Cryogenic Applications: Limits Of Electrocaloric Cooling At Low Temperatures

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Background and Objectives

Electrocaloric cooling represents a significant advancement in solid-state refrigeration technology, emerging as a promising alternative to conventional vapor-compression systems. The phenomenon, first observed in the 1930s, involves temperature changes in dielectric materials when subjected to varying electric fields. This technology has gained renewed interest over the past two decades due to its potential for energy efficiency, environmental friendliness, and compact design capabilities.

The evolution of electrocaloric cooling technology has been marked by several key milestones. Initial discoveries focused on ferroelectric materials exhibiting modest temperature changes. A breakthrough came in 2006 when researchers demonstrated giant electrocaloric effects in thin films, achieving temperature changes of several degrees Kelvin. This discovery catalyzed intensive research efforts worldwide, expanding the material library and enhancing understanding of the underlying physical mechanisms.

Current technological objectives in electrocaloric cooling research center on addressing fundamental limitations at cryogenic temperatures. While the technology shows promise at room temperature and above, its efficiency and effectiveness diminish significantly as temperatures approach cryogenic levels (typically below 123K). This limitation presents a critical challenge for applications requiring deep cooling, such as quantum computing, superconducting devices, and specialized scientific instrumentation.

The primary goal of current research is to understand the physical boundaries that constrain electrocaloric effects at low temperatures. These include reduced polarizability of materials, quantum effects becoming dominant, and thermal conductivity changes. Researchers aim to develop novel materials and device architectures that can maintain substantial electrocaloric effects even at temperatures approaching absolute zero.

Another key objective is to bridge the gap between theoretical models and experimental results. Current theoretical frameworks inadequately explain the observed diminishing returns of electrocaloric cooling at cryogenic temperatures, necessitating more sophisticated models that incorporate quantum mechanical effects and non-linear material responses.

From an application perspective, the technology aims to achieve cooling power densities competitive with established cryogenic technologies while maintaining the inherent advantages of solid-state cooling. This includes developing cascaded systems that can efficiently span wide temperature ranges from ambient to cryogenic conditions.

The field is also focused on material discovery and engineering, seeking compounds with enhanced electrocaloric properties at low temperatures. This includes exploring composite materials, nanostructured systems, and novel material classes beyond traditional ferroelectrics, such as relaxor ferroelectrics and antiferroelectric materials that might exhibit unique behaviors in cryogenic environments.

The evolution of electrocaloric cooling technology has been marked by several key milestones. Initial discoveries focused on ferroelectric materials exhibiting modest temperature changes. A breakthrough came in 2006 when researchers demonstrated giant electrocaloric effects in thin films, achieving temperature changes of several degrees Kelvin. This discovery catalyzed intensive research efforts worldwide, expanding the material library and enhancing understanding of the underlying physical mechanisms.

Current technological objectives in electrocaloric cooling research center on addressing fundamental limitations at cryogenic temperatures. While the technology shows promise at room temperature and above, its efficiency and effectiveness diminish significantly as temperatures approach cryogenic levels (typically below 123K). This limitation presents a critical challenge for applications requiring deep cooling, such as quantum computing, superconducting devices, and specialized scientific instrumentation.

The primary goal of current research is to understand the physical boundaries that constrain electrocaloric effects at low temperatures. These include reduced polarizability of materials, quantum effects becoming dominant, and thermal conductivity changes. Researchers aim to develop novel materials and device architectures that can maintain substantial electrocaloric effects even at temperatures approaching absolute zero.

Another key objective is to bridge the gap between theoretical models and experimental results. Current theoretical frameworks inadequately explain the observed diminishing returns of electrocaloric cooling at cryogenic temperatures, necessitating more sophisticated models that incorporate quantum mechanical effects and non-linear material responses.

From an application perspective, the technology aims to achieve cooling power densities competitive with established cryogenic technologies while maintaining the inherent advantages of solid-state cooling. This includes developing cascaded systems that can efficiently span wide temperature ranges from ambient to cryogenic conditions.

The field is also focused on material discovery and engineering, seeking compounds with enhanced electrocaloric properties at low temperatures. This includes exploring composite materials, nanostructured systems, and novel material classes beyond traditional ferroelectrics, such as relaxor ferroelectrics and antiferroelectric materials that might exhibit unique behaviors in cryogenic environments.

Market Analysis for Cryogenic Cooling Technologies

The global cryogenic cooling technology market is experiencing robust growth, driven primarily by increasing applications in healthcare, electronics, energy, and scientific research sectors. Currently valued at approximately 22 billion USD, the market is projected to expand at a compound annual growth rate of 6.8% through 2028, with electrocaloric cooling technologies representing an emerging segment with significant potential for disruption.

Healthcare applications constitute the largest market share at 38%, with MRI machines and biospecimen preservation being primary demand drivers. The semiconductor industry follows closely at 27%, where ultra-low temperature environments are essential for advanced manufacturing processes and quantum computing development. Space exploration and scientific research collectively account for 18% of market demand, while energy and other industrial applications comprise the remaining 17%.

Geographically, North America leads with 42% market share due to substantial investments in healthcare infrastructure and advanced research facilities. Asia-Pacific represents the fastest-growing region with a 9.2% growth rate, fueled by China's and South Korea's expanding semiconductor industries and Japan's medical technology advancements. Europe holds 28% of the market, with particularly strong demand in Germany and France for scientific research applications.

