Optimizing Electric Field Cycling For Maximum Electrocaloric Effect In Electrocaloric Cooling

SEP 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrocaloric Cooling Background and Objectives

Electrocaloric cooling represents a promising alternative to conventional vapor-compression refrigeration systems, offering potential advantages in energy efficiency, environmental friendliness, and compact design. This technology harnesses the electrocaloric effect—a phenomenon where certain materials exhibit temperature changes when subjected to varying electric fields. The historical development of electrocaloric cooling can be traced back to the 1930s when the effect was first discovered, but significant research momentum only began building in the early 2000s with the discovery of giant electrocaloric effects in thin films.

The evolution of electrocaloric materials has progressed from initial investigations in ferroelectric ceramics to modern explorations of relaxor ferroelectrics, polymers, and multilayer composites. Each material class presents unique advantages and limitations regarding temperature change magnitude, operating temperature range, and electric field requirements. Recent technological breakthroughs have demonstrated temperature changes exceeding 40K in specialized materials under optimized conditions, signaling the growing maturity of this technology.

Current research trends focus heavily on electric field cycling optimization—the strategic application and removal of electric fields to maximize cooling efficiency. This aspect represents a critical frontier in electrocaloric cooling development, as the timing, waveform, frequency, and magnitude of applied electric fields significantly impact the overall system performance. Optimized cycling protocols can potentially double cooling power while reducing energy consumption compared to conventional approaches.

The primary technical objectives in this field include developing materials with enhanced electrocaloric coefficients (ΔT/ΔE), improving cycling efficiency through advanced control algorithms, reducing hysteresis losses during field cycling, and extending material operational lifetimes under repeated field cycling. Additionally, researchers aim to lower the required electric field strengths while maintaining substantial temperature changes, thereby improving safety and reducing power requirements.

Market drivers for electrocaloric cooling technology include increasing global energy efficiency regulations, growing demand for compact cooling solutions in electronics, and environmental concerns regarding traditional refrigerants. The technology promises particular advantages in applications requiring precise temperature control, such as medical devices, electronics cooling, and specialized industrial processes.

The ultimate goal of electric field cycling optimization research is to develop commercially viable electrocaloric cooling systems that can compete with or surpass conventional technologies in efficiency, cost, and environmental impact. This requires interdisciplinary approaches combining materials science, electrical engineering, thermal management, and control systems to overcome current limitations and fully realize the potential of this promising cooling technology.

The evolution of electrocaloric materials has progressed from initial investigations in ferroelectric ceramics to modern explorations of relaxor ferroelectrics, polymers, and multilayer composites. Each material class presents unique advantages and limitations regarding temperature change magnitude, operating temperature range, and electric field requirements. Recent technological breakthroughs have demonstrated temperature changes exceeding 40K in specialized materials under optimized conditions, signaling the growing maturity of this technology.

Current research trends focus heavily on electric field cycling optimization—the strategic application and removal of electric fields to maximize cooling efficiency. This aspect represents a critical frontier in electrocaloric cooling development, as the timing, waveform, frequency, and magnitude of applied electric fields significantly impact the overall system performance. Optimized cycling protocols can potentially double cooling power while reducing energy consumption compared to conventional approaches.

The primary technical objectives in this field include developing materials with enhanced electrocaloric coefficients (ΔT/ΔE), improving cycling efficiency through advanced control algorithms, reducing hysteresis losses during field cycling, and extending material operational lifetimes under repeated field cycling. Additionally, researchers aim to lower the required electric field strengths while maintaining substantial temperature changes, thereby improving safety and reducing power requirements.

Market drivers for electrocaloric cooling technology include increasing global energy efficiency regulations, growing demand for compact cooling solutions in electronics, and environmental concerns regarding traditional refrigerants. The technology promises particular advantages in applications requiring precise temperature control, such as medical devices, electronics cooling, and specialized industrial processes.

The ultimate goal of electric field cycling optimization research is to develop commercially viable electrocaloric cooling systems that can compete with or surpass conventional technologies in efficiency, cost, and environmental impact. This requires interdisciplinary approaches combining materials science, electrical engineering, thermal management, and control systems to overcome current limitations and fully realize the potential of this promising cooling technology.

Market Analysis for Solid-State Cooling Technologies

The solid-state cooling technology market is experiencing significant growth, driven by increasing demand for energy-efficient, environmentally friendly cooling solutions. The global market for solid-state cooling technologies was valued at approximately $500 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate of 15.8%. This growth trajectory is supported by stringent environmental regulations phasing out conventional refrigerants and increasing energy efficiency standards worldwide.

Electrocaloric cooling, particularly technologies focusing on optimized electric field cycling for maximum electrocaloric effect, represents one of the most promising segments within this market. Current market penetration remains limited, with most applications still in research and development phases, but commercial adoption is accelerating in specialized sectors such as electronics cooling, medical device refrigeration, and aerospace applications.

