Sustainability Assessment: Recycling And End-Of-Life For CMC Parts

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Recycling Background and Objectives

Ceramic Matrix Composites (CMCs) have emerged as critical materials in high-performance applications, particularly in aerospace, defense, and energy sectors. These advanced materials offer exceptional thermal resistance, mechanical strength, and weight reduction compared to traditional metal alloys. However, as CMC adoption increases across industries, the environmental impact of their lifecycle has become a growing concern. The recycling and end-of-life management of CMC parts represent significant challenges due to their complex composition and manufacturing processes.

The evolution of CMC technology has progressed from laboratory curiosities in the 1970s to commercial applications in the 1990s, with accelerated industrial adoption in the past decade. This rapid growth has not been matched by corresponding advances in recycling methodologies. While the aerospace industry has established recycling protocols for conventional materials like aluminum and titanium alloys, CMCs present unique challenges due to their heterogeneous nature, combining ceramic matrices with various fiber reinforcements and interface coatings.

Current sustainability frameworks inadequately address the specific challenges of CMC recycling. The primary objective of this technical assessment is to evaluate existing and emerging technologies for CMC recycling, identify technical barriers, and propose potential pathways toward more sustainable CMC lifecycle management. This includes examining chemical, thermal, and mechanical recycling approaches, as well as exploring opportunities for material recovery and reuse.

The environmental impact of CMCs extends beyond manufacturing to include end-of-life considerations. With stricter environmental regulations being implemented globally, industries utilizing CMCs face increasing pressure to demonstrate responsible material stewardship. This assessment aims to quantify the environmental footprint of current CMC disposal methods and evaluate the potential benefits of implementing comprehensive recycling strategies.

Economic factors also play a crucial role in CMC recycling feasibility. Many CMCs contain valuable elements such as silicon, carbon, and in some cases, rare earth elements. Recovering these materials could offset recycling costs while reducing dependency on primary resource extraction. This assessment will analyze the economic viability of various recycling approaches, considering material recovery value against processing costs.

The technical goals of this assessment include mapping the current state of CMC recycling technologies, identifying promising research directions, establishing metrics for recycling efficiency, and developing a roadmap for industrial implementation. By addressing these objectives, this research aims to contribute to the development of a circular economy approach for CMCs, ensuring their continued technological benefits while minimizing environmental impact.

The evolution of CMC technology has progressed from laboratory curiosities in the 1970s to commercial applications in the 1990s, with accelerated industrial adoption in the past decade. This rapid growth has not been matched by corresponding advances in recycling methodologies. While the aerospace industry has established recycling protocols for conventional materials like aluminum and titanium alloys, CMCs present unique challenges due to their heterogeneous nature, combining ceramic matrices with various fiber reinforcements and interface coatings.

Current sustainability frameworks inadequately address the specific challenges of CMC recycling. The primary objective of this technical assessment is to evaluate existing and emerging technologies for CMC recycling, identify technical barriers, and propose potential pathways toward more sustainable CMC lifecycle management. This includes examining chemical, thermal, and mechanical recycling approaches, as well as exploring opportunities for material recovery and reuse.

The environmental impact of CMCs extends beyond manufacturing to include end-of-life considerations. With stricter environmental regulations being implemented globally, industries utilizing CMCs face increasing pressure to demonstrate responsible material stewardship. This assessment aims to quantify the environmental footprint of current CMC disposal methods and evaluate the potential benefits of implementing comprehensive recycling strategies.

Economic factors also play a crucial role in CMC recycling feasibility. Many CMCs contain valuable elements such as silicon, carbon, and in some cases, rare earth elements. Recovering these materials could offset recycling costs while reducing dependency on primary resource extraction. This assessment will analyze the economic viability of various recycling approaches, considering material recovery value against processing costs.

The technical goals of this assessment include mapping the current state of CMC recycling technologies, identifying promising research directions, establishing metrics for recycling efficiency, and developing a roadmap for industrial implementation. By addressing these objectives, this research aims to contribute to the development of a circular economy approach for CMCs, ensuring their continued technological benefits while minimizing environmental impact.

