Testing Protocols For CMCs Under Extreme Pressure And Temperature

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Testing Background and Objectives

Ceramic Matrix Composites (CMCs) represent a revolutionary class of materials that have emerged as critical components in high-performance applications across aerospace, energy, and defense sectors. The development of CMCs dates back to the 1970s, with significant advancements occurring in the 1990s and 2000s as manufacturing techniques matured. These materials combine the high-temperature capabilities of ceramics with improved fracture toughness and damage tolerance, making them ideal candidates for extreme operating environments.

The evolution of CMCs has been driven by increasing demands for materials that can withstand higher temperatures and pressures while maintaining structural integrity. Traditional superalloys typically reach their operational limits at temperatures around 1100°C, whereas advanced CMCs can function effectively at temperatures exceeding 1400°C. This temperature advantage, coupled with their lower density compared to metallic alternatives, has positioned CMCs as transformative materials for next-generation turbine engines, hypersonic vehicles, and advanced energy systems.

Despite their promising attributes, the widespread adoption of CMCs has been hindered by challenges in accurately predicting their behavior under extreme conditions. Conventional testing methodologies developed for metals or monolithic ceramics often prove inadequate for capturing the complex failure mechanisms and property degradation of CMCs when subjected to combined extreme pressure and temperature environments.

The primary objective of CMC testing protocols is to establish standardized, reliable methods for evaluating material performance under conditions that accurately simulate real-world operational environments. This includes developing test fixtures capable of simultaneously applying high temperatures (>1400°C) and high pressures while measuring critical material responses such as creep behavior, oxidation resistance, and microstructural evolution.

Additionally, these testing protocols aim to bridge the gap between laboratory-scale evaluation and component-level performance prediction. This requires innovative approaches to accelerated testing that can compress decades of service life into manageable test durations while maintaining relevance to actual application conditions. The correlation between accelerated test results and long-term performance represents a significant technical challenge that must be addressed.

Furthermore, testing protocols must evolve to accommodate the increasing complexity of CMC architectures, including variations in fiber types, matrix compositions, interface coatings, and manufacturing processes. The sensitivity of CMC properties to these variables necessitates testing methodologies that can isolate and quantify their individual and combined effects on material performance under extreme conditions.

The evolution of CMCs has been driven by increasing demands for materials that can withstand higher temperatures and pressures while maintaining structural integrity. Traditional superalloys typically reach their operational limits at temperatures around 1100°C, whereas advanced CMCs can function effectively at temperatures exceeding 1400°C. This temperature advantage, coupled with their lower density compared to metallic alternatives, has positioned CMCs as transformative materials for next-generation turbine engines, hypersonic vehicles, and advanced energy systems.

Despite their promising attributes, the widespread adoption of CMCs has been hindered by challenges in accurately predicting their behavior under extreme conditions. Conventional testing methodologies developed for metals or monolithic ceramics often prove inadequate for capturing the complex failure mechanisms and property degradation of CMCs when subjected to combined extreme pressure and temperature environments.

The primary objective of CMC testing protocols is to establish standardized, reliable methods for evaluating material performance under conditions that accurately simulate real-world operational environments. This includes developing test fixtures capable of simultaneously applying high temperatures (>1400°C) and high pressures while measuring critical material responses such as creep behavior, oxidation resistance, and microstructural evolution.

Additionally, these testing protocols aim to bridge the gap between laboratory-scale evaluation and component-level performance prediction. This requires innovative approaches to accelerated testing that can compress decades of service life into manageable test durations while maintaining relevance to actual application conditions. The correlation between accelerated test results and long-term performance represents a significant technical challenge that must be addressed.

Furthermore, testing protocols must evolve to accommodate the increasing complexity of CMC architectures, including variations in fiber types, matrix compositions, interface coatings, and manufacturing processes. The sensitivity of CMC properties to these variables necessitates testing methodologies that can isolate and quantify their individual and combined effects on material performance under extreme conditions.