The market landscape is characterized by distinct regional variations. North America leads in research investment and patent activity related to electrocaloric cooling technologies, while Asia-Pacific demonstrates the fastest growth rate, particularly in China and South Korea where government initiatives strongly support green technology development. Europe maintains a strong position due to stringent environmental regulations driving adoption of alternative cooling technologies.

Key market drivers include increasing miniaturization of electronic devices requiring precise thermal management, growing demand for silent cooling solutions in consumer applications, and the push for reduced carbon footprints in commercial and residential buildings. The healthcare sector represents a particularly promising vertical, with requirements for precise temperature control in drug storage and medical equipment.

Market challenges include high initial costs compared to conventional vapor-compression systems, with electrocaloric cooling systems currently costing 2.5-3 times more than traditional alternatives. Technical barriers related to material fatigue during electric field cycling and scaling challenges for larger cooling capacities also remain significant market constraints.

Consumer awareness and acceptance represent another market challenge, with limited understanding of solid-state cooling benefits among end-users. However, this is gradually improving as sustainability becomes a more prominent purchasing consideration, particularly in premium market segments.

Industry analysts predict that as manufacturing scales and material science advances, particularly in optimizing electric field cycling techniques, production costs will decrease by approximately 40% over the next five years, significantly expanding market opportunities beyond current niche applications into mainstream cooling markets.

Electrocaloric cooling, particularly technologies focusing on optimized electric field cycling for maximum electrocaloric effect, represents one of the most promising segments within this market. Current market penetration remains limited, with most applications still in research and development phases, but commercial adoption is accelerating in specialized sectors such as electronics cooling, medical device refrigeration, and aerospace applications.

The market landscape is characterized by distinct regional variations. North America leads in research investment and patent activity related to electrocaloric cooling technologies, while Asia-Pacific demonstrates the fastest growth rate, particularly in China and South Korea where government initiatives strongly support green technology development. Europe maintains a strong position due to stringent environmental regulations driving adoption of alternative cooling technologies.

Key market drivers include increasing miniaturization of electronic devices requiring precise thermal management, growing demand for silent cooling solutions in consumer applications, and the push for reduced carbon footprints in commercial and residential buildings. The healthcare sector represents a particularly promising vertical, with requirements for precise temperature control in drug storage and medical equipment.

Market challenges include high initial costs compared to conventional vapor-compression systems, with electrocaloric cooling systems currently costing 2.5-3 times more than traditional alternatives. Technical barriers related to material fatigue during electric field cycling and scaling challenges for larger cooling capacities also remain significant market constraints.

Consumer awareness and acceptance represent another market challenge, with limited understanding of solid-state cooling benefits among end-users. However, this is gradually improving as sustainability becomes a more prominent purchasing consideration, particularly in premium market segments.

Industry analysts predict that as manufacturing scales and material science advances, particularly in optimizing electric field cycling techniques, production costs will decrease by approximately 40% over the next five years, significantly expanding market opportunities beyond current niche applications into mainstream cooling markets.

Current Challenges in Electric Field Cycling Optimization

The optimization of electric field cycling for maximizing the electrocaloric effect presents several significant challenges that impede the widespread implementation of electrocaloric cooling technologies. One primary obstacle is the inherent trade-off between field strength and cycling frequency. While higher electric fields generally produce stronger electrocaloric effects, they also increase the risk of dielectric breakdown and accelerate material fatigue. Conversely, higher cycling frequencies improve cooling power density but exacerbate joule heating and reduce the time available for heat transfer processes.

Material degradation under repeated high-field cycling constitutes another major challenge. Ferroelectric materials, which exhibit the strongest electrocaloric responses, often suffer from polarization fatigue, microcracking, and eventual breakdown after numerous field cycles. This degradation progressively diminishes the electrocaloric effect and shortens device lifespan, making long-term reliability a significant concern for commercial applications.

The electrical efficiency of field cycling systems presents additional complications. Current approaches typically require charging and discharging capacitive electrocaloric elements, resulting in substantial energy losses, particularly at high frequencies. Although energy recovery circuits can partially mitigate these losses, they add complexity, cost, and weight to cooling systems, compromising their practical viability.

Thermal management during field cycling also remains problematic. The heat generated through dielectric losses and joule heating can counteract the desired cooling effect, especially in compact designs where heat dissipation pathways are limited. This parasitic heating reduces overall system efficiency and restricts the achievable temperature span.

Field uniformity across electrocaloric materials represents another technical hurdle. Non-uniform electric fields lead to localized hotspots, uneven cooling, and accelerated material degradation. Achieving uniform field distribution becomes increasingly difficult with thicker electrocaloric elements or complex geometries designed to enhance heat exchange.

The integration of field cycling with efficient heat transfer mechanisms poses additional challenges. The timing between field application and heat exchange must be precisely coordinated to maximize cooling performance. Current designs struggle to balance the competing requirements of good electrical insulation and excellent thermal conductivity at material interfaces.

