Thin-Film Deposition Methods For High-Performance Electrocaloric Layers In Electrocaloric Cooling

SEP 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling represents a promising alternative to conventional vapor-compression refrigeration systems, offering potential advantages in energy efficiency, environmental friendliness, and compact design. The technology leverages the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. This effect was first discovered in the 1930s but remained largely unexplored until recent decades due to limitations in material science and fabrication techniques.

The evolution of electrocaloric cooling technology has accelerated significantly since the early 2000s, with breakthrough research demonstrating substantial temperature changes in thin-film ferroelectric materials. This progress has been driven by advancements in material science, particularly in the development of high-performance ferroelectric and antiferroelectric materials that exhibit strong electrocaloric responses.

Thin-film deposition methods have emerged as a critical enabling technology for electrocaloric cooling systems. These methods allow for the precise fabrication of electrocaloric layers with controlled thickness, composition, and microstructure—factors that directly influence cooling performance. The development trajectory has moved from bulk ceramics toward thin films, which offer enhanced electric field tolerance, faster thermal response, and improved integration capabilities.

Current research focuses on optimizing thin-film deposition techniques to create electrocaloric layers that maximize temperature change while maintaining structural integrity under high electric fields. Key deposition methods include physical vapor deposition (PVD), chemical vapor deposition (CVD), pulsed laser deposition (PLD), and solution-based techniques such as sol-gel processing and chemical solution deposition (CSD).

The primary technical objectives in this field include developing deposition methods that can produce uniform, defect-free electrocaloric layers with enhanced electrocaloric coefficients. Researchers aim to achieve temperature changes exceeding 10°C under practical operating conditions, which would make electrocaloric cooling competitive with conventional technologies. Additional goals include improving cycling stability, reducing hysteresis effects, and developing scalable fabrication processes suitable for commercial production.

Looking forward, the technology roadmap for electrocaloric cooling envisions the development of multi-layered structures with optimized interfaces, novel material compositions with enhanced electrocaloric properties, and advanced deposition techniques that enable precise control over film microstructure and crystallinity. The ultimate goal is to establish thin-film electrocaloric devices as a viable, energy-efficient cooling solution for applications ranging from electronics thermal management to residential and commercial refrigeration.

The evolution of electrocaloric cooling technology has accelerated significantly since the early 2000s, with breakthrough research demonstrating substantial temperature changes in thin-film ferroelectric materials. This progress has been driven by advancements in material science, particularly in the development of high-performance ferroelectric and antiferroelectric materials that exhibit strong electrocaloric responses.

Thin-film deposition methods have emerged as a critical enabling technology for electrocaloric cooling systems. These methods allow for the precise fabrication of electrocaloric layers with controlled thickness, composition, and microstructure—factors that directly influence cooling performance. The development trajectory has moved from bulk ceramics toward thin films, which offer enhanced electric field tolerance, faster thermal response, and improved integration capabilities.

Current research focuses on optimizing thin-film deposition techniques to create electrocaloric layers that maximize temperature change while maintaining structural integrity under high electric fields. Key deposition methods include physical vapor deposition (PVD), chemical vapor deposition (CVD), pulsed laser deposition (PLD), and solution-based techniques such as sol-gel processing and chemical solution deposition (CSD).

The primary technical objectives in this field include developing deposition methods that can produce uniform, defect-free electrocaloric layers with enhanced electrocaloric coefficients. Researchers aim to achieve temperature changes exceeding 10°C under practical operating conditions, which would make electrocaloric cooling competitive with conventional technologies. Additional goals include improving cycling stability, reducing hysteresis effects, and developing scalable fabrication processes suitable for commercial production.

Looking forward, the technology roadmap for electrocaloric cooling envisions the development of multi-layered structures with optimized interfaces, novel material compositions with enhanced electrocaloric properties, and advanced deposition techniques that enable precise control over film microstructure and crystallinity. The ultimate goal is to establish thin-film electrocaloric devices as a viable, energy-efficient cooling solution for applications ranging from electronics thermal management to residential and commercial refrigeration.

Market Analysis for Solid-State Cooling Solutions

The solid-state cooling market is experiencing significant growth as industries seek more environmentally friendly and energy-efficient alternatives to conventional vapor-compression cooling systems. The global market for solid-state cooling technologies was valued at approximately $500 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate of 15.7%.

