Inspection Standards And Certification Pathways For CMC Aero Parts

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Aero Parts Inspection Background and Objectives

Ceramic Matrix Composites (CMCs) represent a revolutionary class of materials that have emerged as critical components in modern aerospace applications. Since their initial development in the 1970s, CMCs have evolved from experimental materials to essential elements in high-performance aircraft engines and structural components. The technological trajectory of CMCs has been characterized by continuous improvements in material composition, manufacturing processes, and performance capabilities, particularly in high-temperature environments where traditional metallic alloys reach their operational limits.

The aerospace industry's pursuit of greater fuel efficiency, reduced emissions, and enhanced durability has accelerated the adoption of CMC components in critical applications. These materials offer exceptional thermal resistance, maintaining structural integrity at temperatures exceeding 1200°C while providing significant weight reduction compared to conventional superalloys. This combination of properties makes CMCs particularly valuable for components exposed to extreme conditions in aircraft engines, including turbine blades, combustor liners, and exhaust systems.

Despite their promising attributes, the widespread implementation of CMC components faces significant challenges related to inspection and certification. Traditional non-destructive testing (NDT) methods developed for metallic components often prove inadequate for detecting defects in the complex microstructure of CMCs. The heterogeneous nature of these composites, consisting of ceramic fibers embedded in a ceramic matrix with interfacial coatings, creates unique inspection challenges that conventional techniques struggle to address effectively.

The primary technical objective in this domain is to develop robust, reliable, and standardized inspection methodologies specifically tailored to CMC aero parts. These methods must be capable of detecting critical defects such as delaminations, matrix cracks, fiber breaks, and porosity variations that could compromise component integrity during service. Furthermore, inspection techniques must be adaptable to complex geometries and accessible for both manufacturing quality control and in-service maintenance inspections.

Beyond technical capabilities, there is an urgent need to establish comprehensive certification pathways that validate both the materials and inspection methods. Current aerospace certification frameworks, largely designed around metallic components, require significant adaptation to accommodate the unique characteristics and failure modes of CMCs. The development of industry-wide standards for CMC inspection represents a critical step toward broader adoption of these materials in safety-critical aerospace applications.

This technical research aims to comprehensively evaluate existing inspection technologies, identify promising emerging techniques, and outline potential certification pathways that could accelerate the integration of CMC components into next-generation aircraft systems while maintaining the stringent safety requirements of the aerospace industry.

The aerospace industry's pursuit of greater fuel efficiency, reduced emissions, and enhanced durability has accelerated the adoption of CMC components in critical applications. These materials offer exceptional thermal resistance, maintaining structural integrity at temperatures exceeding 1200°C while providing significant weight reduction compared to conventional superalloys. This combination of properties makes CMCs particularly valuable for components exposed to extreme conditions in aircraft engines, including turbine blades, combustor liners, and exhaust systems.

Despite their promising attributes, the widespread implementation of CMC components faces significant challenges related to inspection and certification. Traditional non-destructive testing (NDT) methods developed for metallic components often prove inadequate for detecting defects in the complex microstructure of CMCs. The heterogeneous nature of these composites, consisting of ceramic fibers embedded in a ceramic matrix with interfacial coatings, creates unique inspection challenges that conventional techniques struggle to address effectively.

The primary technical objective in this domain is to develop robust, reliable, and standardized inspection methodologies specifically tailored to CMC aero parts. These methods must be capable of detecting critical defects such as delaminations, matrix cracks, fiber breaks, and porosity variations that could compromise component integrity during service. Furthermore, inspection techniques must be adaptable to complex geometries and accessible for both manufacturing quality control and in-service maintenance inspections.

Beyond technical capabilities, there is an urgent need to establish comprehensive certification pathways that validate both the materials and inspection methods. Current aerospace certification frameworks, largely designed around metallic components, require significant adaptation to accommodate the unique characteristics and failure modes of CMCs. The development of industry-wide standards for CMC inspection represents a critical step toward broader adoption of these materials in safety-critical aerospace applications.

