Supply Chain Considerations For Electrocaloric Material Precursors In Electrocaloric Cooling

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Technology Background and Objectives

Electrocaloric cooling technology represents a promising alternative to conventional vapor-compression refrigeration systems, offering potential advantages in energy efficiency, environmental impact, and system miniaturization. The technology leverages the electrocaloric effect, a phenomenon where certain materials exhibit temperature changes when subjected to an electric field. This effect was first observed in the 1930s but remained largely unexplored for practical cooling applications until recent decades.

The evolution of electrocaloric cooling technology has been marked by significant breakthroughs in material science. Early research focused primarily on ferroelectric ceramics, which demonstrated modest electrocaloric effects. However, the discovery of giant electrocaloric effects in thin films of lead zirconate titanate (PZT) and related materials in the early 2000s sparked renewed interest in this technology for practical cooling applications.

Recent technological advancements have expanded the material palette to include polymer-based electrocaloric materials, relaxor ferroelectrics, and various composite systems. These developments have progressively enhanced the temperature change capabilities, operational temperature ranges, and overall efficiency of electrocaloric cooling systems.

The primary technical objective in this field is to develop commercially viable electrocaloric cooling systems that can compete with or surpass conventional refrigeration technologies in terms of efficiency, cost-effectiveness, and environmental sustainability. This requires addressing several interconnected challenges, including material optimization, device design, and system integration.

Material optimization goals include increasing the electrocaloric temperature change, reducing the required electric field, expanding the operational temperature range, and ensuring long-term stability and reliability. Device design objectives focus on maximizing heat transfer efficiency, optimizing the thermodynamic cycle, and developing effective heat exchange mechanisms.

A critical but often overlooked aspect of electrocaloric technology development is the supply chain for precursor materials. The availability, cost, and quality consistency of these precursors significantly impact the scalability and commercial viability of electrocaloric cooling systems. Many high-performance electrocaloric materials require specialized precursors that may have limited availability or face supply chain vulnerabilities.

Understanding these supply chain considerations is essential for strategic technology planning and risk assessment. The global distribution of precursor materials, geopolitical factors affecting their availability, and potential alternatives all need careful evaluation to ensure sustainable technology development and eventual commercialization of electrocaloric cooling systems.

The ultimate goal is to establish electrocaloric cooling as a mainstream technology that can address growing cooling needs worldwide while minimizing environmental impact and energy consumption, particularly in applications where conventional cooling technologies face limitations or sustainability challenges.

The evolution of electrocaloric cooling technology has been marked by significant breakthroughs in material science. Early research focused primarily on ferroelectric ceramics, which demonstrated modest electrocaloric effects. However, the discovery of giant electrocaloric effects in thin films of lead zirconate titanate (PZT) and related materials in the early 2000s sparked renewed interest in this technology for practical cooling applications.

Recent technological advancements have expanded the material palette to include polymer-based electrocaloric materials, relaxor ferroelectrics, and various composite systems. These developments have progressively enhanced the temperature change capabilities, operational temperature ranges, and overall efficiency of electrocaloric cooling systems.

The primary technical objective in this field is to develop commercially viable electrocaloric cooling systems that can compete with or surpass conventional refrigeration technologies in terms of efficiency, cost-effectiveness, and environmental sustainability. This requires addressing several interconnected challenges, including material optimization, device design, and system integration.

Material optimization goals include increasing the electrocaloric temperature change, reducing the required electric field, expanding the operational temperature range, and ensuring long-term stability and reliability. Device design objectives focus on maximizing heat transfer efficiency, optimizing the thermodynamic cycle, and developing effective heat exchange mechanisms.

A critical but often overlooked aspect of electrocaloric technology development is the supply chain for precursor materials. The availability, cost, and quality consistency of these precursors significantly impact the scalability and commercial viability of electrocaloric cooling systems. Many high-performance electrocaloric materials require specialized precursors that may have limited availability or face supply chain vulnerabilities.

