Additive Manufacturing Hybrid Routes For CMC Preforms

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Preform Additive Manufacturing Background and Objectives

Ceramic Matrix Composites (CMCs) represent a critical class of advanced materials characterized by their exceptional thermal resistance, mechanical strength, and lightweight properties. The evolution of CMC technology has progressed significantly over the past four decades, transitioning from laboratory curiosities to essential components in aerospace, defense, and energy sectors. Traditional manufacturing methods for CMC preforms have predominantly relied on labor-intensive processes including hand lay-up, filament winding, and chemical vapor infiltration, which present limitations in geometric complexity, reproducibility, and production efficiency.

Additive Manufacturing (AM) has emerged as a transformative approach to fabricating CMC preforms, offering unprecedented design freedom and potential for functional integration. The convergence of AM technologies with CMC fabrication represents a paradigm shift in high-temperature material processing, enabling complex internal architectures and tailored property gradients previously unattainable through conventional methods.

The primary objective of hybrid AM routes for CMC preforms is to overcome the inherent limitations of traditional manufacturing processes while capitalizing on the unique capabilities of various additive techniques. These hybrid approaches aim to combine the precision of digital fabrication with the established reliability of conventional CMC processing routes, creating synergistic manufacturing pathways that enhance both performance and producibility.

Current technological objectives focus on developing scalable AM processes capable of producing CMC preforms with controlled fiber architecture, minimal defect density, and reproducible material properties. Specific goals include achieving near-net-shape manufacturing to reduce post-processing requirements, enabling multi-material integration for functionally graded components, and establishing process parameters that ensure consistent quality across varying geometries and scales.

The trajectory of CMC preform additive manufacturing is increasingly oriented toward process hybridization, where complementary techniques are strategically combined to address the multifaceted challenges of ceramic composite fabrication. This includes the integration of extrusion-based methods with photopolymerization, powder bed fusion with directed energy deposition, and the incorporation of in-situ monitoring systems for real-time quality control.

As the technology continues to mature, research emphasis is shifting toward establishing standardized methodologies for characterizing AM-produced CMC preforms, developing specialized feedstock materials optimized for additive processes, and creating computational tools that can accurately predict the performance of complex CMC architectures manufactured through hybrid routes.

Additive Manufacturing (AM) has emerged as a transformative approach to fabricating CMC preforms, offering unprecedented design freedom and potential for functional integration. The convergence of AM technologies with CMC fabrication represents a paradigm shift in high-temperature material processing, enabling complex internal architectures and tailored property gradients previously unattainable through conventional methods.

The primary objective of hybrid AM routes for CMC preforms is to overcome the inherent limitations of traditional manufacturing processes while capitalizing on the unique capabilities of various additive techniques. These hybrid approaches aim to combine the precision of digital fabrication with the established reliability of conventional CMC processing routes, creating synergistic manufacturing pathways that enhance both performance and producibility.

Current technological objectives focus on developing scalable AM processes capable of producing CMC preforms with controlled fiber architecture, minimal defect density, and reproducible material properties. Specific goals include achieving near-net-shape manufacturing to reduce post-processing requirements, enabling multi-material integration for functionally graded components, and establishing process parameters that ensure consistent quality across varying geometries and scales.

The trajectory of CMC preform additive manufacturing is increasingly oriented toward process hybridization, where complementary techniques are strategically combined to address the multifaceted challenges of ceramic composite fabrication. This includes the integration of extrusion-based methods with photopolymerization, powder bed fusion with directed energy deposition, and the incorporation of in-situ monitoring systems for real-time quality control.

As the technology continues to mature, research emphasis is shifting toward establishing standardized methodologies for characterizing AM-produced CMC preforms, developing specialized feedstock materials optimized for additive processes, and creating computational tools that can accurately predict the performance of complex CMC architectures manufactured through hybrid routes.

Market Analysis for Hybrid CMC Manufacturing Technologies

The global market for Ceramic Matrix Composites (CMCs) is experiencing robust growth, projected to reach $7.5 billion by 2028, with a compound annual growth rate of approximately 12.4% from 2023. This growth is primarily driven by increasing demand in aerospace, defense, and energy sectors where high-temperature performance and weight reduction are critical factors.