This technical research aims to comprehensively evaluate existing inspection technologies, identify promising emerging techniques, and outline potential certification pathways that could accelerate the integration of CMC components into next-generation aircraft systems while maintaining the stringent safety requirements of the aerospace industry.

Market Requirements Analysis for CMC Aerospace Components

The aerospace industry is witnessing a significant shift towards advanced materials, with Ceramic Matrix Composites (CMCs) emerging as critical components for next-generation aircraft engines and structures. Market analysis indicates that the global CMC aerospace components market is projected to grow at a compound annual growth rate of 12.3% through 2030, driven primarily by the increasing demand for fuel-efficient aircraft and stringent emission regulations.

Commercial aviation represents the largest market segment for CMC aerospace components, accounting for approximately 65% of the total market share. Engine manufacturers are particularly interested in CMC applications for turbine blades, combustor liners, and exhaust systems due to their superior temperature resistance and weight reduction capabilities. Boeing and Airbus have both announced plans to incorporate more CMC components in their next-generation aircraft, creating substantial market pull.

Defense aerospace applications constitute the second-largest market segment, with military aircraft manufacturers seeking CMC solutions for enhanced performance in extreme operating conditions. The defense sector values CMC components for their ability to withstand higher temperatures, which translates to increased thrust and operational capabilities for combat aircraft.

Market requirements for CMC aerospace components are increasingly stringent. Airlines and aircraft manufacturers demand components that can reduce fuel consumption by at least 15% compared to traditional nickel-based superalloys. Additionally, there is a growing requirement for CMC parts that can extend maintenance intervals by 25-30%, significantly reducing aircraft downtime and operational costs.

Reliability remains paramount in aerospace applications, with the market demanding CMC components that demonstrate consistent performance over 20,000+ flight hours. This necessitates robust inspection standards and certification pathways that can verify the long-term integrity of these components under various operational conditions.

Environmental regulations are also shaping market requirements, with the International Civil Aviation Organization (ICAO) setting ambitious targets for reducing carbon emissions. CMC components that can withstand higher operating temperatures enable more efficient combustion processes, directly contributing to reduced emissions and helping manufacturers meet these regulatory requirements.

Supply chain considerations have emerged as a critical market factor, with aerospace OEMs requiring suppliers to demonstrate reliable production capabilities and consistent quality. The certification of CMC components requires extensive testing and validation, creating demand for standardized inspection protocols that can be implemented across the global supply chain.

Cost remains a significant barrier to wider adoption, with the market requiring CMC components that can achieve price parity with traditional materials within a reasonable timeframe. Current CMC components can cost 5-8 times more than their metallic counterparts, necessitating innovations in manufacturing processes and inspection techniques to reduce production costs while maintaining quality standards.

Commercial aviation represents the largest market segment for CMC aerospace components, accounting for approximately 65% of the total market share. Engine manufacturers are particularly interested in CMC applications for turbine blades, combustor liners, and exhaust systems due to their superior temperature resistance and weight reduction capabilities. Boeing and Airbus have both announced plans to incorporate more CMC components in their next-generation aircraft, creating substantial market pull.

Defense aerospace applications constitute the second-largest market segment, with military aircraft manufacturers seeking CMC solutions for enhanced performance in extreme operating conditions. The defense sector values CMC components for their ability to withstand higher temperatures, which translates to increased thrust and operational capabilities for combat aircraft.

Market requirements for CMC aerospace components are increasingly stringent. Airlines and aircraft manufacturers demand components that can reduce fuel consumption by at least 15% compared to traditional nickel-based superalloys. Additionally, there is a growing requirement for CMC parts that can extend maintenance intervals by 25-30%, significantly reducing aircraft downtime and operational costs.

Reliability remains paramount in aerospace applications, with the market demanding CMC components that demonstrate consistent performance over 20,000+ flight hours. This necessitates robust inspection standards and certification pathways that can verify the long-term integrity of these components under various operational conditions.