Market Demand Analysis for Extreme Condition CMCs

The global market for Ceramic Matrix Composites (CMCs) designed for extreme conditions is experiencing robust growth, driven primarily by increasing demands in aerospace, defense, and energy sectors. Current market valuations indicate the extreme condition CMCs segment reached approximately $4.5 billion in 2022, with projections suggesting a compound annual growth rate of 11.7% through 2030, potentially reaching $12.3 billion by the end of the decade.

Aerospace and defense industries represent the largest market segments, collectively accounting for over 60% of current demand. This is primarily attributed to the critical need for materials capable of withstanding the extreme operational environments of next-generation aircraft engines, hypersonic vehicles, and advanced propulsion systems. The commercial aviation sector's push toward more fuel-efficient engines has particularly accelerated demand, as CMCs enable higher operating temperatures and subsequently improved thermodynamic efficiency.

Energy sector applications constitute another significant market driver, representing approximately 22% of current demand. Power generation systems, particularly gas turbines and nuclear reactors, require materials that maintain structural integrity under extreme temperature gradients and pressure conditions. The ongoing global energy transition has further intensified interest in CMCs for renewable energy applications, including concentrated solar power systems and advanced geothermal technologies.

Regional market analysis reveals North America currently leads global consumption at 38%, followed by Europe (29%) and Asia-Pacific (26%). However, the highest growth rates are projected in the Asia-Pacific region, particularly in China, Japan, and India, where substantial investments in aerospace and energy infrastructure are underway.

Industry surveys indicate that 78% of end-users cite inadequate testing protocols as a significant barrier to wider CMC adoption. The lack of standardized testing methodologies that accurately simulate combined extreme pressure and temperature conditions has created market uncertainty regarding long-term performance reliability. This represents a critical gap between laboratory material development and commercial implementation.

Market research further reveals that 83% of potential industrial adopters require comprehensive performance data under simultaneous extreme pressure and temperature conditions before committing to large-scale implementation. This underscores the urgent market need for advanced testing protocols that can accurately predict material behavior in real-world extreme environments.

The economic value proposition for improved testing protocols is compelling, with industry analysts estimating that enhanced testing capabilities could accelerate market adoption by 15-20%, potentially unlocking an additional $1.8 billion in market value by 2028 through increased confidence in material performance and reliability.

Aerospace and defense industries represent the largest market segments, collectively accounting for over 60% of current demand. This is primarily attributed to the critical need for materials capable of withstanding the extreme operational environments of next-generation aircraft engines, hypersonic vehicles, and advanced propulsion systems. The commercial aviation sector's push toward more fuel-efficient engines has particularly accelerated demand, as CMCs enable higher operating temperatures and subsequently improved thermodynamic efficiency.

Energy sector applications constitute another significant market driver, representing approximately 22% of current demand. Power generation systems, particularly gas turbines and nuclear reactors, require materials that maintain structural integrity under extreme temperature gradients and pressure conditions. The ongoing global energy transition has further intensified interest in CMCs for renewable energy applications, including concentrated solar power systems and advanced geothermal technologies.

Regional market analysis reveals North America currently leads global consumption at 38%, followed by Europe (29%) and Asia-Pacific (26%). However, the highest growth rates are projected in the Asia-Pacific region, particularly in China, Japan, and India, where substantial investments in aerospace and energy infrastructure are underway.

Industry surveys indicate that 78% of end-users cite inadequate testing protocols as a significant barrier to wider CMC adoption. The lack of standardized testing methodologies that accurately simulate combined extreme pressure and temperature conditions has created market uncertainty regarding long-term performance reliability. This represents a critical gap between laboratory material development and commercial implementation.

Market research further reveals that 83% of potential industrial adopters require comprehensive performance data under simultaneous extreme pressure and temperature conditions before committing to large-scale implementation. This underscores the urgent market need for advanced testing protocols that can accurately predict material behavior in real-world extreme environments.

The economic value proposition for improved testing protocols is compelling, with industry analysts estimating that enhanced testing capabilities could accelerate market adoption by 15-20%, potentially unlocking an additional $1.8 billion in market value by 2028 through increased confidence in material performance and reliability.