Electrocaloric cooling, as a subset of solid-state cooling technologies, is gaining particular attention due to its potential for higher efficiency and reduced environmental impact. Unlike traditional cooling methods that rely on refrigerants with high global warming potential, electrocaloric cooling utilizes electric field-induced thermal changes in materials, offering a cleaner alternative with zero direct greenhouse gas emissions.

The demand for electrocaloric cooling solutions is being driven by several key factors. First, increasingly stringent environmental regulations worldwide are pushing industries to adopt more sustainable cooling technologies. The phase-down of hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol has accelerated the search for alternative cooling methods.

Second, the growing energy consumption of cooling systems, which currently accounts for approximately 20% of global electricity usage, has created urgent demand for more efficient solutions. Electrocaloric cooling systems have demonstrated theoretical efficiency levels approaching 60-70% of Carnot efficiency, significantly higher than conventional vapor-compression systems.

The consumer electronics sector represents the largest current market opportunity, with an estimated 38% market share for solid-state cooling applications. Thermal management challenges in increasingly powerful yet compact devices have created immediate demand for innovative cooling solutions. The automotive sector follows closely at 27%, driven by the rapid growth of electric vehicles requiring efficient battery thermal management systems.

Medical and pharmaceutical applications constitute another significant market segment (18%), where precise temperature control is critical for storing sensitive biological materials and medications. The remaining market share is distributed across industrial applications, aerospace, and other specialized sectors.

Geographically, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization and increasing adoption of advanced cooling technologies in countries like China, Japan, and South Korea.

Electrocaloric cooling, as a subset of solid-state cooling technologies, is gaining particular attention due to its potential for higher efficiency and reduced environmental impact. Unlike traditional cooling methods that rely on refrigerants with high global warming potential, electrocaloric cooling utilizes electric field-induced thermal changes in materials, offering a cleaner alternative with zero direct greenhouse gas emissions.

The demand for electrocaloric cooling solutions is being driven by several key factors. First, increasingly stringent environmental regulations worldwide are pushing industries to adopt more sustainable cooling technologies. The phase-down of hydrofluorocarbons (HFCs) under the Kigali Amendment to the Montreal Protocol has accelerated the search for alternative cooling methods.

Second, the growing energy consumption of cooling systems, which currently accounts for approximately 20% of global electricity usage, has created urgent demand for more efficient solutions. Electrocaloric cooling systems have demonstrated theoretical efficiency levels approaching 60-70% of Carnot efficiency, significantly higher than conventional vapor-compression systems.

The consumer electronics sector represents the largest current market opportunity, with an estimated 38% market share for solid-state cooling applications. Thermal management challenges in increasingly powerful yet compact devices have created immediate demand for innovative cooling solutions. The automotive sector follows closely at 27%, driven by the rapid growth of electric vehicles requiring efficient battery thermal management systems.

Medical and pharmaceutical applications constitute another significant market segment (18%), where precise temperature control is critical for storing sensitive biological materials and medications. The remaining market share is distributed across industrial applications, aerospace, and other specialized sectors.

Geographically, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization and increasing adoption of advanced cooling technologies in countries like China, Japan, and South Korea.

Current Challenges in Thin-Film Electrocaloric Materials

Despite significant advancements in thin-film electrocaloric materials, several critical challenges continue to impede their widespread implementation in practical cooling applications. The fabrication of high-quality electrocaloric thin films with consistent properties remains a significant hurdle. Current deposition methods often struggle to achieve uniform thickness and composition across large areas, leading to performance variations that compromise cooling efficiency.

Material stability presents another major challenge, as electrocaloric materials must withstand repeated thermal and electrical cycling without degradation. Many promising materials exhibit excellent initial performance but suffer from fatigue effects, with their electrocaloric response diminishing significantly after multiple operational cycles. This fatigue phenomenon is particularly pronounced in lead-based materials, which otherwise demonstrate superior electrocaloric effects.

Interface engineering between the electrocaloric layer and electrodes represents a complex technical barrier. Poor interfaces can lead to electrical leakage, reduced breakdown strength, and diminished overall performance. Current deposition techniques often fail to create atomically smooth interfaces, resulting in localized electric field concentrations that trigger premature breakdown during operation.