Environmental regulations are also shaping market requirements, with the International Civil Aviation Organization (ICAO) setting ambitious targets for reducing carbon emissions. CMC components that can withstand higher operating temperatures enable more efficient combustion processes, directly contributing to reduced emissions and helping manufacturers meet these regulatory requirements.

Supply chain considerations have emerged as a critical market factor, with aerospace OEMs requiring suppliers to demonstrate reliable production capabilities and consistent quality. The certification of CMC components requires extensive testing and validation, creating demand for standardized inspection protocols that can be implemented across the global supply chain.

Cost remains a significant barrier to wider adoption, with the market requiring CMC components that can achieve price parity with traditional materials within a reasonable timeframe. Current CMC components can cost 5-8 times more than their metallic counterparts, necessitating innovations in manufacturing processes and inspection techniques to reduce production costs while maintaining quality standards.

Current Inspection Challenges and Global Standards

The inspection of Ceramic Matrix Composite (CMC) aero parts presents unique challenges due to the complex microstructure and material properties that differ significantly from traditional metallic components. Current non-destructive testing (NDT) methods often struggle to detect critical defects in CMC materials, particularly internal delaminations, fiber breakage, and matrix cracking that can compromise structural integrity during service.

X-ray computed tomography (CT) has emerged as a primary inspection tool, but faces limitations in resolution when examining large components and struggles with detecting tight cracks parallel to fiber orientation. Additionally, ultrasonic testing encounters significant challenges due to the high acoustic attenuation and complex wave propagation patterns in heterogeneous CMC structures, resulting in signal interpretation difficulties.

Global standardization efforts remain fragmented, with different regulatory bodies establishing varying requirements. The Federal Aviation Administration (FAA) in the United States, the European Union Aviation Safety Agency (EASA), and the Civil Aviation Administration of China (CAAC) each maintain distinct certification pathways for CMC components, creating compliance challenges for manufacturers operating in multiple markets.

Industry standards such as ASTM C1793 and C1819 provide guidelines for CMC material characterization, but comprehensive inspection standards specifically tailored for aerospace applications remain underdeveloped. This regulatory gap has led to inconsistent quality assurance practices across the industry, potentially compromising safety and reliability.

The certification process for CMC aero parts typically requires extensive testing and validation, including material qualification, process control verification, and component-level testing. However, the lack of standardized acceptance criteria for inspection results creates uncertainty in certification outcomes and increases development costs.

Recent collaborative initiatives between aerospace primes, material suppliers, and regulatory bodies aim to establish harmonized inspection protocols. The CMC Aerospace Materials Handbook, developed through industry consortium efforts, represents a step toward standardization but requires broader international adoption.

Emerging technologies such as infrared thermography, digital image correlation, and acoustic emission monitoring show promise for enhancing CMC inspection capabilities, but their integration into certification pathways remains limited by the absence of validated acceptance standards and qualified procedures.

The development of physics-based models and simulation tools to predict defect formation and growth in CMC components offers potential for establishing more robust inspection criteria, though validation of these models against real-world performance data presents ongoing challenges for the industry.

X-ray computed tomography (CT) has emerged as a primary inspection tool, but faces limitations in resolution when examining large components and struggles with detecting tight cracks parallel to fiber orientation. Additionally, ultrasonic testing encounters significant challenges due to the high acoustic attenuation and complex wave propagation patterns in heterogeneous CMC structures, resulting in signal interpretation difficulties.

Global standardization efforts remain fragmented, with different regulatory bodies establishing varying requirements. The Federal Aviation Administration (FAA) in the United States, the European Union Aviation Safety Agency (EASA), and the Civil Aviation Administration of China (CAAC) each maintain distinct certification pathways for CMC components, creating compliance challenges for manufacturers operating in multiple markets.