The electrocaloric cooling segment, while currently representing only 3% of the total cryogenic cooling market, is attracting significant investment attention due to its potential efficiency advantages over conventional gas-compression systems. Venture capital funding for electrocaloric technology startups has increased by 215% over the past three years, reaching 780 million USD in 2022.

Key market challenges include the high initial capital expenditure required for cryogenic systems, with typical industrial installations ranging from 500,000 to 3 million USD depending on scale and temperature requirements. Operating costs present another barrier, as conventional cryogenic systems consume substantial energy, averaging 15-20% of total facility energy usage in applicable industries.

Customer demand is increasingly focused on energy efficiency, with 76% of procurement specialists citing operational cost reduction as their primary consideration when evaluating new cryogenic technologies. This trend strongly favors electrocaloric solutions, which theoretically offer 30-40% energy savings compared to traditional methods, though practical implementations have yet to fully realize this potential at very low temperatures.

Market forecasts indicate that breakthrough technologies capable of efficient cooling below 20K could capture up to 12% of the total cryogenic market within five years of commercialization, representing a potential 3 billion USD opportunity for companies that successfully overcome the current technical limitations of electrocaloric cooling at extreme low temperatures.

Healthcare applications constitute the largest market share at 38%, with MRI machines and biospecimen preservation being primary demand drivers. The semiconductor industry follows closely at 27%, where ultra-low temperature environments are essential for advanced manufacturing processes and quantum computing development. Space exploration and scientific research collectively account for 18% of market demand, while energy and other industrial applications comprise the remaining 17%.

Geographically, North America leads with 42% market share due to substantial investments in healthcare infrastructure and advanced research facilities. Asia-Pacific represents the fastest-growing region with a 9.2% growth rate, fueled by China's and South Korea's expanding semiconductor industries and Japan's medical technology advancements. Europe holds 28% of the market, with particularly strong demand in Germany and France for scientific research applications.

The electrocaloric cooling segment, while currently representing only 3% of the total cryogenic cooling market, is attracting significant investment attention due to its potential efficiency advantages over conventional gas-compression systems. Venture capital funding for electrocaloric technology startups has increased by 215% over the past three years, reaching 780 million USD in 2022.

Key market challenges include the high initial capital expenditure required for cryogenic systems, with typical industrial installations ranging from 500,000 to 3 million USD depending on scale and temperature requirements. Operating costs present another barrier, as conventional cryogenic systems consume substantial energy, averaging 15-20% of total facility energy usage in applicable industries.

Customer demand is increasingly focused on energy efficiency, with 76% of procurement specialists citing operational cost reduction as their primary consideration when evaluating new cryogenic technologies. This trend strongly favors electrocaloric solutions, which theoretically offer 30-40% energy savings compared to traditional methods, though practical implementations have yet to fully realize this potential at very low temperatures.

Market forecasts indicate that breakthrough technologies capable of efficient cooling below 20K could capture up to 12% of the total cryogenic market within five years of commercialization, representing a potential 3 billion USD opportunity for companies that successfully overcome the current technical limitations of electrocaloric cooling at extreme low temperatures.

Current Limitations of Electrocaloric Materials at Low Temperatures

Electrocaloric (EC) materials face significant challenges when operating at cryogenic temperatures, primarily due to the fundamental physics governing their behavior. The electrocaloric effect—a temperature change in a material when an electric field is applied or removed—diminishes substantially as temperatures approach absolute zero. This limitation stems from the reduced thermal energy available for dipole reorientation, which is the core mechanism behind the EC effect.

At low temperatures (typically below 50K), the entropy change that drives cooling becomes increasingly restricted. Quantum mechanical effects begin to dominate, and the classical thermodynamic models that accurately predict EC performance at higher temperatures become less reliable. Measurements have shown that the electrocaloric coefficient (ΔT/ΔE) decreases almost exponentially as temperature drops below 100K, making conventional EC materials inefficient for deep cryogenic applications.

Material properties also change dramatically at cryogenic temperatures. Many promising EC materials, particularly ferroelectric ceramics like BaTiO₃ and PbZr₁₋ₓTiₓO₃ (PZT), experience significant reduction in their dielectric permittivity and polarization response. The decreased mobility of dipoles at low temperatures results in diminished entropy changes upon field application, directly impacting cooling capacity.

Another critical limitation is the electrical breakdown strength of materials at cryogenic temperatures. While some materials show improved breakdown strength when cooled, the extremely high electric fields required to produce meaningful EC effects at low temperatures often exceed practical operational limits, creating reliability and safety concerns for real-world applications.

Thermal conductivity presents a paradoxical challenge: while higher thermal conductivity is generally beneficial for heat transfer in cooling applications, it also accelerates thermal leakage that counteracts the desired temperature gradient. At cryogenic temperatures, managing this balance becomes increasingly difficult as the specific heat capacity of materials decreases substantially.

The integration of EC materials into functional cooling systems faces additional hurdles at low temperatures. Conventional heat exchange fluids become highly viscous or freeze entirely, requiring specialized cryogenic working fluids. Mechanical components must also be designed to operate reliably under extreme temperature conditions, adding complexity and cost.

