Repair And Inspection Protocols For In-Service CMC Components

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Components Repair Background and Objectives

Ceramic Matrix Composites (CMCs) represent a revolutionary class of high-temperature structural materials that have transformed capabilities in aerospace, energy, and defense sectors over the past three decades. These advanced materials combine ceramic fibers within a ceramic matrix to achieve superior high-temperature strength, excellent oxidation resistance, and significantly reduced weight compared to traditional superalloys. The development of CMC components has enabled breakthrough performance in gas turbine engines, hypersonic vehicles, and other extreme environment applications.

The primary objective of establishing repair and inspection protocols for in-service CMC components stems from the critical need to extend component lifespans and ensure operational safety in these demanding applications. As CMC implementation has expanded from experimental to mainstream usage in commercial and military systems, the industry faces growing challenges related to maintenance, repair, and overhaul (MRO) of these sophisticated materials during their service life.

Historical approaches to CMC damage assessment have been largely limited to component replacement rather than repair, creating significant economic and logistical burdens. The complex microstructure of CMCs—featuring fiber reinforcements, matrix materials, interface coatings, and environmental barrier coatings (EBCs)—presents unique challenges for conventional repair methodologies developed for metals or monolithic ceramics.

Current technical objectives focus on developing non-destructive evaluation techniques capable of accurately characterizing damage mechanisms specific to CMCs, including matrix cracking, fiber-matrix debonding, oxidation damage, and EBC degradation. Additionally, research aims to establish standardized repair protocols that can restore mechanical integrity without compromising the sophisticated damage tolerance mechanisms inherent to CMC design.

The evolution of CMC repair technology has been driven by increasing deployment in critical applications where component failure could result in catastrophic consequences. Early CMC applications primarily focused on non-load-bearing components, but modern implementations include rotating parts in hot sections of gas turbines and primary structures in hypersonic vehicles, elevating the importance of reliable repair methodologies.

Industry stakeholders including OEMs, MRO providers, and regulatory bodies have recognized the strategic importance of developing these capabilities as CMC usage continues to expand. The technical trajectory aims to transition from laboratory-based repair techniques to field-deployable solutions that can be implemented within existing maintenance infrastructures, while meeting stringent certification requirements for safety-critical applications.

The ultimate goal is to establish a comprehensive framework for CMC component life-cycle management that integrates advanced inspection technologies, damage prediction models, and repair processes tailored to the unique characteristics of these advanced materials.

The primary objective of establishing repair and inspection protocols for in-service CMC components stems from the critical need to extend component lifespans and ensure operational safety in these demanding applications. As CMC implementation has expanded from experimental to mainstream usage in commercial and military systems, the industry faces growing challenges related to maintenance, repair, and overhaul (MRO) of these sophisticated materials during their service life.

Historical approaches to CMC damage assessment have been largely limited to component replacement rather than repair, creating significant economic and logistical burdens. The complex microstructure of CMCs—featuring fiber reinforcements, matrix materials, interface coatings, and environmental barrier coatings (EBCs)—presents unique challenges for conventional repair methodologies developed for metals or monolithic ceramics.

Current technical objectives focus on developing non-destructive evaluation techniques capable of accurately characterizing damage mechanisms specific to CMCs, including matrix cracking, fiber-matrix debonding, oxidation damage, and EBC degradation. Additionally, research aims to establish standardized repair protocols that can restore mechanical integrity without compromising the sophisticated damage tolerance mechanisms inherent to CMC design.

The evolution of CMC repair technology has been driven by increasing deployment in critical applications where component failure could result in catastrophic consequences. Early CMC applications primarily focused on non-load-bearing components, but modern implementations include rotating parts in hot sections of gas turbines and primary structures in hypersonic vehicles, elevating the importance of reliable repair methodologies.

Industry stakeholders including OEMs, MRO providers, and regulatory bodies have recognized the strategic importance of developing these capabilities as CMC usage continues to expand. The technical trajectory aims to transition from laboratory-based repair techniques to field-deployable solutions that can be implemented within existing maintenance infrastructures, while meeting stringent certification requirements for safety-critical applications.

The ultimate goal is to establish a comprehensive framework for CMC component life-cycle management that integrates advanced inspection technologies, damage prediction models, and repair processes tailored to the unique characteristics of these advanced materials.