Industry standards such as ASTM C1793 and C1819 provide guidelines for CMC material characterization, but comprehensive inspection standards specifically tailored for aerospace applications remain underdeveloped. This regulatory gap has led to inconsistent quality assurance practices across the industry, potentially compromising safety and reliability.

The certification process for CMC aero parts typically requires extensive testing and validation, including material qualification, process control verification, and component-level testing. However, the lack of standardized acceptance criteria for inspection results creates uncertainty in certification outcomes and increases development costs.

Recent collaborative initiatives between aerospace primes, material suppliers, and regulatory bodies aim to establish harmonized inspection protocols. The CMC Aerospace Materials Handbook, developed through industry consortium efforts, represents a step toward standardization but requires broader international adoption.

Emerging technologies such as infrared thermography, digital image correlation, and acoustic emission monitoring show promise for enhancing CMC inspection capabilities, but their integration into certification pathways remains limited by the absence of validated acceptance standards and qualified procedures.

The development of physics-based models and simulation tools to predict defect formation and growth in CMC components offers potential for establishing more robust inspection criteria, though validation of these models against real-world performance data presents ongoing challenges for the industry.

Current Inspection and Certification Protocols

01 Non-destructive testing methods for CMC aero parts

Various non-destructive testing methods are employed for inspecting ceramic matrix composite aero parts to ensure their integrity without causing damage. These methods include ultrasonic testing, X-ray computed tomography, infrared thermography, and acoustic emission techniques. These inspection methods help detect defects, delaminations, cracks, and other structural anomalies in CMC components used in aerospace applications, ensuring they meet the required safety and performance standards.- Non-destructive testing methods for CMC aerospace components: Various non-destructive testing methods are employed for inspecting ceramic matrix composite aerospace parts to ensure structural integrity without damaging the components. These methods include ultrasonic testing, X-ray computed tomography, infrared thermography, and acoustic emission techniques. These inspection methods help detect internal defects, delaminations, porosity issues, and other structural anomalies that could compromise the performance of CMC components in aerospace applications.

- Certification standards and regulatory compliance for CMC aerospace parts: Certification pathways for ceramic matrix composite aerospace components involve meeting stringent regulatory requirements established by aviation authorities. This includes compliance with airworthiness directives, quality management systems, and material qualification processes. The certification process typically requires extensive testing, documentation of manufacturing processes, and demonstration of consistent quality control measures to ensure that CMC parts meet performance and safety standards for aerospace applications.

- Manufacturing quality control and inspection protocols for CMC components: Quality control during the manufacturing process of ceramic matrix composite components involves specific inspection protocols at various production stages. This includes raw material verification, process monitoring during composite fabrication, dimensional inspection, and surface finish evaluation. These protocols help ensure that the final CMC aerospace parts meet design specifications and performance requirements, with particular attention to critical features that affect aerodynamic performance and structural integrity.

- Performance testing and validation methods for CMC aero parts: Performance validation of ceramic matrix composite aerospace components involves subjecting the parts to conditions that simulate or exceed operational environments. This includes high-temperature testing, thermal cycling, mechanical load testing, and environmental exposure tests. These validation methods help verify that CMC components can withstand the extreme conditions encountered in aerospace applications, including high temperatures, oxidative environments, and mechanical stresses during flight operations.

- Material characterization and property verification for aerospace CMCs: Material characterization for ceramic matrix composites used in aerospace applications involves comprehensive analysis of physical, chemical, and mechanical properties. This includes microstructural analysis, fiber-matrix interface evaluation, porosity assessment, and determination of thermal and mechanical properties. These characterization methods ensure that the CMC materials meet the required specifications for aerospace use, with particular focus on high-temperature stability, oxidation resistance, and mechanical strength under various operating conditions.