Current state-of-the-art EC materials show cooling capabilities that drop below practical utility thresholds (typically <0.1K temperature change) when operating below 20K. This performance gap represents a fundamental barrier to implementing EC technology for applications requiring temperatures approaching absolute zero, such as quantum computing hardware, superconducting electronics, and certain space-based instruments.

At low temperatures (typically below 50K), the entropy change that drives cooling becomes increasingly restricted. Quantum mechanical effects begin to dominate, and the classical thermodynamic models that accurately predict EC performance at higher temperatures become less reliable. Measurements have shown that the electrocaloric coefficient (ΔT/ΔE) decreases almost exponentially as temperature drops below 100K, making conventional EC materials inefficient for deep cryogenic applications.

Material properties also change dramatically at cryogenic temperatures. Many promising EC materials, particularly ferroelectric ceramics like BaTiO₃ and PbZr₁₋ₓTiₓO₃ (PZT), experience significant reduction in their dielectric permittivity and polarization response. The decreased mobility of dipoles at low temperatures results in diminished entropy changes upon field application, directly impacting cooling capacity.

Another critical limitation is the electrical breakdown strength of materials at cryogenic temperatures. While some materials show improved breakdown strength when cooled, the extremely high electric fields required to produce meaningful EC effects at low temperatures often exceed practical operational limits, creating reliability and safety concerns for real-world applications.

Thermal conductivity presents a paradoxical challenge: while higher thermal conductivity is generally beneficial for heat transfer in cooling applications, it also accelerates thermal leakage that counteracts the desired temperature gradient. At cryogenic temperatures, managing this balance becomes increasingly difficult as the specific heat capacity of materials decreases substantially.

The integration of EC materials into functional cooling systems faces additional hurdles at low temperatures. Conventional heat exchange fluids become highly viscous or freeze entirely, requiring specialized cryogenic working fluids. Mechanical components must also be designed to operate reliably under extreme temperature conditions, adding complexity and cost.

Current state-of-the-art EC materials show cooling capabilities that drop below practical utility thresholds (typically <0.1K temperature change) when operating below 20K. This performance gap represents a fundamental barrier to implementing EC technology for applications requiring temperatures approaching absolute zero, such as quantum computing hardware, superconducting electronics, and certain space-based instruments.

Existing Electrocaloric Cooling Implementation Approaches

01 Electrocaloric materials for efficient cooling systems

Electrocaloric materials exhibit temperature changes when subjected to electric fields, making them suitable for cooling applications. These materials can be engineered to maximize their cooling efficiency by optimizing their composition, structure, and electrical properties. Advanced electrocaloric materials with enhanced thermal properties can significantly improve the coefficient of performance (COP) of cooling systems while reducing energy consumption compared to conventional vapor-compression systems.- Electrocaloric materials for efficient cooling: Various electrocaloric materials can be used to enhance cooling efficiency in electrocaloric systems. These materials exhibit a temperature change when an electric field is applied or removed. Materials such as relaxor ferroelectrics, polymers, and ceramic-polymer composites have shown promising electrocaloric effects. The selection of appropriate materials with high electrocaloric coefficients is crucial for maximizing the cooling efficiency of electrocaloric systems.

- Cooling cycle optimization techniques: Optimizing the cooling cycle in electrocaloric systems significantly improves efficiency. This includes precise control of the electric field application and removal timing, heat transfer mechanisms, and cycle frequency. Advanced cycle designs incorporate regenerative processes, multi-stage configurations, and cascaded systems to maximize the temperature differential and cooling capacity. Proper thermal management during the cycle phases ensures that maximum cooling efficiency is achieved.

- Heat transfer enhancement methods: Efficient heat transfer is critical for electrocaloric cooling performance. Various methods are employed to enhance heat exchange between the electrocaloric material and the heat source/sink. These include using specialized heat transfer fluids, increasing contact surface area, implementing microchannel designs, and employing thermal switches. Improved heat transfer reduces thermal resistance and cycle time, leading to higher cooling power and coefficient of performance.

- System architecture and device integration: The overall architecture of electrocaloric cooling systems plays a crucial role in determining efficiency. Innovative designs include compact arrangements of electrocaloric elements, integration with existing cooling systems, and modular approaches that allow for scalability. Advanced system architectures incorporate optimized fluid flow paths, reduced parasitic heat loads, and efficient electrical connections to minimize energy losses and maximize cooling performance.

- Control strategies and power management: Sophisticated control strategies and power management techniques significantly improve the efficiency of electrocaloric cooling systems. These include adaptive control algorithms that respond to varying cooling demands, pulse width modulation of the applied electric field, and energy recovery circuits that capture and reuse electrical energy. Advanced sensing and feedback mechanisms enable real-time optimization of operating parameters to maintain maximum cooling efficiency under different conditions.