Understanding these supply chain considerations is essential for strategic technology planning and risk assessment. The global distribution of precursor materials, geopolitical factors affecting their availability, and potential alternatives all need careful evaluation to ensure sustainable technology development and eventual commercialization of electrocaloric cooling systems.

The ultimate goal is to establish electrocaloric cooling as a mainstream technology that can address growing cooling needs worldwide while minimizing environmental impact and energy consumption, particularly in applications where conventional cooling technologies face limitations or sustainability challenges.

Market Analysis for Electrocaloric Cooling Solutions

The global market for cooling technologies is experiencing significant transformation as environmental regulations and energy efficiency demands drive innovation. Electrocaloric cooling represents an emerging technology with substantial market potential, positioned to disrupt conventional vapor-compression cooling systems that dominate current markets. Current projections indicate the alternative cooling technologies market could reach $20 billion by 2030, with electrocaloric solutions potentially capturing 15-20% of this segment.

Consumer electronics represents the most immediate market opportunity for electrocaloric cooling, particularly in applications requiring precise temperature control in compact spaces. Smartphone manufacturers and data center operators have expressed growing interest, with several major technology companies initiating pilot programs to evaluate integration feasibility. The miniaturization trend in electronics continues to create thermal management challenges that conventional cooling struggles to address effectively.

Commercial refrigeration presents another substantial market segment, valued at approximately $30 billion globally, where electrocaloric technologies could provide significant energy efficiency improvements. Early adopters are likely to be premium commercial refrigeration providers seeking differentiation through sustainability credentials and operating cost reductions. Industry analysis suggests potential energy savings of 25-30% compared to conventional systems.

Automotive cooling systems represent a third key market, particularly as electric vehicles proliferate. The EV thermal management market is growing at 17% annually, creating opportunities for electrocaloric solutions that can efficiently manage battery temperatures while consuming minimal power. Several automotive manufacturers have established research partnerships focused on electrocaloric integration for next-generation vehicles.

Market barriers include cost considerations, with current electrocaloric material production remaining significantly more expensive than conventional alternatives. Supply chain analysis indicates material precursor costs must decrease by approximately 40% to achieve commercial viability in mass-market applications. Additionally, manufacturing scalability presents challenges, as current production methods for high-performance electrocaloric materials remain laboratory-focused rather than industry-optimized.

Regional market analysis shows North America and Europe leading in research investment, while Asia-Pacific demonstrates the fastest growth in cooling technology adoption. China has recently increased funding for alternative cooling technologies by 35%, recognizing both environmental benefits and strategic industrial advantages in developing domestic capabilities.

Consumer awareness of cooling technology environmental impacts is increasing, with 62% of surveyed consumers in developed markets expressing willingness to pay premium prices for more sustainable cooling solutions. This trend supports market entry strategies focusing on premium segments before pursuing broader commercialization as economies of scale reduce production costs.

Consumer electronics represents the most immediate market opportunity for electrocaloric cooling, particularly in applications requiring precise temperature control in compact spaces. Smartphone manufacturers and data center operators have expressed growing interest, with several major technology companies initiating pilot programs to evaluate integration feasibility. The miniaturization trend in electronics continues to create thermal management challenges that conventional cooling struggles to address effectively.

Commercial refrigeration presents another substantial market segment, valued at approximately $30 billion globally, where electrocaloric technologies could provide significant energy efficiency improvements. Early adopters are likely to be premium commercial refrigeration providers seeking differentiation through sustainability credentials and operating cost reductions. Industry analysis suggests potential energy savings of 25-30% compared to conventional systems.

Automotive cooling systems represent a third key market, particularly as electric vehicles proliferate. The EV thermal management market is growing at 17% annually, creating opportunities for electrocaloric solutions that can efficiently manage battery temperatures while consuming minimal power. Several automotive manufacturers have established research partnerships focused on electrocaloric integration for next-generation vehicles.