Scaling production while maintaining quality poses substantial difficulties. Laboratory-scale deposition methods that produce excellent results often cannot be directly transferred to industrial-scale production. Techniques like pulsed laser deposition (PLD) yield high-quality films but are inherently limited in throughput and substrate size compatibility, making them impractical for commercial manufacturing.

The substrate constraint issue further complicates development efforts. Many high-performance electrocaloric materials require specific crystalline substrates for epitaxial growth, which are expensive and limit integration possibilities with existing cooling system components. Developing deposition methods that can produce high-quality films on flexible or silicon-compatible substrates remains an ongoing challenge.

Thickness optimization presents a critical trade-off. While thinner films can operate at lower voltages, they provide smaller absolute temperature changes. Conversely, thicker films offer larger cooling capacity but require higher operating voltages and often develop more defects during deposition. Current deposition technologies struggle to find the optimal balance between these competing factors.

Environmental and regulatory concerns add another layer of complexity, particularly for lead-based materials that demonstrate superior electrocaloric properties. The development of lead-free alternatives with comparable performance using existing deposition methods has proven challenging, with most alternatives showing significantly reduced electrocaloric effects.

Material stability presents another major challenge, as electrocaloric materials must withstand repeated thermal and electrical cycling without degradation. Many promising materials exhibit excellent initial performance but suffer from fatigue effects, with their electrocaloric response diminishing significantly after multiple operational cycles. This fatigue phenomenon is particularly pronounced in lead-based materials, which otherwise demonstrate superior electrocaloric effects.

Interface engineering between the electrocaloric layer and electrodes represents a complex technical barrier. Poor interfaces can lead to electrical leakage, reduced breakdown strength, and diminished overall performance. Current deposition techniques often fail to create atomically smooth interfaces, resulting in localized electric field concentrations that trigger premature breakdown during operation.

Scaling production while maintaining quality poses substantial difficulties. Laboratory-scale deposition methods that produce excellent results often cannot be directly transferred to industrial-scale production. Techniques like pulsed laser deposition (PLD) yield high-quality films but are inherently limited in throughput and substrate size compatibility, making them impractical for commercial manufacturing.

The substrate constraint issue further complicates development efforts. Many high-performance electrocaloric materials require specific crystalline substrates for epitaxial growth, which are expensive and limit integration possibilities with existing cooling system components. Developing deposition methods that can produce high-quality films on flexible or silicon-compatible substrates remains an ongoing challenge.

Thickness optimization presents a critical trade-off. While thinner films can operate at lower voltages, they provide smaller absolute temperature changes. Conversely, thicker films offer larger cooling capacity but require higher operating voltages and often develop more defects during deposition. Current deposition technologies struggle to find the optimal balance between these competing factors.

Environmental and regulatory concerns add another layer of complexity, particularly for lead-based materials that demonstrate superior electrocaloric properties. The development of lead-free alternatives with comparable performance using existing deposition methods has proven challenging, with most alternatives showing significantly reduced electrocaloric effects.

State-of-the-Art Thin-Film Deposition Methods

01 Physical Vapor Deposition Techniques for Electrocaloric Films

Physical vapor deposition (PVD) methods such as sputtering, pulsed laser deposition (PLD), and thermal evaporation are effective for creating high-quality electrocaloric thin films with precise thickness control. These techniques allow for the deposition of various electrocaloric materials including relaxor ferroelectrics and doped perovskites with enhanced cooling properties. The controlled growth environment enables optimization of crystallinity and microstructure, which directly impacts the electrocaloric performance of the resulting layers.- Physical Vapor Deposition Techniques for Electrocaloric Films: Physical vapor deposition (PVD) methods such as sputtering, pulsed laser deposition, and thermal evaporation are effective for creating high-quality electrocaloric thin films with precise thickness control. These techniques allow for the deposition of various electrocaloric materials including ferroelectric polymers and ceramic oxides with controlled crystallinity and orientation, which directly impacts the electrocaloric performance. The vacuum environment during PVD processes ensures minimal contamination, resulting in films with superior electrocaloric properties.

- Chemical Vapor Deposition Methods for Enhanced Electrocaloric Performance: Chemical vapor deposition (CVD) techniques, including atomic layer deposition (ALD) and metal-organic chemical vapor deposition (MOCVD), enable the creation of highly uniform electrocaloric thin films with excellent conformality and precise composition control. These methods facilitate the growth of complex multi-component electrocaloric materials with tailored interfaces and layer structures. The ability to deposit films at lower temperatures compared to some physical methods helps preserve the electrocaloric properties of temperature-sensitive materials and allows for better integration with various substrate materials.