Hybrid manufacturing approaches for CMC preforms represent a significant market opportunity within this broader landscape. These technologies combine traditional manufacturing methods with additive manufacturing to overcome limitations of purely conventional or purely additive approaches. The market for hybrid CMC manufacturing technologies is currently estimated at $1.2 billion and is expected to grow at a faster rate than the overall CMC market.

Aerospace remains the dominant application sector, accounting for approximately 45% of the hybrid CMC manufacturing market. The commercial aviation segment specifically seeks these materials for next-generation engine components, where fuel efficiency improvements of 15-20% can be achieved through weight reduction and higher operating temperatures. Military aerospace applications constitute another 20% of the market, with particular focus on hypersonic vehicle components.

The energy sector represents the second-largest market segment at 30%, with gas turbines being the primary application. As global energy demands increase and efficiency standards become more stringent, the need for advanced materials capable of withstanding extreme conditions continues to grow. Industrial applications account for the remaining 5% of the market, though this segment is expected to expand as manufacturing costs decrease.

Geographically, North America leads the market with 40% share, followed by Europe (30%) and Asia-Pacific (25%). China's investments in aerospace and energy infrastructure are rapidly increasing its market share, with projected growth rates exceeding 15% annually in the region.

Key market drivers include increasing fuel efficiency requirements in transportation, growing demand for sustainable energy solutions, and defense modernization programs. The market also benefits from ongoing materials science advancements that continue to improve CMC performance characteristics while reducing production costs.

Market barriers include high manufacturing costs, complex certification processes for critical components, and limited production scalability. The average cost of hybrid-manufactured CMC components remains 3-5 times higher than conventional alternatives, though this gap is narrowing as technologies mature and production volumes increase.

Customer requirements are evolving toward more customized solutions with shorter development cycles, creating opportunities for flexible manufacturing approaches that can rapidly iterate designs while maintaining high performance standards.

Hybrid manufacturing approaches for CMC preforms represent a significant market opportunity within this broader landscape. These technologies combine traditional manufacturing methods with additive manufacturing to overcome limitations of purely conventional or purely additive approaches. The market for hybrid CMC manufacturing technologies is currently estimated at $1.2 billion and is expected to grow at a faster rate than the overall CMC market.

Aerospace remains the dominant application sector, accounting for approximately 45% of the hybrid CMC manufacturing market. The commercial aviation segment specifically seeks these materials for next-generation engine components, where fuel efficiency improvements of 15-20% can be achieved through weight reduction and higher operating temperatures. Military aerospace applications constitute another 20% of the market, with particular focus on hypersonic vehicle components.

The energy sector represents the second-largest market segment at 30%, with gas turbines being the primary application. As global energy demands increase and efficiency standards become more stringent, the need for advanced materials capable of withstanding extreme conditions continues to grow. Industrial applications account for the remaining 5% of the market, though this segment is expected to expand as manufacturing costs decrease.

Geographically, North America leads the market with 40% share, followed by Europe (30%) and Asia-Pacific (25%). China's investments in aerospace and energy infrastructure are rapidly increasing its market share, with projected growth rates exceeding 15% annually in the region.

Key market drivers include increasing fuel efficiency requirements in transportation, growing demand for sustainable energy solutions, and defense modernization programs. The market also benefits from ongoing materials science advancements that continue to improve CMC performance characteristics while reducing production costs.

Market barriers include high manufacturing costs, complex certification processes for critical components, and limited production scalability. The average cost of hybrid-manufactured CMC components remains 3-5 times higher than conventional alternatives, though this gap is narrowing as technologies mature and production volumes increase.

Customer requirements are evolving toward more customized solutions with shorter development cycles, creating opportunities for flexible manufacturing approaches that can rapidly iterate designs while maintaining high performance standards.

Current State and Challenges in CMC Preform Fabrication

The current state of Ceramic Matrix Composite (CMC) preform fabrication presents a complex landscape of technological achievements and persistent challenges. Traditional manufacturing methods for CMC preforms, including slurry infiltration, chemical vapor infiltration, and polymer impregnation, have established a foundation for industrial applications but face significant limitations in geometric complexity, process efficiency, and cost-effectiveness.

