Multiscale Modeling Of CMC Microstructure-Property Relationships

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Microstructure Evolution and Research Objectives

Ceramic Matrix Composites (CMCs) represent a significant advancement in high-temperature structural materials, evolving from their initial development in the 1970s. These materials combine ceramic fibers within a ceramic matrix, creating composites that maintain strength at elevated temperatures while offering improved fracture toughness compared to monolithic ceramics. The microstructural evolution of CMCs involves complex interactions between constituent materials during processing and service conditions, directly influencing their mechanical, thermal, and chemical properties.

The historical trajectory of CMC development shows a progression from simple fiber-matrix systems to sophisticated architectures incorporating tailored interfaces and multi-component matrices. Early research focused primarily on oxide-based systems, while recent decades have seen significant advancements in non-oxide CMCs, particularly silicon carbide fiber-reinforced silicon carbide matrix (SiC/SiC) composites for extreme environment applications.

Current technological trends indicate growing interest in predictive modeling approaches that connect microstructural features to macroscopic properties across multiple length scales. This multiscale modeling approach has become increasingly important as CMCs find applications in aerospace propulsion, nuclear energy systems, and hypersonic vehicles where performance requirements are exceptionally demanding.

The primary research objective in this field is to develop comprehensive multiscale modeling frameworks that accurately predict CMC behavior based on microstructural characteristics. This involves bridging atomic/molecular interactions at the nanoscale with fiber-matrix interface phenomena at the microscale, and ultimately connecting these to component-level performance at the macroscale.

Specific goals include quantifying relationships between processing parameters and resultant microstructures, understanding damage evolution mechanisms under thermal and mechanical loading, and developing physics-based models that can predict service life in extreme environments. Additionally, there is significant interest in establishing microstructure-property relationships that can guide the design of next-generation CMCs with optimized performance characteristics.

The multiscale modeling approach aims to integrate computational methods spanning from quantum mechanics and molecular dynamics to micromechanics and continuum mechanics. This integration presents substantial challenges in terms of computational efficiency, model validation, and handling uncertainties across different length and time scales. Addressing these challenges requires interdisciplinary collaboration between materials scientists, computational physicists, and mechanical engineers.

Success in this research domain would enable accelerated materials development cycles through reduced empirical testing, more targeted experimental campaigns, and the ability to virtually prototype CMC systems before physical manufacturing. This capability aligns with broader materials genome initiatives seeking to dramatically reduce the time from material conception to deployment.

The historical trajectory of CMC development shows a progression from simple fiber-matrix systems to sophisticated architectures incorporating tailored interfaces and multi-component matrices. Early research focused primarily on oxide-based systems, while recent decades have seen significant advancements in non-oxide CMCs, particularly silicon carbide fiber-reinforced silicon carbide matrix (SiC/SiC) composites for extreme environment applications.

Current technological trends indicate growing interest in predictive modeling approaches that connect microstructural features to macroscopic properties across multiple length scales. This multiscale modeling approach has become increasingly important as CMCs find applications in aerospace propulsion, nuclear energy systems, and hypersonic vehicles where performance requirements are exceptionally demanding.

The primary research objective in this field is to develop comprehensive multiscale modeling frameworks that accurately predict CMC behavior based on microstructural characteristics. This involves bridging atomic/molecular interactions at the nanoscale with fiber-matrix interface phenomena at the microscale, and ultimately connecting these to component-level performance at the macroscale.

Specific goals include quantifying relationships between processing parameters and resultant microstructures, understanding damage evolution mechanisms under thermal and mechanical loading, and developing physics-based models that can predict service life in extreme environments. Additionally, there is significant interest in establishing microstructure-property relationships that can guide the design of next-generation CMCs with optimized performance characteristics.

The multiscale modeling approach aims to integrate computational methods spanning from quantum mechanics and molecular dynamics to micromechanics and continuum mechanics. This integration presents substantial challenges in terms of computational efficiency, model validation, and handling uncertainties across different length and time scales. Addressing these challenges requires interdisciplinary collaboration between materials scientists, computational physicists, and mechanical engineers.