02 Certification standards and regulatory compliance for CMC aerospace components

Certification pathways for ceramic matrix composite aerospace parts involve meeting specific regulatory requirements established by aviation authorities. These standards include material qualification, process validation, quality control procedures, and performance testing under simulated operating conditions. Manufacturers must demonstrate compliance with these standards to obtain certification for CMC components used in aircraft engines and other critical aerospace applications, ensuring they meet stringent safety and reliability requirements.Expand Specific Solutions03 Manufacturing quality control and inspection techniques for CMC components

Quality control during the manufacturing process of ceramic matrix composite components involves specialized inspection techniques to ensure consistent production quality. These techniques include in-process monitoring, dimensional verification, surface finish evaluation, and microstructural analysis. Manufacturers implement rigorous quality control protocols to detect and address manufacturing defects early in the production process, ensuring that finished CMC aero parts meet the required specifications and performance criteria.Expand Specific Solutions04 Material characterization and performance validation for CMC aero applications

Material characterization and performance validation are essential aspects of CMC aero parts inspection and certification. This involves testing the mechanical properties, thermal stability, oxidation resistance, and fatigue behavior of ceramic matrix composites under various operating conditions. Advanced testing methodologies are employed to validate that CMC materials meet the performance requirements for aerospace applications, including high-temperature environments and extreme mechanical loads encountered in aircraft engines.Expand Specific Solutions05 Damage assessment and service life prediction for CMC aerospace components

Damage assessment and service life prediction methodologies are crucial for ensuring the long-term reliability of CMC aerospace components. These approaches involve periodic inspections, damage tolerance evaluation, and predictive modeling to estimate the remaining useful life of components. By implementing comprehensive damage assessment protocols and service life prediction models, manufacturers and operators can establish appropriate maintenance intervals and replacement schedules for CMC aero parts, enhancing safety and operational efficiency.Expand Specific Solutions

Key Industry Players and Certification Bodies

The CMC aero parts inspection and certification landscape is evolving rapidly as the industry transitions from early adoption to commercial implementation. The market is projected to grow significantly as ceramic matrix composites become critical for next-generation aircraft engines, offering weight reduction and higher temperature capabilities. Leading players include established aerospace giants like GE, Safran, and RTX (Pratt & Whitney), who have made substantial investments in CMC technology development. Safran Ceramics has emerged as a specialized entity focused on thermo-structural composites, while Chinese entities like AECC Commercial Aircraft Engine and AVIC Shenyang are accelerating their capabilities. The certification pathways remain challenging, with regulatory bodies working to standardize testing protocols as the technology matures from experimental to production-ready status.

General Electric Company

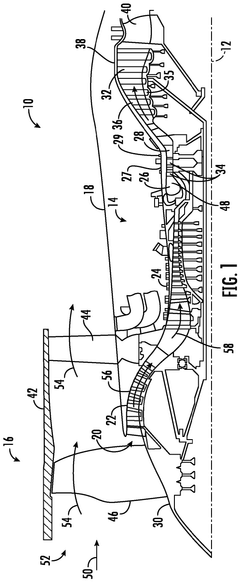

Technical Solution: GE has developed comprehensive inspection standards for CMC (Ceramic Matrix Composites) aero parts through their Advanced Technology Centers. Their approach includes multi-stage quality control processes starting from raw material verification to final component validation. GE utilizes advanced non-destructive testing (NDT) methods including computed tomography (CT) scanning, thermography, and ultrasonic inspection specifically calibrated for CMC microstructures. Their certification pathway involves a stage-gate process with material qualification, process verification, component testing, and system integration validation. GE has established proprietary standards that exceed FAA requirements, particularly for their LEAP engine components where CMCs are used in the high-pressure turbine section. Their certification process includes extensive testing under simulated operating conditions, with components subjected to thermal cycling between -65°F and 2400°F to verify durability and performance consistency.

Strengths: Industry-leading experience with CMC implementation in commercial engines; established relationships with regulatory bodies; comprehensive in-house testing capabilities. Weaknesses: Proprietary standards may limit industry-wide adoption; high certification costs may impact smaller component applications; lengthy qualification timeline compared to traditional materials.

