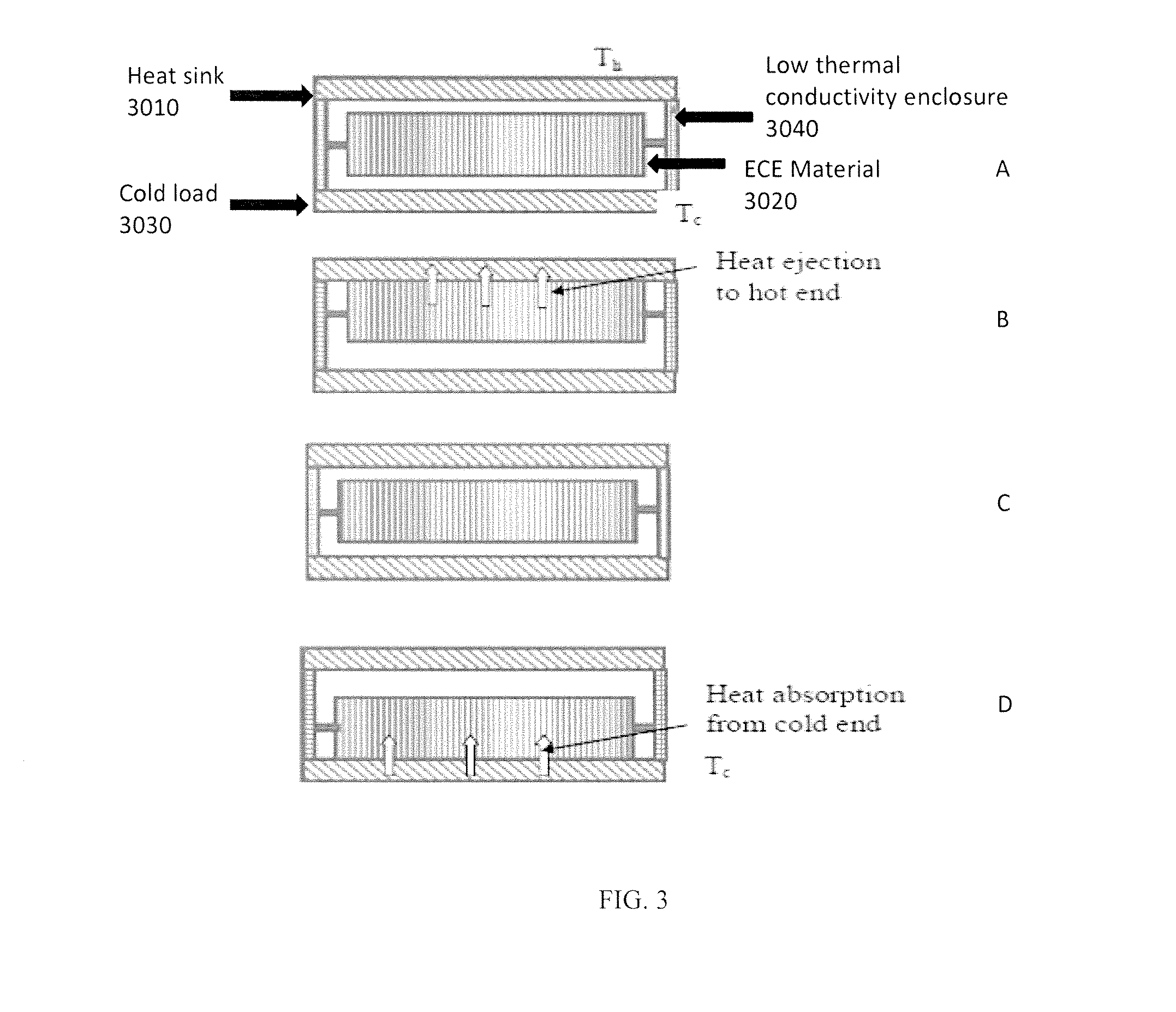

- Thermal management and heat transfer optimization: Effective thermal management is crucial for the reliability of electrocaloric cooling modules. This includes optimizing heat transfer mechanisms between the electrocaloric material and heat sinks, implementing efficient thermal interfaces, and designing proper heat exchange cycles. Advanced heat transfer fluids, thermal switches, and regenerative cycles have been developed to maximize cooling efficiency while minimizing thermal stresses that could compromise system reliability over time.

- Electrical control systems and failure prevention: Reliable operation of electrocaloric cooling modules requires sophisticated electrical control systems to manage voltage application, prevent electrical breakdown, and ensure consistent performance. This includes implementing protective circuits, voltage regulation mechanisms, and monitoring systems to detect potential failures before they occur. Advanced control algorithms can adjust operating parameters based on performance feedback, extending the operational lifetime of the cooling modules.