- Solution-Based Deposition for Flexible Electrocaloric Layers: Solution-based deposition methods such as sol-gel processing, spin coating, and chemical solution deposition offer cost-effective approaches for fabricating electrocaloric thin films on various substrates, including flexible ones. These techniques allow for easy doping and composition modification to enhance electrocaloric properties. The ability to process at relatively low temperatures makes these methods suitable for creating electrocaloric layers on temperature-sensitive substrates, enabling applications in flexible cooling devices and wearable electronics.

- Multilayer and Nanocomposite Structures for Enhanced Electrocaloric Effect: Advanced thin-film deposition strategies focusing on multilayer structures, superlattices, and nanocomposites can significantly enhance electrocaloric performance. By engineering interfaces between different materials or creating controlled heterostructures, the electrocaloric coefficient can be substantially improved. These approaches allow for the combination of materials with complementary properties, strain engineering at interfaces, and creation of unique polarization profiles that maximize the temperature change under applied electric fields, leading to superior cooling efficiency in electrocaloric devices.

- Post-Deposition Processing for Optimized Electrocaloric Performance: Various post-deposition treatments such as thermal annealing, electric field cycling, and controlled atmosphere processing can significantly enhance the electrocaloric properties of thin films. These processes help optimize crystal structure, reduce defects, and improve domain mobility in ferroelectric materials. Techniques like rapid thermal annealing and laser annealing allow for precise control of crystallization processes without damaging temperature-sensitive substrates. Post-deposition surface treatments can also improve electrode interfaces, reducing leakage currents and enabling higher operating electric fields for enhanced electrocaloric effects.

02 Chemical Vapor Deposition Methods for Electrocaloric Materials

Chemical vapor deposition (CVD) techniques, including atomic layer deposition (ALD) and metal-organic CVD (MOCVD), provide excellent conformality and composition control for electrocaloric thin films. These methods enable the growth of uniform electrocaloric layers with precise stoichiometry and reduced defect density. The ability to deposit materials at lower temperatures compared to some physical methods helps preserve the electrocaloric properties while allowing for complex multilayer structures that enhance cooling efficiency.Expand Specific Solutions03 Solution-Based Deposition for Flexible Electrocaloric Films

Solution-based methods such as sol-gel processing, chemical solution deposition, and spin coating offer cost-effective approaches for fabricating electrocaloric thin films on various substrates, including flexible ones. These techniques allow for easy doping and composition modification to enhance electrocaloric properties. The ability to create large-area films with controlled thickness and composition makes these methods particularly suitable for scalable manufacturing of electrocaloric cooling devices.Expand Specific Solutions04 Post-Deposition Treatment for Enhanced Electrocaloric Performance

Various post-deposition treatments, including thermal annealing, rapid thermal processing, and electric field treatment, can significantly improve the electrocaloric properties of thin films. These processes help optimize crystal structure, reduce defects, and enhance domain mobility in ferroelectric materials. Controlled cooling rates and atmosphere during annealing are crucial for developing the desired microstructure that maximizes the electrocaloric effect, resulting in higher cooling efficiency for practical applications.Expand Specific Solutions05 Multilayer and Composite Structures for Enhanced Cooling

Advanced thin-film architectures incorporating multilayer structures, superlattices, and nanocomposites can significantly enhance electrocaloric performance. These engineered structures create interfaces and strain effects that amplify the electrocaloric response. By alternating layers of different electrocaloric materials or incorporating nanoparticles into a matrix, these composite structures can achieve higher temperature changes under applied electric fields compared to single-layer films, making them promising for next-generation cooling applications.Expand Specific Solutions