Globally, research institutions and industrial manufacturers have made substantial progress in developing CMC preforms with enhanced mechanical properties and thermal resistance. However, the integration of these materials into mainstream aerospace, energy, and automotive applications remains constrained by manufacturing bottlenecks. The United States, Japan, Germany, and China lead in CMC research, with each region focusing on different application domains and manufacturing approaches.

A critical challenge in current CMC preform fabrication is achieving uniform fiber distribution and controlled porosity throughout complex geometries. Conventional techniques often result in inconsistent fiber orientation and density variations, compromising the structural integrity and performance predictability of the final components. Additionally, the time-intensive nature of traditional layup processes significantly impacts production scalability and economic viability.

Material compatibility issues represent another substantial hurdle, particularly at the interface between fibers and matrix materials. Current coating technologies struggle to provide optimal fiber protection during high-temperature processing while maintaining strong interfacial bonding. This challenge is exacerbated when attempting to incorporate multiple material systems within a single preform structure.

The energy consumption and environmental impact of conventional CMC manufacturing processes also present significant concerns. Many established techniques require multiple high-temperature processing steps, resulting in substantial energy expenditure and potential environmental hazards from chemical precursors and byproducts.

Quality control and repeatability remain persistent challenges across the industry. The multi-step nature of traditional fabrication routes introduces numerous variables that can affect final component quality, making consistent production difficult to achieve at scale. Non-destructive evaluation techniques for in-process monitoring have improved but still lack the precision needed for comprehensive quality assurance.

From a geographical perspective, research centers in North America focus predominantly on aerospace applications, European institutions emphasize automotive and energy sector implementations, while Asian research hubs prioritize electronic and industrial applications. This regional specialization has created knowledge silos that sometimes impede cross-sector technology transfer and standardization efforts.

Globally, research institutions and industrial manufacturers have made substantial progress in developing CMC preforms with enhanced mechanical properties and thermal resistance. However, the integration of these materials into mainstream aerospace, energy, and automotive applications remains constrained by manufacturing bottlenecks. The United States, Japan, Germany, and China lead in CMC research, with each region focusing on different application domains and manufacturing approaches.

A critical challenge in current CMC preform fabrication is achieving uniform fiber distribution and controlled porosity throughout complex geometries. Conventional techniques often result in inconsistent fiber orientation and density variations, compromising the structural integrity and performance predictability of the final components. Additionally, the time-intensive nature of traditional layup processes significantly impacts production scalability and economic viability.

Material compatibility issues represent another substantial hurdle, particularly at the interface between fibers and matrix materials. Current coating technologies struggle to provide optimal fiber protection during high-temperature processing while maintaining strong interfacial bonding. This challenge is exacerbated when attempting to incorporate multiple material systems within a single preform structure.

The energy consumption and environmental impact of conventional CMC manufacturing processes also present significant concerns. Many established techniques require multiple high-temperature processing steps, resulting in substantial energy expenditure and potential environmental hazards from chemical precursors and byproducts.

Quality control and repeatability remain persistent challenges across the industry. The multi-step nature of traditional fabrication routes introduces numerous variables that can affect final component quality, making consistent production difficult to achieve at scale. Non-destructive evaluation techniques for in-process monitoring have improved but still lack the precision needed for comprehensive quality assurance.

From a geographical perspective, research centers in North America focus predominantly on aerospace applications, European institutions emphasize automotive and energy sector implementations, while Asian research hubs prioritize electronic and industrial applications. This regional specialization has created knowledge silos that sometimes impede cross-sector technology transfer and standardization efforts.

Current Hybrid Routes for CMC Preform Production

01 Hybrid manufacturing processes combining additive and subtractive methods

Hybrid manufacturing approaches that integrate additive manufacturing with traditional subtractive techniques to create preforms. These processes leverage the advantages of both methods, allowing for complex geometries from additive manufacturing while achieving precision finishing through subtractive processes. This combination enables the production of high-quality components with improved material properties and dimensional accuracy that would be difficult to achieve using either method alone.- Hybrid manufacturing processes combining additive and subtractive techniques: Hybrid manufacturing approaches that integrate additive manufacturing with subtractive processes like machining or finishing operations. These combined methods allow for the creation of complex preforms with improved surface quality and dimensional accuracy. The hybrid route leverages the advantages of both additive techniques for building complex geometries and subtractive techniques for achieving precision finishing, resulting in higher quality components with reduced production time.