02 Cooling cycle optimization techniques

Various techniques can be employed to optimize the electrocaloric cooling cycle for maximum efficiency. These include implementing regenerative cycles, optimizing the timing of electric field application and removal, and designing efficient heat transfer mechanisms. Advanced control algorithms can dynamically adjust operating parameters based on cooling demand and ambient conditions, further enhancing system efficiency. Multi-stage cooling arrangements can also be implemented to achieve greater temperature differentials and improved overall performance.Expand Specific Solutions03 Heat transfer mechanisms in electrocaloric systems

Efficient heat transfer between the electrocaloric material and the heat source/sink is crucial for maximizing cooling efficiency. Various heat transfer mechanisms can be employed, including direct contact, fluid-based heat exchange, and thermal switches. The design of heat exchangers with minimal thermal resistance and the selection of appropriate heat transfer fluids can significantly impact the overall system performance. Advanced thermal management techniques can reduce parasitic heat losses and improve the effective cooling capacity.Expand Specific Solutions04 System design and integration for enhanced efficiency

The overall design and integration of electrocaloric cooling systems play a significant role in determining their efficiency. Factors such as component arrangement, insulation, and system architecture can be optimized to minimize energy losses. Compact designs with reduced thermal mass can improve response times and cycling efficiency. Integration with energy recovery systems and smart controls can further enhance performance. Modular approaches allow for scalable solutions adaptable to various cooling requirements.Expand Specific Solutions05 Performance metrics and efficiency evaluation methods

Various metrics and methods are used to evaluate the efficiency of electrocaloric cooling systems. These include coefficient of performance (COP), energy efficiency ratio (EER), and specific cooling power. Standardized testing protocols enable comparison between different electrocaloric systems and with conventional cooling technologies. Advanced measurement techniques can accurately determine the electrocaloric effect and system performance under various operating conditions, helping to identify optimization opportunities and validate theoretical models.Expand Specific Solutions

Leading Organizations in Electrocaloric Research and Development

Electrocaloric cooling at cryogenic temperatures represents an emerging frontier in refrigeration technology, currently in early development stages with limited market penetration. The global cryogenic equipment market, valued at approximately $20 billion, shows significant growth potential as industries seek energy-efficient cooling alternatives. Technical maturity varies considerably among key players: academic institutions (Southern University of Science & Technology, Oxford, Tongji University) focus on fundamental research, while established industrial entities (Air Liquide, Oxford Instruments, Raytheon) possess advanced manufacturing capabilities. Specialized companies like kiutra GmbH and Photon Spot are developing niche applications, while major corporations (Samsung, Haier) explore commercial implementations. The technology faces significant challenges in achieving efficient cooling below 10K, with current research concentrated on novel materials and system designs to overcome thermodynamic limitations.

Air Liquide SA

Technical Solution: Air Liquide在低温电热冷却领域开发了混合制冷技术方案,结合传统气体液化与新型电热材料。其Turbo-Brayton系列制冷系统采用闭环氦气循环,能够提供20-80K温度范围内的高效冷却,并通过集成电热冷却模块实现精确温度调节。针对电热冷却在低温下效率降低的问题,Air Liquide开发了多层次复合电热材料,在不同温度区间优化性能。公司的CRYOCAP™技术将传统气体液化与电热冷却相结合,显著提高了能源效率。Air Liquide还研发了专用于超导应用的冷却系统,通过精确控制温度梯度,解决了电热材料在低温下热滞后效应增强的问题。其创新的热交换器设计增强了低温环境下的热传导效率,使电热冷却在接近绝对零度的环境中仍能发挥有限但有效的温度调节功能。

优势:全球供应链网络完善,气体液化技术领先,系统可靠性高,能源效率优异,适用温度范围广。缺点:系统体积较大,初始投资成本高,在极低温(<4K)应用中效率受限,技术转型速度相对较慢。

Oxford Instruments NanoTechnology Tools Ltd.