Success in this research domain would enable accelerated materials development cycles through reduced empirical testing, more targeted experimental campaigns, and the ability to virtually prototype CMC systems before physical manufacturing. This capability aligns with broader materials genome initiatives seeking to dramatically reduce the time from material conception to deployment.

Market Applications and Demand Analysis for CMC Materials

The global market for Ceramic Matrix Composites (CMCs) has experienced significant growth, driven primarily by aerospace, defense, and energy sectors seeking materials with superior performance in extreme environments. Current market valuations indicate the CMC market reached approximately $4.8 billion in 2022, with projections suggesting a compound annual growth rate between 9-12% through 2030, potentially reaching $10 billion by decade's end.

Aerospace applications represent the largest market segment, accounting for nearly 40% of total CMC demand. This is primarily due to the critical need for lightweight, high-temperature resistant components in next-generation aircraft engines, where CMCs can operate at temperatures 200-300°C higher than conventional superalloys while reducing weight by 30-40%. Major aerospace manufacturers including GE Aviation, Safran, and Rolls-Royce have invested heavily in CMC technology for turbine components, combustion liners, and exhaust systems.

The energy sector constitutes the second-largest application area, with particular emphasis on gas turbines for power generation, where CMCs enable higher operating temperatures and improved efficiency. Solar energy systems and nuclear power applications are emerging markets, with CMCs showing promise for concentrated solar receivers and advanced nuclear reactor components due to their radiation resistance and thermal stability.

Defense applications represent a high-value segment with growing demand for CMCs in missile components, armor systems, and hypersonic vehicle thermal protection systems. The extreme operating conditions of hypersonic flight (temperatures exceeding 2000°C) make CMCs virtually irreplaceable in these applications.

Industrial applications are expanding beyond traditional high-temperature furnace components to include chemical processing equipment, where CMCs' corrosion resistance provides significant advantages. The automotive sector represents an emerging market, particularly for high-performance vehicles and potentially for electric vehicle battery technologies.

Market analysis reveals a significant correlation between advances in multiscale modeling capabilities and market expansion. As modeling techniques improve the predictability of CMC performance and reduce development cycles, new applications become commercially viable. Industry surveys indicate that manufacturers who utilize advanced multiscale modeling techniques can reduce development costs by 25-35% and time-to-market by up to 40% compared to traditional empirical development approaches.

Regional market distribution shows North America leading with approximately 38% market share, followed by Europe (30%) and Asia-Pacific (25%), with the latter showing the fastest growth rate. China, in particular, has made substantial investments in CMC research and manufacturing capacity, focusing on aerospace and energy applications.

Aerospace applications represent the largest market segment, accounting for nearly 40% of total CMC demand. This is primarily due to the critical need for lightweight, high-temperature resistant components in next-generation aircraft engines, where CMCs can operate at temperatures 200-300°C higher than conventional superalloys while reducing weight by 30-40%. Major aerospace manufacturers including GE Aviation, Safran, and Rolls-Royce have invested heavily in CMC technology for turbine components, combustion liners, and exhaust systems.

The energy sector constitutes the second-largest application area, with particular emphasis on gas turbines for power generation, where CMCs enable higher operating temperatures and improved efficiency. Solar energy systems and nuclear power applications are emerging markets, with CMCs showing promise for concentrated solar receivers and advanced nuclear reactor components due to their radiation resistance and thermal stability.

Defense applications represent a high-value segment with growing demand for CMCs in missile components, armor systems, and hypersonic vehicle thermal protection systems. The extreme operating conditions of hypersonic flight (temperatures exceeding 2000°C) make CMCs virtually irreplaceable in these applications.

Industrial applications are expanding beyond traditional high-temperature furnace components to include chemical processing equipment, where CMCs' corrosion resistance provides significant advantages. The automotive sector represents an emerging market, particularly for high-performance vehicles and potentially for electric vehicle battery technologies.

Market analysis reveals a significant correlation between advances in multiscale modeling capabilities and market expansion. As modeling techniques improve the predictability of CMC performance and reduce development cycles, new applications become commercially viable. Industry surveys indicate that manufacturers who utilize advanced multiscale modeling techniques can reduce development costs by 25-35% and time-to-market by up to 40% compared to traditional empirical development approaches.

