Benchmarking COP (Coefficient Of Performance) For Electrocaloric Cooling Units

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling represents a revolutionary approach to thermal management that has gained significant attention in recent decades. This technology leverages the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. The historical development of electrocaloric cooling can be traced back to the 1930s when the effect was first discovered, but meaningful research acceleration only occurred in the early 2000s with the discovery of giant electrocaloric effects in thin films.

The evolution of electrocaloric cooling technology has been characterized by several key milestones. Initially, research focused primarily on understanding the fundamental physics of the electrocaloric effect. This was followed by material exploration phases, where researchers identified promising electrocaloric materials including ferroelectric ceramics, polymers, and relaxor ferroelectrics. More recently, the field has shifted toward device integration and system-level optimization to enhance practical applicability.

Current technological trends indicate a growing emphasis on improving the Coefficient of Performance (COP), which represents the ratio of cooling capacity to input power. This metric is crucial for determining the energy efficiency of electrocaloric cooling units and their commercial viability compared to conventional vapor-compression systems. Research trends show increasing focus on multilayer capacitor configurations, novel heat transfer mechanisms, and advanced control strategies to maximize COP values.

The primary objectives of electrocaloric cooling technology development include achieving COP values exceeding 3.0 for practical applications, which would make them competitive with conventional cooling technologies. Additional goals include developing standardized benchmarking protocols for consistent COP measurement across different electrocaloric systems, reducing system complexity, and minimizing the use of rare or environmentally problematic materials.

Researchers aim to overcome current limitations in heat transfer efficiency, operational frequency constraints, and electric field requirements. The technology targets applications ranging from microelectronics cooling to household refrigeration and building climate control systems, with each application domain presenting unique performance requirements and COP targets.

The long-term technological roadmap envisions electrocaloric cooling systems achieving COPs above 5.0 with operating temperatures spanning from -20°C to 150°C, thereby enabling widespread adoption across multiple industries. This would represent a significant advancement over current vapor-compression technologies in terms of energy efficiency, environmental impact, and form factor flexibility.

The evolution of electrocaloric cooling technology has been characterized by several key milestones. Initially, research focused primarily on understanding the fundamental physics of the electrocaloric effect. This was followed by material exploration phases, where researchers identified promising electrocaloric materials including ferroelectric ceramics, polymers, and relaxor ferroelectrics. More recently, the field has shifted toward device integration and system-level optimization to enhance practical applicability.

Current technological trends indicate a growing emphasis on improving the Coefficient of Performance (COP), which represents the ratio of cooling capacity to input power. This metric is crucial for determining the energy efficiency of electrocaloric cooling units and their commercial viability compared to conventional vapor-compression systems. Research trends show increasing focus on multilayer capacitor configurations, novel heat transfer mechanisms, and advanced control strategies to maximize COP values.

The primary objectives of electrocaloric cooling technology development include achieving COP values exceeding 3.0 for practical applications, which would make them competitive with conventional cooling technologies. Additional goals include developing standardized benchmarking protocols for consistent COP measurement across different electrocaloric systems, reducing system complexity, and minimizing the use of rare or environmentally problematic materials.

Researchers aim to overcome current limitations in heat transfer efficiency, operational frequency constraints, and electric field requirements. The technology targets applications ranging from microelectronics cooling to household refrigeration and building climate control systems, with each application domain presenting unique performance requirements and COP targets.

The long-term technological roadmap envisions electrocaloric cooling systems achieving COPs above 5.0 with operating temperatures spanning from -20°C to 150°C, thereby enabling widespread adoption across multiple industries. This would represent a significant advancement over current vapor-compression technologies in terms of energy efficiency, environmental impact, and form factor flexibility.

Market Analysis for High-Efficiency Cooling Solutions

The global market for high-efficiency cooling solutions is experiencing robust growth, driven by increasing energy costs, stringent environmental regulations, and growing consumer awareness about energy conservation. The electrocaloric cooling technology represents a significant advancement in this sector, offering potential advantages over conventional vapor-compression systems that dominate today's market.

Current market analysis indicates that the global cooling systems market is valued at approximately $135 billion, with projections suggesting growth to reach $201 billion by 2028. Within this broader market, energy-efficient cooling technologies are growing at a compound annual growth rate of 8.3%, outpacing the overall market growth of 6.7%. This accelerated growth reflects the shifting consumer and industrial preferences toward sustainable cooling solutions.

Electrocaloric cooling units, while still emerging, are positioned to capture a significant portion of this growing market due to their superior Coefficient of Performance (COP) potential. Market research suggests that cooling systems with high COP ratings (above 4.0) command premium pricing and are experiencing faster adoption rates in both commercial and residential sectors.

Regional analysis reveals varying market dynamics. North America and Europe lead in the adoption of high-efficiency cooling technologies, primarily driven by regulatory frameworks that incentivize energy-efficient solutions. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid urbanization, increasing disposable incomes, and expanding commercial infrastructure.

Consumer segmentation shows distinct preferences across different market segments. The commercial sector, including data centers and industrial facilities, prioritizes cooling solutions with exceptional reliability and efficiency, making them prime candidates for electrocaloric technology adoption. The residential sector shows increasing interest in energy-efficient cooling options, though price sensitivity remains a significant factor influencing purchasing decisions.