Finally, control systems for optimizing field cycling parameters in real-time remain underdeveloped. Adaptive control strategies that can respond to changing thermal loads, ambient conditions, and material aging effects are necessary for maintaining optimal performance across varying operating conditions, but current implementations lack the sophistication required for commercial viability.

Material degradation under repeated high-field cycling constitutes another major challenge. Ferroelectric materials, which exhibit the strongest electrocaloric responses, often suffer from polarization fatigue, microcracking, and eventual breakdown after numerous field cycles. This degradation progressively diminishes the electrocaloric effect and shortens device lifespan, making long-term reliability a significant concern for commercial applications.

The electrical efficiency of field cycling systems presents additional complications. Current approaches typically require charging and discharging capacitive electrocaloric elements, resulting in substantial energy losses, particularly at high frequencies. Although energy recovery circuits can partially mitigate these losses, they add complexity, cost, and weight to cooling systems, compromising their practical viability.

Thermal management during field cycling also remains problematic. The heat generated through dielectric losses and joule heating can counteract the desired cooling effect, especially in compact designs where heat dissipation pathways are limited. This parasitic heating reduces overall system efficiency and restricts the achievable temperature span.

Field uniformity across electrocaloric materials represents another technical hurdle. Non-uniform electric fields lead to localized hotspots, uneven cooling, and accelerated material degradation. Achieving uniform field distribution becomes increasingly difficult with thicker electrocaloric elements or complex geometries designed to enhance heat exchange.

The integration of field cycling with efficient heat transfer mechanisms poses additional challenges. The timing between field application and heat exchange must be precisely coordinated to maximize cooling performance. Current designs struggle to balance the competing requirements of good electrical insulation and excellent thermal conductivity at material interfaces.

Finally, control systems for optimizing field cycling parameters in real-time remain underdeveloped. Adaptive control strategies that can respond to changing thermal loads, ambient conditions, and material aging effects are necessary for maintaining optimal performance across varying operating conditions, but current implementations lack the sophistication required for commercial viability.