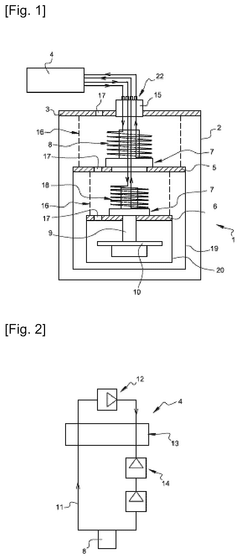

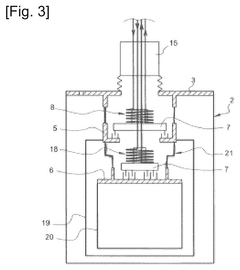

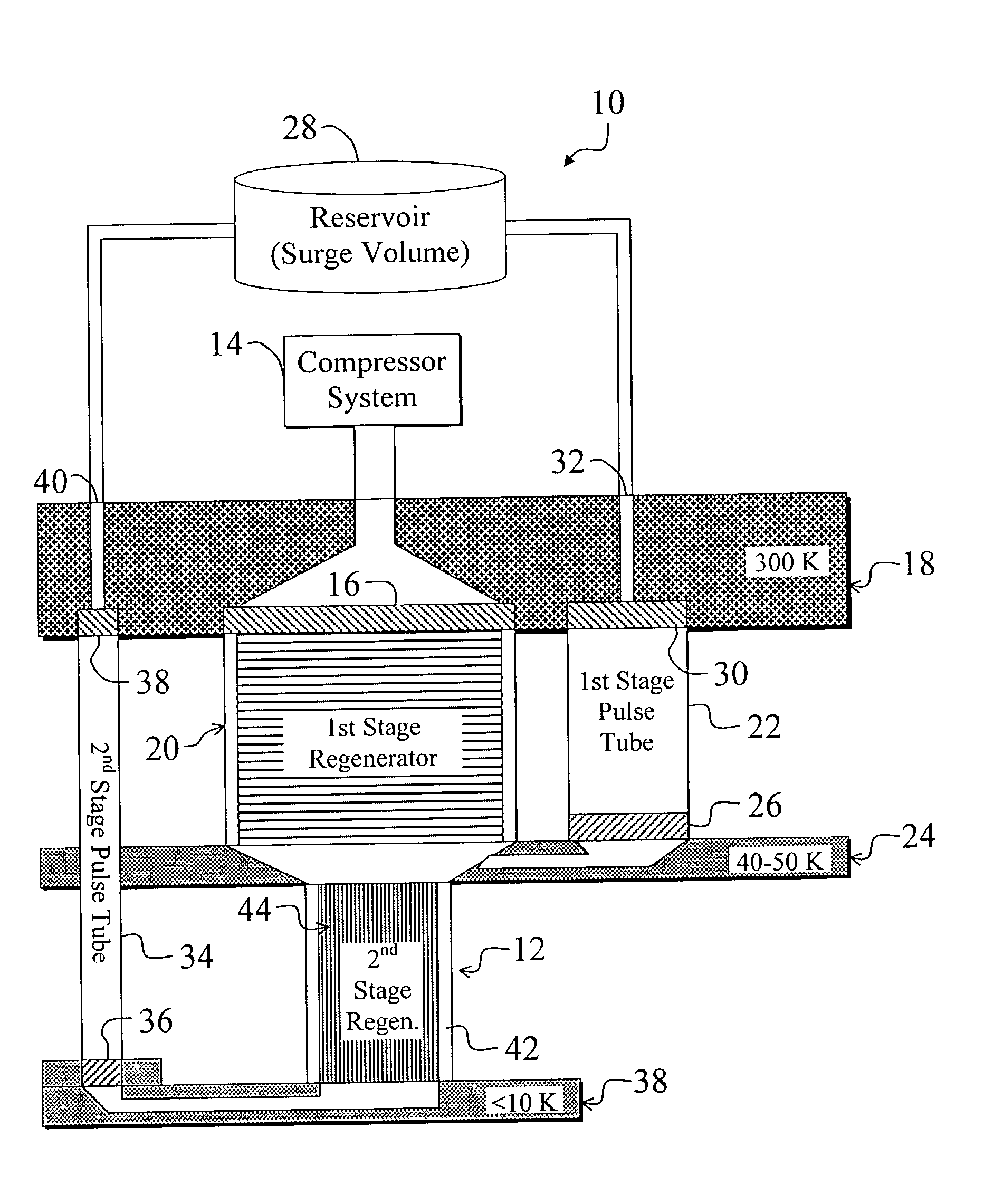

Technical Solution: Oxford Instruments在低温电热冷却领域开发了先进的脉冲管制冷机(Pulse Tube Coolers)和干式稀释制冷机(Dry Dilution Refrigerators)技术方案。其Triton系列干式稀释制冷机结合了脉冲管预冷和3He/4He混合物循环,能够在无液氦条件下实现低至10毫开尔文的超低温。针对电热冷却在低温环境下效率降低的问题,Oxford Instruments采用了多级冷却策略,先通过机械制冷将温度降至4-10K范围,再利用电热材料进行精确温度控制。公司还开发了专用的低温电子学和传感器系统,能够在极低温环境下精确测量和控制电热效应。其OptistatDry系统特别设计用于光谱学和磁学研究,集成了电热控制模块,实现了±0.1K的温度稳定性,为研究电热材料在低温下的性能提供了理想平台。

优势:技术成熟度高,产品线完整,温度控制精度高,系统集成度好,售后服务网络全球覆盖。缺点:系统复杂度高,价格昂贵,能源效率在某些工作温度范围内不如竞争对手,设备体积较大,不适合空间受限的应用场景。

Critical Patents and Breakthroughs in Low-Temperature Electrocaloric Effects

Cryogenic refrigeration device

PatentPendingUS20250020369A1

Innovation

- The device employs a cryogenic cooler with a cycle fluid thermodynamic cycle and a set of heat exchangers to achieve multiple cold temperatures, using a liquefied cycle fluid like helium or nitrogen, with separate heat exchangers connected mechanically and arranged vertically, allowing for efficient cooling and reheating without direct contact with the enclosure's internal gas volume.