- Near-net shape preform fabrication using additive manufacturing: Additive manufacturing techniques are used to create near-net shape preforms that require minimal additional processing. These methods allow for the production of complex geometries with internal features that would be difficult or impossible to achieve using traditional manufacturing methods. The preforms are designed to closely match the final part dimensions, reducing material waste and subsequent machining operations while enabling customization for specific applications.

- Multi-material additive manufacturing for composite preforms: Advanced techniques for creating preforms using multiple materials through additive manufacturing processes. These approaches enable the fabrication of composite structures with tailored properties in different regions of the component. By strategically combining materials during the build process, manufacturers can create preforms with optimized mechanical properties, thermal characteristics, or electrical conductivity based on functional requirements of the final part.

- Layer-by-layer deposition techniques for specialized preforms: Various layer-by-layer deposition methods used in additive manufacturing to create specialized preforms with controlled microstructures. These techniques include powder bed fusion, directed energy deposition, and material extrusion processes that can be tailored to specific material systems. The controlled deposition allows for precise manipulation of material properties, enabling the creation of preforms with gradient structures, controlled porosity, or specific crystalline orientations.

- Post-processing treatments for additively manufactured preforms: Various post-processing methods applied to additively manufactured preforms to enhance their properties and performance. These treatments include heat treatment, hot isostatic pressing, surface modification, and infiltration techniques. Post-processing is essential for improving the density, mechanical properties, and surface characteristics of the preforms, addressing common limitations of additive manufacturing such as porosity, residual stresses, and surface roughness.

02 Material preform preparation for composite structures

Techniques for preparing material preforms specifically designed for composite structures. These methods involve creating preforms that serve as the foundation for composite parts, often using fiber placement, weaving, or other textile processes before integration with additive manufacturing steps. The preforms are engineered to provide specific mechanical properties, fiber orientations, and structural integrity that enhance the final composite component's performance.Expand Specific Solutions03 Metal-based additive manufacturing for preforms

Specialized additive manufacturing techniques for creating metal preforms that can be further processed through secondary operations. These methods include selective laser melting, electron beam melting, and direct metal deposition to create near-net-shape metal preforms. The processes focus on controlling microstructure, minimizing defects, and achieving desired mechanical properties in the metal preforms before subsequent processing steps.Expand Specific Solutions04 Multi-material and functionally graded preforms

Advanced manufacturing approaches for creating preforms with multiple materials or functionally graded properties. These techniques enable the production of preforms with spatially varying composition, microstructure, or properties to meet specific performance requirements. The methods involve precise control of material deposition, interface bonding, and property transitions to create preforms with tailored characteristics for specific applications.Expand Specific Solutions05 Process control and optimization for hybrid preform manufacturing

Systems and methods for monitoring, controlling, and optimizing hybrid manufacturing processes for preforms. These approaches incorporate sensors, feedback systems, and computational models to ensure quality, repeatability, and efficiency in preform production. Advanced control strategies manage process parameters, material feed rates, energy input, and cooling conditions to minimize defects and achieve consistent preform properties across production runs.Expand Specific Solutions

Leading Organizations in Hybrid CMC Manufacturing

The Additive Manufacturing Hybrid Routes for CMC Preforms market is in an early growth phase, characterized by increasing adoption of advanced composite manufacturing techniques. The global market size is estimated to reach $2.5-3 billion by 2027, driven by aerospace, defense, and energy sector demands. Technologically, the field is transitioning from experimental to commercial applications, with varying maturity levels across different processes. Leading players include established aerospace corporations (General Electric, RTX Corp., Boeing) investing heavily in R&D, specialized additive manufacturing companies (Continuous Composites, Relativity Space, EOS GmbH) developing proprietary technologies, and academic institutions (Northwestern Polytechnical University, Central South University) conducting foundational research. The competitive landscape features strategic partnerships between industrial players and research institutions to accelerate technology commercialization and address manufacturing challenges.