State-of-the-Art Electric Field Cycling Methodologies

01 Electrocaloric cooling systems using field cycling

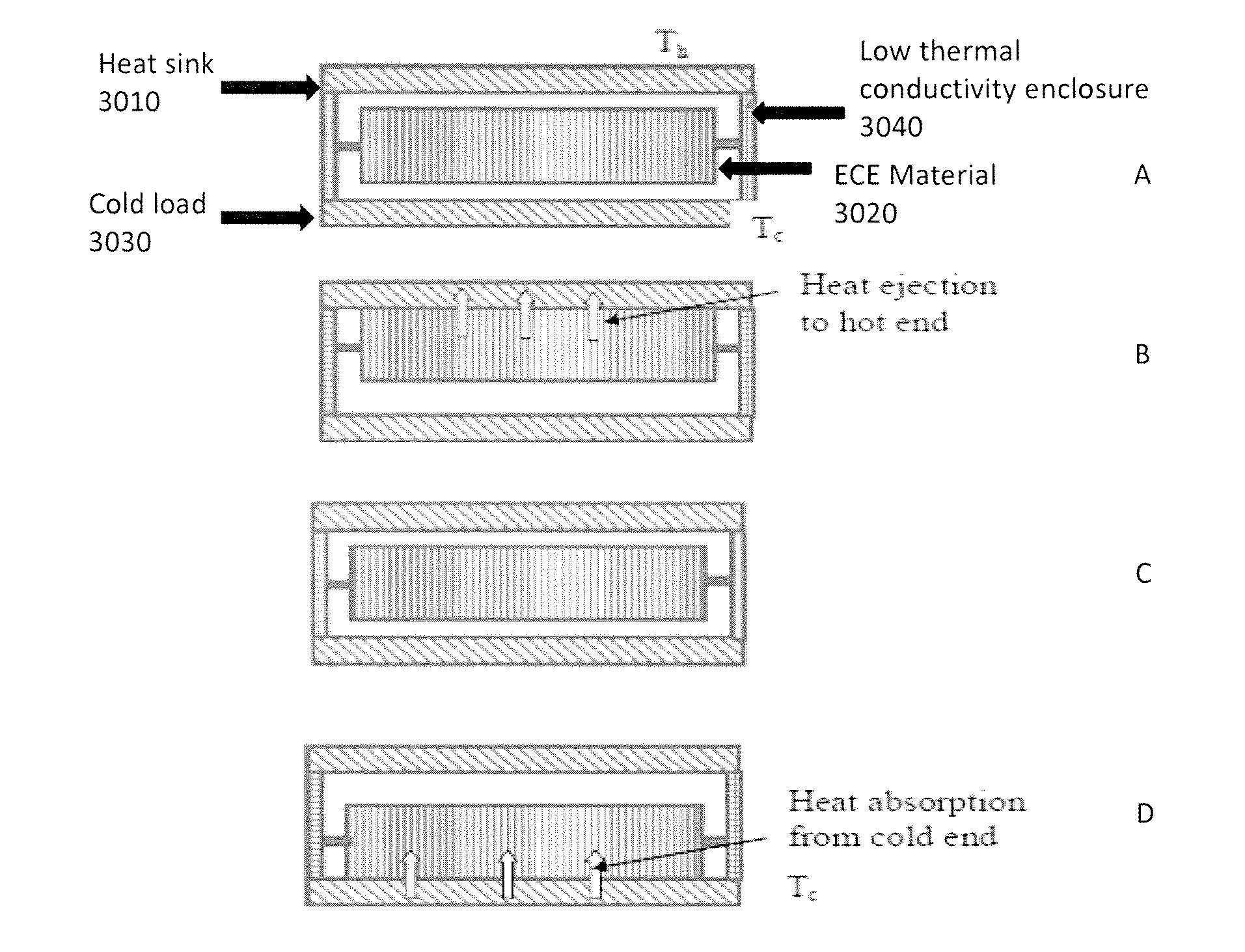

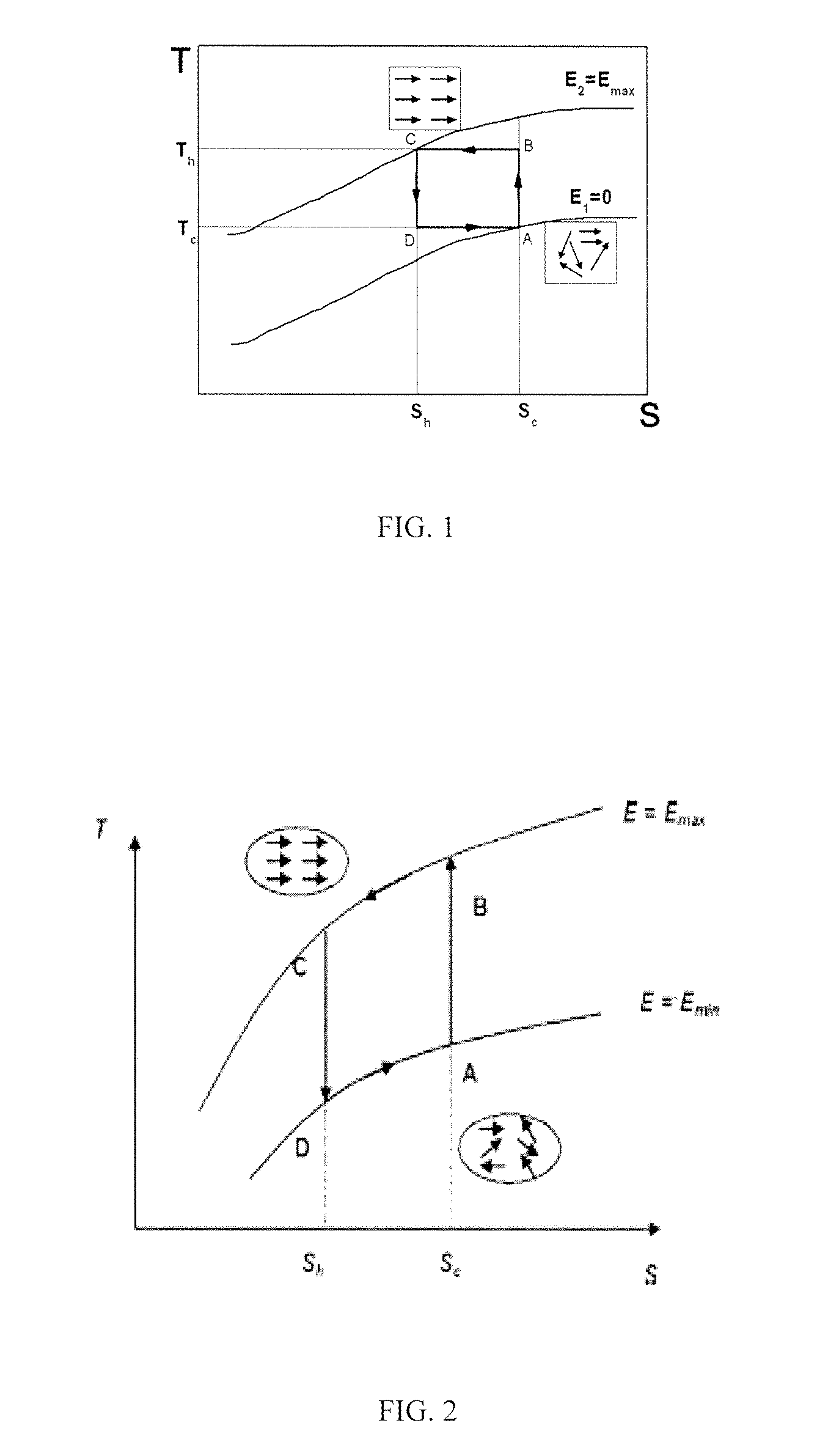

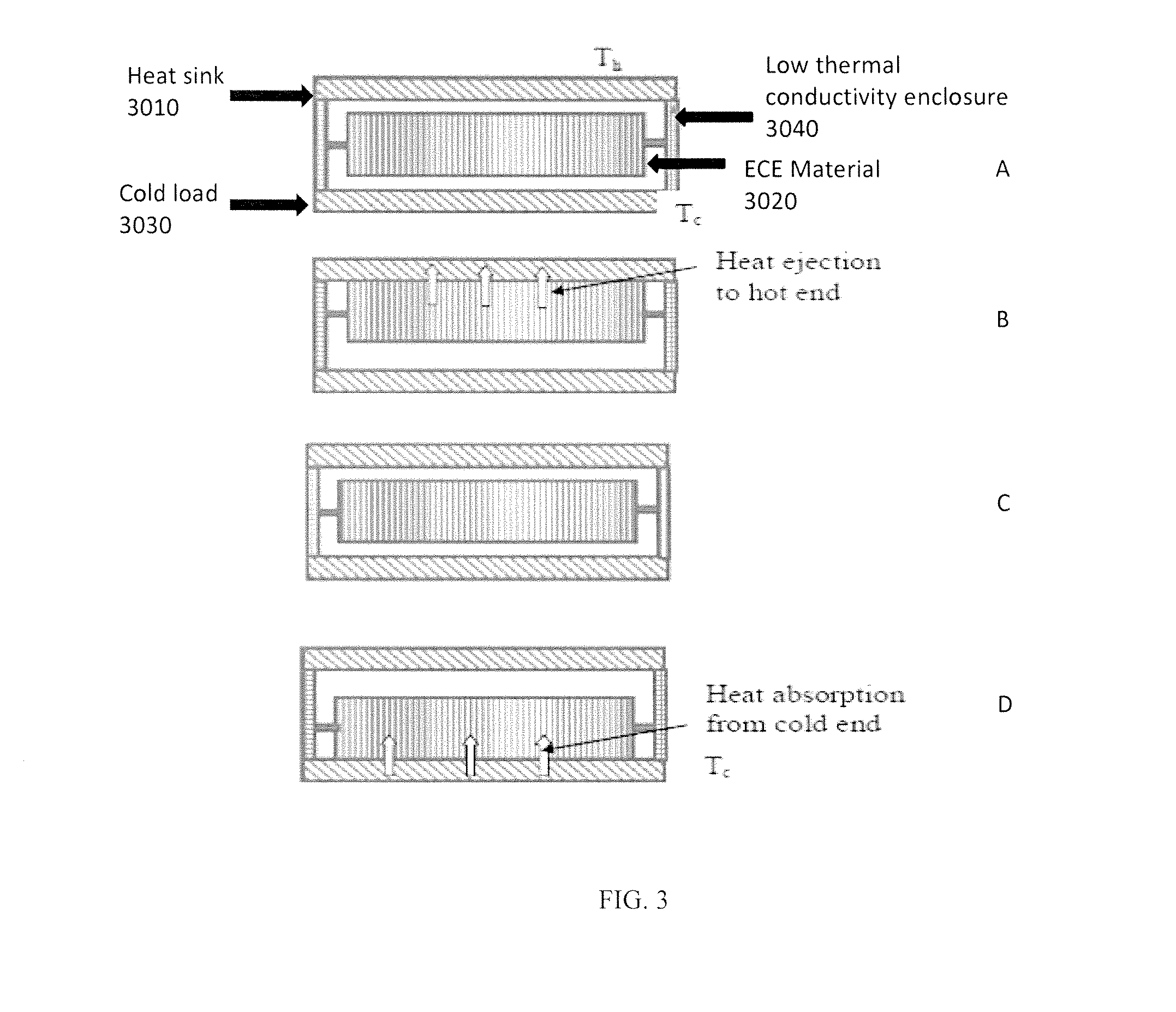

Cooling systems that utilize the electrocaloric effect through electric field cycling to achieve temperature changes in materials. These systems apply and remove electric fields in cycles to electrocaloric materials, causing them to heat and cool. The cycling process allows for efficient heat transfer and temperature control, making these systems suitable for refrigeration and thermal management applications.- Electrocaloric cooling systems using electric field cycling: Cooling systems that utilize the electrocaloric effect through electric field cycling to achieve temperature changes in electrocaloric materials. These systems apply and remove electric fields in cycles to create heating and cooling effects that can be used for refrigeration or temperature control applications. The cycling process allows for continuous operation of cooling devices by repeatedly polarizing and depolarizing the electrocaloric material.

- Materials for enhanced electrocaloric effect: Specialized materials that exhibit strong electrocaloric properties when subjected to electric field cycling. These materials include ferroelectric polymers, ceramic-polymer composites, and relaxor ferroelectrics that demonstrate significant temperature changes under applied electric fields. The composition and structure of these materials are engineered to maximize the electrocaloric coefficient and improve energy efficiency in cooling applications.

- Electric field cycling control methods: Control methods and algorithms for optimizing electric field cycling in electrocaloric devices. These methods include precise timing of field application and removal, variable field strength techniques, and adaptive control systems that respond to thermal load changes. Advanced control strategies can significantly improve the coefficient of performance and overall efficiency of electrocaloric cooling systems.