Leading Companies and Research Institutions in Electrocaloric Technology

The electrocaloric cooling technology market is currently in its early growth phase, with thin-film deposition methods emerging as critical enablers for high-performance cooling systems. The global market size is projected to expand significantly as energy-efficient cooling alternatives gain traction. Technologically, companies like Applied Materials, GLOBALFOUNDRIES, and Samsung Electronics are leading development with advanced deposition capabilities, while Tokyo Electron and ULVAC contribute specialized thin-film equipment solutions. Academic institutions including MIT and Northwestern University are advancing fundamental research. The technology maturity varies across deposition methods, with atomic layer deposition (ALD) and pulsed laser deposition (PLD) showing promising results for electrocaloric layers, though commercial-scale manufacturing processes still require optimization for cost-effective implementation.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced thin-film deposition technologies specifically optimized for electrocaloric materials. Their primary approach utilizes Atomic Layer Deposition (ALD) for creating highly uniform electrocaloric layers with precise thickness control down to the atomic level. This method enables the deposition of complex oxide materials with excellent conformality and step coverage, critical for high-performance electrocaloric cooling applications. The company has also pioneered Physical Vapor Deposition (PVD) techniques with enhanced target utilization and improved film quality for electrocaloric materials. Their Metal-Organic Chemical Vapor Deposition (MOCVD) systems allow for the growth of epitaxial electrocaloric thin films with controlled stoichiometry and crystallinity. Applied Materials' integrated cluster tools enable multiple deposition steps without breaking vacuum, reducing contamination and improving interface quality between electrocaloric layers and electrodes.

Strengths: Industry-leading precision in layer thickness control and composition uniformity across large substrates. Their equipment offers excellent scalability for high-volume manufacturing with demonstrated reliability. Weaknesses: Higher capital equipment costs compared to simpler deposition methods, and some processes require specialized precursors that may have limited availability or higher costs.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed proprietary thin-film deposition technologies specifically tailored for high-performance electrocaloric materials. Their approach centers on advanced Pulsed Laser Deposition (PLD) systems that enable the creation of complex oxide electrocaloric films with precise stoichiometry control. Samsung's PLD technology utilizes specialized laser optics and beam homogenization techniques to ensure uniform energy distribution across the target material, resulting in consistent film properties across large substrate areas. The company has also integrated in-situ RHEED (Reflection High-Energy Electron Diffraction) monitoring capabilities that allow real-time observation of crystalline structure development during deposition, enabling precise control over film growth modes. Samsung has further developed hybrid deposition approaches that combine PLD with other techniques such as RF sputtering to create multilayer structures with optimized interfaces between electrocaloric layers and electrodes. Their systems feature advanced substrate temperature control with rapid thermal processing capabilities, allowing for precise manipulation of crystallization kinetics in electrocaloric materials.

Strengths: Exceptional control over film crystallinity and orientation, which directly impacts electrocaloric performance. Their integrated monitoring systems enable superior process control and reproducibility. Weaknesses: PLD systems typically have lower throughput compared to some industrial deposition methods, potentially limiting mass production capabilities. The process requires careful optimization for each material composition.

Critical Patents and Breakthroughs in Electrocaloric Layer Fabrication

Method for forming thin film using two types of silicon precursor compounds

PatentWO2025018802A1

Innovation

- A method using two types of silicon precursor compounds, represented by specific formulas, is introduced to enable atomic layer deposition at temperatures below 500°C, allowing for conformal deposition and adjustment of thin film morphology and crystallinity.

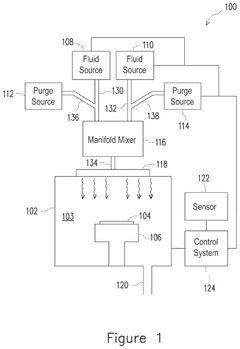

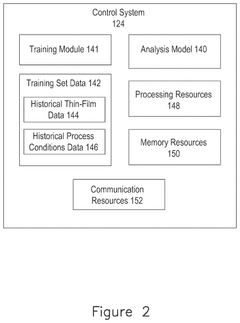

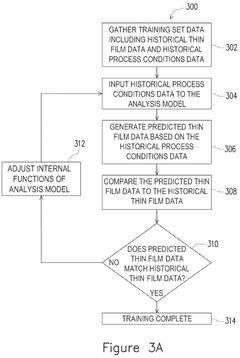

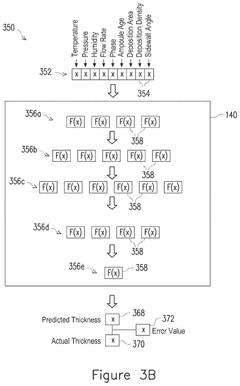

System and method for dynamically adjusting thin-film deposition parameters

PatentActiveUS12371791B2

Innovation

- A thin-film deposition system utilizing a control system with machine learning to dynamically adjust process parameters, including fluid flow rates and chamber conditions, based on historical data and real-time feedback from byproduct sensors to ensure thin films meet target specifications.

