Quality Control And NDE Methods For CMC Turbine Parts

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Turbine Parts QC Background and Objectives

Ceramic Matrix Composites (CMCs) represent a revolutionary advancement in turbine engine technology, offering superior high-temperature capabilities compared to traditional metallic components. The evolution of CMCs in aerospace applications began in the 1970s, with significant acceleration in development during the 1990s and 2000s. These materials combine ceramic fibers within a ceramic matrix, creating components that maintain structural integrity at temperatures exceeding 1200°C while offering reduced weight and improved durability compared to nickel-based superalloys.

The primary technical objective in CMC turbine part quality control is to establish reliable, non-destructive evaluation methods that can detect critical defects without compromising the integrity of these expensive components. This includes identifying matrix cracks, delaminations, fiber breaks, and porosity variations that could lead to catastrophic failure under extreme operating conditions. Additionally, there is a pressing need to develop in-process monitoring techniques that can identify manufacturing defects early in the production cycle.

Current quality control methods for CMCs have evolved from traditional metallurgical inspection techniques but require significant adaptation due to the unique material properties and failure mechanisms of composites. The industry is transitioning from primarily destructive testing methods toward more sophisticated non-destructive evaluation (NDE) approaches that can be applied throughout the manufacturing process and component lifecycle.

The technical landscape is further complicated by the variety of CMC systems in development, including SiC/SiC, C/SiC, and oxide/oxide composites, each requiring tailored inspection protocols. Material variability and complex geometries of turbine components present additional challenges for consistent quality assessment. The development of standardized testing procedures remains an ongoing challenge in the field.

Recent technological trends indicate a shift toward digital integration of quality control systems, with increasing emphasis on in-situ monitoring during manufacturing and predictive maintenance capabilities during service. Machine learning algorithms are being developed to enhance defect recognition and classification in CMC components, potentially revolutionizing the inspection process.

The ultimate goal of CMC turbine parts quality control is to establish a comprehensive framework that ensures component reliability while enabling cost-effective manufacturing at scale. This includes developing inspection technologies that can be seamlessly integrated into production lines, creating digital twins for virtual testing, and establishing industry-wide standards for CMC component certification. Success in these objectives will be critical for the broader adoption of CMCs in next-generation turbine engines across aerospace and power generation sectors.

The primary technical objective in CMC turbine part quality control is to establish reliable, non-destructive evaluation methods that can detect critical defects without compromising the integrity of these expensive components. This includes identifying matrix cracks, delaminations, fiber breaks, and porosity variations that could lead to catastrophic failure under extreme operating conditions. Additionally, there is a pressing need to develop in-process monitoring techniques that can identify manufacturing defects early in the production cycle.

Current quality control methods for CMCs have evolved from traditional metallurgical inspection techniques but require significant adaptation due to the unique material properties and failure mechanisms of composites. The industry is transitioning from primarily destructive testing methods toward more sophisticated non-destructive evaluation (NDE) approaches that can be applied throughout the manufacturing process and component lifecycle.

The technical landscape is further complicated by the variety of CMC systems in development, including SiC/SiC, C/SiC, and oxide/oxide composites, each requiring tailored inspection protocols. Material variability and complex geometries of turbine components present additional challenges for consistent quality assessment. The development of standardized testing procedures remains an ongoing challenge in the field.

Recent technological trends indicate a shift toward digital integration of quality control systems, with increasing emphasis on in-situ monitoring during manufacturing and predictive maintenance capabilities during service. Machine learning algorithms are being developed to enhance defect recognition and classification in CMC components, potentially revolutionizing the inspection process.

The ultimate goal of CMC turbine parts quality control is to establish a comprehensive framework that ensures component reliability while enabling cost-effective manufacturing at scale. This includes developing inspection technologies that can be seamlessly integrated into production lines, creating digital twins for virtual testing, and establishing industry-wide standards for CMC component certification. Success in these objectives will be critical for the broader adoption of CMCs in next-generation turbine engines across aerospace and power generation sectors.