Market barriers include cost considerations, with current electrocaloric material production remaining significantly more expensive than conventional alternatives. Supply chain analysis indicates material precursor costs must decrease by approximately 40% to achieve commercial viability in mass-market applications. Additionally, manufacturing scalability presents challenges, as current production methods for high-performance electrocaloric materials remain laboratory-focused rather than industry-optimized.

Regional market analysis shows North America and Europe leading in research investment, while Asia-Pacific demonstrates the fastest growth in cooling technology adoption. China has recently increased funding for alternative cooling technologies by 35%, recognizing both environmental benefits and strategic industrial advantages in developing domestic capabilities.

Consumer awareness of cooling technology environmental impacts is increasing, with 62% of surveyed consumers in developed markets expressing willingness to pay premium prices for more sustainable cooling solutions. This trend supports market entry strategies focusing on premium segments before pursuing broader commercialization as economies of scale reduce production costs.

Current Challenges in Electrocaloric Material Supply Chain

The electrocaloric material supply chain faces significant challenges that impede the widespread commercialization of electrocaloric cooling technologies. Raw material sourcing represents a primary concern, particularly for high-performance electrocaloric materials which often require rare earth elements and specialty chemicals. These materials frequently originate from geopolitically sensitive regions, creating vulnerability to supply disruptions and price volatility. For instance, materials like lead zirconate titanate (PZT) and relaxor ferroelectrics contain elements subject to strict environmental regulations and geographically concentrated mining operations.

Manufacturing scalability presents another substantial hurdle. Current production methods for advanced electrocaloric materials predominantly rely on laboratory-scale processes that are difficult to scale industrially while maintaining consistent material properties. Techniques such as sol-gel processing, hydrothermal synthesis, and solid-state reactions often require precise control of reaction conditions that become increasingly challenging at larger scales. This scalability gap creates a significant bottleneck between promising research results and commercial viability.

Quality control and material consistency pose persistent challenges throughout the supply chain. Electrocaloric performance is highly sensitive to minor variations in composition, crystal structure, and defect concentration. The lack of standardized testing protocols and quality metrics across the industry further complicates supplier qualification and material validation processes. This inconsistency increases manufacturing costs and reduces yield rates, particularly for high-performance applications requiring precise temperature control.

Regulatory compliance adds another layer of complexity to the supply chain. Many high-performance electrocaloric materials contain lead and other toxic elements that face increasing restrictions under environmental regulations like RoHS in Europe and similar frameworks globally. This regulatory landscape necessitates investment in alternative material development and adaptation of existing supply chains, creating additional costs and uncertainties for manufacturers.

The fragmented nature of the current supply chain ecosystem presents strategic challenges for technology developers. With few suppliers specializing in electrocaloric materials, companies face limited options for sourcing critical components. This supplier concentration increases business risk and potentially constrains innovation through limited material options. Furthermore, the nascent state of the industry means that suppliers often lack the economies of scale needed to drive down costs to competitive levels compared to conventional cooling technologies.

Manufacturing scalability presents another substantial hurdle. Current production methods for advanced electrocaloric materials predominantly rely on laboratory-scale processes that are difficult to scale industrially while maintaining consistent material properties. Techniques such as sol-gel processing, hydrothermal synthesis, and solid-state reactions often require precise control of reaction conditions that become increasingly challenging at larger scales. This scalability gap creates a significant bottleneck between promising research results and commercial viability.

Quality control and material consistency pose persistent challenges throughout the supply chain. Electrocaloric performance is highly sensitive to minor variations in composition, crystal structure, and defect concentration. The lack of standardized testing protocols and quality metrics across the industry further complicates supplier qualification and material validation processes. This inconsistency increases manufacturing costs and reduces yield rates, particularly for high-performance applications requiring precise temperature control.