Market Demand Analysis for Sustainable CMC Solutions

The global market for sustainable Ceramic Matrix Composite (CMC) solutions is experiencing significant growth driven by increasing environmental regulations and corporate sustainability initiatives. Current market analysis indicates that aerospace and defense sectors represent the largest demand segments, accounting for approximately 40% of the sustainable CMC market. This is primarily due to the stringent performance requirements and high-value nature of components in these industries, which justify the investment in advanced recycling technologies.

Industrial sectors, including power generation and automotive applications, are emerging as the fastest-growing market segments with annual growth rates exceeding 12%. This acceleration is largely attributed to tightening emissions standards and the push for more efficient energy systems where CMCs offer substantial performance advantages over traditional materials.

Consumer awareness regarding sustainable manufacturing practices has created market pressure across all industries utilizing advanced materials. A recent industry survey revealed that 78% of OEMs now include sustainability metrics in their supplier evaluation criteria, with 65% specifically requesting end-of-life management plans for composite components.

The economic value proposition for sustainable CMC solutions is increasingly compelling. Life cycle assessments demonstrate that despite higher initial costs, CMC components with established recycling pathways can reduce total ownership costs by 15-30% compared to conventional alternatives when considering the full product lifecycle. This economic benefit is particularly pronounced in applications with high replacement frequencies or where material recovery has significant value.

Regional market analysis shows Europe leading in demand for sustainable CMC solutions, driven by the European Green Deal and circular economy regulations. North America follows closely, with particular strength in aerospace applications, while the Asia-Pacific region represents the fastest-growing market with expanding industrial applications and strengthening environmental policies.

Market forecasts project the global sustainable CMC solutions market to reach $3.2 billion by 2028, with recycling and end-of-life management services comprising approximately $780 million of this total. This represents a compound annual growth rate of 14.5% for the recycling segment specifically, outpacing the overall CMC market growth.

Customer requirements are evolving beyond simple recyclability to demand comprehensive end-of-life solutions including take-back programs, material passports, and closed-loop manufacturing systems. This shift is creating new business model opportunities for material suppliers and specialized recycling service providers within the CMC value chain.

Industrial sectors, including power generation and automotive applications, are emerging as the fastest-growing market segments with annual growth rates exceeding 12%. This acceleration is largely attributed to tightening emissions standards and the push for more efficient energy systems where CMCs offer substantial performance advantages over traditional materials.

Consumer awareness regarding sustainable manufacturing practices has created market pressure across all industries utilizing advanced materials. A recent industry survey revealed that 78% of OEMs now include sustainability metrics in their supplier evaluation criteria, with 65% specifically requesting end-of-life management plans for composite components.

The economic value proposition for sustainable CMC solutions is increasingly compelling. Life cycle assessments demonstrate that despite higher initial costs, CMC components with established recycling pathways can reduce total ownership costs by 15-30% compared to conventional alternatives when considering the full product lifecycle. This economic benefit is particularly pronounced in applications with high replacement frequencies or where material recovery has significant value.

Regional market analysis shows Europe leading in demand for sustainable CMC solutions, driven by the European Green Deal and circular economy regulations. North America follows closely, with particular strength in aerospace applications, while the Asia-Pacific region represents the fastest-growing market with expanding industrial applications and strengthening environmental policies.

Market forecasts project the global sustainable CMC solutions market to reach $3.2 billion by 2028, with recycling and end-of-life management services comprising approximately $780 million of this total. This represents a compound annual growth rate of 14.5% for the recycling segment specifically, outpacing the overall CMC market growth.

Customer requirements are evolving beyond simple recyclability to demand comprehensive end-of-life solutions including take-back programs, material passports, and closed-loop manufacturing systems. This shift is creating new business model opportunities for material suppliers and specialized recycling service providers within the CMC value chain.

Current Challenges in CMC End-of-Life Management

The management of Ceramic Matrix Composites (CMCs) at the end of their lifecycle presents significant challenges due to their complex material composition and structural properties. Unlike traditional materials, CMCs consist of ceramic fibers embedded in a ceramic matrix, often incorporating various additives and coatings that enhance performance but complicate recycling processes. The heterogeneous nature of these composites makes separation of constituent materials extremely difficult using conventional recycling technologies.

One of the primary obstacles in CMC end-of-life management is the lack of established recycling infrastructure specifically designed for these advanced materials. While recycling pathways exist for metals and certain polymers, the high-temperature processing required for CMCs and their chemical stability present unique technical barriers. Current recycling facilities are not equipped with the specialized equipment needed to handle the extreme conditions required for CMC processing.