Current Challenges in High-Pressure Temperature Testing

Testing Ceramic Matrix Composites (CMCs) under extreme pressure and temperature conditions presents significant technical challenges that impede accurate performance evaluation and material development. Current testing methodologies struggle to simultaneously maintain precise control over both high-pressure and high-temperature environments, particularly when temperatures exceed 1500°C and pressures reach several GPa.

The primary challenge lies in instrumentation limitations. Conventional sensors and measurement devices often fail or provide unreliable data when exposed to extreme conditions. Thermocouples degrade rapidly above 1600°C, while pressure transducers suffer from thermal drift and calibration issues when subjected to temperature fluctuations. This creates substantial uncertainty in test results, making it difficult to establish reliable material performance baselines.

Material interaction problems further complicate testing protocols. Test fixtures and containment vessels can chemically react with CMC specimens at elevated temperatures, introducing contamination that alters material properties and compromises test validity. Additionally, differential thermal expansion between test equipment and specimens creates unintended mechanical stresses that can mask or amplify the actual material response being measured.

Uniformity control represents another significant hurdle. Achieving homogeneous temperature and pressure distribution throughout test specimens becomes increasingly difficult as specimen size increases. Temperature gradients within samples can exceed 100°C/cm in some extreme testing scenarios, leading to non-representative stress states and localized failure mechanisms that do not accurately reflect real-world performance.

Data acquisition and real-time monitoring capabilities remain severely constrained in extreme testing environments. The harsh conditions prevent direct observation of failure progression, limiting researchers' ability to understand dynamic material behavior. Most current systems rely on post-test analysis, which fails to capture critical transient phenomena during testing.

Standardization deficiencies further undermine testing reliability. Unlike conventional materials, CMCs lack universally accepted testing protocols for extreme conditions. This absence of standardization makes cross-comparison between different research institutions problematic and hinders collaborative advancement in the field.

Scaling issues present additional complications. Laboratory-scale tests often fail to accurately predict component-level performance due to size effects and geometric considerations. The inability to conduct full-scale testing under representative conditions forces engineers to rely heavily on modeling and simulation, which require extensive validation data that current testing limitations cannot adequately provide.

The primary challenge lies in instrumentation limitations. Conventional sensors and measurement devices often fail or provide unreliable data when exposed to extreme conditions. Thermocouples degrade rapidly above 1600°C, while pressure transducers suffer from thermal drift and calibration issues when subjected to temperature fluctuations. This creates substantial uncertainty in test results, making it difficult to establish reliable material performance baselines.

Material interaction problems further complicate testing protocols. Test fixtures and containment vessels can chemically react with CMC specimens at elevated temperatures, introducing contamination that alters material properties and compromises test validity. Additionally, differential thermal expansion between test equipment and specimens creates unintended mechanical stresses that can mask or amplify the actual material response being measured.

Uniformity control represents another significant hurdle. Achieving homogeneous temperature and pressure distribution throughout test specimens becomes increasingly difficult as specimen size increases. Temperature gradients within samples can exceed 100°C/cm in some extreme testing scenarios, leading to non-representative stress states and localized failure mechanisms that do not accurately reflect real-world performance.

Data acquisition and real-time monitoring capabilities remain severely constrained in extreme testing environments. The harsh conditions prevent direct observation of failure progression, limiting researchers' ability to understand dynamic material behavior. Most current systems rely on post-test analysis, which fails to capture critical transient phenomena during testing.

Standardization deficiencies further undermine testing reliability. Unlike conventional materials, CMCs lack universally accepted testing protocols for extreme conditions. This absence of standardization makes cross-comparison between different research institutions problematic and hinders collaborative advancement in the field.

Scaling issues present additional complications. Laboratory-scale tests often fail to accurately predict component-level performance due to size effects and geometric considerations. The inability to conduct full-scale testing under representative conditions forces engineers to rely heavily on modeling and simulation, which require extensive validation data that current testing limitations cannot adequately provide.