Environmental Impact and Sustainability of Electrocaloric Cooling

Electrocaloric cooling technology represents a promising alternative to conventional vapor-compression refrigeration systems, offering potential environmental benefits through reduced greenhouse gas emissions and energy consumption. The environmental impact of electrocaloric cooling systems is significantly influenced by the thin-film deposition methods used in their manufacturing process.

Traditional cooling technologies rely heavily on refrigerants with high global warming potential (GWP), contributing substantially to climate change. In contrast, electrocaloric cooling systems utilize solid-state materials that eliminate the need for these harmful refrigerants. The environmental footprint of these systems is primarily determined by the manufacturing processes, particularly the thin-film deposition methods employed for creating high-performance electrocaloric layers.

Various deposition techniques such as pulsed laser deposition (PLD), chemical vapor deposition (CVD), and sputtering differ considerably in their environmental impact profiles. PLD, while offering precise control over film composition, requires significant energy input and may involve toxic precursors. CVD processes often utilize hazardous gases and chemicals that require careful handling and disposal. Sputtering techniques generally have lower environmental impacts but may still consume substantial energy.

Life cycle assessment (LCA) studies indicate that the environmental benefits of electrocaloric cooling systems can be maximized through optimization of deposition parameters and selection of environmentally benign precursor materials. Recent innovations in green chemistry approaches to thin-film deposition have demonstrated potential for reducing toxic waste generation and energy consumption while maintaining high-performance electrocaloric properties.

The sustainability of electrocaloric cooling technology is further enhanced by the longevity and recyclability of the materials used. Unlike conventional refrigeration systems that require regular refrigerant replacement, properly manufactured electrocaloric devices can operate efficiently for extended periods without significant material degradation. End-of-life considerations for these systems are increasingly important, with research focusing on designing devices for easier disassembly and material recovery.

Energy efficiency during operation represents another critical environmental aspect of electrocaloric cooling systems. Advanced thin-film deposition methods that produce highly uniform electrocaloric layers with optimized interfaces can significantly improve the coefficient of performance (COP), reducing the overall energy consumption during the product lifecycle.

Regulatory frameworks worldwide are increasingly recognizing the environmental advantages of solid-state cooling technologies. Policies promoting low-carbon technologies and restricting high-GWP refrigerants are creating favorable conditions for the adoption of electrocaloric cooling systems, further driving research into environmentally sustainable thin-film deposition methods.

Traditional cooling technologies rely heavily on refrigerants with high global warming potential (GWP), contributing substantially to climate change. In contrast, electrocaloric cooling systems utilize solid-state materials that eliminate the need for these harmful refrigerants. The environmental footprint of these systems is primarily determined by the manufacturing processes, particularly the thin-film deposition methods employed for creating high-performance electrocaloric layers.

Various deposition techniques such as pulsed laser deposition (PLD), chemical vapor deposition (CVD), and sputtering differ considerably in their environmental impact profiles. PLD, while offering precise control over film composition, requires significant energy input and may involve toxic precursors. CVD processes often utilize hazardous gases and chemicals that require careful handling and disposal. Sputtering techniques generally have lower environmental impacts but may still consume substantial energy.

Life cycle assessment (LCA) studies indicate that the environmental benefits of electrocaloric cooling systems can be maximized through optimization of deposition parameters and selection of environmentally benign precursor materials. Recent innovations in green chemistry approaches to thin-film deposition have demonstrated potential for reducing toxic waste generation and energy consumption while maintaining high-performance electrocaloric properties.

The sustainability of electrocaloric cooling technology is further enhanced by the longevity and recyclability of the materials used. Unlike conventional refrigeration systems that require regular refrigerant replacement, properly manufactured electrocaloric devices can operate efficiently for extended periods without significant material degradation. End-of-life considerations for these systems are increasingly important, with research focusing on designing devices for easier disassembly and material recovery.

Energy efficiency during operation represents another critical environmental aspect of electrocaloric cooling systems. Advanced thin-film deposition methods that produce highly uniform electrocaloric layers with optimized interfaces can significantly improve the coefficient of performance (COP), reducing the overall energy consumption during the product lifecycle.