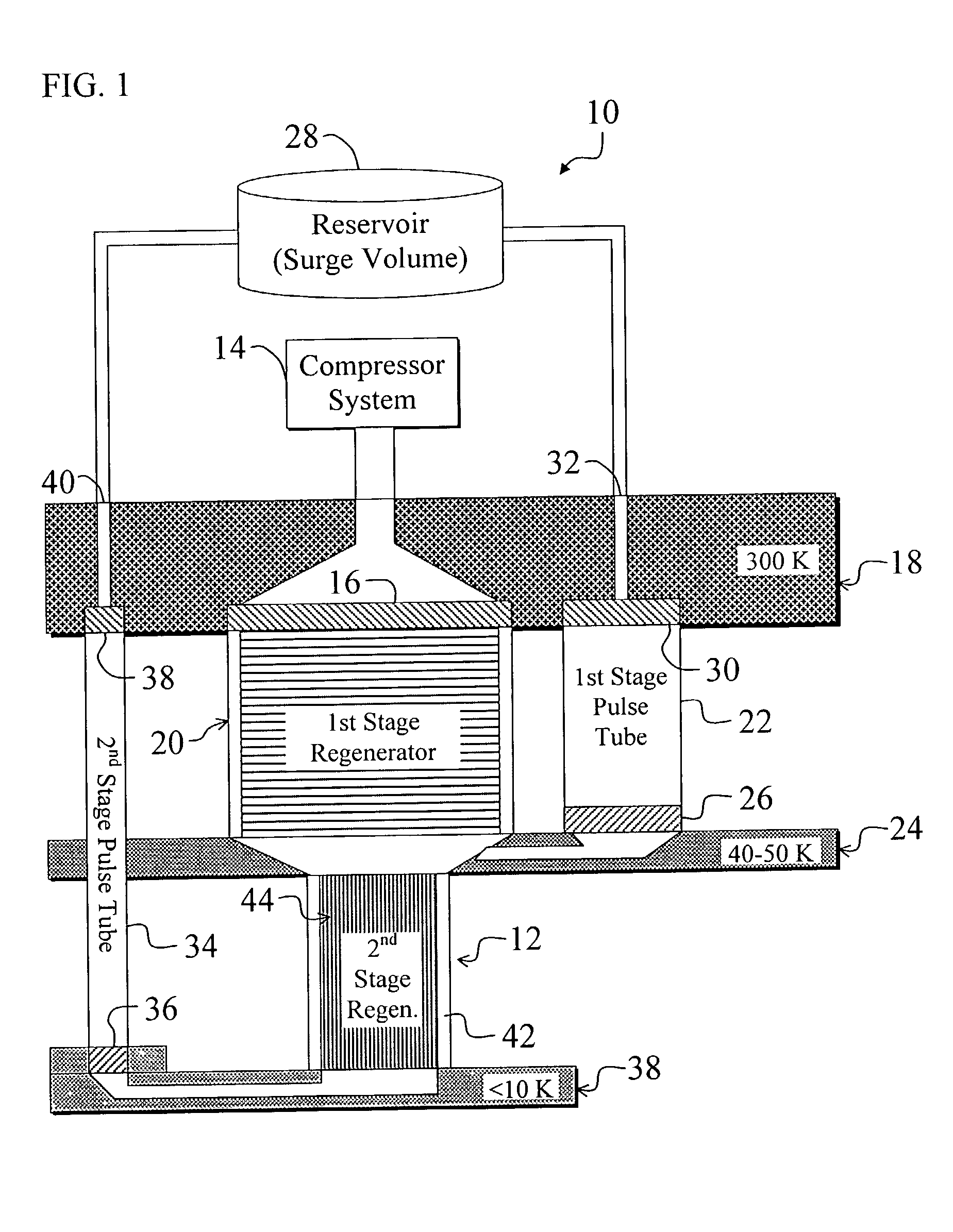

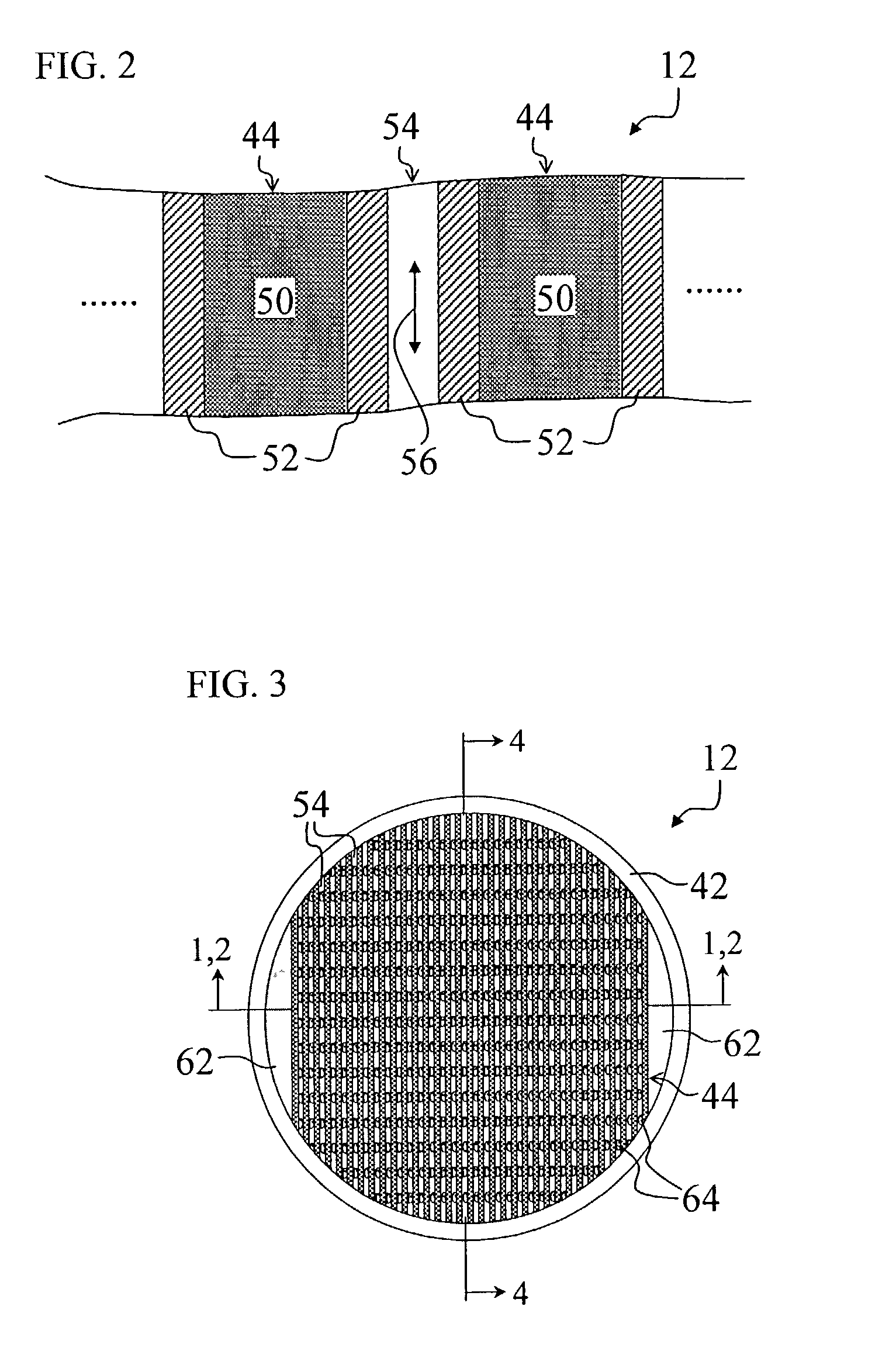

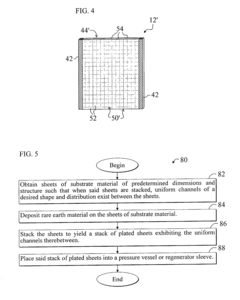

High-frequency, low-temperature regenerative heat exchanger

PatentInactiveUS20040000149A1

Innovation

- A regenerator design featuring a substrate with rare earth material deposited on its surface, providing a high thermal penetration depth and efficient heat transfer, allowing for compact, lightweight, and high-frequency operation at temperatures below 15 K, utilizing a substrate with channels or pores and a matrix porosity of approximately 15% to enhance thermal regeneration.

Material Science Challenges in Extreme Temperature Applications

The extreme temperature conditions encountered in cryogenic applications present significant challenges for materials science, particularly in the context of electrocaloric cooling technologies. At low temperatures approaching absolute zero, conventional materials exhibit dramatically altered properties that can limit cooling efficiency and operational capabilities.

Primary materials challenges include the significant reduction in thermal conductivity of most substances at cryogenic temperatures, which impedes heat transfer essential for cooling cycles. Additionally, many materials become increasingly brittle, with reduced ductility and toughness, raising reliability concerns for mechanical components in cooling systems.

Electrical properties undergo substantial changes as well, with semiconductors potentially losing their characteristic behaviors and superconducting transitions occurring in certain materials. These transitions fundamentally alter how materials interact with electric fields, directly impacting electrocaloric effects that rely on such interactions.

The electrocaloric effect itself—the temperature change in dielectric materials under varying electric fields—faces diminishing returns at extremely low temperatures. This occurs because thermal energy becomes increasingly scarce, and the entropy changes that drive electrocaloric cooling become progressively smaller, following thermodynamic principles.