Safran SA

Technical Solution: Safran has established a specialized CMC inspection and certification framework through their dedicated subsidiary, Safran Ceramics. Their approach integrates material science expertise with aerospace certification requirements, focusing on standardized testing protocols for SiC/SiC composites used in engine hot section components. Safran's inspection standards include specialized X-ray diffraction techniques to detect crystallographic defects, laser ultrasonic testing for internal structure analysis, and thermal imaging for stress pattern identification. Their certification pathway follows a three-tier approach: material qualification, manufacturing process certification, and component performance validation. Safran has developed proprietary algorithms for defect characterization that can identify microstructural anomalies as small as 50 microns. Their certification process includes accelerated aging tests that simulate 30,000+ hours of engine operation to validate long-term material stability and performance degradation patterns under various operating conditions.

Strengths: Dedicated CMC research facility with specialized expertise; established European certification pathways through EASA collaboration; vertical integration from material development to component manufacturing. Weaknesses: Standards primarily optimized for their own manufacturing processes; limited public documentation on certification specifics; higher initial certification costs compared to traditional materials.

Critical Technologies for CMC Non-Destructive Testing

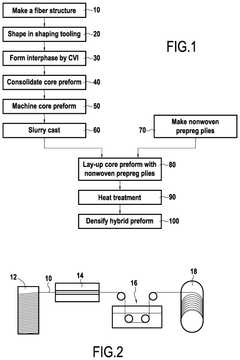

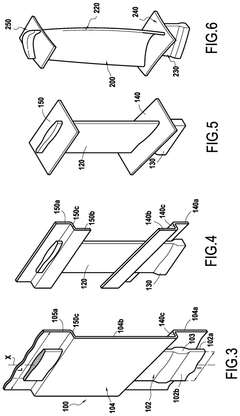

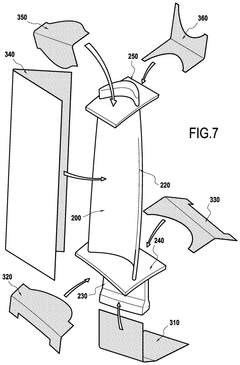

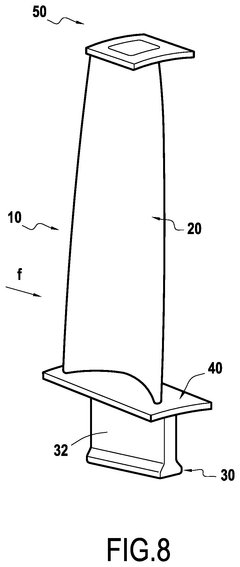

Method for manufacturing a part made from CMC

PatentActiveUS12110256B2

Innovation

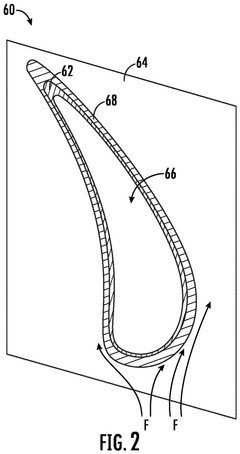

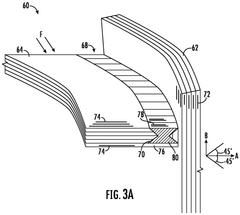

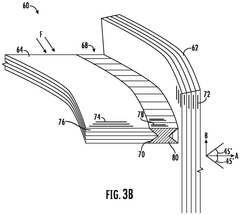

- A process involving three-dimensional or multilayer weaving of fibrous structures, followed by interphase deposition, partial densification, powder deposition in porosity, draping with pre-impregnated non-woven fibers, and heat treatment to form a hybrid fibrous preform, which is then densified using a silicon-based infiltration composition to achieve a smooth surface finish and reduced porosity.