Regulatory frameworks worldwide are increasingly recognizing the environmental advantages of solid-state cooling technologies. Policies promoting low-carbon technologies and restricting high-GWP refrigerants are creating favorable conditions for the adoption of electrocaloric cooling systems, further driving research into environmentally sustainable thin-film deposition methods.

Scalability and Manufacturing Considerations

The scalability of thin-film deposition methods for electrocaloric layers represents a critical factor in the commercial viability of electrocaloric cooling technologies. Current laboratory-scale deposition techniques face significant challenges when transitioning to mass production environments. Physical vapor deposition (PVD) methods such as sputtering and pulsed laser deposition demonstrate excellent film quality but suffer from low throughput and high equipment costs when scaled to industrial levels.

Chemical vapor deposition (CVD) offers better scalability potential through its ability to coat larger surface areas simultaneously. However, maintaining uniform film thickness and composition across large substrates remains problematic, particularly for complex electrocaloric materials requiring precise stoichiometry. The development of modified CVD processes with enhanced precursor delivery systems shows promise for addressing these uniformity issues.

Solution-based methods including sol-gel and chemical solution deposition present the most economically viable scaling options, with significantly lower capital equipment requirements. These approaches enable roll-to-roll processing capabilities that could dramatically increase production volumes. Nevertheless, these methods currently struggle with achieving the same level of crystallinity and electrocaloric performance as vacuum-based techniques, necessitating additional post-deposition thermal treatments.

Manufacturing considerations extend beyond the deposition process itself to include substrate preparation, interface engineering, and electrode integration. The selection of substrate materials must balance thermal expansion compatibility, cost, and mechanical properties. Flexible substrates, while desirable for certain applications, introduce additional processing complexities that impact yield rates and performance consistency.

Quality control represents another significant manufacturing challenge. In-line monitoring systems capable of detecting defects, thickness variations, and compositional irregularities without disrupting production flow are essential but currently underdeveloped for electrocaloric materials. Advanced characterization techniques adapted for production environments could significantly improve manufacturing yields.

Cost modeling indicates that material utilization efficiency during deposition significantly impacts economic viability. Conventional PVD techniques typically achieve material utilization rates below 30%, whereas solution-based methods can reach 70-90%. Recycling of target materials and precursors presents an opportunity to further improve cost structures, though implementation remains limited in current manufacturing setups.

Environmental considerations and regulatory compliance add another dimension to manufacturing scalability. Many high-performance electrocaloric materials contain lead or other regulated substances, necessitating the development of containment systems and waste management protocols that comply with increasingly stringent environmental regulations while maintaining production efficiency.

Chemical vapor deposition (CVD) offers better scalability potential through its ability to coat larger surface areas simultaneously. However, maintaining uniform film thickness and composition across large substrates remains problematic, particularly for complex electrocaloric materials requiring precise stoichiometry. The development of modified CVD processes with enhanced precursor delivery systems shows promise for addressing these uniformity issues.

Solution-based methods including sol-gel and chemical solution deposition present the most economically viable scaling options, with significantly lower capital equipment requirements. These approaches enable roll-to-roll processing capabilities that could dramatically increase production volumes. Nevertheless, these methods currently struggle with achieving the same level of crystallinity and electrocaloric performance as vacuum-based techniques, necessitating additional post-deposition thermal treatments.

Manufacturing considerations extend beyond the deposition process itself to include substrate preparation, interface engineering, and electrode integration. The selection of substrate materials must balance thermal expansion compatibility, cost, and mechanical properties. Flexible substrates, while desirable for certain applications, introduce additional processing complexities that impact yield rates and performance consistency.

Quality control represents another significant manufacturing challenge. In-line monitoring systems capable of detecting defects, thickness variations, and compositional irregularities without disrupting production flow are essential but currently underdeveloped for electrocaloric materials. Advanced characterization techniques adapted for production environments could significantly improve manufacturing yields.

Cost modeling indicates that material utilization efficiency during deposition significantly impacts economic viability. Conventional PVD techniques typically achieve material utilization rates below 30%, whereas solution-based methods can reach 70-90%. Recycling of target materials and precursors presents an opportunity to further improve cost structures, though implementation remains limited in current manufacturing setups.

Environmental considerations and regulatory compliance add another dimension to manufacturing scalability. Many high-performance electrocaloric materials contain lead or other regulated substances, necessitating the development of containment systems and waste management protocols that comply with increasingly stringent environmental regulations while maintaining production efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!