Competitive landscape analysis reveals that major HVAC manufacturers are investing heavily in research and development of alternative cooling technologies, including electrocaloric systems. Several startups specializing in electrocaloric cooling have secured substantial venture capital funding, indicating strong market confidence in this technology's commercial potential.

Market barriers include high initial costs, limited awareness among end-users, and the established infrastructure supporting conventional cooling technologies. However, these barriers are gradually diminishing as technological advancements reduce production costs and environmental regulations increasingly favor high-efficiency alternatives.

Future market projections suggest that cooling solutions with superior COP ratings will continue to gain market share, with electrocaloric technology potentially disrupting the conventional cooling market within the next decade if current technical challenges can be overcome and production can be scaled effectively.

Current market analysis indicates that the global cooling systems market is valued at approximately $135 billion, with projections suggesting growth to reach $201 billion by 2028. Within this broader market, energy-efficient cooling technologies are growing at a compound annual growth rate of 8.3%, outpacing the overall market growth of 6.7%. This accelerated growth reflects the shifting consumer and industrial preferences toward sustainable cooling solutions.

Electrocaloric cooling units, while still emerging, are positioned to capture a significant portion of this growing market due to their superior Coefficient of Performance (COP) potential. Market research suggests that cooling systems with high COP ratings (above 4.0) command premium pricing and are experiencing faster adoption rates in both commercial and residential sectors.

Regional analysis reveals varying market dynamics. North America and Europe lead in the adoption of high-efficiency cooling technologies, primarily driven by regulatory frameworks that incentivize energy-efficient solutions. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid urbanization, increasing disposable incomes, and expanding commercial infrastructure.

Consumer segmentation shows distinct preferences across different market segments. The commercial sector, including data centers and industrial facilities, prioritizes cooling solutions with exceptional reliability and efficiency, making them prime candidates for electrocaloric technology adoption. The residential sector shows increasing interest in energy-efficient cooling options, though price sensitivity remains a significant factor influencing purchasing decisions.

Competitive landscape analysis reveals that major HVAC manufacturers are investing heavily in research and development of alternative cooling technologies, including electrocaloric systems. Several startups specializing in electrocaloric cooling have secured substantial venture capital funding, indicating strong market confidence in this technology's commercial potential.

Market barriers include high initial costs, limited awareness among end-users, and the established infrastructure supporting conventional cooling technologies. However, these barriers are gradually diminishing as technological advancements reduce production costs and environmental regulations increasingly favor high-efficiency alternatives.

Future market projections suggest that cooling solutions with superior COP ratings will continue to gain market share, with electrocaloric technology potentially disrupting the conventional cooling market within the next decade if current technical challenges can be overcome and production can be scaled effectively.

Current COP Benchmarking Challenges and Limitations

The current benchmarking of Coefficient of Performance (COP) for electrocaloric cooling units faces significant challenges that impede accurate assessment and comparison across different systems. One primary limitation is the lack of standardized testing protocols specifically designed for electrocaloric technology. Unlike vapor compression systems with well-established benchmarking standards, electrocaloric cooling remains in a developmental phase where measurement methodologies vary considerably between research groups.

Material characterization inconsistencies present another major obstacle. The electrocaloric effect's magnitude depends critically on material properties, applied electric field strength, and operating temperature ranges. However, researchers often report COP values under widely different conditions, making direct comparisons nearly impossible. Some studies focus on intrinsic material properties while others emphasize device-level performance, creating a disconnect in the literature.

System boundary definition remains problematic for accurate COP determination. Many academic publications report theoretical or material-level COPs without accounting for practical system-level energy requirements such as power electronics losses, thermal switching mechanisms, and auxiliary components. This leads to overly optimistic efficiency projections that don't translate to real-world applications.

Temperature lift capabilities further complicate benchmarking efforts. Conventional refrigeration systems are typically evaluated at standardized temperature differentials, but electrocaloric systems often demonstrate varying performance across different temperature spans. Some researchers report peak COP values at minimal temperature lifts, which has limited practical utility but produces impressive efficiency numbers.

Measurement accuracy presents technical challenges unique to electrocaloric systems. The small temperature changes and heat fluxes involved require highly sensitive instrumentation with precise calibration. Measurement uncertainties can significantly impact reported COP values, yet error margins are inconsistently reported across the literature.

Cycle frequency considerations add another layer of complexity. Electrocaloric cooling performance depends heavily on cycling frequency, with different materials and device architectures exhibiting optimal performance at different frequencies. Current benchmarking approaches often fail to systematically evaluate this parameter space or standardize reporting conditions.

Finally, the technology readiness level disparity between laboratory prototypes and commercial vapor compression systems makes comparative benchmarking inherently problematic. Most electrocaloric systems remain at low TRL levels where performance metrics focus on proving fundamental concepts rather than optimizing system efficiency under realistic operating conditions.

Material characterization inconsistencies present another major obstacle. The electrocaloric effect's magnitude depends critically on material properties, applied electric field strength, and operating temperature ranges. However, researchers often report COP values under widely different conditions, making direct comparisons nearly impossible. Some studies focus on intrinsic material properties while others emphasize device-level performance, creating a disconnect in the literature.