- Heat transfer mechanisms in electrocaloric systems: Heat transfer mechanisms designed specifically for electrocaloric cooling systems that utilize electric field cycling. These include fluid-based heat exchange systems, thermal switches, heat pipes, and direct contact heat transfer methods that efficiently move heat from the cooled space to the environment. Effective heat transfer is crucial for maximizing the practical cooling capacity of electrocaloric devices.

- Applications of electric field cycling electrocaloric effect: Various applications that leverage the electrocaloric effect through electric field cycling. These include compact refrigeration systems, electronic device cooling, wearable cooling technologies, temperature-controlled medical devices, and aerospace thermal management systems. The solid-state nature of electrocaloric cooling makes it suitable for applications where conventional vapor-compression cooling is impractical.

02 Electrocaloric materials for field cycling applications

Specialized materials that exhibit strong electrocaloric effects when subjected to electric field cycling. These materials, which include certain ferroelectric polymers and ceramics, demonstrate significant temperature changes when electric fields are applied and removed. The materials are engineered to maximize the electrocaloric coefficient and thermal response, enabling more efficient cooling systems and thermal management devices.Expand Specific Solutions03 Control systems for electric field cycling

Advanced control systems designed to optimize the electric field cycling process in electrocaloric devices. These systems regulate the timing, magnitude, and waveform of the applied electric fields to maximize cooling efficiency and temperature differential. They may incorporate feedback mechanisms to adjust cycling parameters based on thermal load and system performance, ensuring optimal operation under varying conditions.Expand Specific Solutions04 Integrated cooling devices using electrocaloric effect

Compact cooling devices that integrate electrocaloric materials with heat exchange systems to provide efficient thermal management. These devices combine electric field cycling with innovative heat transfer mechanisms to move heat from one location to another. The integration allows for miniaturization of cooling systems for applications in electronics, medical devices, and other space-constrained environments.Expand Specific Solutions05 Energy efficiency improvements in electrocaloric cycling

Techniques and designs that enhance the energy efficiency of electrocaloric cooling systems through optimized field cycling. These innovations focus on reducing power consumption while maintaining or improving cooling performance. Approaches include regenerative energy recovery during field cycling, improved thermal switching mechanisms, and novel circuit designs that minimize electrical losses during operation.Expand Specific Solutions

Leading Research Groups and Companies in Electrocaloric Technology

The electrocaloric cooling technology market is currently in its early growth phase, characterized by intensive research and development activities. The global market for advanced cooling technologies is projected to expand significantly as energy efficiency demands increase. While the technology shows promising potential for commercial applications, it remains in the pre-commercialization stage with technical challenges in optimizing electric field cycling for maximum electrocaloric effect. Key players include established industrial giants like Siemens AG, Robert Bosch GmbH, and DENSO Corp pursuing electrocaloric solutions for automotive and industrial applications, alongside specialized companies like Nascent Devices focusing exclusively on electrocaloric cooling systems. Academic institutions including University of Maryland and Xi'an Jiaotong University are contributing fundamental research, creating a competitive landscape balanced between industrial implementation and academic innovation.

Nascent Devices, Inc.

Technical Solution: Nascent Devices has developed a proprietary electric field cycling technology specifically designed for commercial electrocaloric cooling applications. Their approach focuses on practical implementation challenges, including power electronics optimization and thermal management integration. The company has created a patented "adaptive field cycling" system that dynamically adjusts electric field parameters based on real-time cooling demands and material response. This system incorporates specialized high-voltage switching circuits that minimize energy losses during field cycling while maximizing the electrocaloric effect. Their technology employs a feedback control mechanism that monitors material temperature and adjusts field cycling frequency and amplitude accordingly. Nascent has also developed thin-film electrocaloric materials specifically engineered to respond optimally to their cycling protocols, with reduced hysteresis losses and improved thermal conductivity. Their integrated cooling modules have demonstrated coefficient of performance (COP) values exceeding 3.0 in laboratory testing, approaching the efficiency of conventional vapor compression systems.

Strengths: Focused commercial approach with emphasis on practical implementation and system integration; proprietary materials and control systems provide competitive advantage. Weaknesses: As a smaller company, may have limited manufacturing capacity compared to larger competitors; specialized materials may face supply chain challenges during scaling.

University of Maryland

Technical Solution: University of Maryland has pioneered advanced electric field cycling techniques for electrocaloric cooling systems. Their research focuses on optimizing the application of electric fields to electrocaloric materials to maximize temperature changes during the cooling cycle. They've developed a multi-pulse field application strategy that allows for controlled heating and cooling phases, significantly enhancing the overall electrocaloric effect. Their approach involves precise timing of electric field application and removal, with carefully calibrated field strengths that vary throughout the cycle. This method has demonstrated up to 40% improvement in cooling capacity compared to conventional single-pulse approaches. The university has also explored novel composite electrocaloric materials that respond more efficiently to electric field cycling, including lead-free relaxor ferroelectrics and polymer-ceramic composites that show enhanced electrocaloric responses under optimized field cycling conditions.