Market Demand Analysis for Advanced NDE Methods

The global market for advanced Non-Destructive Evaluation (NDE) methods for Ceramic Matrix Composite (CMC) turbine parts is experiencing significant growth, driven by the increasing adoption of CMCs in aerospace, defense, and power generation sectors. Current market estimates value the specialized NDE segment for high-temperature composites at approximately $1.2 billion, with a projected annual growth rate of 8-10% through 2030.

Aerospace and defense industries represent the largest demand segment, accounting for nearly 60% of the market. This dominance stems from stringent safety requirements and the critical nature of turbine components in aircraft engines and military applications. Commercial aviation's push toward more fuel-efficient engines has accelerated the integration of CMC components, consequently driving demand for sophisticated inspection technologies capable of detecting subsurface defects without compromising structural integrity.

Power generation represents the second-largest market segment at 25%, with particular growth in gas turbine applications where CMCs offer significant performance advantages at high operating temperatures. The remaining market share is distributed across automotive, industrial manufacturing, and research institutions developing next-generation materials and components.

Geographically, North America leads the market with 40% share, followed by Europe (30%) and Asia-Pacific (25%). China and Japan are demonstrating the fastest growth rates as they expand their aerospace manufacturing capabilities and invest heavily in advanced materials technology.

Key market drivers include increasingly stringent regulatory requirements for component certification, the growing complexity of CMC structures requiring specialized inspection protocols, and the economic imperative to extend component service life through early defect detection. Industry surveys indicate that 78% of turbine manufacturers consider advanced NDE capabilities essential for their CMC implementation roadmaps.

Customer requirements are evolving toward integrated inspection systems that offer real-time monitoring capabilities, higher resolution for detecting micro-scale defects, and compatibility with complex geometries characteristic of modern turbine designs. There is particularly strong demand for NDE methods that can be applied throughout the component lifecycle – from manufacturing quality control to in-service inspection and remaining life assessment.

The market also shows increasing preference for multi-modal NDE solutions that combine complementary techniques such as thermography, ultrasonic testing, and X-ray computed tomography to provide comprehensive defect characterization. This trend is reflected in recent procurement patterns where 65% of new NDE equipment purchases involve integrated systems rather than single-technology solutions.

Aerospace and defense industries represent the largest demand segment, accounting for nearly 60% of the market. This dominance stems from stringent safety requirements and the critical nature of turbine components in aircraft engines and military applications. Commercial aviation's push toward more fuel-efficient engines has accelerated the integration of CMC components, consequently driving demand for sophisticated inspection technologies capable of detecting subsurface defects without compromising structural integrity.

Power generation represents the second-largest market segment at 25%, with particular growth in gas turbine applications where CMCs offer significant performance advantages at high operating temperatures. The remaining market share is distributed across automotive, industrial manufacturing, and research institutions developing next-generation materials and components.

Geographically, North America leads the market with 40% share, followed by Europe (30%) and Asia-Pacific (25%). China and Japan are demonstrating the fastest growth rates as they expand their aerospace manufacturing capabilities and invest heavily in advanced materials technology.

Key market drivers include increasingly stringent regulatory requirements for component certification, the growing complexity of CMC structures requiring specialized inspection protocols, and the economic imperative to extend component service life through early defect detection. Industry surveys indicate that 78% of turbine manufacturers consider advanced NDE capabilities essential for their CMC implementation roadmaps.

Customer requirements are evolving toward integrated inspection systems that offer real-time monitoring capabilities, higher resolution for detecting micro-scale defects, and compatibility with complex geometries characteristic of modern turbine designs. There is particularly strong demand for NDE methods that can be applied throughout the component lifecycle – from manufacturing quality control to in-service inspection and remaining life assessment.

The market also shows increasing preference for multi-modal NDE solutions that combine complementary techniques such as thermography, ultrasonic testing, and X-ray computed tomography to provide comprehensive defect characterization. This trend is reflected in recent procurement patterns where 65% of new NDE equipment purchases involve integrated systems rather than single-technology solutions.