Regulatory compliance adds another layer of complexity to the supply chain. Many high-performance electrocaloric materials contain lead and other toxic elements that face increasing restrictions under environmental regulations like RoHS in Europe and similar frameworks globally. This regulatory landscape necessitates investment in alternative material development and adaptation of existing supply chains, creating additional costs and uncertainties for manufacturers.

The fragmented nature of the current supply chain ecosystem presents strategic challenges for technology developers. With few suppliers specializing in electrocaloric materials, companies face limited options for sourcing critical components. This supplier concentration increases business risk and potentially constrains innovation through limited material options. Furthermore, the nascent state of the industry means that suppliers often lack the economies of scale needed to drive down costs to competitive levels compared to conventional cooling technologies.

Existing Procurement Strategies for Electrocaloric Precursors

01 Polymer-based electrocaloric materials

Polymer-based materials serve as effective precursors for electrocaloric applications due to their flexibility, processability, and strong electrocaloric effect. These materials, including ferroelectric polymers like polyvinylidene fluoride (PVDF) and its copolymers, can be synthesized through various polymerization methods. The precursors can be modified with additives to enhance their electrocaloric properties, resulting in materials suitable for cooling applications with improved energy efficiency and environmental friendliness.- Electrocaloric material compositions for cooling applications: Various compositions of electrocaloric materials are used as precursors for developing cooling systems. These materials exhibit temperature changes when subjected to electric fields, making them suitable for refrigeration applications. The compositions typically include ferroelectric polymers, relaxor ferroelectrics, and ceramic-polymer composites that demonstrate significant electrocaloric effects at relatively low operating voltages. These materials can be processed into thin films or bulk structures to maximize the cooling efficiency in compact refrigeration systems.

- Manufacturing methods for electrocaloric precursor materials: Specialized manufacturing techniques are employed to produce electrocaloric material precursors with enhanced properties. These methods include solution processing, sol-gel synthesis, chemical vapor deposition, and melt processing. The manufacturing processes are designed to control the crystallinity, grain size, and orientation of the electrocaloric materials, which directly impact their performance. Advanced techniques like nanofabrication and multilayer deposition are used to create optimized structures that maximize the electrocaloric effect for cooling applications.

- Polymer-based electrocaloric material precursors: Polymer-based materials serve as important precursors for electrocaloric applications due to their flexibility, processability, and tunable properties. These include fluoropolymers like polyvinylidene fluoride (PVDF) and its copolymers, which exhibit strong electrocaloric responses. The polymeric precursors can be modified with various additives and fillers to enhance their electrocaloric performance. These materials offer advantages such as lightweight construction, mechanical flexibility, and compatibility with roll-to-roll processing for large-scale manufacturing of cooling devices.

- Ceramic and oxide-based electrocaloric precursors: Ceramic and oxide-based materials form another important category of electrocaloric precursors. These include perovskite structures, lead zirconate titanate (PZT), barium titanate, and other complex oxides that demonstrate significant electrocaloric effects. The precursors are typically synthesized through solid-state reactions, hydrothermal methods, or chemical co-precipitation. These materials offer high temperature stability, large electrocaloric coefficients, and can be tailored for specific operating temperature ranges by adjusting their composition and dopants.

- Integration of electrocaloric materials into cooling devices: Methods for integrating electrocaloric material precursors into functional cooling devices involve specialized techniques for device fabrication and system integration. These include electrode deposition, encapsulation, thermal management systems, and control electronics. The integration process must address challenges such as electrical insulation, thermal cycling stability, and efficient heat transfer. Advanced designs incorporate regenerative cycles, cascaded structures, and microfluidic heat exchangers to maximize the cooling performance of the electrocaloric materials in practical refrigeration applications.