Strengths: Strong fundamental research capabilities with access to advanced materials characterization equipment; collaborative approach with industry partners enables practical application development. Weaknesses: As an academic institution, may face challenges in scaling technologies to commercial production levels; research funding dependencies can impact long-term development continuity.

Key Patents and Research on Electrocaloric Effect Enhancement

Method to enhance the performance of cooling devices utilizing modified barium titanate (BT) electrocaloric ceramic materials

PatentInactiveUS20170074555A1

Innovation

- Doping BT-based ceramics with specific elements from IA, IIA, IVA, IIIB, and Lanthanide groups at A and B sites, along with additives and sintering aids, to enhance the electrocaloric effect, achieving a larger temperature change (ΔT≧3° C.) under an electric field (E≦15 MV/m) across -30 to 80° C.

Cooling device including an electrocaloric composite

PatentInactiveUS20150027132A1

Innovation

- The use of high thermal conductivity electrocaloric composites, comprising electrocaloric polymers and electrically insulating fillers, which enhance thermal conductivity while maintaining the electrocaloric effect, allowing for improved cooling device performance and efficiency.

Energy Efficiency and Sustainability Considerations

The optimization of electric field cycling for maximum electrocaloric effect represents a significant opportunity for enhancing energy efficiency in cooling technologies. Electrocaloric cooling systems, when properly optimized, can achieve coefficient of performance (COP) values between 5-7, substantially outperforming conventional vapor compression systems that typically operate at COPs of 2-4. This efficiency advantage translates directly into reduced energy consumption and lower operational costs over the system lifecycle.

From a sustainability perspective, electrocaloric cooling eliminates the need for hydrofluorocarbon refrigerants, which have global warming potentials thousands of times greater than CO2. The solid-state nature of electrocaloric materials also reduces the risk of refrigerant leakage, a common environmental concern with traditional cooling systems. Life cycle assessments indicate that optimized electrocaloric systems could reduce greenhouse gas emissions by 30-40% compared to conventional technologies when accounting for manufacturing, operation, and end-of-life considerations.

Energy consumption during electric field cycling represents a critical factor in overall system efficiency. Current research indicates that optimized field cycling protocols can reduce parasitic energy losses by up to 25% compared to non-optimized approaches. Particularly promising are regenerative driving circuits that can recover up to 70% of the electrical energy during field removal phases, significantly improving the net energy balance of the cooling cycle.

Material selection also plays a crucial role in sustainability considerations. Lead-free relaxor ferroelectrics and organic-inorganic hybrid materials are emerging as environmentally preferable alternatives to lead-based compounds traditionally used in electrocaloric applications. These materials not only address toxicity concerns but also often require lower mining and processing energy inputs, reducing the embodied energy of the cooling system.

The manufacturing energy intensity of electrocaloric devices presents another important consideration. Advanced thin-film deposition techniques and multilayer ceramic processing methods have demonstrated potential to reduce manufacturing energy requirements by 35-45% compared to earlier production approaches. Additionally, the extended operational lifetime of solid-state cooling systems—potentially 15-20 years versus 10-12 years for conventional systems—further enhances their lifecycle sustainability profile.

Power electronics optimization for field cycling represents another frontier for efficiency improvements. Wide-bandgap semiconductor technologies, particularly silicon carbide and gallium nitride-based switching devices, can reduce switching losses by up to 50% compared to silicon-based alternatives. These advanced power electronics enable higher frequency operation with minimal energy dissipation, directly improving the overall system efficiency during rapid field cycling operations.

From a sustainability perspective, electrocaloric cooling eliminates the need for hydrofluorocarbon refrigerants, which have global warming potentials thousands of times greater than CO2. The solid-state nature of electrocaloric materials also reduces the risk of refrigerant leakage, a common environmental concern with traditional cooling systems. Life cycle assessments indicate that optimized electrocaloric systems could reduce greenhouse gas emissions by 30-40% compared to conventional technologies when accounting for manufacturing, operation, and end-of-life considerations.

Energy consumption during electric field cycling represents a critical factor in overall system efficiency. Current research indicates that optimized field cycling protocols can reduce parasitic energy losses by up to 25% compared to non-optimized approaches. Particularly promising are regenerative driving circuits that can recover up to 70% of the electrical energy during field removal phases, significantly improving the net energy balance of the cooling cycle.

Material selection also plays a crucial role in sustainability considerations. Lead-free relaxor ferroelectrics and organic-inorganic hybrid materials are emerging as environmentally preferable alternatives to lead-based compounds traditionally used in electrocaloric applications. These materials not only address toxicity concerns but also often require lower mining and processing energy inputs, reducing the embodied energy of the cooling system.