Current State and Challenges in CMC Inspection

The global landscape of Ceramic Matrix Composite (CMC) inspection presents a complex array of technological achievements alongside persistent challenges. Currently, the industry employs several non-destructive evaluation (NDE) methods for CMC turbine parts, including X-ray computed tomography (CT), ultrasonic testing, infrared thermography, and acoustic emission techniques. These methods have demonstrated varying degrees of effectiveness in detecting critical defects such as delaminations, porosity variations, and fiber misalignments that can compromise structural integrity.

X-ray CT scanning stands as the gold standard for volumetric inspection, offering high-resolution 3D visualization of internal structures. However, its widespread implementation faces significant barriers including prohibitive equipment costs, lengthy scanning times, and limitations in examining large or geometrically complex turbine components. These constraints make it impractical for high-volume production environments despite its technical superiority.

Ultrasonic testing provides good sensitivity to delaminations and matrix cracks but struggles with the inherent acoustic impedance variations in CMC materials. The anisotropic nature of CMCs creates complex wave propagation patterns that complicate signal interpretation, often resulting in false positives or missed defects. Current research focuses on advanced signal processing algorithms and phased array techniques to overcome these limitations.

Infrared thermography offers rapid, large-area inspection capabilities but suffers from limited depth penetration and resolution. While effective for near-surface defect detection, it cannot reliably identify critical flaws in thicker sections of turbine components. Recent developments in pulse-phase and lock-in thermography show promise but require further refinement for CMC-specific applications.

A fundamental challenge across all inspection methods is the establishment of appropriate accept/reject criteria for CMC components. Unlike metallic materials with well-established damage tolerance models, the complex failure mechanisms of CMCs make it difficult to correlate detected defects with actual performance impacts. This knowledge gap necessitates conservative inspection standards that may lead to unnecessary rejections of serviceable parts.

The geographical distribution of CMC inspection expertise remains heavily concentrated in advanced aerospace manufacturing centers in the United States, Europe, and Japan. This concentration creates barriers to wider adoption of CMC technologies in emerging markets. Additionally, the proprietary nature of many inspection protocols developed by major aerospace companies limits knowledge sharing and standardization efforts across the industry.

Standardization represents another significant hurdle, with limited consensus on inspection procedures, equipment calibration, and defect classification systems. Current efforts by organizations such as ASTM International and the Aerospace Industries Association aim to develop unified standards, but progress remains slow due to the relative novelty of CMC applications in turbine components.

X-ray CT scanning stands as the gold standard for volumetric inspection, offering high-resolution 3D visualization of internal structures. However, its widespread implementation faces significant barriers including prohibitive equipment costs, lengthy scanning times, and limitations in examining large or geometrically complex turbine components. These constraints make it impractical for high-volume production environments despite its technical superiority.

Ultrasonic testing provides good sensitivity to delaminations and matrix cracks but struggles with the inherent acoustic impedance variations in CMC materials. The anisotropic nature of CMCs creates complex wave propagation patterns that complicate signal interpretation, often resulting in false positives or missed defects. Current research focuses on advanced signal processing algorithms and phased array techniques to overcome these limitations.

Infrared thermography offers rapid, large-area inspection capabilities but suffers from limited depth penetration and resolution. While effective for near-surface defect detection, it cannot reliably identify critical flaws in thicker sections of turbine components. Recent developments in pulse-phase and lock-in thermography show promise but require further refinement for CMC-specific applications.

A fundamental challenge across all inspection methods is the establishment of appropriate accept/reject criteria for CMC components. Unlike metallic materials with well-established damage tolerance models, the complex failure mechanisms of CMCs make it difficult to correlate detected defects with actual performance impacts. This knowledge gap necessitates conservative inspection standards that may lead to unnecessary rejections of serviceable parts.