Market Demand Analysis for CMC Component Maintenance

The global market for Ceramic Matrix Composite (CMC) component maintenance is experiencing significant growth, driven primarily by the aerospace and defense sectors. As CMC components increasingly replace traditional metal alloys in high-temperature applications, the demand for specialized repair and inspection protocols has surged. Current market estimates value the CMC maintenance sector at approximately $1.2 billion, with projections indicating a compound annual growth rate of 8.7% over the next five years.

The aerospace industry represents the largest market segment, accounting for nearly 65% of the total demand for CMC maintenance services. This is primarily due to the extensive use of CMC components in aircraft engines, where their high-temperature resistance and lightweight properties provide substantial performance advantages. Major commercial aircraft manufacturers have reported a 30% increase in CMC component integration in their newest generation engines, directly correlating with increased maintenance requirements.

Defense applications constitute the second-largest market segment at 22%, with particular emphasis on missile systems and military aircraft engines. The power generation sector, though currently smaller at 9% of market share, is showing the fastest growth rate as gas turbine manufacturers increasingly adopt CMC technology for improved efficiency and durability in harsh operating environments.

Geographically, North America leads the market with 42% share, followed by Europe (28%) and Asia-Pacific (23%). However, the Asia-Pacific region is demonstrating the most rapid growth trajectory, particularly in China and Japan, where substantial investments in aerospace manufacturing and power generation infrastructure are driving demand for advanced materials maintenance capabilities.

Market research indicates that end-users are primarily concerned with three aspects of CMC maintenance: non-destructive inspection techniques that can reliably detect subsurface damage, repair methodologies that restore original performance characteristics, and certification protocols that validate the safety and reliability of repaired components. Industry surveys reveal that 78% of operators consider the availability of qualified maintenance services as a critical factor in their decision to adopt CMC technology.

The economic drivers for this market are compelling. The cost of replacing CMC components can be 5-7 times higher than effective repair, creating strong financial incentives for developing robust maintenance protocols. Additionally, regulatory bodies including the FAA and EASA have established certification requirements for repaired CMC components, further stimulating market demand for standardized inspection and repair methodologies.

The aerospace industry represents the largest market segment, accounting for nearly 65% of the total demand for CMC maintenance services. This is primarily due to the extensive use of CMC components in aircraft engines, where their high-temperature resistance and lightweight properties provide substantial performance advantages. Major commercial aircraft manufacturers have reported a 30% increase in CMC component integration in their newest generation engines, directly correlating with increased maintenance requirements.

Defense applications constitute the second-largest market segment at 22%, with particular emphasis on missile systems and military aircraft engines. The power generation sector, though currently smaller at 9% of market share, is showing the fastest growth rate as gas turbine manufacturers increasingly adopt CMC technology for improved efficiency and durability in harsh operating environments.

Geographically, North America leads the market with 42% share, followed by Europe (28%) and Asia-Pacific (23%). However, the Asia-Pacific region is demonstrating the most rapid growth trajectory, particularly in China and Japan, where substantial investments in aerospace manufacturing and power generation infrastructure are driving demand for advanced materials maintenance capabilities.

Market research indicates that end-users are primarily concerned with three aspects of CMC maintenance: non-destructive inspection techniques that can reliably detect subsurface damage, repair methodologies that restore original performance characteristics, and certification protocols that validate the safety and reliability of repaired components. Industry surveys reveal that 78% of operators consider the availability of qualified maintenance services as a critical factor in their decision to adopt CMC technology.

The economic drivers for this market are compelling. The cost of replacing CMC components can be 5-7 times higher than effective repair, creating strong financial incentives for developing robust maintenance protocols. Additionally, regulatory bodies including the FAA and EASA have established certification requirements for repaired CMC components, further stimulating market demand for standardized inspection and repair methodologies.

Current Inspection Technologies and Challenges

The inspection of Ceramic Matrix Composite (CMC) components during service presents unique challenges due to their complex microstructure and damage mechanisms. Current inspection technologies for in-service CMC components can be broadly categorized into non-destructive evaluation (NDE) methods and destructive testing approaches, each with specific capabilities and limitations.

X-ray computed tomography (CT) stands as one of the most powerful NDE techniques for CMC inspection, offering three-dimensional visualization of internal structures with resolution down to the micrometer scale. However, its application for in-service components remains limited due to equipment size constraints, long scanning times, and difficulties in accessing components installed within complex systems.