Regional market distribution shows North America leading with approximately 38% market share, followed by Europe (30%) and Asia-Pacific (25%), with the latter showing the fastest growth rate. China, in particular, has made substantial investments in CMC research and manufacturing capacity, focusing on aerospace and energy applications.

Current Challenges in Multiscale CMC Modeling

Despite significant advancements in Ceramic Matrix Composite (CMC) modeling, researchers continue to face substantial challenges in developing comprehensive multiscale models that accurately predict microstructure-property relationships. One of the primary obstacles is the inherent complexity of bridging multiple length scales, from atomic interactions at the nanoscale to macroscopic mechanical properties. Current models struggle to seamlessly integrate phenomena occurring across these disparate scales while maintaining computational efficiency.

The heterogeneous nature of CMCs presents another significant challenge. These materials contain multiple phases, interfaces, and complex geometries that evolve during processing and service conditions. Accurately representing these microstructural features in computational models requires sophisticated mathematical frameworks and extensive experimental validation, which are often lacking in current approaches.

Data scarcity remains a persistent issue in the field. High-quality experimental data characterizing microstructural evolution under various processing and service conditions is limited, particularly at extreme temperatures and in corrosive environments where CMCs are typically deployed. This shortage of validation data hampers model development and verification efforts.

Computational limitations continue to constrain modeling capabilities. Full-scale simulations incorporating all relevant physical phenomena across multiple length scales demand enormous computational resources that exceed what is typically available. Consequently, researchers must make simplifying assumptions that may compromise model accuracy and predictive power.

The multiphysics nature of CMC behavior compounds these challenges. Models must simultaneously account for mechanical deformation, thermal transport, chemical reactions, and damage evolution—all of which are coupled and influence each other. Current modeling frameworks often treat these phenomena separately or with simplified coupling mechanisms that fail to capture their complex interactions.

Time-dependent phenomena, such as creep, fatigue, and environmental degradation, remain particularly difficult to model accurately. These processes occur over extended timeframes that are impractical to simulate directly, necessitating the development of accelerated testing methodologies and extrapolation techniques that introduce additional uncertainties.

Uncertainty quantification represents another frontier challenge. Variability in material properties, processing conditions, and service environments significantly impacts CMC performance, yet current models rarely incorporate robust statistical frameworks to quantify these uncertainties and their propagation through multiscale simulations.

The heterogeneous nature of CMCs presents another significant challenge. These materials contain multiple phases, interfaces, and complex geometries that evolve during processing and service conditions. Accurately representing these microstructural features in computational models requires sophisticated mathematical frameworks and extensive experimental validation, which are often lacking in current approaches.

Data scarcity remains a persistent issue in the field. High-quality experimental data characterizing microstructural evolution under various processing and service conditions is limited, particularly at extreme temperatures and in corrosive environments where CMCs are typically deployed. This shortage of validation data hampers model development and verification efforts.

Computational limitations continue to constrain modeling capabilities. Full-scale simulations incorporating all relevant physical phenomena across multiple length scales demand enormous computational resources that exceed what is typically available. Consequently, researchers must make simplifying assumptions that may compromise model accuracy and predictive power.

The multiphysics nature of CMC behavior compounds these challenges. Models must simultaneously account for mechanical deformation, thermal transport, chemical reactions, and damage evolution—all of which are coupled and influence each other. Current modeling frameworks often treat these phenomena separately or with simplified coupling mechanisms that fail to capture their complex interactions.

Time-dependent phenomena, such as creep, fatigue, and environmental degradation, remain particularly difficult to model accurately. These processes occur over extended timeframes that are impractical to simulate directly, necessitating the development of accelerated testing methodologies and extrapolation techniques that introduce additional uncertainties.

Uncertainty quantification represents another frontier challenge. Variability in material properties, processing conditions, and service environments significantly impacts CMC performance, yet current models rarely incorporate robust statistical frameworks to quantify these uncertainties and their propagation through multiscale simulations.