02 Ceramic and oxide-based electrocaloric precursors

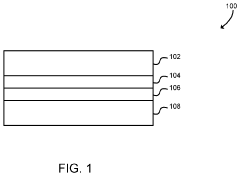

Ceramic and oxide-based materials, particularly perovskite structures, are important precursors for electrocaloric applications. These materials include barium titanate, lead zirconate titanate, and other complex oxides that exhibit strong electrocaloric effects. The precursors can be synthesized through sol-gel methods, solid-state reactions, or hydrothermal processes, allowing for precise control of composition and structure. These materials offer high temperature stability and significant temperature changes under applied electric fields.Expand Specific Solutions03 Multilayer and composite electrocaloric structures

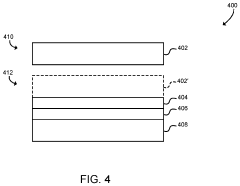

Multilayer and composite structures combine different electrocaloric materials to enhance overall performance. These structures can be created by layering different precursor materials, resulting in improved electrocaloric effects through interface engineering. The precursors for these composites often include combinations of polymers, ceramics, or hybrid materials that are processed to form integrated structures. This approach allows for optimization of both the electrocaloric effect and mechanical properties, making them suitable for practical cooling applications.Expand Specific Solutions04 Thin film electrocaloric material fabrication

Thin film electrocaloric materials offer advantages in terms of response time and integration capabilities. The precursors for these materials are typically solutions or suspensions that can be deposited through techniques such as spin coating, chemical vapor deposition, or pulsed laser deposition. These precursor solutions are carefully formulated to control film thickness, crystallinity, and microstructure. The resulting thin films can achieve large electrocaloric effects at lower voltages, making them suitable for microelectronic cooling applications.Expand Specific Solutions05 Novel electrocaloric cooling system designs

Advanced cooling system designs leverage electrocaloric materials in innovative configurations to maximize cooling efficiency. These systems incorporate electrocaloric material precursors into regenerative heat exchange systems, active cooling devices, or thermal management solutions. The precursor materials are selected and processed to optimize their integration into practical cooling devices. These systems often include heat transfer fluids, thermal switches, or mechanical designs that enhance the practical application of the electrocaloric effect for refrigeration and temperature control.Expand Specific Solutions

Key Suppliers and Manufacturers in Electrocaloric Industry

The electrocaloric cooling technology market is currently in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market size remains relatively small but is projected to expand as energy efficiency demands increase. From a technical maturity perspective, the supply chain for electrocaloric material precursors presents notable challenges. Leading players include established HVAC manufacturers like Carrier Corp. and United Technologies, alongside materials specialists such as IBU-tec and Samsung Electro-Mechanics. Academic institutions including University of Maryland and Harvard College are driving fundamental research, while industrial giants like Robert Bosch, Siemens Energy, and AUDI AG are exploring applications in automotive and energy sectors. Chinese companies like Guangdong Bangpu and XTC New Energy Materials are increasingly significant in material supply chains, leveraging their expertise in battery materials.

Carrier Corp.

Technical Solution: Carrier Corp. has developed an advanced electrocaloric cooling system utilizing specialized material precursors with optimized supply chain integration. Their approach focuses on using lead-free relaxor ferroelectric materials, particularly modified barium titanate (BaTiO3) compounds that demonstrate significant electrocaloric effects at lower voltages. Carrier has established a vertically integrated supply chain for these critical materials, working with specialized chemical suppliers to ensure consistent quality of high-purity precursors. Their manufacturing process incorporates precise stoichiometric control during synthesis to achieve optimal electrocaloric properties. The company has implemented rigorous quality control protocols for raw material sourcing, with particular attention to rare earth dopants that enhance the electrocaloric effect. Carrier's system design integrates these materials into compact, energy-efficient cooling modules that can operate with reduced environmental impact compared to conventional vapor-compression systems[1].

Strengths: Established HVAC industry presence provides extensive distribution networks and manufacturing capabilities. Their vertical integration approach ensures quality control throughout the supply chain. Weaknesses: Relatively high initial material costs compared to conventional cooling technologies, and potential challenges in scaling production of specialized electrocaloric materials to meet commercial demand.