The geographical distribution of CMC inspection expertise remains heavily concentrated in advanced aerospace manufacturing centers in the United States, Europe, and Japan. This concentration creates barriers to wider adoption of CMC technologies in emerging markets. Additionally, the proprietary nature of many inspection protocols developed by major aerospace companies limits knowledge sharing and standardization efforts across the industry.

Standardization represents another significant hurdle, with limited consensus on inspection procedures, equipment calibration, and defect classification systems. Current efforts by organizations such as ASTM International and the Aerospace Industries Association aim to develop unified standards, but progress remains slow due to the relative novelty of CMC applications in turbine components.

Current NDE Solutions for CMC Turbine Components

01 Non-Destructive Evaluation (NDE) Methods for CMC Turbine Parts

Various non-destructive evaluation methods are employed to inspect ceramic matrix composite (CMC) turbine parts without causing damage. These techniques include ultrasonic testing, X-ray computed tomography, infrared thermography, and acoustic emission testing. These methods allow for the detection of internal defects, delaminations, porosity issues, and microcracks that could compromise the structural integrity of CMC components in turbine engines.- Non-Destructive Evaluation (NDE) Methods for CMC Turbine Parts: Various non-destructive evaluation techniques are employed to inspect ceramic matrix composite (CMC) turbine components without causing damage. These methods include ultrasonic testing, X-ray computed tomography, infrared thermography, and acoustic emission testing. These techniques allow for the detection of internal defects, delaminations, porosity issues, and microcracks in CMC components while maintaining the structural integrity of the parts being inspected.

- Quality Control Systems for CMC Turbine Component Manufacturing: Comprehensive quality control systems are implemented throughout the manufacturing process of ceramic matrix composite turbine components. These systems include in-line monitoring, statistical process control, automated inspection stations, and digital twin technology for real-time quality assessment. The implementation of these quality control systems ensures consistency in production, reduces variability, and helps maintain high standards for critical turbine components.

- Surface Inspection and Coating Quality Assessment for CMC Turbine Parts: Specialized techniques are used to evaluate the surface quality and coating integrity of ceramic matrix composite turbine components. These include optical profilometry, scanning electron microscopy, eddy current testing, and laser-based surface analysis. These methods help identify surface irregularities, coating delamination, erosion damage, and other defects that could affect aerodynamic performance or thermal protection of the turbine parts.

- Thermal and Mechanical Testing of CMC Turbine Components: Rigorous thermal and mechanical testing protocols are established to evaluate the performance and durability of ceramic matrix composite turbine parts under operational conditions. These tests include high-temperature cycling, thermal shock resistance, creep testing, fatigue testing, and vibration analysis. The testing procedures help validate the design specifications and ensure that the CMC components can withstand the extreme conditions experienced in gas turbine engines.

- Automated Inspection Systems and Machine Learning for CMC Quality Control: Advanced automated inspection systems incorporating artificial intelligence and machine learning algorithms are developed for ceramic matrix composite turbine part quality control. These systems use computer vision, pattern recognition, and predictive analytics to detect defects, classify anomalies, and predict potential failures. The integration of these technologies improves inspection accuracy, reduces human error, and enables more efficient quality control processes for complex CMC components.

02 Quality Control Systems for CMC Turbine Component Manufacturing

Comprehensive quality control systems are implemented throughout the manufacturing process of CMC turbine parts. These systems include in-line monitoring, statistical process control, automated inspection stations, and digital twin technology. Such quality control measures ensure consistency in material properties, dimensional accuracy, and surface finish of the final components, which are critical for turbine performance and reliability.Expand Specific Solutions03 Surface Inspection and Coating Quality Assessment for CMC Turbine Parts

Specialized techniques are used to evaluate the surface quality and coating integrity of CMC turbine components. These include optical profilometry, scanning electron microscopy, eddy current testing, and laser-based surface analysis. These methods help identify surface irregularities, coating delamination, erosion damage, and thermal barrier coating defects that could lead to premature failure during turbine operation.Expand Specific Solutions04 In-Service Monitoring and Lifecycle Assessment of CMC Turbine Components