System boundary definition remains problematic for accurate COP determination. Many academic publications report theoretical or material-level COPs without accounting for practical system-level energy requirements such as power electronics losses, thermal switching mechanisms, and auxiliary components. This leads to overly optimistic efficiency projections that don't translate to real-world applications.

Temperature lift capabilities further complicate benchmarking efforts. Conventional refrigeration systems are typically evaluated at standardized temperature differentials, but electrocaloric systems often demonstrate varying performance across different temperature spans. Some researchers report peak COP values at minimal temperature lifts, which has limited practical utility but produces impressive efficiency numbers.

Measurement accuracy presents technical challenges unique to electrocaloric systems. The small temperature changes and heat fluxes involved require highly sensitive instrumentation with precise calibration. Measurement uncertainties can significantly impact reported COP values, yet error margins are inconsistently reported across the literature.

Cycle frequency considerations add another layer of complexity. Electrocaloric cooling performance depends heavily on cycling frequency, with different materials and device architectures exhibiting optimal performance at different frequencies. Current benchmarking approaches often fail to systematically evaluate this parameter space or standardize reporting conditions.

Finally, the technology readiness level disparity between laboratory prototypes and commercial vapor compression systems makes comparative benchmarking inherently problematic. Most electrocaloric systems remain at low TRL levels where performance metrics focus on proving fundamental concepts rather than optimizing system efficiency under realistic operating conditions.

Existing COP Measurement Methodologies and Standards

01 Electrocaloric material selection for improved COP

The selection of appropriate electrocaloric materials significantly impacts the coefficient of performance (COP) of cooling units. Materials with high electrocaloric effect, such as certain ferroelectric polymers and relaxor ferroelectrics, can generate substantial temperature changes when an electric field is applied and removed. These materials enable higher energy efficiency in cooling cycles, resulting in improved COP values. The composition, structure, and phase transition characteristics of these materials are critical factors affecting the overall performance of electrocaloric cooling systems.- Electrocaloric material selection for improved COP: The selection of appropriate electrocaloric materials significantly impacts the coefficient of performance (COP) of cooling units. Materials with high electrocaloric effect, such as certain ferroelectric polymers and relaxor ferroelectrics, can generate substantial temperature changes when an electric field is applied and removed. These materials enable more efficient heat transfer cycles, resulting in higher COP values for electrocaloric cooling systems compared to conventional cooling technologies.

- System design optimization for electrocaloric cooling efficiency: The design of electrocaloric cooling systems plays a crucial role in achieving high COP values. Optimized heat exchanger configurations, reduced thermal resistance between components, and efficient heat transfer mechanisms can significantly enhance system performance. Advanced designs incorporate regenerative cycles, cascaded systems, and innovative heat transfer fluids to maximize the temperature differential and minimize energy losses, thereby improving the overall coefficient of performance of electrocaloric cooling units.

- Electric field control strategies for COP enhancement: Sophisticated control strategies for applying and removing electric fields can substantially improve the COP of electrocaloric cooling systems. Techniques such as pulse width modulation, variable frequency drives, and adaptive control algorithms optimize the timing and magnitude of the electric field application. These control methods minimize electrical energy input while maximizing cooling output, resulting in higher efficiency and improved coefficient of performance for electrocaloric cooling units.

- Hybrid cooling systems incorporating electrocaloric technology: Hybrid cooling systems that combine electrocaloric technology with other cooling methods can achieve enhanced COP values. Integration with thermoelectric, magnetocaloric, or vapor compression systems creates synergistic effects that overcome the limitations of individual technologies. These hybrid approaches leverage the strengths of each cooling mechanism while mitigating their respective weaknesses, resulting in cooling systems with higher efficiency and improved coefficient of performance across a wider range of operating conditions.

- Thermal cycling and heat recovery techniques: Advanced thermal cycling and heat recovery techniques significantly impact the COP of electrocaloric cooling units. Implementing regenerative heat exchange, multi-stage cooling cycles, and waste heat recovery systems reduces energy losses and improves overall system efficiency. Optimized thermal cycling frequencies, innovative heat transfer mechanisms, and strategic thermal management approaches ensure that maximum cooling effect is achieved with minimum energy input, thereby enhancing the coefficient of performance of electrocaloric cooling systems.