Continuous Composites LLC

Technical Solution: Continuous Composites has developed a revolutionary hybrid manufacturing approach for CMC preforms called Continuous Fiber 3D Printing (CF3D). This technology combines continuous fiber impregnation with rapid UV curing in a free-space printing process that eliminates the need for traditional tooling. Their system utilizes specialized ceramic-loaded photopolymer resins that are impregnated into continuous ceramic fibers (such as silicon carbide or alumina) immediately before deposition. The impregnated fibers are precisely placed using a multi-axis robotic system and instantly cured with UV light, creating self-supporting structures with exceptional green strength[6]. This approach enables the creation of complex 3D fiber architectures that would be impossible with traditional manufacturing methods. The CF3D process includes proprietary fiber spreading and wetting technologies that ensure uniform matrix distribution and minimize porosity. After printing, the components undergo controlled thermal processing to convert the polymer matrix to ceramic while maintaining fiber integrity. Continuous Composites has demonstrated this technology for aerospace and energy applications, achieving up to 75% reduction in manufacturing time compared to conventional CMC processes.

Strengths: Toolless manufacturing capability significantly reduces production costs; ability to create complex fiber architectures in true 3D space; rapid processing compared to traditional CMC manufacturing. Weaknesses: Limited to UV-curable preceramic polymer systems; challenges in achieving very high ceramic density; relatively new technology with limited long-term performance data.

General Electric Company

Technical Solution: GE has developed a comprehensive hybrid additive manufacturing approach for CMC preforms that combines direct ink writing and automated fiber placement technologies. Their system utilizes specialized ceramic slurries with controlled rheological properties for precise deposition of ceramic matrices, while simultaneously placing continuous reinforcement fibers in optimized orientations. GE's process incorporates in-situ UV curing to stabilize structures during fabrication and employs proprietary thermal processing protocols for controlled pyrolysis and densification. This hybrid approach enables the creation of complex geometric features with tailored fiber architectures that would be impossible with conventional manufacturing methods[1][3]. GE has successfully applied this technology to produce CMC components for jet engines, achieving up to 30% weight reduction compared to traditional metal parts while maintaining thermal stability at temperatures exceeding 2400°F.

Strengths: Exceptional integration of multiple AM technologies allowing precise control of both matrix and fiber placement; established industrial-scale production capabilities; proven performance in extreme aerospace environments. Weaknesses: High capital equipment costs; relatively slow production rates compared to conventional methods; requires specialized expertise for process optimization.

Key Technical Innovations in CMC Additive Manufacturing

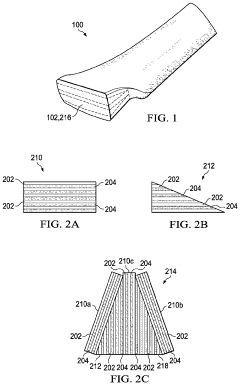

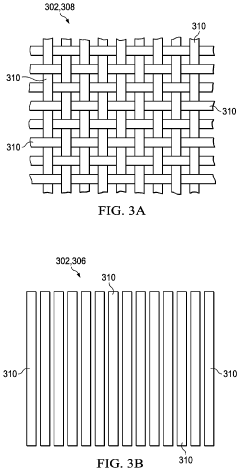

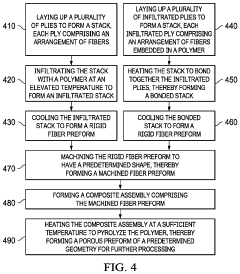

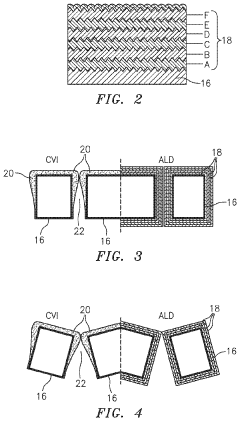

Method of making a fiber preform for ceramic matrix composite (CMC) fabrication

PatentActiveUS20190359531A1

Innovation

- A method utilizing a fugitive polymer binder and machining to form a rigid fiber preform, where plies are laid up in simple geometries, infiltrated with polymer, and then machined to precise dimensions, allowing for the creation of complex geometries without the logistical challenges of individual ply cutting and arrangement.