The energy intensity of potential recycling processes poses another significant challenge. The strong chemical bonds in ceramic materials necessitate high-energy inputs for decomposition or separation, often making recycling economically unfeasible compared to virgin material production. This energy-cost imbalance creates a substantial barrier to implementing sustainable end-of-life solutions for CMC components.

Material degradation during service life further complicates recycling efforts. CMCs used in high-temperature applications often experience microstructural changes, oxidation, and contamination that alter their properties and chemical composition. These changes make it difficult to predict the behavior of recycled materials and ensure consistent quality in secondary applications, limiting their market value and potential uses.

The aerospace and energy sectors, which are primary users of CMC components, face regulatory uncertainties regarding end-of-life management. Current waste management regulations were largely developed before the widespread adoption of advanced composites, creating compliance challenges for organizations seeking to responsibly dispose of or recycle CMC parts. This regulatory gap impedes the development of standardized approaches to CMC recycling.

Knowledge gaps in material science also hinder progress in this area. Limited research exists on the long-term environmental impacts of CMC disposal in landfills or through incineration. Understanding the potential for leaching of constituent elements or the formation of hazardous byproducts during thermal treatment remains incomplete, making risk assessment difficult for waste management decision-makers.

Cross-industry collaboration is currently insufficient to address these challenges holistically. The specialized nature of CMC applications has resulted in siloed knowledge and limited sharing of best practices across sectors, slowing the development of innovative recycling technologies and circular economy approaches for these materials.

One of the primary obstacles in CMC end-of-life management is the lack of established recycling infrastructure specifically designed for these advanced materials. While recycling pathways exist for metals and certain polymers, the high-temperature processing required for CMCs and their chemical stability present unique technical barriers. Current recycling facilities are not equipped with the specialized equipment needed to handle the extreme conditions required for CMC processing.

The energy intensity of potential recycling processes poses another significant challenge. The strong chemical bonds in ceramic materials necessitate high-energy inputs for decomposition or separation, often making recycling economically unfeasible compared to virgin material production. This energy-cost imbalance creates a substantial barrier to implementing sustainable end-of-life solutions for CMC components.

Material degradation during service life further complicates recycling efforts. CMCs used in high-temperature applications often experience microstructural changes, oxidation, and contamination that alter their properties and chemical composition. These changes make it difficult to predict the behavior of recycled materials and ensure consistent quality in secondary applications, limiting their market value and potential uses.

The aerospace and energy sectors, which are primary users of CMC components, face regulatory uncertainties regarding end-of-life management. Current waste management regulations were largely developed before the widespread adoption of advanced composites, creating compliance challenges for organizations seeking to responsibly dispose of or recycle CMC parts. This regulatory gap impedes the development of standardized approaches to CMC recycling.

Knowledge gaps in material science also hinder progress in this area. Limited research exists on the long-term environmental impacts of CMC disposal in landfills or through incineration. Understanding the potential for leaching of constituent elements or the formation of hazardous byproducts during thermal treatment remains incomplete, making risk assessment difficult for waste management decision-makers.

Cross-industry collaboration is currently insufficient to address these challenges holistically. The specialized nature of CMC applications has resulted in siloed knowledge and limited sharing of best practices across sectors, slowing the development of innovative recycling technologies and circular economy approaches for these materials.

Existing CMC Recycling Methodologies

01 Mechanical recycling methods for CMC parts

Mechanical recycling methods involve physical processes to recover valuable materials from end-of-life ceramic matrix composites. These methods include crushing, grinding, and separation techniques to break down the composite structure and isolate reusable components. The recovered materials can be repurposed in new manufacturing processes, reducing waste and conserving resources. Mechanical recycling is particularly effective for CMC parts that cannot be thermally recycled due to their composition.- Mechanical recycling methods for CMC parts: Mechanical recycling methods involve physical processes to recover valuable materials from end-of-life ceramic matrix composites. These methods include crushing, grinding, and separation techniques to break down the composite structure and isolate reusable components. The recovered materials can be repurposed in new manufacturing processes, reducing waste and conserving resources. Mechanical recycling is particularly effective for CMCs with recoverable fibers or particles that maintain their structural integrity after processing.