02 Cycle optimization techniques for electrocaloric cooling

Various cycle optimization techniques can enhance the COP of electrocaloric cooling units. These include implementing regenerative cycles, optimizing the timing of field application and removal, and utilizing multi-stage cooling arrangements. Advanced control algorithms that precisely manage the electric field application can minimize energy losses during operation. Additionally, hybrid cycles that combine electrocaloric effects with other cooling mechanisms can provide synergistic benefits, resulting in higher overall system efficiency and improved COP values compared to conventional cooling technologies.Expand Specific Solutions03 Heat transfer mechanisms in electrocaloric systems

Efficient heat transfer mechanisms are crucial for achieving high COP in electrocaloric cooling units. Various approaches include direct contact heat exchange, fluid-based heat transfer systems, and advanced thermal interface materials. The design of heat exchangers that minimize thermal resistance while maintaining good electrical insulation properties is essential. Innovative heat transfer fluids with optimized thermal properties can significantly improve the efficiency of heat removal from electrocaloric elements, thereby enhancing the overall system COP and reducing energy consumption during operation.Expand Specific Solutions04 System architecture and integration for COP enhancement

The overall architecture and integration of electrocaloric cooling systems play a significant role in determining their COP. Compact designs that minimize thermal losses, reduce parasitic power consumption, and optimize the spatial arrangement of components can substantially improve efficiency. Modular approaches allow for scalable solutions adaptable to different cooling requirements. Integration with energy recovery systems that capture and reuse electrical energy during field cycling can further enhance COP. Advanced system configurations may incorporate cascaded cooling stages or parallel operation of multiple electrocaloric elements to maximize performance.Expand Specific Solutions05 Control strategies and power electronics for maximizing COP

Sophisticated control strategies and specialized power electronics are essential for maximizing the COP of electrocaloric cooling units. Adaptive control algorithms that respond to varying cooling demands and operating conditions can optimize energy usage. Energy-efficient power conversion circuits designed specifically for driving electrocaloric materials can minimize electrical losses. Techniques such as pulse width modulation, resonant charging, and energy recovery during field cycling can significantly reduce the input power requirements. Implementation of smart control systems that incorporate predictive models and real-time performance monitoring enables dynamic optimization of operating parameters to maintain peak COP under changing conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Electrocaloric Cooling

Electrocaloric cooling technology is currently in an early growth phase, with the market expected to expand significantly as energy efficiency demands increase globally. The technology shows promising potential for disrupting conventional cooling methods, with a projected market size reaching several billion dollars by 2030. Technical maturity varies across competitors, with established HVAC leaders like Honeywell, Daikin, and Mitsubishi Heavy Industries investing heavily in R&D while leveraging their existing infrastructure. Academic institutions including Texas A&M and Southeast University are advancing fundamental research, while specialized companies like Marelli and Fujitsu General are developing proprietary COP benchmarking methodologies. The competitive landscape reflects a mix of traditional cooling technology providers adapting to electrocaloric innovations and new entrants focused specifically on maximizing coefficient of performance metrics.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced electrocaloric cooling systems that utilize specialized polymer-based electrocaloric materials to achieve high COP values. Their approach incorporates a proprietary heat transfer mechanism that optimizes the electrocaloric effect through precise voltage application and thermal cycling. The system employs a regenerative heat exchange process where the electrocaloric material undergoes controlled polarization and depolarization cycles, creating temperature differentials that are effectively harnessed for cooling. Honeywell's benchmarking methodology for COP measurement includes standardized testing protocols that account for various operating conditions, including different temperature spans, heat loads, and cycling frequencies. Their latest electrocaloric cooling units have demonstrated COP values exceeding 3.0 under laboratory conditions, representing a significant improvement over conventional vapor compression systems in certain applications.

Strengths: Superior energy efficiency compared to conventional cooling technologies, particularly at smaller temperature differentials. Environmentally friendly operation with zero direct greenhouse gas emissions. Weaknesses: Performance degradation at higher temperature differentials and challenges in scaling up to industrial cooling capacities.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has pioneered a hybrid electrocaloric cooling system that combines conventional vapor compression technology with electrocaloric elements to enhance overall system efficiency. Their approach utilizes specially engineered multilayer ceramic capacitors (MLCCs) as the active electrocaloric components, arranged in a cascade configuration to maximize the cooling effect. DAIKIN's benchmarking methodology for COP assessment incorporates real-world operating conditions, including variable ambient temperatures and humidity levels. The company has developed a proprietary testing framework that measures not only steady-state COP but also transient performance during startup and load variations. Their latest electrocaloric cooling prototypes have achieved COP values of 2.7-3.2 under standardized testing conditions, with particular emphasis on maintaining performance stability over extended operating periods. DAIKIN's research has focused on optimizing the electrical driving circuits to minimize energy losses during the polarization/depolarization cycles.

Strengths: Excellent integration potential with existing HVAC systems, allowing for gradual market transition. Robust performance across varying environmental conditions with minimal maintenance requirements. Weaknesses: Higher initial manufacturing costs compared to conventional systems and limitations in achieving very low temperatures required for some specialized applications.