The manufacturing energy intensity of electrocaloric devices presents another important consideration. Advanced thin-film deposition techniques and multilayer ceramic processing methods have demonstrated potential to reduce manufacturing energy requirements by 35-45% compared to earlier production approaches. Additionally, the extended operational lifetime of solid-state cooling systems—potentially 15-20 years versus 10-12 years for conventional systems—further enhances their lifecycle sustainability profile.

Power electronics optimization for field cycling represents another frontier for efficiency improvements. Wide-bandgap semiconductor technologies, particularly silicon carbide and gallium nitride-based switching devices, can reduce switching losses by up to 50% compared to silicon-based alternatives. These advanced power electronics enable higher frequency operation with minimal energy dissipation, directly improving the overall system efficiency during rapid field cycling operations.

Material Science Advancements for Electrocaloric Applications

Recent advancements in material science have significantly propelled the field of electrocaloric cooling forward, creating new possibilities for efficient solid-state refrigeration technologies. The development of novel materials with enhanced electrocaloric properties has been crucial in overcoming traditional limitations in cooling efficiency and operational stability.

Ferroelectric polymers, particularly polyvinylidene fluoride (PVDF) and its copolymers, have emerged as promising candidates due to their flexibility, processability, and substantial electrocaloric effect at relatively low electric fields. These materials demonstrate temperature changes of up to 12°C under optimal conditions, representing a significant improvement over earlier generations.

Ceramic-based materials, including lead zirconate titanate (PZT) and barium titanate (BaTiO3), have also shown remarkable progress through compositional engineering and nanostructuring. Recent research has achieved enhanced electrocaloric responses by precisely controlling grain size and boundary effects, resulting in more efficient energy conversion during the electric field cycling process.

Multilayer composite structures combining different electrocaloric materials have demonstrated superior performance by leveraging the complementary properties of various components. These engineered composites can maintain high electrocaloric coefficients across broader temperature ranges, addressing one of the key challenges in practical application development.

Thin-film technology has revolutionized material fabrication for electrocaloric applications, enabling precise control over crystallographic orientation and domain structure. Films with thicknesses in the sub-micron range have exhibited enhanced electrocaloric responses due to reduced thermal mass and more efficient heat transfer characteristics, critical factors for optimizing electric field cycling protocols.

Relaxor ferroelectrics represent another significant advancement, offering broader temperature operation ranges and reduced hysteresis losses during field cycling. These materials demonstrate excellent electrocaloric properties near room temperature, making them particularly valuable for consumer and commercial cooling applications.

Doping strategies have emerged as effective approaches to enhance electrocaloric performance. Strategic incorporation of specific elements can modify the Curie temperature, broaden the temperature range of operation, and increase the overall electrocaloric effect magnitude, directly impacting the efficiency of electric field cycling protocols.

Advanced characterization techniques, including in-situ temperature mapping and high-resolution structural analysis during electric field application, have provided unprecedented insights into material behavior under operational conditions. This fundamental understanding has guided the development of materials specifically engineered to withstand the rigors of repeated electric field cycling while maintaining optimal electrocaloric performance.

Ferroelectric polymers, particularly polyvinylidene fluoride (PVDF) and its copolymers, have emerged as promising candidates due to their flexibility, processability, and substantial electrocaloric effect at relatively low electric fields. These materials demonstrate temperature changes of up to 12°C under optimal conditions, representing a significant improvement over earlier generations.

Ceramic-based materials, including lead zirconate titanate (PZT) and barium titanate (BaTiO3), have also shown remarkable progress through compositional engineering and nanostructuring. Recent research has achieved enhanced electrocaloric responses by precisely controlling grain size and boundary effects, resulting in more efficient energy conversion during the electric field cycling process.

Multilayer composite structures combining different electrocaloric materials have demonstrated superior performance by leveraging the complementary properties of various components. These engineered composites can maintain high electrocaloric coefficients across broader temperature ranges, addressing one of the key challenges in practical application development.

Thin-film technology has revolutionized material fabrication for electrocaloric applications, enabling precise control over crystallographic orientation and domain structure. Films with thicknesses in the sub-micron range have exhibited enhanced electrocaloric responses due to reduced thermal mass and more efficient heat transfer characteristics, critical factors for optimizing electric field cycling protocols.

Relaxor ferroelectrics represent another significant advancement, offering broader temperature operation ranges and reduced hysteresis losses during field cycling. These materials demonstrate excellent electrocaloric properties near room temperature, making them particularly valuable for consumer and commercial cooling applications.

Doping strategies have emerged as effective approaches to enhance electrocaloric performance. Strategic incorporation of specific elements can modify the Curie temperature, broaden the temperature range of operation, and increase the overall electrocaloric effect magnitude, directly impacting the efficiency of electric field cycling protocols.

Advanced characterization techniques, including in-situ temperature mapping and high-resolution structural analysis during electric field application, have provided unprecedented insights into material behavior under operational conditions. This fundamental understanding has guided the development of materials specifically engineered to withstand the rigors of repeated electric field cycling while maintaining optimal electrocaloric performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!