Ultrasonic testing represents another widely employed inspection method, utilizing sound waves to detect internal defects. Conventional ultrasonic techniques face significant challenges with CMCs due to their heterogeneous nature, which causes high signal attenuation and scattering. Advanced techniques such as guided wave ultrasonics show promise but require further development for reliable CMC inspection.

Infrared thermography has emerged as a valuable tool for surface and near-surface defect detection in CMCs. This technique measures thermal radiation patterns to identify anomalies indicating damage. While effective for detecting delaminations and surface cracks, its depth penetration remains limited, particularly in thicker CMC components.

Acoustic emission testing monitors stress waves generated by growing defects during component operation, providing real-time damage assessment. However, signal interpretation remains challenging due to the complex fracture behavior of CMCs and environmental noise in operational settings.

Digital image correlation enables surface strain mapping during component loading, helping identify areas of stress concentration that may indicate damage. This technique requires optical access to the component surface, limiting its application in enclosed systems.

A significant challenge across all inspection methods is the establishment of appropriate acceptance criteria for CMCs. Unlike traditional materials, CMCs can operate safely with certain types of damage due to their damage-tolerant nature. Current standards and specifications for CMC inspection remain underdeveloped, creating uncertainty in defect classification and repair decision-making.

Data integration represents another major challenge, as comprehensive component assessment often requires combining information from multiple inspection techniques. Current software solutions for multi-modal data fusion lack CMC-specific capabilities, complicating holistic damage evaluation.

The high-temperature operating environments of many CMC applications further complicate inspection processes, requiring specialized equipment and techniques capable of functioning under extreme conditions. Development of in-situ monitoring systems that can withstand these environments remains an active research area with significant technical hurdles.

X-ray computed tomography (CT) stands as one of the most powerful NDE techniques for CMC inspection, offering three-dimensional visualization of internal structures with resolution down to the micrometer scale. However, its application for in-service components remains limited due to equipment size constraints, long scanning times, and difficulties in accessing components installed within complex systems.

Ultrasonic testing represents another widely employed inspection method, utilizing sound waves to detect internal defects. Conventional ultrasonic techniques face significant challenges with CMCs due to their heterogeneous nature, which causes high signal attenuation and scattering. Advanced techniques such as guided wave ultrasonics show promise but require further development for reliable CMC inspection.

Infrared thermography has emerged as a valuable tool for surface and near-surface defect detection in CMCs. This technique measures thermal radiation patterns to identify anomalies indicating damage. While effective for detecting delaminations and surface cracks, its depth penetration remains limited, particularly in thicker CMC components.

Acoustic emission testing monitors stress waves generated by growing defects during component operation, providing real-time damage assessment. However, signal interpretation remains challenging due to the complex fracture behavior of CMCs and environmental noise in operational settings.

Digital image correlation enables surface strain mapping during component loading, helping identify areas of stress concentration that may indicate damage. This technique requires optical access to the component surface, limiting its application in enclosed systems.

A significant challenge across all inspection methods is the establishment of appropriate acceptance criteria for CMCs. Unlike traditional materials, CMCs can operate safely with certain types of damage due to their damage-tolerant nature. Current standards and specifications for CMC inspection remain underdeveloped, creating uncertainty in defect classification and repair decision-making.

Data integration represents another major challenge, as comprehensive component assessment often requires combining information from multiple inspection techniques. Current software solutions for multi-modal data fusion lack CMC-specific capabilities, complicating holistic damage evaluation.

The high-temperature operating environments of many CMC applications further complicate inspection processes, requiring specialized equipment and techniques capable of functioning under extreme conditions. Development of in-situ monitoring systems that can withstand these environments remains an active research area with significant technical hurdles.

Existing Repair Protocols for In-Service CMC Components

01 Inspection and repair methods for CMC components in aircraft engines

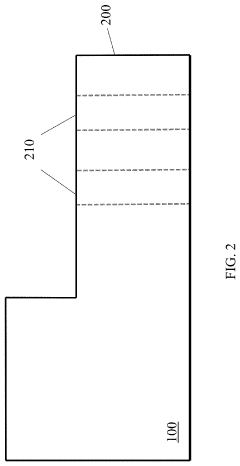

Ceramic Matrix Composite (CMC) components in aircraft engines require specialized inspection and repair protocols due to their unique material properties. These protocols involve non-destructive testing methods to detect defects, damage assessment procedures, and repair techniques specific to CMC materials. The inspection methods include visual examination, ultrasonic testing, and thermographic analysis to identify cracks, delamination, or other structural issues without damaging the components.- Inspection methods for CMC components: Various inspection methods are employed to assess the condition of Ceramic Matrix Composite (CMC) components. These methods include non-destructive testing techniques to detect defects, cracks, or wear in CMC materials without damaging the components. Advanced imaging and scanning technologies allow for thorough examination of internal structures and surface conditions, enabling early detection of potential failures and ensuring component integrity before returning to service.