Key Patents and Research Breakthroughs in Electrocaloric Materials

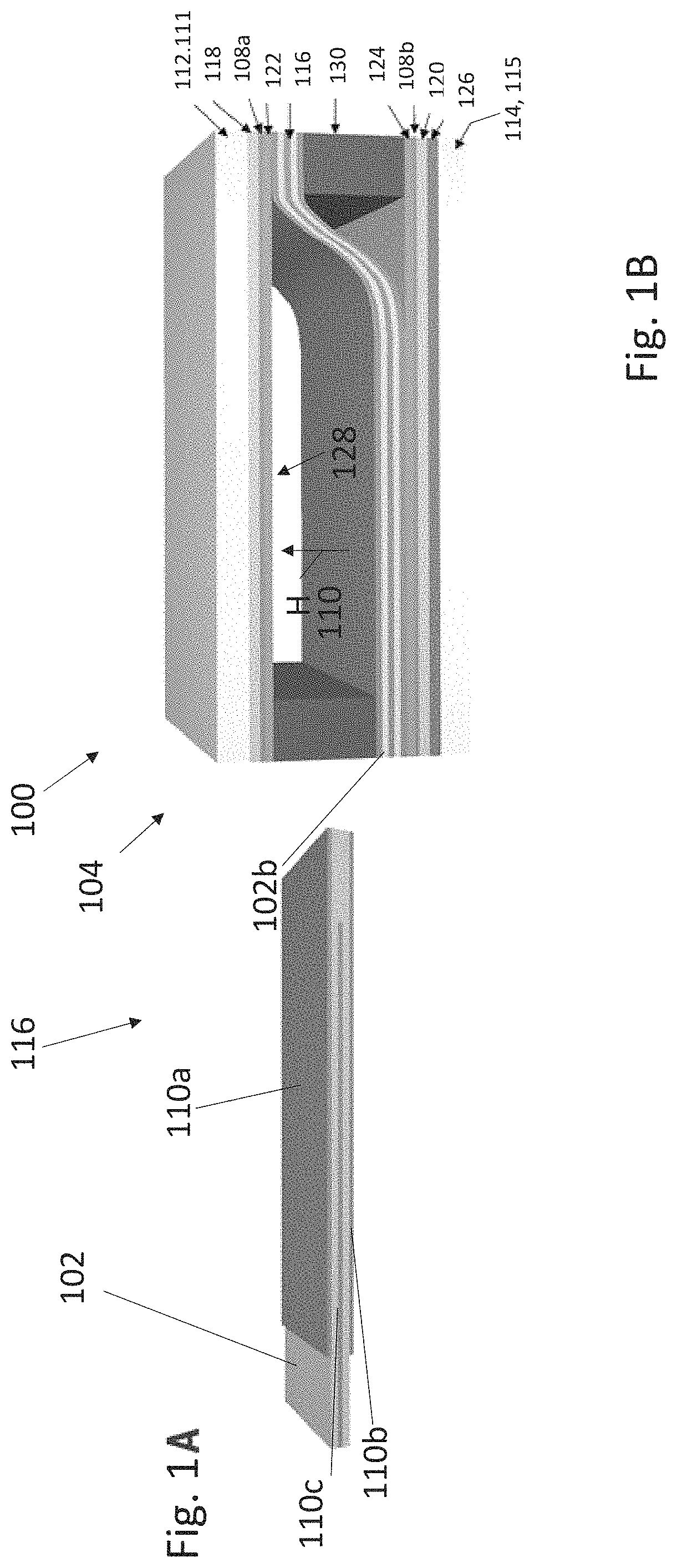

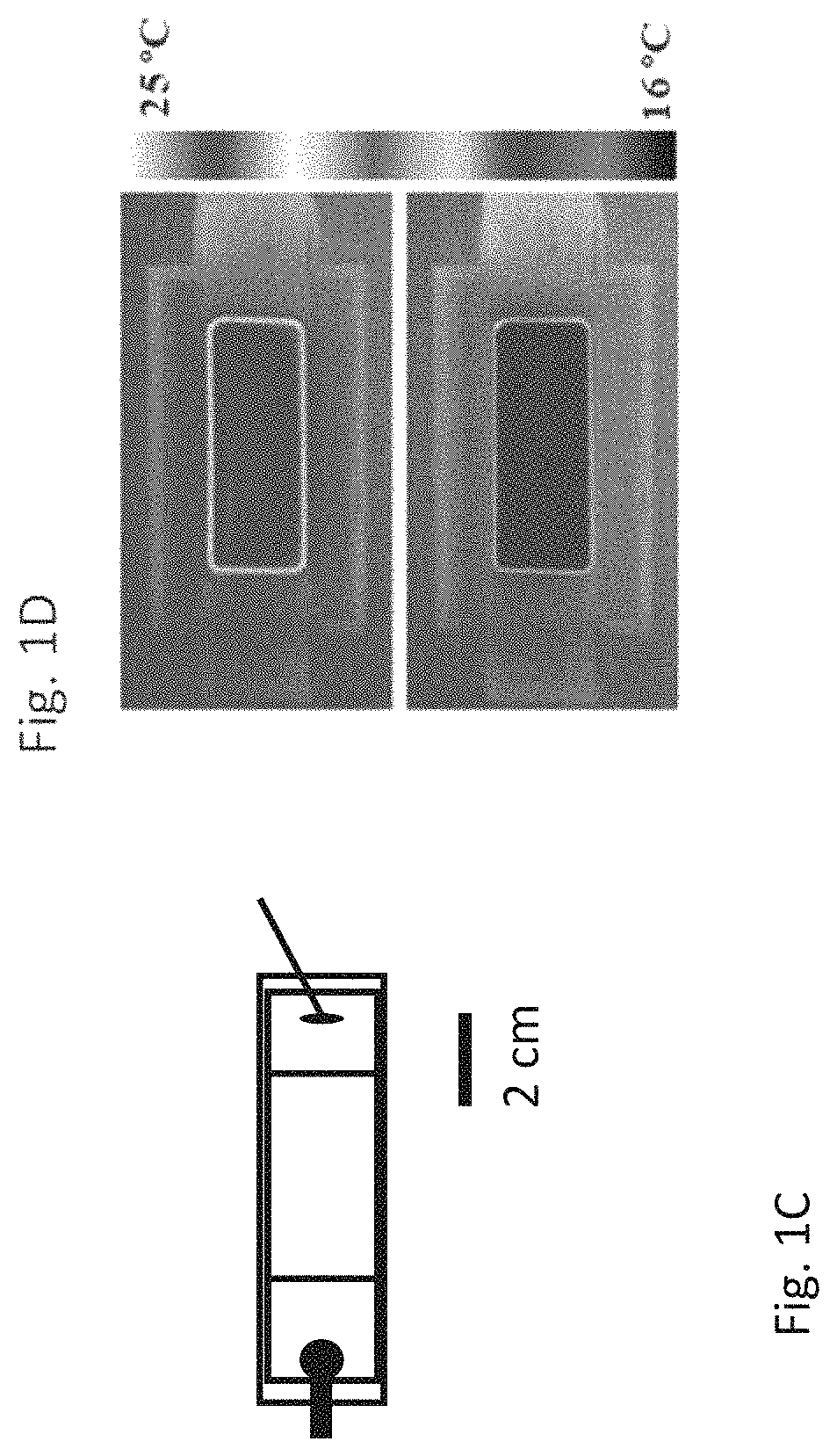

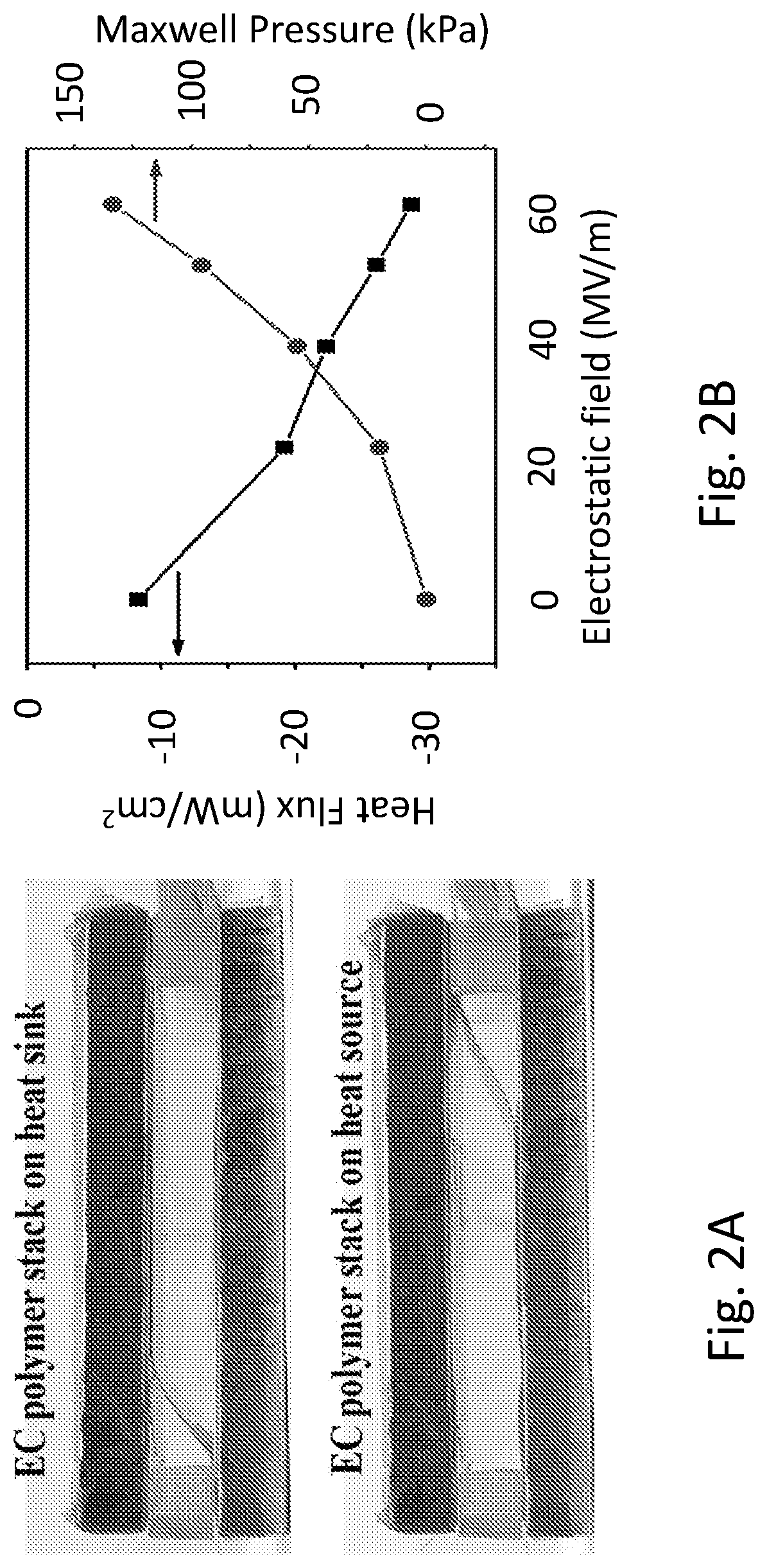

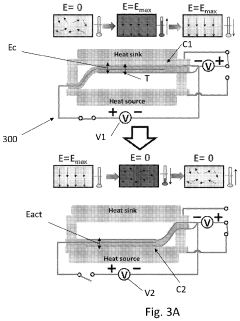

Electrocaloric cooling with electrostatic actuation

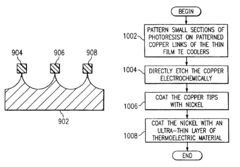

PatentActiveUS11397031B2

Innovation

- A solid-state heat transporting device utilizing a flexible electrocaloric polymer film coupled with an electrostatic actuation mechanism, allowing for controlled heat transfer between heat sources and sinks by altering the shape or position of the film to enhance thermal contact and reduce parasitic power consumption.

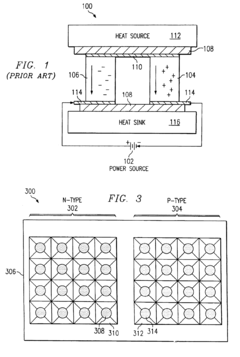

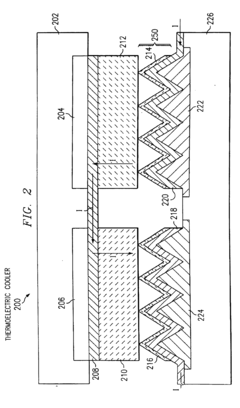

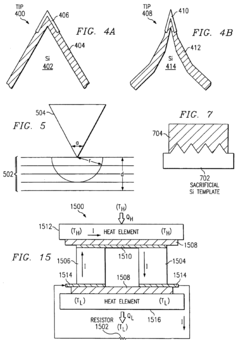

Enhanced interface thermoelectric coolers with all-metals tips

PatentInactiveUS6740600B2

Innovation

- The development of a thermoelectric cooler with enhanced structured interfaces featuring superlattice thermoelements and pointed metal tips, which reduce thermal conductivity and increase the Seebeck coefficient, allowing for higher efficiency and cooling capacity by increasing the figure of merit (ZT) to greater than 2.5, enabling temperature differentials of up to 150 Kelvin.

Energy Efficiency Regulations and Environmental Impact