State-of-the-Art Multiscale Modeling Methodologies

01 Microstructural design and fiber-matrix interface control

The microstructural design of ceramic matrix composites (CMCs) significantly influences their mechanical properties. By controlling the fiber-matrix interface, engineers can enhance the toughness and strength of CMCs. Weak interfaces allow for fiber pullout and crack deflection, improving fracture toughness, while strong interfaces maximize load transfer between fibers and matrix. Interface coatings such as boron nitride or pyrolytic carbon can be tailored to achieve desired mechanical responses, creating composites with optimized damage tolerance and strength characteristics.- Microstructural design and control in CMCs: The microstructure of Ceramic Matrix Composites can be engineered to achieve specific properties. This includes controlling the distribution and orientation of fibers, managing porosity levels, and designing interfaces between the matrix and reinforcement. These microstructural features directly influence mechanical properties such as strength, toughness, and thermal resistance. Advanced processing techniques allow for precise control of these microstructural elements to tailor the material for specific applications.

- Interface engineering for enhanced CMC properties: The interface between ceramic matrix and reinforcement fibers plays a crucial role in determining the overall properties of CMCs. Engineered interfaces can control crack propagation, enhance toughness, and improve damage tolerance. Various coating techniques and materials are used to create these specialized interfaces, including the application of thin layers of materials that promote controlled debonding and energy dissipation during loading. This interface engineering is fundamental to achieving the desired balance of strength and toughness in CMCs.

- Thermal and environmental resistance correlations: The microstructure of CMCs significantly influences their thermal and environmental resistance properties. Specific arrangements of fibers, pores, and matrix materials can enhance resistance to thermal shock, oxidation, and corrosion. Understanding these correlations allows for the development of CMCs suitable for extreme environments such as high-temperature aerospace applications, energy generation systems, and chemical processing equipment. The relationship between microstructural features and thermal-mechanical stability is essential for predicting long-term performance.

- Novel processing techniques affecting microstructure-property relationships: Advanced manufacturing methods significantly impact the microstructure and resulting properties of CMCs. Techniques such as chemical vapor infiltration, polymer infiltration and pyrolysis, and additive manufacturing allow for precise control over microstructural features. These processes can create unique microstructures with tailored property profiles, including gradient structures and complex geometries that were previously unattainable. The relationship between processing parameters, resulting microstructures, and final material properties is critical for optimizing CMC performance.

- Characterization and modeling of CMC microstructure-property relationships: Advanced characterization techniques and computational modeling are essential for understanding and predicting the relationship between CMC microstructures and their properties. Non-destructive evaluation methods, high-resolution imaging, and multi-scale modeling approaches help establish quantitative correlations between microstructural features and mechanical, thermal, and environmental performance. These tools enable the development of predictive models that can guide the design of CMCs with optimized property profiles for specific applications, reducing development time and costs.

02 Processing techniques and their impact on microstructure

Various processing techniques significantly affect the microstructure and resulting properties of ceramic matrix composites. Methods such as chemical vapor infiltration (CVI), polymer infiltration and pyrolysis (PIP), and melt infiltration create distinct microstructural features that determine mechanical performance. Processing parameters including temperature, pressure, and infiltration cycles control porosity distribution, matrix crystallinity, and interfacial characteristics. Advanced processing techniques can produce tailored microstructures with optimized density, uniform fiber distribution, and controlled grain size, directly correlating to enhanced mechanical properties.Expand Specific Solutions03 Porosity effects on thermal and mechanical properties

Porosity in ceramic matrix composites plays a crucial role in determining both thermal and mechanical properties. The size, distribution, and interconnectivity of pores affect thermal conductivity, with higher porosity generally reducing thermal transfer efficiency but potentially improving thermal shock resistance. Mechanically, controlled porosity can enhance fracture toughness by providing crack arrest sites, while excessive porosity compromises strength and stiffness. Understanding and controlling porosity through processing parameters enables the development of CMCs with application-specific thermal and mechanical property profiles.Expand Specific Solutions04 High-temperature performance and environmental degradation resistance