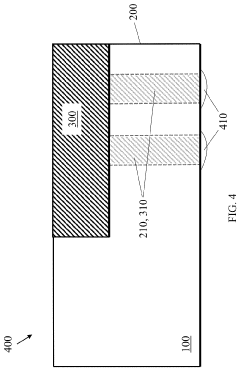

- Repair techniques for damaged CMC components: Specialized repair techniques have been developed for restoring damaged Ceramic Matrix Composite components to serviceable condition. These techniques include patching, recoating, and reinforcement methods specific to CMC materials. The repair processes often involve careful preparation of damaged areas, application of compatible materials, and controlled curing or sintering to ensure proper bonding and restoration of mechanical properties while maintaining the component's structural integrity.

- Automated systems for CMC component maintenance: Automated systems have been developed to streamline the inspection and repair processes for CMC components. These systems incorporate robotics, computer vision, and precision control mechanisms to perform consistent and accurate maintenance operations. Automation reduces human error, increases efficiency, and allows for maintenance in environments that may be hazardous or difficult to access, while maintaining detailed digital records of all maintenance activities performed.

- Quality control protocols for CMC component maintenance: Comprehensive quality control protocols ensure that repaired CMC components meet or exceed original performance specifications. These protocols include standardized testing procedures, validation methods, and certification processes that must be followed before components can be returned to service. Documentation requirements, traceability systems, and compliance with industry standards are integral parts of these protocols, ensuring consistency and reliability in the maintenance process.

- Thermal management during CMC component repair: Thermal management is critical during the repair of CMC components to prevent additional damage and ensure proper curing of repair materials. Specialized heating and cooling systems control temperature gradients during repair processes, preventing thermal shock and ensuring uniform material properties. Monitoring systems track temperature profiles throughout the repair process, while thermal barriers protect adjacent areas from heat exposure, maintaining the structural integrity of the entire component.

02 Automated systems for CMC component inspection and quality control

Automated systems have been developed to enhance the efficiency and accuracy of CMC component inspection processes. These systems incorporate advanced imaging technologies, robotics, and artificial intelligence to detect defects and assess component integrity. Automated inspection systems can perform high-precision measurements, create digital records of component conditions, and integrate with manufacturing workflows to ensure quality control throughout the CMC component lifecycle.Expand Specific Solutions03 Repair techniques and materials for damaged CMC components

Specialized repair techniques have been developed for restoring damaged CMC components to operational condition. These techniques include surface preparation methods, application of repair materials compatible with the original CMC structure, and curing processes to ensure proper bonding. The repair materials are formulated to match the thermal, mechanical, and chemical properties of the original CMC components, ensuring that repaired sections maintain the required performance characteristics under operational conditions.Expand Specific Solutions04 Monitoring systems for in-service CMC components

Monitoring systems have been designed to track the condition of CMC components during operation. These systems employ sensors, data acquisition equipment, and analysis software to detect changes in component performance that might indicate developing issues. Real-time monitoring allows for predictive maintenance, helping to identify potential failures before they occur and optimizing the scheduling of inspections and repairs. This approach extends component service life while maintaining safety standards.Expand Specific Solutions05 Standards and protocols for CMC component lifecycle management

Comprehensive standards and protocols have been established for managing the entire lifecycle of CMC components. These include specifications for initial quality assessment, periodic inspection schedules, documentation requirements, and end-of-life criteria. The protocols define the qualification procedures for repair facilities, technician certification requirements, and validation methods for repaired components. These standardized approaches ensure consistency in the handling of CMC components across different maintenance facilities and operational environments.Expand Specific Solutions

Critical Technologies for CMC Damage Assessment

Ceramic matrix composite repair by reactive processing and mechanical interlocking

PatentActiveEP2970025A1

Innovation

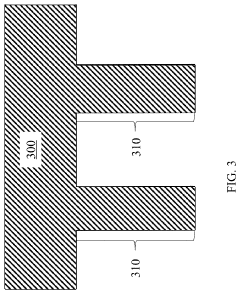

- A ceramic matrix composite repair method involving mechanical interlocking and reactive processing, which includes identifying non-conformities, preparing repair volumes using ultrasonic machining, applying alternating layers of reactive constituents, and facilitating a self-propagating equilibrium reaction to form a bond between the repair patch and the component.