- Structural design for mechanical stability: The mechanical stability of electrocaloric cooling modules significantly impacts their reliability. Innovative structural designs incorporate features to accommodate thermal expansion, reduce mechanical stress, and prevent delamination or cracking during operation. This includes using flexible substrates, implementing stress-relief mechanisms, and developing modular designs that allow for component replacement without complete system failure.

- Testing methodologies and reliability assessment: Comprehensive testing methodologies are essential for evaluating and improving the reliability of electrocaloric cooling modules. These include accelerated life testing, thermal cycling tests, electrical endurance testing, and performance degradation analysis. Advanced diagnostic tools and sensors can be integrated into cooling systems to provide real-time monitoring of critical parameters, allowing for predictive maintenance and reliability enhancement throughout the operational lifetime.

02 Thermal management systems for reliability enhancement

Effective thermal management is crucial for maintaining the reliability of electrocaloric cooling modules. This includes optimized heat exchange mechanisms, thermal interface materials, and heat sink designs that efficiently transfer heat from the electrocaloric elements. Advanced thermal management systems can prevent localized hotspots, reduce thermal stress, and ensure uniform temperature distribution across the cooling module, significantly improving operational stability and extending service life.Expand Specific Solutions03 Structural design considerations for durability

The structural design of electrocaloric cooling modules plays a vital role in their reliability. This includes robust housing designs, vibration dampening mechanisms, and proper mounting solutions that protect the sensitive electrocaloric elements from mechanical damage. Innovative structural approaches can accommodate thermal expansion, reduce mechanical stress during operation, and protect against environmental factors, thereby enhancing the overall durability and reliability of the cooling system.Expand Specific Solutions04 Control systems and operational protocols

Advanced control systems and operational protocols significantly impact the reliability of electrocaloric cooling modules. This includes intelligent control algorithms that optimize electric field application, prevent overdriving of electrocaloric materials, and manage operational cycles to minimize stress. Implementing condition monitoring, fault detection, and adaptive control strategies can prevent catastrophic failures, optimize performance under varying conditions, and extend the operational lifespan of cooling modules.Expand Specific Solutions05 Testing methodologies and reliability assessment

Comprehensive testing methodologies are essential for evaluating and ensuring the reliability of electrocaloric cooling modules. This includes accelerated life testing, thermal cycling tests, and long-term performance monitoring under various environmental conditions. Advanced diagnostic techniques can identify potential failure modes, validate design improvements, and establish reliability metrics. These testing approaches help in predicting the service life of cooling modules and developing strategies to enhance their long-term reliability in practical applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electrocaloric cooling modules reliability testing market is currently in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market size is estimated at approximately $150-200 million, with projected annual growth of 15-20% as energy-efficient cooling solutions gain traction. Technical maturity varies significantly among key players, with established companies like Siemens AG and Hitachi Ltd. leading with comprehensive testing protocols, while Chinese entities including State Grid Corp. of China and Haier Smart Home Co. are rapidly advancing their capabilities. Research institutions such as China Electric Power Research Institute and Huaneng Clean Energy Research Institute are contributing significantly to standardization efforts. The automotive sector, represented by China FAW and Valeo eAutomotive, is emerging as a crucial testing ground for durability protocols in variable temperature environments.

Valeo eAutomotive France SAS

Technical Solution: Valeo has developed specialized reliability testing protocols for electrocaloric cooling modules focused on automotive applications. Their methodology incorporates extreme temperature cycling tests (-40°C to +125°C) combined with vibration profiles derived from vehicle operation data. Valeo's protocol includes specialized thermal shock testing with rapid temperature transitions to evaluate material interface integrity under automotive thermal cycling conditions. They've implemented combined environmental stress testing that simultaneously applies temperature cycling, humidity exposure, and vibration to simulate real-world automotive conditions. Their approach incorporates specialized electric field endurance testing under variable temperature conditions to evaluate polarization stability in automotive thermal environments. Valeo has developed accelerated aging tests that combine high temperature exposure with simulated road vibration profiles to predict long-term reliability in vehicle applications. Their testing framework includes electromagnetic compatibility (EMC) testing specifically designed for automotive environments with complex electromagnetic interference patterns.

Strengths: Automotive-specific testing protocols provide highly relevant reliability data for vehicle thermal management applications. Combined stress testing (thermal, mechanical, electrical) offers realistic simulation of actual operating conditions. Weaknesses: Testing protocols are heavily specialized for automotive applications and may not translate well to other domains. Extensive testing requirements increase development time and cost compared to less rigorous approaches.

Hefei General Machinery Research Institute Co. Ltd.