- Chemical recycling and material recovery from CMCs: Chemical recycling processes use solvents, acids, or other chemical agents to break down ceramic matrix composites and recover valuable constituents. These methods can selectively dissolve matrix materials while preserving reinforcement fibers or extract specific high-value elements from complex CMC structures. Chemical approaches often achieve higher purity in recovered materials compared to mechanical methods, making them suitable for applications requiring high-quality recycled components. Advanced chemical processes can also neutralize hazardous substances that might be present in certain CMC formulations.

- Thermal treatment for CMC recycling: Thermal treatment methods utilize high temperatures to process end-of-life ceramic matrix composites for material recovery. These techniques include pyrolysis, sintering, and controlled oxidation processes that can break chemical bonds within the composite structure. Thermal recycling is particularly effective for separating ceramic components from organic binders or for recovering high-temperature resistant fibers. The process can also transform certain CMC waste materials into new useful forms with different properties suitable for secondary applications.

- Remanufacturing and repurposing of CMC components: Remanufacturing approaches focus on extending the useful life of ceramic matrix composite parts through repair, refurbishment, or repurposing. These methods include techniques for assessing remaining component life, repairing localized damage, and adapting used CMC parts for alternative applications. Advanced inspection technologies help identify components suitable for remanufacturing versus those requiring full recycling. This approach maximizes the value extracted from the original manufacturing investment and reduces the environmental impact compared to producing new components.

- Life cycle assessment and sustainable design for CMCs: Life cycle assessment methodologies evaluate the environmental impact of ceramic matrix composites from production through end-of-life. These approaches incorporate design strategies that facilitate eventual recycling or safe disposal of CMC components. Considerations include material selection, joining methods, and component architecture that enable easier separation of materials at end-of-life. Advanced modeling techniques help predict component degradation and optimize maintenance schedules to extend service life before recycling becomes necessary. This holistic approach improves the overall sustainability of CMC applications.

02 Chemical recycling processes for CMC materials

Chemical recycling processes utilize various chemical reactions to break down ceramic matrix composites into their constituent materials. These methods often involve acid leaching, solvent extraction, or chemical dissolution to separate the ceramic matrix from reinforcement fibers. The recovered materials can then be purified and reused in new applications. Chemical recycling offers advantages in recovering high-purity materials from complex CMC structures while minimizing environmental impact compared to traditional disposal methods.Expand Specific Solutions03 Thermal treatment for CMC recycling

Thermal treatment methods utilize high temperatures to process end-of-life ceramic matrix composites. These techniques include pyrolysis, gasification, and high-temperature decomposition to break down the composite structure. The process can effectively separate ceramic materials from reinforcement fibers and organic components, allowing for material recovery. Thermal recycling is particularly suitable for CMC parts containing carbon or silicon carbide matrices, as it can efficiently recover valuable materials while reducing environmental impact.Expand Specific Solutions04 Remanufacturing and repurposing of CMC components

Remanufacturing and repurposing approaches focus on extending the useful life of ceramic matrix composite parts through repair, refurbishment, or conversion to new applications. These methods involve inspection, cleaning, and restoration of damaged components to return them to service condition. Alternatively, end-of-life CMC parts can be repurposed for less demanding applications. This approach maximizes the value of the original materials and manufacturing investment while reducing waste and environmental impact compared to complete recycling or disposal.Expand Specific Solutions05 Life cycle assessment and sustainable disposal of CMC waste

Life cycle assessment methodologies evaluate the environmental impact of ceramic matrix composites from production through disposal. These approaches consider energy consumption, resource utilization, and waste generation throughout the CMC lifecycle. For materials that cannot be recycled, sustainable disposal methods are developed to minimize environmental harm. This includes specialized landfill procedures, encapsulation techniques, or transformation into environmentally benign forms. Comprehensive life cycle management ensures responsible handling of CMC materials at end-of-life.Expand Specific Solutions

Key Industry Players in CMC Sustainability

The sustainability assessment for recycling and end-of-life CMC parts is in an emerging growth phase, with the global market expected to expand significantly as automotive and aerospace industries face increasing regulatory pressure for circular economy solutions. The technology maturity varies across key players: established industrial giants like Siemens, Volkswagen, and Bosch lead with comprehensive recycling frameworks, while Johnson Matthey and voestalpine focus on specialized material recovery processes. Academic institutions including Nanjing University of Aeronautics & Astronautics and Dalian University of Technology are advancing fundamental research, while energy corporations like State Grid Corp. of China and China Southern Power Grid are developing applications for recovered materials in power infrastructure. The competitive landscape reflects a transition from experimental approaches to industrialized solutions.