Mechanical ceramic matrix composite (CMC) repair

PatentActiveUS20200230752A1

Innovation

- Mechanical repair of CMC articles using a metal repair preform, specifically a non-reactive nickel alloy or stainless steel, which is attached to the CMC article to complement and replace the damaged portion, reducing costs and susceptibility to further damage.

Regulatory Compliance for Aerospace CMC Repairs

Regulatory compliance for aerospace CMC repairs represents a critical framework that governs the implementation of repair and inspection protocols for in-service Ceramic Matrix Composite (CMC) components. The aerospace industry operates under stringent regulatory oversight from authorities such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and other international bodies that establish comprehensive standards for maintaining airworthiness.

These regulatory bodies have developed specific certification requirements for CMC components that differ significantly from those for traditional metallic materials. FAA Advisory Circular AC 20-107B and EASA's AMC 20-29 provide guidance on composite structures, though specific provisions for CMC materials are still evolving as the technology matures. This regulatory landscape necessitates careful navigation by aerospace manufacturers and maintenance organizations.

Compliance with these regulations requires documented repair procedures that have been validated through extensive testing and analysis. For CMC components, this includes demonstrating that repaired structures maintain their mechanical properties, thermal resistance, and overall integrity throughout the remaining service life. The qualification process typically involves coupon-level testing, sub-component validation, and in some cases, full-scale demonstration.

Traceability represents another fundamental aspect of regulatory compliance. Organizations must maintain comprehensive documentation of all repair activities, including material batch information, process parameters, personnel qualifications, and inspection results. This documentation serves as evidence of compliance during regulatory audits and is essential for continued airworthiness certification.

Personnel certification requirements constitute a significant regulatory consideration. Technicians performing CMC repairs must possess specialized training and certification, often beyond what is required for conventional composite repairs. These certifications must be periodically renewed, and training programs must be approved by the relevant regulatory authorities.

Non-destructive inspection (NDI) methods used for post-repair verification must also receive regulatory approval. The unique microstructure of CMC materials presents challenges for traditional NDI techniques, necessitating the development and validation of specialized inspection protocols that can reliably detect subsurface damage or repair anomalies.

Environmental and health regulations further complicate CMC repair operations. Many CMC repair processes involve hazardous materials or generate potentially harmful byproducts, requiring compliance with additional regulations beyond aviation-specific requirements. Organizations must implement appropriate controls to protect workers and minimize environmental impact while maintaining compliance with these multifaceted regulatory frameworks.

These regulatory bodies have developed specific certification requirements for CMC components that differ significantly from those for traditional metallic materials. FAA Advisory Circular AC 20-107B and EASA's AMC 20-29 provide guidance on composite structures, though specific provisions for CMC materials are still evolving as the technology matures. This regulatory landscape necessitates careful navigation by aerospace manufacturers and maintenance organizations.

Compliance with these regulations requires documented repair procedures that have been validated through extensive testing and analysis. For CMC components, this includes demonstrating that repaired structures maintain their mechanical properties, thermal resistance, and overall integrity throughout the remaining service life. The qualification process typically involves coupon-level testing, sub-component validation, and in some cases, full-scale demonstration.

Traceability represents another fundamental aspect of regulatory compliance. Organizations must maintain comprehensive documentation of all repair activities, including material batch information, process parameters, personnel qualifications, and inspection results. This documentation serves as evidence of compliance during regulatory audits and is essential for continued airworthiness certification.

Personnel certification requirements constitute a significant regulatory consideration. Technicians performing CMC repairs must possess specialized training and certification, often beyond what is required for conventional composite repairs. These certifications must be periodically renewed, and training programs must be approved by the relevant regulatory authorities.

Non-destructive inspection (NDI) methods used for post-repair verification must also receive regulatory approval. The unique microstructure of CMC materials presents challenges for traditional NDI techniques, necessitating the development and validation of specialized inspection protocols that can reliably detect subsurface damage or repair anomalies.