Current Protocols for Extreme Condition Testing

01 Mechanical and thermal testing protocols for CMCs

Various mechanical and thermal testing protocols are used to evaluate the performance of Ceramic Matrix Composites under different conditions. These include tensile strength tests, compression tests, flexural tests, and thermal cycling tests to assess the material's behavior under mechanical loads and temperature variations. These testing protocols help in understanding the structural integrity and durability of CMCs in high-temperature applications.- Mechanical testing methods for CMCs: Various mechanical testing protocols are used to evaluate the performance of Ceramic Matrix Composites under different stress conditions. These include tensile strength tests, compression tests, flexural strength measurements, and fatigue testing. These methods help determine the structural integrity and mechanical properties of CMCs under various loading conditions, which is crucial for applications in high-stress environments such as aerospace and energy sectors.

- Thermal and environmental testing of CMCs: Testing protocols for evaluating CMCs under extreme thermal and environmental conditions are essential for understanding their performance limits. These include high-temperature exposure tests, thermal cycling, thermal shock resistance, and environmental exposure testing in corrosive or oxidative atmospheres. Such tests help determine the durability and reliability of CMCs in harsh operating environments like gas turbines and combustion chambers.

- Non-destructive evaluation techniques for CMCs: Non-destructive testing methods are employed to inspect and evaluate CMCs without causing damage to the material. These techniques include ultrasonic testing, X-ray computed tomography, infrared thermography, and acoustic emission monitoring. These methods allow for the detection of internal defects, delaminations, matrix cracks, and other structural anomalies that might affect the performance and safety of CMC components.

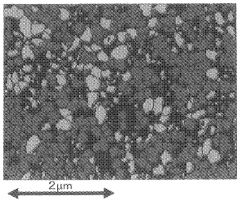

- Microstructural characterization of CMCs: Protocols for analyzing the microstructure of CMCs involve examining the fiber-matrix interface, porosity distribution, phase composition, and crystalline structure. Techniques such as scanning electron microscopy, transmission electron microscopy, X-ray diffraction, and energy-dispersive X-ray spectroscopy are commonly used. These analyses help understand the relationship between processing parameters, microstructure, and the resulting mechanical and thermal properties of CMCs.

- Standardized testing procedures for CMC qualification: Standardized testing protocols have been developed for the qualification and certification of CMCs for specific applications. These include ASTM standards, ISO procedures, and industry-specific test methods that evaluate properties such as interlaminar shear strength, fiber-matrix bond strength, and oxidation resistance. These standardized procedures ensure consistency in testing and allow for meaningful comparison of different CMC materials and manufacturing processes.

02 Environmental and oxidation resistance testing for CMCs

Testing protocols for evaluating the environmental and oxidation resistance of Ceramic Matrix Composites involve exposing the materials to harsh environments, including high-temperature oxidizing atmospheres, water vapor, and corrosive agents. These tests assess the material's resistance to degradation and its ability to maintain structural integrity under extreme conditions, which is crucial for applications in aerospace and energy sectors.Expand Specific Solutions03 Non-destructive evaluation techniques for CMCs

Non-destructive evaluation techniques are employed to inspect and characterize Ceramic Matrix Composites without causing damage. These include ultrasonic testing, X-ray computed tomography, infrared thermography, and acoustic emission monitoring. These methods help in detecting defects, delaminations, and microstructural changes in CMCs, ensuring quality control during manufacturing and in-service inspection.Expand Specific Solutions04 Manufacturing quality control testing for CMCs

Quality control testing during the manufacturing of Ceramic Matrix Composites involves evaluating the consistency of raw materials, monitoring processing parameters, and assessing the final product properties. These tests include fiber distribution analysis, matrix infiltration assessment, porosity measurements, and dimensional stability checks. Such protocols ensure that the produced CMCs meet the required specifications and performance standards.Expand Specific Solutions05 Durability and lifetime prediction testing for CMCs

Testing protocols for predicting the durability and lifetime of Ceramic Matrix Composites include accelerated aging tests, fatigue testing, creep testing, and cyclic loading under various environmental conditions. These tests help in understanding the long-term behavior of CMCs and developing models to predict their service life in applications such as gas turbine engines, aerospace components, and nuclear reactors.Expand Specific Solutions