Siemens AG

Technical Solution: Siemens AG has implemented "CircularCeramic," a holistic approach to CMC sustainability assessment and end-of-life management focused on power generation and industrial applications. Their technology addresses the full lifecycle of ceramic matrix composites used in gas turbines, high-temperature industrial equipment, and energy storage systems. Siemens' recycling process begins with detailed component assessment using advanced non-destructive testing to determine whether refurbishment is possible. For end-of-life recycling, they employ a combination of mechanical processing and chemical treatments optimized for oxide-based CMCs. Their proprietary chemical recycling process uses selective dissolution techniques that can recover up to 80% of ceramic fibers while maintaining fiber length and surface characteristics. Siemens has integrated this recycling capability with their manufacturing operations, creating a closed-loop system that incorporates recovered materials into new production. The company has also developed comprehensive sustainability metrics that quantify environmental impacts, energy consumption, and resource efficiency across the CMC lifecycle, allowing for continuous improvement in design and processing.

Strengths: Well-integrated with manufacturing operations; achieves high recovery rates for oxide-based CMCs; comprehensive sustainability assessment guides design improvements. Weaknesses: Process optimization still needed for non-oxide CMCs; chemical processes require careful waste management; economic viability depends on scale.

Volkswagen AG

Technical Solution: Volkswagen AG has developed a comprehensive Ceramic Matrix Composite (CMC) recycling program called "CircularCMC" that integrates into their broader circular economy strategy. Their approach involves a multi-stage process for CMC parts recovery, particularly from automotive applications. The technology employs mechanical separation followed by chemical treatment to recover valuable ceramic fibers and matrix materials. Volkswagen's system includes specialized high-temperature pyrolysis chambers operating at 1200-1500°C that effectively separate the ceramic components from binding materials while preserving fiber integrity. Their process achieves up to 85% material recovery rates for silicon carbide-based CMCs. The company has also implemented a digital tracking system that monitors CMC components throughout their lifecycle, facilitating efficient collection and sorting at end-of-life. Volkswagen has established dedicated recycling facilities in Germany and China specifically designed for processing automotive CMC components from exhaust systems, brake components, and powertrain parts.

Strengths: Highly integrated with existing automotive recycling infrastructure; achieves significant recovery rates for high-value ceramic fibers; digital tracking enhances collection efficiency. Weaknesses: Process remains energy-intensive; limited to specific CMC compositions commonly used in automotive applications; economic viability depends on sufficient volume of end-of-life parts.

Critical Technologies for CMC Material Recovery

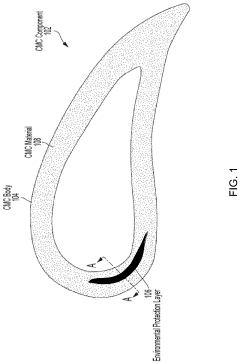

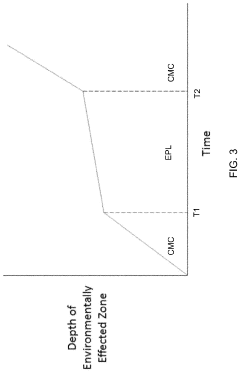

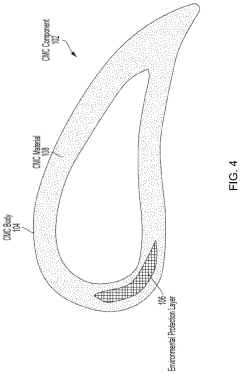

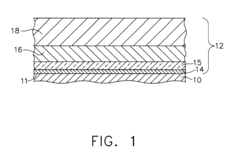

Recession resistant intermediate layer for CMC vane

PatentActiveUS20210246081A1

Innovation

- A ceramic matrix composite component is developed with an embedded environmental protection layer made of higher-resistant ceramics, such as silicon carbide or rare earth silicates, which surrounds the CMC material, enhancing both impact and environmental resistance by slowing damage progression and preventing thermally-induced cracking.