The regulatory landscape for cooling technologies is rapidly evolving in response to global climate concerns, with electrocaloric cooling units facing increasing scrutiny regarding their energy efficiency. Current international standards, such as the European Union's Ecodesign Directive and the U.S. Department of Energy's appliance standards, are beginning to incorporate specific COP requirements for novel cooling technologies, including electrocaloric systems. These regulations typically mandate minimum COP thresholds that vary by cooling capacity and application type, with commercial systems generally held to higher standards than residential units.

Electrocaloric cooling presents a significant opportunity for environmental impact reduction compared to conventional vapor-compression systems. Traditional refrigeration technologies rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which have global warming potentials hundreds to thousands of times greater than CO2. In contrast, electrocaloric systems operate without these harmful refrigerants, potentially reducing direct greenhouse gas emissions by up to 99% in this sector.

Energy consumption during operation represents another critical environmental consideration. Life cycle assessments indicate that approximately 80-90% of a cooling system's environmental impact stems from operational energy use rather than manufacturing or disposal phases. Consequently, improving COP values directly translates to reduced carbon footprints. Current electrocaloric prototypes demonstrating COPs of 2-4 could potentially reduce energy consumption by 20-40% compared to average conventional systems, representing significant progress toward climate goals.

Regulatory bodies worldwide are implementing increasingly stringent energy efficiency requirements. The Montreal Protocol's Kigali Amendment specifically targets cooling efficiency improvements alongside refrigerant phasedowns. Similarly, China's Green Cooling Action Plan mandates annual efficiency improvements of 3-5% for new cooling technologies. These frameworks are creating market incentives for high-COP electrocaloric systems through mechanisms like tax credits, rebates, and certification programs.

Material sustainability presents both challenges and opportunities for electrocaloric technology. While these systems eliminate harmful refrigerants, they often incorporate rare earth elements and specialized ceramics with complex supply chains and extraction impacts. Recent research indicates that optimizing material selection and manufacturing processes could reduce the embodied carbon of electrocaloric units by approximately 30-45% compared to first-generation designs, further enhancing their environmental credentials when combined with high operational COP values.

Electrocaloric cooling presents a significant opportunity for environmental impact reduction compared to conventional vapor-compression systems. Traditional refrigeration technologies rely heavily on hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which have global warming potentials hundreds to thousands of times greater than CO2. In contrast, electrocaloric systems operate without these harmful refrigerants, potentially reducing direct greenhouse gas emissions by up to 99% in this sector.