Leading Organizations in CMC Testing Research

The testing protocols for Ceramic Matrix Composites (CMCs) under extreme pressure and temperature represent an emerging technological field currently in its growth phase. The global market for advanced high-temperature materials testing is projected to reach approximately $3.5 billion by 2025, driven by aerospace, energy, and defense applications. Leading players in this specialized domain include established aerospace giants like Rolls-Royce Plc and Boeing Co., who leverage CMCs for next-generation engine components, alongside specialized research institutions such as Suzhou Nuclear Power Research Institute and AECC Commercial Aircraft Engine Co. The technology remains in mid-maturity stage, with significant R&D investments from Siemens AG and CGN Power focusing on standardizing testing methodologies for materials operating in extreme environments, particularly for nuclear and aerospace applications where reliability under extreme conditions is critical.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed comprehensive testing protocols for Ceramic Matrix Composites (CMCs) that simulate extreme operational environments in aerospace applications. Their approach includes high-temperature mechanical testing facilities capable of reaching 1600°C while simultaneously applying mechanical loads up to 100 MPa. The company employs specialized thermal gradient testing methods that accurately replicate the rapid temperature fluctuations experienced in jet engine components. Their protocols incorporate acoustic emission monitoring systems to detect microcracking during testing, providing real-time data on material degradation under extreme conditions. Rolls-Royce has also pioneered cyclic pressure testing methodologies that combine thermal cycling with pressure differentials to evaluate CMC performance in turbine environments.

Strengths: Industry-leading facilities capable of simulating actual engine operating conditions; extensive experience with aerospace-grade CMCs; comprehensive data collection systems. Weaknesses: Testing protocols primarily optimized for aerospace applications rather than broader industrial uses; high cost of specialized testing equipment limits throughput.

The Boeing Co.

Technical Solution: Boeing has established advanced testing protocols for CMCs focused on aerospace structural applications under extreme conditions. Their methodology includes combined thermal-mechanical testing in specialized environmental chambers that can simulate temperatures from -65°C to 1800°C while applying multi-axial loads. Boeing's protocols feature proprietary non-destructive evaluation techniques including digital image correlation and thermography to monitor real-time material response during testing. The company has developed accelerated life testing procedures that compress decades of service conditions into manageable test timeframes through carefully calibrated thermal and pressure cycling. Their testing infrastructure includes hypersonic wind tunnels modified to evaluate CMC performance under extreme aerothermal conditions representative of hypersonic flight regimes.

Strengths: Comprehensive testing capabilities spanning the full range of aerospace environmental conditions; advanced non-destructive evaluation techniques; ability to correlate test results with flight data. Weaknesses: Testing protocols primarily focused on structural rather than propulsion applications; limited public disclosure of testing methodologies due to proprietary concerns.

Critical Technologies in CMC Performance Evaluation

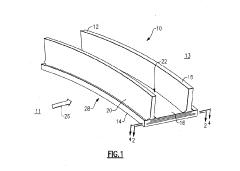

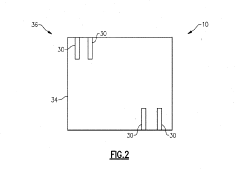

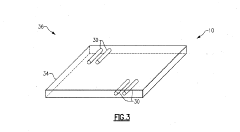

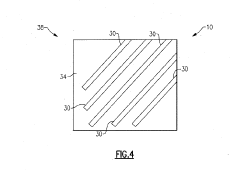

Ceramic matrix composite component including cooling channels in multiple plies and production method

PatentActiveJP2021098650A

Innovation

- The formation of ceramic matrix composite components with multiple cooling channels within ceramic matrix composite plies, aligned with the fibers to maintain structural integrity and reduce thermal stress, using sacrificial fibers to create elongated functional features that form cooling channels during the manufacturing process.

Ceramic-matrix composite material and production method therefor

PatentWO2023248910A1

Innovation

- Incorporating a ceramic matrix composed of multiple components, including specific composite oxides such as spinel, mullite, and YAG, along with alumina, and using ceramic continuous fibers like alumina and mullite, to create a CMC with improved thermal stability and strength retention.

Material Degradation Mechanisms Under Extreme Conditions

Ceramic Matrix Composites (CMCs) exposed to extreme pressure and temperature conditions undergo several degradation mechanisms that significantly impact their performance and longevity. The primary degradation pathway involves oxidation processes, particularly in high-temperature environments where oxygen penetrates the material structure through microcracks and pores. This oxidation leads to the formation of volatile species and glass phases that compromise the mechanical integrity of the composite.