Slurry compositions for making environmental barrier coatings and environmental barrier coatings comprising the same

PatentActiveEP2287131A3

Innovation

- The development of slurry compositions for EBCs that include a sintering aid, allowing for lower sintering temperatures and the formation of dense, hermetic seals, comprising a bond coat layer, transition layer, and outer layer with specific porosity levels, made using a slurry deposition cycle that includes sintering aids to densify and strengthen the coating.

Environmental Impact Assessment of CMC Lifecycle

The environmental impact assessment of Ceramic Matrix Composites (CMCs) throughout their lifecycle reveals significant considerations for sustainable manufacturing and utilization. CMCs, while offering superior performance in high-temperature applications compared to traditional materials, present unique environmental challenges that must be systematically evaluated.

Primary lifecycle assessment indicates that CMC production processes are energy-intensive, requiring temperatures exceeding 1000°C during manufacturing phases. This results in substantial carbon emissions, estimated at 30-45 kg CO2 equivalent per kilogram of finished CMC component, significantly higher than conventional metal alloys. The manufacturing process also involves potentially hazardous chemicals for matrix infiltration and fiber coating, including methyltrichlorosilane and various boron compounds.

Resource consumption analysis demonstrates that CMCs utilize rare earth elements and specialized minerals with limited global reserves. The extraction of these materials often occurs in environmentally sensitive regions, creating additional ecological pressure through habitat disruption and potential water contamination. Studies indicate that each ton of CMC precursor materials may impact approximately 2-3 hectares of land through mining operations.

Waste generation during CMC production presents another environmental concern. Manufacturing yields typically range from 70-85%, meaning 15-30% of raw materials become production waste. This waste often contains compounds difficult to process in conventional recycling streams due to their chemical stability and composite nature.

In-service environmental benefits partially offset production impacts. CMCs enable higher operating temperatures in turbines and engines, improving thermodynamic efficiency by 2-4% compared to metal alternatives. This efficiency gain translates to reduced lifetime fuel consumption and associated emissions, particularly in aerospace and power generation applications.

End-of-life assessment reveals significant challenges in CMC recycling. The strong chemical bonds between ceramic matrices and reinforcing fibers make separation extremely difficult using conventional recycling technologies. Current recycling rates for CMC components remain below 10%, compared to 60-80% for many metal alloys. Research indicates potential for improvement through emerging technologies such as chemical dissolution methods and high-temperature plasma processing.

Comparative lifecycle analysis shows that despite higher initial environmental impact, CMCs may achieve environmental parity with traditional materials after 3-7 years of operation in high-performance applications, depending on use intensity and efficiency gains realized.

Primary lifecycle assessment indicates that CMC production processes are energy-intensive, requiring temperatures exceeding 1000°C during manufacturing phases. This results in substantial carbon emissions, estimated at 30-45 kg CO2 equivalent per kilogram of finished CMC component, significantly higher than conventional metal alloys. The manufacturing process also involves potentially hazardous chemicals for matrix infiltration and fiber coating, including methyltrichlorosilane and various boron compounds.

Resource consumption analysis demonstrates that CMCs utilize rare earth elements and specialized minerals with limited global reserves. The extraction of these materials often occurs in environmentally sensitive regions, creating additional ecological pressure through habitat disruption and potential water contamination. Studies indicate that each ton of CMC precursor materials may impact approximately 2-3 hectares of land through mining operations.

Waste generation during CMC production presents another environmental concern. Manufacturing yields typically range from 70-85%, meaning 15-30% of raw materials become production waste. This waste often contains compounds difficult to process in conventional recycling streams due to their chemical stability and composite nature.

In-service environmental benefits partially offset production impacts. CMCs enable higher operating temperatures in turbines and engines, improving thermodynamic efficiency by 2-4% compared to metal alternatives. This efficiency gain translates to reduced lifetime fuel consumption and associated emissions, particularly in aerospace and power generation applications.

End-of-life assessment reveals significant challenges in CMC recycling. The strong chemical bonds between ceramic matrices and reinforcing fibers make separation extremely difficult using conventional recycling technologies. Current recycling rates for CMC components remain below 10%, compared to 60-80% for many metal alloys. Research indicates potential for improvement through emerging technologies such as chemical dissolution methods and high-temperature plasma processing.