Ceramic matrix composite component repairing and joining

PatentPendingEP4596223A1

Innovation

- The method involves placing joining plies with off-plane fiber directions relative to existing plies to improve laminar organization and infiltration, using a ply stack configuration that alternates fiber directions to enhance structural strength and retention mechanisms, followed by heating processes like melt infiltration or brazing to fuse the plies to the repair area.

Regulatory Compliance Framework for Aerospace Materials

The regulatory landscape for Ceramic Matrix Composites (CMCs) in aerospace applications operates within a complex framework of international and national standards. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) serve as primary regulatory bodies establishing certification requirements for aerospace materials. For CMC aero parts specifically, these agencies have developed specialized guidance materials such as FAA Advisory Circular AC 20-107B and EASA's Certification Memorandum CM-S-004, which address composite structure certification considerations.

Compliance pathways for CMC components typically follow a multi-tiered approach. At the material level, qualification must adhere to standards like RTCA DO-160 for environmental testing and SAE Aerospace Material Specifications (AMS). The material qualification process requires extensive testing to establish design allowables and material property databases, often following the building block approach outlined in CMH-17 (Composite Materials Handbook).

Part-level certification involves demonstrating compliance with airworthiness standards through a combination of analysis, testing, and similarity assessments. For CMC parts, this includes specialized testing protocols for high-temperature performance, oxidation resistance, and thermal cycling durability. Manufacturers must establish process specifications and quality control procedures that ensure consistent production of parts meeting the qualified material properties.

Manufacturing facility certification represents another critical element in the regulatory framework. Production facilities must implement quality management systems compliant with AS9100 aerospace standards, with specific provisions for CMC manufacturing processes. This includes specialized training requirements for personnel involved in CMC fabrication and inspection activities.

Inspection protocols for CMC components present unique challenges due to their heterogeneous structure and high-temperature applications. Non-destructive testing (NDT) methods must be validated specifically for CMC materials, with acceptance criteria established through probability of detection (POD) studies. Regulatory bodies typically require demonstration that inspection techniques can reliably detect critical flaw sizes determined through damage tolerance analysis.

Continued airworthiness requirements constitute the final component of the regulatory framework. Operators must implement inspection and maintenance programs specific to CMC components, accounting for their unique degradation mechanisms and failure modes. This includes establishing inspection intervals based on damage growth models validated through accelerated testing programs.

The regulatory landscape continues to evolve as CMC applications expand beyond traditional high-temperature engine components to primary structure applications, necessitating ongoing dialogue between manufacturers, operators, and certification authorities.

Compliance pathways for CMC components typically follow a multi-tiered approach. At the material level, qualification must adhere to standards like RTCA DO-160 for environmental testing and SAE Aerospace Material Specifications (AMS). The material qualification process requires extensive testing to establish design allowables and material property databases, often following the building block approach outlined in CMH-17 (Composite Materials Handbook).

Part-level certification involves demonstrating compliance with airworthiness standards through a combination of analysis, testing, and similarity assessments. For CMC parts, this includes specialized testing protocols for high-temperature performance, oxidation resistance, and thermal cycling durability. Manufacturers must establish process specifications and quality control procedures that ensure consistent production of parts meeting the qualified material properties.

Manufacturing facility certification represents another critical element in the regulatory framework. Production facilities must implement quality management systems compliant with AS9100 aerospace standards, with specific provisions for CMC manufacturing processes. This includes specialized training requirements for personnel involved in CMC fabrication and inspection activities.

Inspection protocols for CMC components present unique challenges due to their heterogeneous structure and high-temperature applications. Non-destructive testing (NDT) methods must be validated specifically for CMC materials, with acceptance criteria established through probability of detection (POD) studies. Regulatory bodies typically require demonstration that inspection techniques can reliably detect critical flaw sizes determined through damage tolerance analysis.

Continued airworthiness requirements constitute the final component of the regulatory framework. Operators must implement inspection and maintenance programs specific to CMC components, accounting for their unique degradation mechanisms and failure modes. This includes establishing inspection intervals based on damage growth models validated through accelerated testing programs.