University of Maryland

Technical Solution: The University of Maryland has pioneered research in electrocaloric materials with a focus on sustainable supply chain development. Their approach centers on developing lead-free relaxor ferroelectric polymer composites that demonstrate enhanced electrocaloric effects at moderate electric fields. The research team has created novel synthesis methods for polymer-ceramic composite materials that combine the flexibility of polymers with the high electrocaloric response of ceramics. Their material system utilizes poly(vinylidene fluoride-trifluoroethylene-chlorofluoroethylene) [P(VDF-TrFE-CFE)] terpolymer matrices embedded with barium strontium titanate nanoparticles, achieving temperature changes of 12-16°C under applied fields of 50-70 MV/m[3]. The university has developed scalable processing techniques that reduce dependency on rare or geopolitically constrained elements, focusing instead on earth-abundant precursors. Their supply chain model emphasizes domestic sourcing of key components and recycling pathways for critical materials, addressing both economic and environmental sustainability concerns[4].

Strengths: Cutting-edge research capabilities with strong focus on sustainable materials and processes; established partnerships with industry leaders for technology transfer. Weaknesses: As an academic institution, faces challenges in large-scale manufacturing implementation and may require industrial partnerships to commercialize technologies effectively.

Critical Patents and Research on Electrocaloric Materials

Electrocaloric assembly

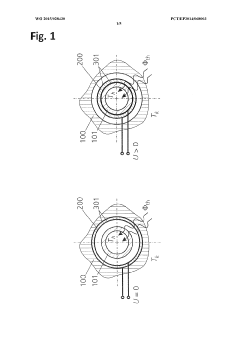

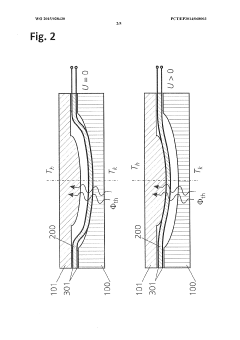

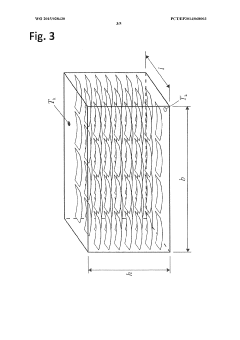

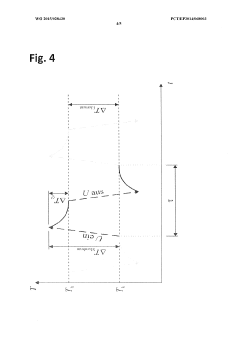

PatentWO2015028430A1

Innovation

- Designing an electrocaloric arrangement where the electrocaloric element, made from ferroelectric or piezoelectric materials, deforms under an electric field to move independently between a heat source and heat sink, utilizing mechanical displacement for heat transfer without continuous electrical energy, and optimizing the arrangement with housing parts and insulation for enhanced thermal efficiency.

Multi-layered electrocaloric heat pump systems and methods

PatentPendingUS20240019179A1

Innovation

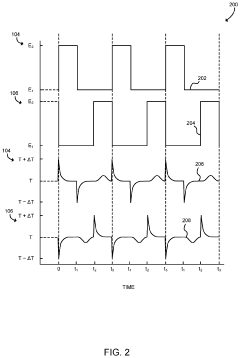

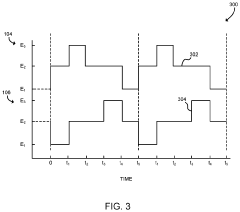

- A cooling system comprising independently controllable electrocaloric material layers separated by conductive or insulative materials, with a controller managing electric fields to move heat energy from a heat source to a heat sink during specific intervals and restore initial conditions, allowing for cyclic heat transfer without moving parts.

Sustainability Aspects of Electrocaloric Material Production

The sustainability of electrocaloric material production represents a critical dimension in evaluating the viability of electrocaloric cooling technologies for widespread adoption. Current production methods for electrocaloric materials, particularly lead-based perovskites and polymer-based materials, raise significant environmental concerns throughout their lifecycle.