Advanced monitoring systems are employed to assess the condition of CMC turbine parts during operation. These include embedded sensors, optical fiber monitoring, acoustic emission detection, and thermal imaging systems. These technologies enable real-time assessment of component health, prediction of remaining useful life, and optimization of maintenance schedules, thereby enhancing turbine reliability and operational efficiency.Expand Specific Solutions05 Defect Analysis and Failure Mode Identification in CMC Turbine Parts

Sophisticated analytical techniques are used to characterize defects and understand failure mechanisms in CMC turbine components. These include fractography, microstructural analysis, finite element modeling, and accelerated life testing. These approaches help identify root causes of failures, improve design parameters, optimize manufacturing processes, and develop more robust quality control standards for next-generation CMC turbine parts.Expand Specific Solutions

Key Industry Players in CMC Quality Control

The Ceramic Matrix Composite (CMC) turbine parts quality control and NDE methods market is in a growth phase, with increasing adoption across aerospace and power generation sectors. The market is expanding due to the superior performance of CMCs at high temperatures, with an estimated global value exceeding $2 billion. Technologically, the field is maturing rapidly with key players developing specialized inspection techniques. Leading companies include Safran (with dedicated subsidiaries Safran Aircraft Engines and Safran Ceramics), GE, Rolls-Royce, and RTX Corp, who are advancing proprietary NDE methods. Chinese entities like XiAn Xinyao and academic institutions are also making significant contributions, while specialized testing companies such as JENTEK Sensors and Etegent Technologies provide complementary inspection technologies.

General Electric Company

Technical Solution: GE has developed a comprehensive suite of NDE methods for CMC turbine parts quality control, including high-resolution computed tomography (CT) scanning that can detect defects as small as 100 microns in complex geometries. Their proprietary Digital Twin technology creates virtual models of CMC components that can be compared with real-time inspection data to predict potential failures before they occur. GE's approach combines traditional methods like ultrasonic testing with advanced techniques such as infrared thermography and acoustic emission monitoring to create a multi-modal inspection protocol. Their LEAP engine program has demonstrated successful implementation of these techniques, with CMC shrouds undergoing rigorous quality control resulting in 99.5% detection rate for critical defects. GE has also pioneered the use of machine learning algorithms that analyze inspection data across thousands of components to continuously improve defect recognition capabilities and reduce false positives by approximately 30% compared to conventional methods.

Strengths: Industry-leading integration of multiple NDE techniques with digital modeling capabilities provides comprehensive defect detection. Their extensive database of CMC component performance enables predictive analytics for quality control. Weaknesses: The complex multi-modal approach requires significant computational resources and specialized training for technicians, potentially limiting deployment in smaller facilities.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has developed a comprehensive quality control system for CMC turbine components called "CeraSight" that integrates multiple NDE methodologies with artificial intelligence for defect recognition. Their approach centers on a multi-modal inspection process that begins with high-frequency ultrasonic arrays using custom-designed transducers optimized for the acoustic properties of ceramic matrices. This is complemented by digital radiography systems capable of detecting density variations as small as 1% within complex geometries. RTX has pioneered the application of terahertz spectroscopy for CMC inspection, which can detect subtle changes in material composition and identify contamination that might affect performance. Their system incorporates in-process monitoring during CMC manufacturing, with embedded sensors tracking temperature profiles and chemical reactions in real-time to ensure consistency. A key innovation is their AI-powered defect recognition software that analyzes inspection data across multiple modalities, correlating findings to build a comprehensive defect profile with 98% accuracy in classifying defect types. The system maintains a digital thread for each component, tracking quality parameters from raw material to finished part and enabling statistical process control to continuously improve manufacturing quality.

Strengths: Their multi-modal approach with AI integration provides exceptional defect characterization capabilities, reducing reliance on human interpretation. The system's ability to correlate findings across different inspection technologies significantly reduces false positives. Weaknesses: The sophisticated AI systems require extensive training data specific to each component design, potentially limiting flexibility when introducing new CMC geometries or compositions.