Comparative lifecycle analysis shows that despite higher initial environmental impact, CMCs may achieve environmental parity with traditional materials after 3-7 years of operation in high-performance applications, depending on use intensity and efficiency gains realized.

Regulatory Framework for CMC Waste Management

The regulatory landscape governing Ceramic Matrix Composite (CMC) waste management is complex and evolving, reflecting the increasing importance of sustainable practices in advanced materials industries. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal provides the foundational framework that influences how CMC waste is classified, handled, and transported across borders. This convention particularly impacts aerospace and energy sectors where CMC components are increasingly utilized.

In the European Union, the Waste Framework Directive (2008/98/EC) establishes the waste hierarchy that prioritizes prevention, reuse, recycling, and recovery over disposal. The EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation further impacts CMC waste management by controlling hazardous substances that may be present in these composites. Additionally, the EU's End-of-Life Vehicle Directive and the Waste Electrical and Electronic Equipment (WEEE) Directive apply to CMC components used in automotive and electronic applications respectively.

The United States approaches CMC waste regulation primarily through the Resource Conservation and Recovery Act (RCRA), which classifies certain ceramic wastes as hazardous if they contain regulated metals or exhibit hazardous characteristics. The Environmental Protection Agency (EPA) has established specific treatment standards for ceramic waste containing toxic metals such as chromium, which is common in some CMC formulations.

Japan has implemented the Law for the Promotion of Effective Utilization of Resources, which encourages manufacturers to design products with recyclability in mind and establishes recycling systems for various materials, including advanced composites. This approach represents a shift toward extended producer responsibility that is gaining traction globally.

Emerging economies like China and India are rapidly developing their regulatory frameworks for advanced materials waste. China's recent environmental protection laws have become increasingly stringent, with the National Sword policy restricting waste imports and promoting domestic recycling infrastructure development that will affect CMC waste streams.

Industry-specific regulations also play a crucial role, particularly in aerospace and defense sectors where CMC applications are expanding. These regulations often include specialized protocols for handling classified materials and components with potential dual-use applications, adding another layer of complexity to CMC waste management.

The regulatory landscape continues to evolve toward circular economy principles, with increasing emphasis on design for disassembly, material recovery, and closed-loop recycling systems. Companies working with CMCs must navigate this complex regulatory environment while anticipating future developments that will likely impose stricter requirements on waste reduction and resource recovery.

In the European Union, the Waste Framework Directive (2008/98/EC) establishes the waste hierarchy that prioritizes prevention, reuse, recycling, and recovery over disposal. The EU's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation further impacts CMC waste management by controlling hazardous substances that may be present in these composites. Additionally, the EU's End-of-Life Vehicle Directive and the Waste Electrical and Electronic Equipment (WEEE) Directive apply to CMC components used in automotive and electronic applications respectively.

The United States approaches CMC waste regulation primarily through the Resource Conservation and Recovery Act (RCRA), which classifies certain ceramic wastes as hazardous if they contain regulated metals or exhibit hazardous characteristics. The Environmental Protection Agency (EPA) has established specific treatment standards for ceramic waste containing toxic metals such as chromium, which is common in some CMC formulations.

Japan has implemented the Law for the Promotion of Effective Utilization of Resources, which encourages manufacturers to design products with recyclability in mind and establishes recycling systems for various materials, including advanced composites. This approach represents a shift toward extended producer responsibility that is gaining traction globally.

Emerging economies like China and India are rapidly developing their regulatory frameworks for advanced materials waste. China's recent environmental protection laws have become increasingly stringent, with the National Sword policy restricting waste imports and promoting domestic recycling infrastructure development that will affect CMC waste streams.

Industry-specific regulations also play a crucial role, particularly in aerospace and defense sectors where CMC applications are expanding. These regulations often include specialized protocols for handling classified materials and components with potential dual-use applications, adding another layer of complexity to CMC waste management.

The regulatory landscape continues to evolve toward circular economy principles, with increasing emphasis on design for disassembly, material recovery, and closed-loop recycling systems. Companies working with CMCs must navigate this complex regulatory environment while anticipating future developments that will likely impose stricter requirements on waste reduction and resource recovery.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!