Material selection becomes critically important, as few substances maintain desirable properties across extreme temperature gradients. Ceramic materials with specialized compositions show promise but require precise engineering to optimize their electrocaloric response in the cryogenic regime.

Interface phenomena between different materials in cooling systems introduce additional complications, with thermal boundary resistance becoming a dominant factor limiting heat transfer efficiency. Thermal expansion mismatches between components can create mechanical stresses that compromise system integrity during thermal cycling.

Advanced composite materials and engineered structures are being developed to address these challenges, including nanoscale architectures that can maintain more consistent properties across temperature ranges. Materials with tailored crystal structures and controlled defect distributions show potential for enhanced performance in extreme cold environments.

Research efforts are increasingly focused on quantum mechanical effects that emerge at ultra-low temperatures, which may offer novel approaches to thermal management beyond classical electrocaloric mechanisms. Understanding and harnessing these quantum effects represents both a significant challenge and opportunity for next-generation cryogenic cooling technologies.

Primary materials challenges include the significant reduction in thermal conductivity of most substances at cryogenic temperatures, which impedes heat transfer essential for cooling cycles. Additionally, many materials become increasingly brittle, with reduced ductility and toughness, raising reliability concerns for mechanical components in cooling systems.

Electrical properties undergo substantial changes as well, with semiconductors potentially losing their characteristic behaviors and superconducting transitions occurring in certain materials. These transitions fundamentally alter how materials interact with electric fields, directly impacting electrocaloric effects that rely on such interactions.