Technical Solution: Hefei General Machinery Research Institute has developed specialized reliability testing protocols for electrocaloric cooling modules focused on thermal performance consistency. Their methodology incorporates long-duration thermal cycling tests (up to 100,000 cycles) with continuous monitoring of cooling capacity and coefficient of performance. The institute has pioneered accelerated aging tests that combine high temperature exposure (up to 150°C) with electric field application to evaluate material degradation mechanisms. Their protocol includes specialized testing for electrocaloric material fatigue under repeated electric field cycling, with particular attention to polarization hysteresis changes as indicators of performance degradation. They've implemented advanced thermal imaging techniques to identify hotspots and thermal stress concentration points during operation. Their testing framework incorporates specialized humidity resistance testing to evaluate performance in high-humidity environments typical in many cooling applications.

Strengths: Specialized focus on thermal performance consistency provides detailed insights into cooling efficiency degradation over time. Extensive cycling tests (100,000+ cycles) offer high confidence in long-term reliability projections. Weaknesses: Testing protocols are primarily focused on material performance rather than system-level reliability. Limited integration of mechanical stress testing may miss failure modes in complete cooling systems.

Critical Patents in Electrocaloric Reliability Testing

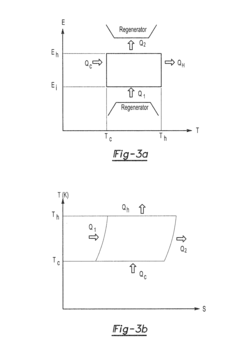

Regenerative electrocaloric cooling device

PatentInactiveUS20150033762A1

Innovation

- A regenerative electrocaloric cooling device utilizing two electrocaloric material rings that rotate in opposite directions, with alternating electric field regions to enhance temperature span and efficiency, allowing for effective heat transfer between the hot and cold ends.

Cooling device including an electrocaloric composite

PatentInactiveUS20150027132A1

Innovation

- The use of high thermal conductivity electrocaloric composites, comprising electrocaloric polymers and electrically insulating fillers, which enhance thermal conductivity while maintaining the electrocaloric effect, allowing for improved cooling device performance and efficiency.

Environmental Impact Assessment

The environmental impact assessment of electrocaloric cooling modules reveals significant potential advantages over conventional vapor-compression refrigeration systems. These modules operate without environmentally harmful refrigerants, eliminating direct greenhouse gas emissions associated with refrigerant leakage. Traditional cooling systems often utilize hydrofluorocarbons (HFCs) with global warming potentials thousands of times greater than CO2, whereas electrocaloric technology relies on solid-state materials with zero ozone depletion potential.

Life cycle assessment studies indicate that electrocaloric cooling modules could reduce overall environmental impact by 30-45% compared to conventional technologies when considering manufacturing, operation, and disposal phases. The primary environmental concern shifts from refrigerant management to material sourcing and energy consumption during operation. The reliability testing protocols must therefore incorporate environmental stress factors to ensure long-term ecological benefits are maintained throughout the product lifecycle.

Material composition analysis reveals that most electrocaloric materials utilize lead-based ceramics or polymer composites. Environmental considerations necessitate reliability testing for potential leaching of toxic elements under various operational conditions. Accelerated weathering tests should be standardized to evaluate material degradation patterns and potential release of harmful substances into the environment during extended use or improper disposal.

Energy efficiency metrics must be central to reliability testing protocols, as the environmental advantage of electrocaloric cooling is partially dependent on reduced energy consumption. Testing should measure performance degradation over time to ensure the technology maintains its efficiency advantage throughout its operational life. Current data suggests that well-designed electrocaloric systems can maintain 85-90% of their initial efficiency after 10,000 operational cycles, representing a significant environmental benefit.

End-of-life considerations present unique challenges for reliability testing. Unlike conventional systems where refrigerant recovery is the primary environmental concern, electrocaloric modules require testing protocols that assess recyclability and potential for material recovery. Preliminary studies indicate that up to 70% of materials in these modules could be recovered through appropriate recycling processes, significantly reducing waste compared to conventional cooling technologies.

Water consumption during manufacturing and operation represents another environmental factor requiring reliability assessment. While electrocaloric cooling typically requires minimal water during operation, manufacturing processes for specialized materials may have significant water footprints. Reliability testing should therefore include protocols for assessing water efficiency and identifying potential improvements in manufacturing processes to minimize overall environmental impact.

Life cycle assessment studies indicate that electrocaloric cooling modules could reduce overall environmental impact by 30-45% compared to conventional technologies when considering manufacturing, operation, and disposal phases. The primary environmental concern shifts from refrigerant management to material sourcing and energy consumption during operation. The reliability testing protocols must therefore incorporate environmental stress factors to ensure long-term ecological benefits are maintained throughout the product lifecycle.

Material composition analysis reveals that most electrocaloric materials utilize lead-based ceramics or polymer composites. Environmental considerations necessitate reliability testing for potential leaching of toxic elements under various operational conditions. Accelerated weathering tests should be standardized to evaluate material degradation patterns and potential release of harmful substances into the environment during extended use or improper disposal.