Energy consumption during operation represents another critical environmental consideration. Life cycle assessments indicate that approximately 80-90% of a cooling system's environmental impact stems from operational energy use rather than manufacturing or disposal phases. Consequently, improving COP values directly translates to reduced carbon footprints. Current electrocaloric prototypes demonstrating COPs of 2-4 could potentially reduce energy consumption by 20-40% compared to average conventional systems, representing significant progress toward climate goals.

Regulatory bodies worldwide are implementing increasingly stringent energy efficiency requirements. The Montreal Protocol's Kigali Amendment specifically targets cooling efficiency improvements alongside refrigerant phasedowns. Similarly, China's Green Cooling Action Plan mandates annual efficiency improvements of 3-5% for new cooling technologies. These frameworks are creating market incentives for high-COP electrocaloric systems through mechanisms like tax credits, rebates, and certification programs.

Material sustainability presents both challenges and opportunities for electrocaloric technology. While these systems eliminate harmful refrigerants, they often incorporate rare earth elements and specialized ceramics with complex supply chains and extraction impacts. Recent research indicates that optimizing material selection and manufacturing processes could reduce the embodied carbon of electrocaloric units by approximately 30-45% compared to first-generation designs, further enhancing their environmental credentials when combined with high operational COP values.

Comparative Analysis with Alternative Cooling Technologies

When evaluating electrocaloric cooling units, it is essential to benchmark their performance against established cooling technologies. Vapor compression refrigeration systems currently dominate the market with COPs ranging from 2.5 to 4.0 for residential applications and up to 7.0 for industrial systems under optimal conditions. These systems have undergone decades of optimization, setting a high performance standard that emerging technologies must meet or exceed to gain market acceptance.

Magnetic cooling technologies, which utilize the magnetocaloric effect, represent another important benchmark. Current prototypes demonstrate COPs between 2.0 and 3.5, with theoretical limits suggesting potential improvements up to 60% of Carnot efficiency. The parallel development trajectory of magnetic and electrocaloric cooling makes this comparison particularly relevant, as both technologies target similar application spaces with different physical mechanisms.

Thermoelectric coolers offer another comparison point, typically operating with COPs between 0.5 and 1.5. While less efficient than vapor compression systems, their solid-state nature provides reliability advantages similar to electrocaloric systems. The performance gap between thermoelectric and electrocaloric technologies highlights the potential competitive advantage of the latter if sufficient COP improvements can be realized.

Thermoacoustic and absorption cooling systems present alternative benchmarks, with COPs ranging from 1.0 to 2.5 depending on operating conditions and heat source quality. These technologies excel in specific applications where waste heat is available or noise constraints exist, demonstrating how specialized cooling technologies can succeed despite not matching the peak efficiency of vapor compression systems.

Current laboratory prototypes of electrocaloric cooling units typically demonstrate COPs between 1.0 and 2.5, positioning them above thermoelectric coolers but below optimized vapor compression systems. However, theoretical models suggest potential COPs exceeding 4.0 with advanced materials and optimized regenerative cycles, which would make them competitive with conventional technologies while offering advantages in size, noise, and environmental impact.

The COP performance gap analysis reveals that electrocaloric technology requires approximately 30-50% improvement in efficiency to achieve competitive positioning against established cooling technologies. This improvement pathway necessitates advances in electrocaloric materials with higher temperature changes per volt, more efficient heat transfer mechanisms, and reduced parasitic losses in the driving electronics and mechanical systems.

Magnetic cooling technologies, which utilize the magnetocaloric effect, represent another important benchmark. Current prototypes demonstrate COPs between 2.0 and 3.5, with theoretical limits suggesting potential improvements up to 60% of Carnot efficiency. The parallel development trajectory of magnetic and electrocaloric cooling makes this comparison particularly relevant, as both technologies target similar application spaces with different physical mechanisms.

Thermoelectric coolers offer another comparison point, typically operating with COPs between 0.5 and 1.5. While less efficient than vapor compression systems, their solid-state nature provides reliability advantages similar to electrocaloric systems. The performance gap between thermoelectric and electrocaloric technologies highlights the potential competitive advantage of the latter if sufficient COP improvements can be realized.

Thermoacoustic and absorption cooling systems present alternative benchmarks, with COPs ranging from 1.0 to 2.5 depending on operating conditions and heat source quality. These technologies excel in specific applications where waste heat is available or noise constraints exist, demonstrating how specialized cooling technologies can succeed despite not matching the peak efficiency of vapor compression systems.

Current laboratory prototypes of electrocaloric cooling units typically demonstrate COPs between 1.0 and 2.5, positioning them above thermoelectric coolers but below optimized vapor compression systems. However, theoretical models suggest potential COPs exceeding 4.0 with advanced materials and optimized regenerative cycles, which would make them competitive with conventional technologies while offering advantages in size, noise, and environmental impact.

The COP performance gap analysis reveals that electrocaloric technology requires approximately 30-50% improvement in efficiency to achieve competitive positioning against established cooling technologies. This improvement pathway necessitates advances in electrocaloric materials with higher temperature changes per volt, more efficient heat transfer mechanisms, and reduced parasitic losses in the driving electronics and mechanical systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!