The electrocaloric effect itself—the temperature change in dielectric materials under varying electric fields—faces diminishing returns at extremely low temperatures. This occurs because thermal energy becomes increasingly scarce, and the entropy changes that drive electrocaloric cooling become progressively smaller, following thermodynamic principles.

Material selection becomes critically important, as few substances maintain desirable properties across extreme temperature gradients. Ceramic materials with specialized compositions show promise but require precise engineering to optimize their electrocaloric response in the cryogenic regime.

Interface phenomena between different materials in cooling systems introduce additional complications, with thermal boundary resistance becoming a dominant factor limiting heat transfer efficiency. Thermal expansion mismatches between components can create mechanical stresses that compromise system integrity during thermal cycling.

Advanced composite materials and engineered structures are being developed to address these challenges, including nanoscale architectures that can maintain more consistent properties across temperature ranges. Materials with tailored crystal structures and controlled defect distributions show potential for enhanced performance in extreme cold environments.

Research efforts are increasingly focused on quantum mechanical effects that emerge at ultra-low temperatures, which may offer novel approaches to thermal management beyond classical electrocaloric mechanisms. Understanding and harnessing these quantum effects represents both a significant challenge and opportunity for next-generation cryogenic cooling technologies.

Energy Efficiency Comparison with Conventional Cryogenic Methods

When evaluating electrocaloric cooling for cryogenic applications, energy efficiency emerges as a critical parameter for comparison with established cooling technologies. Conventional cryogenic cooling methods such as vapor-compression cycles, Gifford-McMahon cryocoolers, pulse tube refrigerators, and Stirling coolers have well-documented efficiency metrics, typically measured by their coefficient of performance (COP) or specific power consumption.

Electrocaloric cooling systems demonstrate promising efficiency advantages at moderate temperature ranges (near room temperature), where they can theoretically achieve 60-70% of Carnot efficiency. However, this advantage diminishes significantly as temperatures approach cryogenic levels. Below 77K, experimental data indicates that electrocaloric materials experience dramatically reduced polarization responses, resulting in smaller temperature changes per cycle and requiring substantially more input energy.

Comparative analysis reveals that at temperatures below 30K, conventional helium-based cryocoolers maintain COPs of approximately 1-2% of Carnot efficiency, while prototype electrocaloric systems struggle to exceed 0.5%. This efficiency gap widens further at ultra-low temperatures (below 10K), where quantum effects begin to dominate material behavior and conventional systems have benefited from decades of engineering optimization.

Power consumption metrics are equally revealing. A typical pulse tube refrigerator operating at 4K requires approximately 12-15 kW of input power to provide 1W of cooling capacity. Current electrocaloric prototypes designed for similar temperature ranges demand 25-30 kW for equivalent cooling output, representing a significant efficiency disadvantage that impacts operational costs and system scalability.

The energy density comparison further illustrates these limitations. While conventional cryocoolers can achieve cooling power densities of 0.5-1 W/cm³ at 20K, electrocaloric systems currently demonstrate only 0.1-0.2 W/cm³ at similar temperatures. This lower energy density necessitates larger system volumes for equivalent cooling capacity, creating additional challenges for space-constrained applications.

Recovery mechanisms present another efficiency consideration. Advanced pulse tube and Stirling cryocoolers incorporate regenerative heat exchangers that recapture up to 40% of system energy, while current electrocaloric cycle designs achieve only 15-25% energy recovery. This regeneration efficiency gap represents a significant barrier to practical implementation in energy-sensitive cryogenic applications.

Electrocaloric cooling systems demonstrate promising efficiency advantages at moderate temperature ranges (near room temperature), where they can theoretically achieve 60-70% of Carnot efficiency. However, this advantage diminishes significantly as temperatures approach cryogenic levels. Below 77K, experimental data indicates that electrocaloric materials experience dramatically reduced polarization responses, resulting in smaller temperature changes per cycle and requiring substantially more input energy.

Comparative analysis reveals that at temperatures below 30K, conventional helium-based cryocoolers maintain COPs of approximately 1-2% of Carnot efficiency, while prototype electrocaloric systems struggle to exceed 0.5%. This efficiency gap widens further at ultra-low temperatures (below 10K), where quantum effects begin to dominate material behavior and conventional systems have benefited from decades of engineering optimization.

Power consumption metrics are equally revealing. A typical pulse tube refrigerator operating at 4K requires approximately 12-15 kW of input power to provide 1W of cooling capacity. Current electrocaloric prototypes designed for similar temperature ranges demand 25-30 kW for equivalent cooling output, representing a significant efficiency disadvantage that impacts operational costs and system scalability.

The energy density comparison further illustrates these limitations. While conventional cryocoolers can achieve cooling power densities of 0.5-1 W/cm³ at 20K, electrocaloric systems currently demonstrate only 0.1-0.2 W/cm³ at similar temperatures. This lower energy density necessitates larger system volumes for equivalent cooling capacity, creating additional challenges for space-constrained applications.

Recovery mechanisms present another efficiency consideration. Advanced pulse tube and Stirling cryocoolers incorporate regenerative heat exchangers that recapture up to 40% of system energy, while current electrocaloric cycle designs achieve only 15-25% energy recovery. This regeneration efficiency gap represents a significant barrier to practical implementation in energy-sensitive cryogenic applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!