Raw material extraction processes for electrocaloric materials often involve mining operations with substantial environmental footprints. The extraction of lead, zirconium, and rare earth elements requires energy-intensive processes that contribute to habitat destruction, water pollution, and greenhouse gas emissions. These environmental impacts must be quantified and mitigated through improved extraction technologies and alternative sourcing strategies.

Manufacturing processes for electrocaloric materials typically involve high-temperature sintering or solution processing methods that consume considerable energy. The carbon footprint associated with these energy-intensive production steps potentially undermines the environmental benefits gained from the improved efficiency of electrocaloric cooling systems. Implementation of renewable energy sources in manufacturing facilities could significantly reduce this environmental burden.

Chemical waste management presents another sustainability challenge in electrocaloric material production. Synthesis routes often utilize toxic solvents, catalysts, and precursors that require specialized disposal procedures. Developing green chemistry approaches with less hazardous reagents and closed-loop recycling systems would enhance the environmental profile of these materials.

End-of-life considerations for electrocaloric devices remain largely unaddressed in current research. The presence of lead and other toxic elements in many high-performance electrocaloric materials complicates recycling efforts and raises concerns about potential environmental contamination. Design for disassembly and material recovery should be integrated into product development cycles.

Water usage in production processes represents another sustainability concern, particularly for solution-based synthesis methods. Water-intensive manufacturing steps contribute to local resource depletion in water-stressed regions. Implementation of water recycling systems and transition to less water-dependent processes could mitigate these impacts.

Regulatory compliance across global markets increasingly demands sustainable production practices. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are driving research toward lead-free alternatives despite their currently lower performance metrics. This regulatory landscape will significantly influence the commercial viability of different electrocaloric material compositions.

Life cycle assessment (LCA) methodologies must be applied to comprehensively evaluate the environmental impacts of electrocaloric materials from cradle to grave. Such analyses would enable meaningful comparisons with conventional cooling technologies and guide sustainable innovation in material design and manufacturing processes.

Raw material extraction processes for electrocaloric materials often involve mining operations with substantial environmental footprints. The extraction of lead, zirconium, and rare earth elements requires energy-intensive processes that contribute to habitat destruction, water pollution, and greenhouse gas emissions. These environmental impacts must be quantified and mitigated through improved extraction technologies and alternative sourcing strategies.

Manufacturing processes for electrocaloric materials typically involve high-temperature sintering or solution processing methods that consume considerable energy. The carbon footprint associated with these energy-intensive production steps potentially undermines the environmental benefits gained from the improved efficiency of electrocaloric cooling systems. Implementation of renewable energy sources in manufacturing facilities could significantly reduce this environmental burden.

Chemical waste management presents another sustainability challenge in electrocaloric material production. Synthesis routes often utilize toxic solvents, catalysts, and precursors that require specialized disposal procedures. Developing green chemistry approaches with less hazardous reagents and closed-loop recycling systems would enhance the environmental profile of these materials.

End-of-life considerations for electrocaloric devices remain largely unaddressed in current research. The presence of lead and other toxic elements in many high-performance electrocaloric materials complicates recycling efforts and raises concerns about potential environmental contamination. Design for disassembly and material recovery should be integrated into product development cycles.

Water usage in production processes represents another sustainability concern, particularly for solution-based synthesis methods. Water-intensive manufacturing steps contribute to local resource depletion in water-stressed regions. Implementation of water recycling systems and transition to less water-dependent processes could mitigate these impacts.

Regulatory compliance across global markets increasingly demands sustainable production practices. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are driving research toward lead-free alternatives despite their currently lower performance metrics. This regulatory landscape will significantly influence the commercial viability of different electrocaloric material compositions.

Life cycle assessment (LCA) methodologies must be applied to comprehensively evaluate the environmental impacts of electrocaloric materials from cradle to grave. Such analyses would enable meaningful comparisons with conventional cooling technologies and guide sustainable innovation in material design and manufacturing processes.