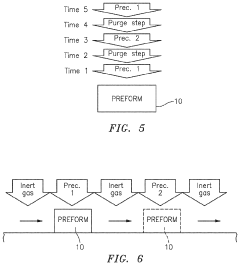

Method for producing a ceramic matrix composite component

PatentActiveUS20200216362A1

Innovation

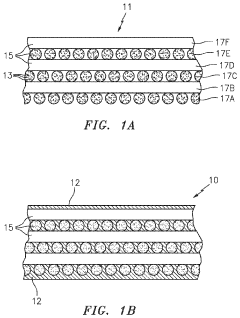

- The method involves using an atomic layer deposition (ALD) process to decrease porosity in CMC preforms, followed by additional material deposition using time-dependent or non-self-limiting processes like CVI, CVD, or PIP, to achieve improved densification and functionality.

Material Science Considerations for CMC Preforms

The selection of appropriate materials for Ceramic Matrix Composite (CMC) preforms in additive manufacturing hybrid routes requires careful consideration of multiple factors that influence both processing capabilities and final component performance. Material compatibility with additive manufacturing techniques presents a primary concern, as materials must possess suitable rheological properties for extrusion-based methods or appropriate particle size distribution for powder bed fusion approaches.

Thermal behavior during processing significantly impacts material selection, with materials needing to withstand the extreme temperature gradients inherent in additive manufacturing without compromising structural integrity. Coefficient of thermal expansion (CTE) mismatch between matrix and reinforcement materials must be minimized to prevent residual stress accumulation and potential microcracking during thermal cycling.

Microstructural development during the manufacturing process directly influences mechanical properties of the final CMC components. Materials that facilitate controlled grain growth and optimal phase distribution during sintering are preferred. The interface characteristics between ceramic matrices and reinforcement materials critically determine fracture toughness and damage tolerance of the resulting composites, with weak interfaces generally promoting crack deflection mechanisms that enhance overall toughness.

Chemical compatibility between constituent materials must be ensured to prevent deleterious reactions during high-temperature processing that could compromise mechanical properties or dimensional stability. Materials that form stable phases throughout the processing temperature range are essential for maintaining consistent performance characteristics.

Environmental stability represents another crucial consideration, particularly for CMCs intended for high-temperature applications in oxidizing or corrosive environments. Materials that form protective oxide scales or demonstrate inherent resistance to environmental degradation are highly valued for long-term service reliability.

Processing-structure-property relationships must be thoroughly understood for selected materials, as additive manufacturing processes can significantly alter microstructural features compared to conventional fabrication methods. This understanding enables tailored material selection to achieve specific performance targets through controlled processing parameters.

Cost considerations and material availability also influence selection decisions, with commercially accessible materials offering advantages in terms of supply chain reliability and economic viability for scaled production. The integration of these material science considerations into the development of hybrid additive manufacturing routes for CMC preforms ultimately determines the technological and commercial success of resulting components in demanding applications.

Thermal behavior during processing significantly impacts material selection, with materials needing to withstand the extreme temperature gradients inherent in additive manufacturing without compromising structural integrity. Coefficient of thermal expansion (CTE) mismatch between matrix and reinforcement materials must be minimized to prevent residual stress accumulation and potential microcracking during thermal cycling.

Microstructural development during the manufacturing process directly influences mechanical properties of the final CMC components. Materials that facilitate controlled grain growth and optimal phase distribution during sintering are preferred. The interface characteristics between ceramic matrices and reinforcement materials critically determine fracture toughness and damage tolerance of the resulting composites, with weak interfaces generally promoting crack deflection mechanisms that enhance overall toughness.

Chemical compatibility between constituent materials must be ensured to prevent deleterious reactions during high-temperature processing that could compromise mechanical properties or dimensional stability. Materials that form stable phases throughout the processing temperature range are essential for maintaining consistent performance characteristics.

Environmental stability represents another crucial consideration, particularly for CMCs intended for high-temperature applications in oxidizing or corrosive environments. Materials that form protective oxide scales or demonstrate inherent resistance to environmental degradation are highly valued for long-term service reliability.

Processing-structure-property relationships must be thoroughly understood for selected materials, as additive manufacturing processes can significantly alter microstructural features compared to conventional fabrication methods. This understanding enables tailored material selection to achieve specific performance targets through controlled processing parameters.