Thermal cycling represents another critical degradation factor, causing differential expansion between the ceramic matrix and reinforcing fibers. These thermal mismatches generate internal stresses that propagate existing microcracks and initiate new ones, creating pathways for further environmental attack. In applications involving hypersonic flight or advanced propulsion systems, these thermal cycles can occur rapidly and repeatedly, accelerating the degradation process.

Chemical interactions between the matrix and fiber components become increasingly aggressive under extreme conditions. At temperatures exceeding 1200°C, interfacial reactions can dissolve protective fiber coatings, leading to direct fiber-matrix bonding that eliminates the crucial crack-deflection mechanisms that provide CMCs their damage tolerance. These reactions often produce brittle interphases that serve as fracture initiation sites.

Creep deformation emerges as a dominant degradation mechanism at sustained high temperatures and pressures. The viscous flow of glassy phases in oxide-based CMCs and grain boundary sliding in non-oxide systems result in dimensional instability and progressive weakening of the material structure. This creep behavior is particularly problematic in load-bearing applications where dimensional stability is critical.

Erosion and ablation mechanisms become significant in high-velocity gas environments, such as those found in rocket nozzles or turbine components. Particulate impacts and high-velocity gas streams physically remove material from the CMC surface, while chemical reactions between the hot gases and the material surface can accelerate material loss through volatilization of reaction products.

Radiation damage presents additional challenges in nuclear applications, where neutron irradiation causes atomic displacement cascades, transmutation reactions, and helium bubble formation. These radiation effects alter the microstructure and mechanical properties of CMCs, often leading to embrittlement and dimensional changes that compromise component functionality.

Understanding these degradation mechanisms is essential for developing effective testing protocols that can accurately predict CMC behavior under extreme conditions and inform material design improvements for enhanced durability in demanding applications.

Thermal cycling represents another critical degradation factor, causing differential expansion between the ceramic matrix and reinforcing fibers. These thermal mismatches generate internal stresses that propagate existing microcracks and initiate new ones, creating pathways for further environmental attack. In applications involving hypersonic flight or advanced propulsion systems, these thermal cycles can occur rapidly and repeatedly, accelerating the degradation process.

Chemical interactions between the matrix and fiber components become increasingly aggressive under extreme conditions. At temperatures exceeding 1200°C, interfacial reactions can dissolve protective fiber coatings, leading to direct fiber-matrix bonding that eliminates the crucial crack-deflection mechanisms that provide CMCs their damage tolerance. These reactions often produce brittle interphases that serve as fracture initiation sites.

Creep deformation emerges as a dominant degradation mechanism at sustained high temperatures and pressures. The viscous flow of glassy phases in oxide-based CMCs and grain boundary sliding in non-oxide systems result in dimensional instability and progressive weakening of the material structure. This creep behavior is particularly problematic in load-bearing applications where dimensional stability is critical.

Erosion and ablation mechanisms become significant in high-velocity gas environments, such as those found in rocket nozzles or turbine components. Particulate impacts and high-velocity gas streams physically remove material from the CMC surface, while chemical reactions between the hot gases and the material surface can accelerate material loss through volatilization of reaction products.

Radiation damage presents additional challenges in nuclear applications, where neutron irradiation causes atomic displacement cascades, transmutation reactions, and helium bubble formation. These radiation effects alter the microstructure and mechanical properties of CMCs, often leading to embrittlement and dimensional changes that compromise component functionality.

Understanding these degradation mechanisms is essential for developing effective testing protocols that can accurately predict CMC behavior under extreme conditions and inform material design improvements for enhanced durability in demanding applications.

Safety Standards for High-Risk Testing Environments

Testing of Ceramic Matrix Composites (CMCs) under extreme conditions necessitates rigorous safety protocols to protect personnel, equipment, and facilities. Current safety standards for high-risk testing environments involving CMCs under extreme pressure and temperature conditions must address multiple critical aspects of operational safety.