Geopolitical Factors Affecting Precursor Availability

The geopolitical landscape significantly impacts the availability and accessibility of precursor materials essential for electrocaloric cooling technologies. The rare earth elements and specialized compounds required for high-performance electrocaloric materials are not evenly distributed globally, creating strategic vulnerabilities in supply chains. China currently dominates the global production of rare earth elements, controlling approximately 85% of processing capacity, which creates potential bottlenecks for manufacturers outside this region.

Trade tensions between major economies have exacerbated supply chain risks for electrocaloric material precursors. The ongoing technology competition between the United States and China has resulted in export restrictions, tariffs, and counter-measures that directly affect the movement of critical materials across borders. These geopolitical frictions have prompted companies to reconsider their sourcing strategies and explore alternative supply routes.

Resource nationalism has emerged as another significant factor, with countries increasingly viewing their mineral resources as strategic assets. Nations like Russia, Bolivia, and Indonesia have implemented policies to restrict exports of raw materials in favor of developing domestic processing capabilities. This trend toward resource protectionism creates additional complexity for global supply chains and may lead to price volatility for key electrocaloric precursors.

Environmental regulations vary substantially across jurisdictions, creating an uneven playing field for precursor production. Stricter environmental standards in Western countries have shifted production to regions with less stringent regulations, potentially creating hidden supply chain vulnerabilities when these regions face environmental crises or regulatory changes. The European Union's REACH regulations and similar frameworks in other regions add compliance costs that affect precursor availability and pricing.

Political instability in resource-rich regions presents another layer of risk. Countries in Africa and South America with significant deposits of critical minerals often face governance challenges that can disrupt mining operations and material exports. The Democratic Republic of Congo, which holds substantial reserves of cobalt and other strategic minerals, exemplifies how political volatility can impact global supply chains.

International alliances are forming to address these geopolitical challenges. The EU's European Raw Materials Alliance and similar initiatives in North America aim to reduce dependency on single-source regions. Japan and South Korea have established strategic reserves of critical materials to buffer against supply disruptions. These collaborative approaches may reshape the geopolitical dynamics of precursor availability in the coming decade.

Trade tensions between major economies have exacerbated supply chain risks for electrocaloric material precursors. The ongoing technology competition between the United States and China has resulted in export restrictions, tariffs, and counter-measures that directly affect the movement of critical materials across borders. These geopolitical frictions have prompted companies to reconsider their sourcing strategies and explore alternative supply routes.

Resource nationalism has emerged as another significant factor, with countries increasingly viewing their mineral resources as strategic assets. Nations like Russia, Bolivia, and Indonesia have implemented policies to restrict exports of raw materials in favor of developing domestic processing capabilities. This trend toward resource protectionism creates additional complexity for global supply chains and may lead to price volatility for key electrocaloric precursors.

Environmental regulations vary substantially across jurisdictions, creating an uneven playing field for precursor production. Stricter environmental standards in Western countries have shifted production to regions with less stringent regulations, potentially creating hidden supply chain vulnerabilities when these regions face environmental crises or regulatory changes. The European Union's REACH regulations and similar frameworks in other regions add compliance costs that affect precursor availability and pricing.

Political instability in resource-rich regions presents another layer of risk. Countries in Africa and South America with significant deposits of critical minerals often face governance challenges that can disrupt mining operations and material exports. The Democratic Republic of Congo, which holds substantial reserves of cobalt and other strategic minerals, exemplifies how political volatility can impact global supply chains.

International alliances are forming to address these geopolitical challenges. The EU's European Raw Materials Alliance and similar initiatives in North America aim to reduce dependency on single-source regions. Japan and South Korea have established strategic reserves of critical materials to buffer against supply disruptions. These collaborative approaches may reshape the geopolitical dynamics of precursor availability in the coming decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!