Critical Technologies in CMC Defect Detection

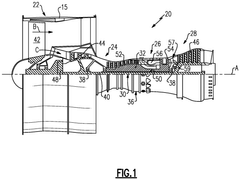

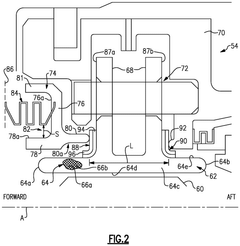

Gas turbine engine

PatentPendingEP4596840A1

Innovation

- A ceramic matrix composite (CMC) body with forward and aft flanges, an annular seal plate, and a flexible W-seal recessed between radially and axially extending walls, along with multi-layered coatings on flanges, to accommodate thermal growth and shrinkage, prevent chemical interactions, and ensure proper positioning.

Standardization and Certification Requirements

The standardization and certification landscape for CMC turbine parts represents a critical framework that ensures safety, reliability, and performance consistency across the aerospace and power generation industries. Currently, several key organizations lead the development of standards, including ASTM International, which has established the C28 Committee specifically for advanced ceramics, and the Ceramic Matrix Composites Working Group that focuses on test methods and quality assurance protocols. The International Organization for Standardization (ISO) has also developed relevant standards through its Technical Committee 206.

For CMC turbine components, certification requirements typically follow a multi-tiered approach. Material qualification requires extensive testing to establish property databases, including tensile strength, fatigue resistance, creep behavior, and environmental durability under simulated service conditions. Component certification demands additional validation through non-destructive evaluation (NDE) methods that must be standardized to ensure consistent detection capabilities across different manufacturing facilities.

The aerospace sector presents particularly stringent requirements, with the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) mandating comprehensive certification processes. These include design approval, production certification, and airworthiness directives specific to CMC components. The energy sector follows similar protocols established by organizations such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code.

A significant challenge in standardization efforts is the proprietary nature of many CMC formulations and manufacturing processes. This has led to industry-specific standards rather than universal protocols, creating potential barriers for new market entrants and complicating supply chain management. Additionally, the rapid evolution of CMC technologies often outpaces standardization efforts, resulting in regulatory gaps for novel materials and processes.

Recent developments include the establishment of round-robin testing programs among major industry players to validate NDE methods for CMC components. These collaborative efforts aim to establish probability of detection (POD) curves that quantify inspection reliability across different defect types and sizes. Such standardization is essential for widespread adoption of CMC turbine parts in critical applications.

Looking forward, the industry is moving toward performance-based certification approaches rather than prescriptive standards, allowing for greater innovation while maintaining safety margins. Digital certification frameworks incorporating material traceability and in-service monitoring data are also emerging as complementary systems to traditional certification processes, potentially streamlining future qualification procedures for advanced CMC turbine components.

For CMC turbine components, certification requirements typically follow a multi-tiered approach. Material qualification requires extensive testing to establish property databases, including tensile strength, fatigue resistance, creep behavior, and environmental durability under simulated service conditions. Component certification demands additional validation through non-destructive evaluation (NDE) methods that must be standardized to ensure consistent detection capabilities across different manufacturing facilities.

The aerospace sector presents particularly stringent requirements, with the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) mandating comprehensive certification processes. These include design approval, production certification, and airworthiness directives specific to CMC components. The energy sector follows similar protocols established by organizations such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code.

A significant challenge in standardization efforts is the proprietary nature of many CMC formulations and manufacturing processes. This has led to industry-specific standards rather than universal protocols, creating potential barriers for new market entrants and complicating supply chain management. Additionally, the rapid evolution of CMC technologies often outpaces standardization efforts, resulting in regulatory gaps for novel materials and processes.

Recent developments include the establishment of round-robin testing programs among major industry players to validate NDE methods for CMC components. These collaborative efforts aim to establish probability of detection (POD) curves that quantify inspection reliability across different defect types and sizes. Such standardization is essential for widespread adoption of CMC turbine parts in critical applications.