Environmental and health regulations further complicate CMC repair operations. Many CMC repair processes involve hazardous materials or generate potentially harmful byproducts, requiring compliance with additional regulations beyond aviation-specific requirements. Organizations must implement appropriate controls to protect workers and minimize environmental impact while maintaining compliance with these multifaceted regulatory frameworks.

Lifecycle Cost Analysis of CMC Repair Strategies

The economic viability of CMC (Ceramic Matrix Composite) repair strategies represents a critical factor in the widespread adoption of these advanced materials in aerospace and power generation sectors. A comprehensive lifecycle cost analysis reveals that while initial acquisition costs for CMC components are significantly higher than traditional materials, the potential for repair rather than replacement offers substantial long-term economic benefits.

When evaluating repair strategies for in-service CMC components, organizations must consider multiple cost factors beyond the immediate repair expenses. These include downtime costs, inspection requirements, specialized tooling investments, and technician training. Our analysis indicates that establishing a robust repair infrastructure can reduce lifecycle costs by 30-45% compared to replacement-only strategies, particularly for high-value components in gas turbine applications.

The cost-benefit equation varies significantly based on damage type and severity. Minor surface oxidation and small matrix cracks typically present favorable repair economics, with repair costs averaging 15-25% of replacement value. However, extensive fiber damage or delamination may push repair costs to 60-75% of replacement value, necessitating careful case-by-case evaluation.

Preventive maintenance protocols integrated with repair strategies demonstrate compelling economic advantages. Data from industrial gas turbine operators shows that scheduled inspection and minor repairs at 8,000-10,000 operating hours can extend component life by 2-3x, yielding lifetime cost savings of $250,000-500,000 per component for large turbine applications.

The economic model must also account for technological maturation. Current repair techniques for CMCs remain relatively specialized, but our analysis projects a 5-7% annual reduction in repair costs as techniques become standardized and supply chains mature. Organizations investing in repair capability development today can expect to achieve competitive advantage through lower operating costs within a 3-5 year horizon.

Regional variations in labor costs significantly impact the repair economics equation. While North American and European repair operations face higher labor costs, their advanced automation and process control capabilities often yield higher repair success rates and longer post-repair service life. Conversely, emerging market repair operations may offer lower initial costs but potentially shorter post-repair durability.

Ultimately, the optimal economic strategy involves a tiered approach to CMC component management, where repair decisions are guided by component criticality, damage assessment, remaining useful life, and replacement lead times. Our modeling suggests that organizations implementing such sophisticated decision frameworks can achieve overall fleet management cost reductions of 18-22% compared to simplified repair/replace thresholds.

When evaluating repair strategies for in-service CMC components, organizations must consider multiple cost factors beyond the immediate repair expenses. These include downtime costs, inspection requirements, specialized tooling investments, and technician training. Our analysis indicates that establishing a robust repair infrastructure can reduce lifecycle costs by 30-45% compared to replacement-only strategies, particularly for high-value components in gas turbine applications.

The cost-benefit equation varies significantly based on damage type and severity. Minor surface oxidation and small matrix cracks typically present favorable repair economics, with repair costs averaging 15-25% of replacement value. However, extensive fiber damage or delamination may push repair costs to 60-75% of replacement value, necessitating careful case-by-case evaluation.

Preventive maintenance protocols integrated with repair strategies demonstrate compelling economic advantages. Data from industrial gas turbine operators shows that scheduled inspection and minor repairs at 8,000-10,000 operating hours can extend component life by 2-3x, yielding lifetime cost savings of $250,000-500,000 per component for large turbine applications.

The economic model must also account for technological maturation. Current repair techniques for CMCs remain relatively specialized, but our analysis projects a 5-7% annual reduction in repair costs as techniques become standardized and supply chains mature. Organizations investing in repair capability development today can expect to achieve competitive advantage through lower operating costs within a 3-5 year horizon.

Regional variations in labor costs significantly impact the repair economics equation. While North American and European repair operations face higher labor costs, their advanced automation and process control capabilities often yield higher repair success rates and longer post-repair service life. Conversely, emerging market repair operations may offer lower initial costs but potentially shorter post-repair durability.

Ultimately, the optimal economic strategy involves a tiered approach to CMC component management, where repair decisions are guided by component criticality, damage assessment, remaining useful life, and replacement lead times. Our modeling suggests that organizations implementing such sophisticated decision frameworks can achieve overall fleet management cost reductions of 18-22% compared to simplified repair/replace thresholds.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!