Energy efficiency metrics must be central to reliability testing protocols, as the environmental advantage of electrocaloric cooling is partially dependent on reduced energy consumption. Testing should measure performance degradation over time to ensure the technology maintains its efficiency advantage throughout its operational life. Current data suggests that well-designed electrocaloric systems can maintain 85-90% of their initial efficiency after 10,000 operational cycles, representing a significant environmental benefit.

End-of-life considerations present unique challenges for reliability testing. Unlike conventional systems where refrigerant recovery is the primary environmental concern, electrocaloric modules require testing protocols that assess recyclability and potential for material recovery. Preliminary studies indicate that up to 70% of materials in these modules could be recovered through appropriate recycling processes, significantly reducing waste compared to conventional cooling technologies.

Water consumption during manufacturing and operation represents another environmental factor requiring reliability assessment. While electrocaloric cooling typically requires minimal water during operation, manufacturing processes for specialized materials may have significant water footprints. Reliability testing should therefore include protocols for assessing water efficiency and identifying potential improvements in manufacturing processes to minimize overall environmental impact.

Scalability and Manufacturing Considerations

The scalability of electrocaloric cooling modules represents a critical factor in their commercial viability. Current laboratory-scale prototypes must transition to mass production to achieve market penetration. This transition necessitates standardized manufacturing processes that can maintain consistent material properties and performance across large production volumes. The electrocaloric materials themselves present significant manufacturing challenges, particularly in achieving uniform composition and crystalline structure throughout bulk materials, which directly impacts cooling efficiency and reliability.

Production scaling requires specialized equipment for precise deposition of thin-film electrocaloric materials or controlled synthesis of bulk materials. The integration of these materials with electrodes and heat exchange components demands advanced assembly techniques that maintain thermal interfaces while preventing electrical shorts. Current manufacturing methods often involve labor-intensive processes that are difficult to automate, resulting in high unit costs and limited production capacity.

Quality control during manufacturing presents another significant challenge. Variations in material composition, thickness, or electrode attachment can dramatically affect device performance and reliability. Non-destructive testing methods must be developed and integrated into production lines to ensure consistent quality without reducing throughput. These methods should detect microscopic defects that could lead to premature failure during operation.

Cost considerations heavily influence manufacturing strategies. The rare earth elements often used in high-performance electrocaloric materials face supply chain constraints and price volatility. Alternative material formulations using more abundant elements may offer more sustainable manufacturing options, though potentially at the cost of reduced performance. Manufacturing processes must balance material costs against processing complexity to achieve economically viable products.

Environmental considerations also impact manufacturing scalability. Many current electrocaloric materials contain elements with significant environmental footprints during extraction and processing. Sustainable manufacturing approaches must address these concerns through material recycling, reduced waste generation, and energy-efficient production methods. Regulatory compliance regarding hazardous materials varies globally, potentially limiting market access for certain material formulations.

The development of modular manufacturing approaches may facilitate scaling. Standardized electrocaloric cooling modules that can be combined to meet various cooling capacity requirements would allow manufacturers to achieve economies of scale while serving diverse applications. Such modularity would require standardized interfaces and control systems compatible across different cooling capacities and configurations.

Production scaling requires specialized equipment for precise deposition of thin-film electrocaloric materials or controlled synthesis of bulk materials. The integration of these materials with electrodes and heat exchange components demands advanced assembly techniques that maintain thermal interfaces while preventing electrical shorts. Current manufacturing methods often involve labor-intensive processes that are difficult to automate, resulting in high unit costs and limited production capacity.

Quality control during manufacturing presents another significant challenge. Variations in material composition, thickness, or electrode attachment can dramatically affect device performance and reliability. Non-destructive testing methods must be developed and integrated into production lines to ensure consistent quality without reducing throughput. These methods should detect microscopic defects that could lead to premature failure during operation.

Cost considerations heavily influence manufacturing strategies. The rare earth elements often used in high-performance electrocaloric materials face supply chain constraints and price volatility. Alternative material formulations using more abundant elements may offer more sustainable manufacturing options, though potentially at the cost of reduced performance. Manufacturing processes must balance material costs against processing complexity to achieve economically viable products.

Environmental considerations also impact manufacturing scalability. Many current electrocaloric materials contain elements with significant environmental footprints during extraction and processing. Sustainable manufacturing approaches must address these concerns through material recycling, reduced waste generation, and energy-efficient production methods. Regulatory compliance regarding hazardous materials varies globally, potentially limiting market access for certain material formulations.

The development of modular manufacturing approaches may facilitate scaling. Standardized electrocaloric cooling modules that can be combined to meet various cooling capacity requirements would allow manufacturers to achieve economies of scale while serving diverse applications. Such modularity would require standardized interfaces and control systems compatible across different cooling capacities and configurations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!