Looking forward, the industry is moving toward performance-based certification approaches rather than prescriptive standards, allowing for greater innovation while maintaining safety margins. Digital certification frameworks incorporating material traceability and in-service monitoring data are also emerging as complementary systems to traditional certification processes, potentially streamlining future qualification procedures for advanced CMC turbine components.

Environmental Impact of CMC Manufacturing QC

The manufacturing and quality control processes for Ceramic Matrix Composites (CMCs) in turbine applications present significant environmental considerations that must be addressed as this technology becomes more widespread. The production of CMCs typically involves energy-intensive processes including high-temperature sintering, chemical vapor infiltration, and precision machining, all of which contribute to considerable carbon emissions. Current estimates suggest that CMC manufacturing can generate 1.5-2.5 times the carbon footprint of conventional nickel-based superalloy production per unit weight, primarily due to the extended processing times and higher temperature requirements.

Water consumption represents another critical environmental concern in CMC quality control operations. Non-destructive evaluation methods such as ultrasonic testing and penetrant inspections often require substantial water usage for coupling mediums and cleaning processes. Research indicates that a single CMC turbine component may require 50-100 gallons of water throughout its quality control cycle, with additional water consumed in cooling systems for manufacturing equipment.

Chemical waste generation from CMC quality control processes poses particular challenges for environmental management. The use of specialized contrast agents in radiographic testing, chemical etchants for microstructural analysis, and various solvents for surface preparation all contribute to hazardous waste streams that require careful handling and disposal. These substances often contain heavy metals, volatile organic compounds, and other environmentally persistent chemicals that can impact ecosystems if improperly managed.

Recent life cycle assessments of CMC manufacturing quality control have identified opportunities for environmental improvement through process optimization. Implementation of dry ultrasonic testing techniques can reduce water consumption by up to 80%, while digital radiography systems eliminate the need for chemical processing of traditional X-ray films. Additionally, closed-loop recycling systems for test fluids have demonstrated potential to reduce chemical waste by 60-70% in leading manufacturing facilities.

The environmental regulatory landscape surrounding CMC quality control is evolving rapidly. In the European Union, the REACH regulations increasingly restrict certain chemicals commonly used in penetrant testing, while the United States EPA has established stricter guidelines for disposal of ceramic processing wastes. Manufacturers implementing comprehensive environmental management systems for their CMC quality control operations have reported 15-25% reductions in compliance costs through proactive waste minimization and substitution of environmentally preferable materials.

Water consumption represents another critical environmental concern in CMC quality control operations. Non-destructive evaluation methods such as ultrasonic testing and penetrant inspections often require substantial water usage for coupling mediums and cleaning processes. Research indicates that a single CMC turbine component may require 50-100 gallons of water throughout its quality control cycle, with additional water consumed in cooling systems for manufacturing equipment.

Chemical waste generation from CMC quality control processes poses particular challenges for environmental management. The use of specialized contrast agents in radiographic testing, chemical etchants for microstructural analysis, and various solvents for surface preparation all contribute to hazardous waste streams that require careful handling and disposal. These substances often contain heavy metals, volatile organic compounds, and other environmentally persistent chemicals that can impact ecosystems if improperly managed.

Recent life cycle assessments of CMC manufacturing quality control have identified opportunities for environmental improvement through process optimization. Implementation of dry ultrasonic testing techniques can reduce water consumption by up to 80%, while digital radiography systems eliminate the need for chemical processing of traditional X-ray films. Additionally, closed-loop recycling systems for test fluids have demonstrated potential to reduce chemical waste by 60-70% in leading manufacturing facilities.

The environmental regulatory landscape surrounding CMC quality control is evolving rapidly. In the European Union, the REACH regulations increasingly restrict certain chemicals commonly used in penetrant testing, while the United States EPA has established stricter guidelines for disposal of ceramic processing wastes. Manufacturers implementing comprehensive environmental management systems for their CMC quality control operations have reported 15-25% reductions in compliance costs through proactive waste minimization and substitution of environmentally preferable materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!