The International Organization for Standardization (ISO) has established baseline requirements through ISO 17025 for testing laboratories, which serves as a foundation for specialized CMC testing environments. These standards require comprehensive risk assessments before any high-temperature or high-pressure testing begins, with particular emphasis on potential failure modes of both the test specimens and testing equipment.

ASTM International has developed specific guidelines (ASTM E2207) for high-temperature testing facilities that mandate redundant safety systems, including emergency shutdown protocols, pressure relief mechanisms, and thermal isolation barriers. These standards require testing chambers to withstand at least 150% of the maximum anticipated operating conditions to provide adequate safety margins.

Personnel safety requirements constitute a significant portion of these standards, mandating specialized training for operators working with extreme testing environments. This includes certification in high-temperature materials handling, pressure system operation, and emergency response procedures. Personal protective equipment specifications are particularly stringent, requiring heat-resistant clothing, face shields with gold reflective coatings for radiant heat protection, and respiratory equipment when testing potentially toxic CMC compositions.

Environmental monitoring systems represent another critical component of safety standards, with requirements for continuous measurement of chamber pressure, temperature gradients, gas composition, and structural integrity. Modern standards increasingly incorporate real-time data analysis systems that can predict potential failures before they occur, automatically initiating controlled shutdown procedures when parameters approach dangerous thresholds.

Facility design standards address containment requirements, specifying that high-risk CMC testing must occur in dedicated areas with reinforced walls, blast-resistant viewing windows, and separate ventilation systems. These standards typically require a minimum safe distance between testing equipment and occupied areas, with remote operation capabilities for tests exceeding certain risk thresholds.

Post-test safety protocols are equally important, covering proper cooling procedures, specimen handling, and waste disposal. These standards recognize that CMCs may retain extreme temperatures for extended periods or release hazardous particulates when damaged, requiring specialized handling procedures even after testing appears complete.

Compliance verification through third-party certification has become increasingly common, with organizations like TÜV or UL providing independent assessment of testing facilities against these safety standards. This certification process typically includes both documentation review and on-site inspection of safety systems and procedures.

The International Organization for Standardization (ISO) has established baseline requirements through ISO 17025 for testing laboratories, which serves as a foundation for specialized CMC testing environments. These standards require comprehensive risk assessments before any high-temperature or high-pressure testing begins, with particular emphasis on potential failure modes of both the test specimens and testing equipment.

ASTM International has developed specific guidelines (ASTM E2207) for high-temperature testing facilities that mandate redundant safety systems, including emergency shutdown protocols, pressure relief mechanisms, and thermal isolation barriers. These standards require testing chambers to withstand at least 150% of the maximum anticipated operating conditions to provide adequate safety margins.

Personnel safety requirements constitute a significant portion of these standards, mandating specialized training for operators working with extreme testing environments. This includes certification in high-temperature materials handling, pressure system operation, and emergency response procedures. Personal protective equipment specifications are particularly stringent, requiring heat-resistant clothing, face shields with gold reflective coatings for radiant heat protection, and respiratory equipment when testing potentially toxic CMC compositions.

Environmental monitoring systems represent another critical component of safety standards, with requirements for continuous measurement of chamber pressure, temperature gradients, gas composition, and structural integrity. Modern standards increasingly incorporate real-time data analysis systems that can predict potential failures before they occur, automatically initiating controlled shutdown procedures when parameters approach dangerous thresholds.

Facility design standards address containment requirements, specifying that high-risk CMC testing must occur in dedicated areas with reinforced walls, blast-resistant viewing windows, and separate ventilation systems. These standards typically require a minimum safe distance between testing equipment and occupied areas, with remote operation capabilities for tests exceeding certain risk thresholds.

Post-test safety protocols are equally important, covering proper cooling procedures, specimen handling, and waste disposal. These standards recognize that CMCs may retain extreme temperatures for extended periods or release hazardous particulates when damaged, requiring specialized handling procedures even after testing appears complete.

Compliance verification through third-party certification has become increasingly common, with organizations like TÜV or UL providing independent assessment of testing facilities against these safety standards. This certification process typically includes both documentation review and on-site inspection of safety systems and procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!