Cost considerations and material availability also influence selection decisions, with commercially accessible materials offering advantages in terms of supply chain reliability and economic viability for scaled production. The integration of these material science considerations into the development of hybrid additive manufacturing routes for CMC preforms ultimately determines the technological and commercial success of resulting components in demanding applications.

Sustainability Aspects of Hybrid CMC Manufacturing

The sustainability implications of hybrid manufacturing approaches for Ceramic Matrix Composites (CMCs) represent a critical dimension in evaluating these emerging technologies. Hybrid manufacturing combines additive manufacturing with conventional techniques, offering potential environmental benefits through reduced material waste, energy consumption optimization, and streamlined production processes.

Material efficiency stands as a primary sustainability advantage of hybrid CMC manufacturing routes. Traditional subtractive manufacturing methods typically generate substantial waste, with material removal rates sometimes exceeding 70% of the initial feedstock. In contrast, hybrid approaches incorporating additive manufacturing can reduce material waste by 30-45% through near-net-shape production capabilities, particularly beneficial given the high embodied energy and cost of advanced ceramic materials.

Energy consumption patterns in hybrid CMC manufacturing demonstrate complex trade-offs. While additive processes may require significant energy input during operation, the overall lifecycle energy footprint can be reduced through elimination of multiple processing steps and reduced post-processing requirements. Research indicates potential energy savings of 15-25% compared to conventional routes, though these figures vary significantly based on specific process combinations and component geometries.

Supply chain considerations further enhance the sustainability profile of hybrid CMC manufacturing. Localized production capabilities reduce transportation-related emissions and energy consumption, while enabling more responsive manufacturing systems. This localization potential decreases the carbon footprint associated with global supply chains by an estimated 10-20% for complex CMC components used in aerospace and energy applications.

End-of-life management represents another sustainability dimension where hybrid manufacturing offers advantages. The precise material placement capabilities of additive processes, when integrated with conventional techniques, can facilitate design approaches that enhance component repairability and recyclability. This design freedom enables more efficient material recovery strategies, potentially increasing the recyclability rate of CMC components by 15-30% compared to conventionally manufactured alternatives.

Regulatory compliance and certification pathways remain challenging aspects of hybrid CMC manufacturing sustainability. The novel nature of these processes necessitates development of new standards and testing protocols to verify environmental performance claims. Industry-academic partnerships are currently establishing frameworks for lifecycle assessment methodologies specifically tailored to hybrid ceramic manufacturing routes, addressing this critical gap in sustainability evaluation.

Material efficiency stands as a primary sustainability advantage of hybrid CMC manufacturing routes. Traditional subtractive manufacturing methods typically generate substantial waste, with material removal rates sometimes exceeding 70% of the initial feedstock. In contrast, hybrid approaches incorporating additive manufacturing can reduce material waste by 30-45% through near-net-shape production capabilities, particularly beneficial given the high embodied energy and cost of advanced ceramic materials.

Energy consumption patterns in hybrid CMC manufacturing demonstrate complex trade-offs. While additive processes may require significant energy input during operation, the overall lifecycle energy footprint can be reduced through elimination of multiple processing steps and reduced post-processing requirements. Research indicates potential energy savings of 15-25% compared to conventional routes, though these figures vary significantly based on specific process combinations and component geometries.

Supply chain considerations further enhance the sustainability profile of hybrid CMC manufacturing. Localized production capabilities reduce transportation-related emissions and energy consumption, while enabling more responsive manufacturing systems. This localization potential decreases the carbon footprint associated with global supply chains by an estimated 10-20% for complex CMC components used in aerospace and energy applications.

End-of-life management represents another sustainability dimension where hybrid manufacturing offers advantages. The precise material placement capabilities of additive processes, when integrated with conventional techniques, can facilitate design approaches that enhance component repairability and recyclability. This design freedom enables more efficient material recovery strategies, potentially increasing the recyclability rate of CMC components by 15-30% compared to conventionally manufactured alternatives.

Regulatory compliance and certification pathways remain challenging aspects of hybrid CMC manufacturing sustainability. The novel nature of these processes necessitates development of new standards and testing protocols to verify environmental performance claims. Industry-academic partnerships are currently establishing frameworks for lifecycle assessment methodologies specifically tailored to hybrid ceramic manufacturing routes, addressing this critical gap in sustainability evaluation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!