The regulatory landscape continues to evolve as CMC applications expand beyond traditional high-temperature engine components to primary structure applications, necessitating ongoing dialogue between manufacturers, operators, and certification authorities.

Risk Management Strategies for CMC Implementation

Implementing Ceramic Matrix Composites (CMCs) in aerospace applications requires comprehensive risk management strategies due to the critical nature of these components. The primary risk categories include material performance variability, manufacturing process inconsistencies, and certification uncertainties. Organizations must develop multi-layered approaches to mitigate these risks throughout the CMC part lifecycle.

Material-related risks can be addressed through rigorous characterization programs that establish statistical databases of material properties across different manufacturing batches. This data-driven approach enables the development of probabilistic design methodologies that account for inherent material variability. Companies should implement strict supplier qualification protocols and maintain ongoing surveillance of raw material quality to ensure consistency.

Manufacturing process risks require detailed process validation protocols with clearly defined control parameters. Statistical Process Control (SPC) methodologies should be implemented to monitor critical process variables and detect deviations before they impact part quality. The establishment of process capability indices for key manufacturing steps provides quantitative measures of process stability and reliability.

Certification risks can be mitigated through early engagement with regulatory authorities and the development of comprehensive certification plans that address the unique characteristics of CMC materials. Building certification experience through phased implementation—starting with less critical components before progressing to primary structures—reduces regulatory uncertainties while building organizational expertise.

Financial risk management strategies should include staged investment approaches that limit exposure until technical and certification milestones are achieved. Cost-sharing partnerships with suppliers, customers, or government agencies can distribute financial risks across the value chain. Additionally, maintaining parallel technology development paths provides fallback options if specific CMC solutions encounter insurmountable challenges.

Operational risk management requires the development of specialized inspection protocols and maintenance procedures tailored to CMC components. Training programs for technical staff must address the unique handling, inspection, and repair requirements of these advanced materials. Organizations should establish clear decision-making frameworks for addressing non-conformances and in-service issues.

Long-term strategic risk management involves continuous technology monitoring to identify emerging alternatives that might disrupt CMC implementation plans. Maintaining flexible manufacturing capabilities that can accommodate evolving CMC formulations and processing methods ensures adaptability to changing technical landscapes and market requirements.

Material-related risks can be addressed through rigorous characterization programs that establish statistical databases of material properties across different manufacturing batches. This data-driven approach enables the development of probabilistic design methodologies that account for inherent material variability. Companies should implement strict supplier qualification protocols and maintain ongoing surveillance of raw material quality to ensure consistency.

Manufacturing process risks require detailed process validation protocols with clearly defined control parameters. Statistical Process Control (SPC) methodologies should be implemented to monitor critical process variables and detect deviations before they impact part quality. The establishment of process capability indices for key manufacturing steps provides quantitative measures of process stability and reliability.

Certification risks can be mitigated through early engagement with regulatory authorities and the development of comprehensive certification plans that address the unique characteristics of CMC materials. Building certification experience through phased implementation—starting with less critical components before progressing to primary structures—reduces regulatory uncertainties while building organizational expertise.

Financial risk management strategies should include staged investment approaches that limit exposure until technical and certification milestones are achieved. Cost-sharing partnerships with suppliers, customers, or government agencies can distribute financial risks across the value chain. Additionally, maintaining parallel technology development paths provides fallback options if specific CMC solutions encounter insurmountable challenges.

Operational risk management requires the development of specialized inspection protocols and maintenance procedures tailored to CMC components. Training programs for technical staff must address the unique handling, inspection, and repair requirements of these advanced materials. Organizations should establish clear decision-making frameworks for addressing non-conformances and in-service issues.

Long-term strategic risk management involves continuous technology monitoring to identify emerging alternatives that might disrupt CMC implementation plans. Maintaining flexible manufacturing capabilities that can accommodate evolving CMC formulations and processing methods ensures adaptability to changing technical landscapes and market requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!