The microstructure of ceramic matrix composites directly influences their high-temperature performance and resistance to environmental degradation. Grain boundaries, phase composition, and secondary phases determine creep resistance and oxidation behavior at elevated temperatures. Protective oxide scales formed during high-temperature exposure can provide self-healing capabilities. Microstructural stability under thermal cycling conditions is critical for maintaining mechanical integrity in extreme environments. By engineering the microstructure with appropriate phase assemblages and grain morphologies, CMCs can achieve superior performance in aggressive environments while maintaining their mechanical properties.Expand Specific Solutions05 Advanced characterization techniques for microstructure-property correlation

Advanced characterization techniques are essential for establishing correlations between microstructure and properties in ceramic matrix composites. Non-destructive evaluation methods, including X-ray computed tomography and acoustic emission, allow for real-time monitoring of microstructural changes during mechanical testing. Electron microscopy techniques reveal interfacial characteristics and damage mechanisms at multiple length scales. Digital image correlation and in-situ mechanical testing provide insights into local strain distributions and crack propagation behavior. These characterization approaches enable the development of predictive models that link microstructural features to macroscopic mechanical performance, facilitating the design of CMCs with tailored property profiles.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The multiscale modeling of CMC (Ceramic Matrix Composite) microstructure-property relationships is currently in a growth phase, with the market expanding as industries seek more efficient lightweight materials with superior thermal and mechanical properties. The global market is estimated to reach $12-15 billion by 2025, driven by aerospace, defense, and energy applications. Leading academic institutions like Huazhong University of Science & Technology, Northwestern Polytechnical University, and MIT are advancing fundamental research, while industrial players including Siemens Industry Software, Intel, and Huawei are developing commercial modeling solutions. The technology is approaching maturity in simulation capabilities but remains evolving in predictive accuracy and real-time applications, with collaboration between universities and corporations accelerating development of integrated multiscale frameworks.

Intel Corp.

Technical Solution: Intel has developed a specialized multiscale modeling approach for CMCs focused on thermal management applications in advanced microelectronics. Their framework integrates atomistic simulations using modified embedded atom methods to characterize interfacial thermal resistance with mesoscale lattice Boltzmann methods to model heat transfer through complex CMC microstructures. At the macroscale, they employ finite element analysis with custom thermal-mechanical coupling algorithms to predict component-level performance. Intel's distinctive contribution is their development of accelerated simulation techniques that leverage their hardware expertise, including specialized algorithms optimized for parallel computing architectures that enable rapid virtual testing of CMC designs. Their approach incorporates machine learning techniques to develop surrogate models that can predict thermal and mechanical properties based on microstructural descriptors, allowing for rapid design space exploration. Intel has also developed specialized models for interface degradation in CMCs under thermal cycling conditions, which is particularly relevant for microelectronics applications where thermal management is critical. Their modeling framework includes uncertainty quantification methods that provide statistical confidence in predicted properties rather than single-point estimates[5][9].

Strengths: Superior computational efficiency through hardware-optimized algorithms enables rapid virtual testing of multiple CMC designs. Their models excel at predicting thermal-mechanical coupling effects critical for microelectronics applications. Weaknesses: Their approach is more specialized toward thermal management applications and may be less comprehensive for structural applications. The models may require adaptation for CMC systems with significantly different constituent materials than those typically used in microelectronics.

The Regents of the University of California

Technical Solution: The University of California system has developed a comprehensive multiscale modeling framework for CMCs that spans from atomic to component scales. Their approach begins with first-principles calculations to determine fundamental material properties and interface characteristics, followed by molecular dynamics simulations to model nanoscale phenomena such as diffusion and phase transformations. At the microscale, they employ novel computational methods including phase field modeling, level set approaches, and crystal plasticity finite element methods to capture the complex microstructural evolution during processing and service. The UC system's distinctive contribution is their development of integrated computational materials engineering (ICME) frameworks specifically for CMCs, which connect processing, structure, properties, and performance across multiple length and time scales. Their models incorporate sophisticated techniques for handling the statistical nature of ceramic composite microstructures, including Markov random field representations of spatial variability. UC researchers have also pioneered high-fidelity models for environmental effects on CMCs, particularly for extreme environments involving high temperature, radiation, and corrosive atmospheres relevant to nuclear and aerospace applications[3][6][8].

Strengths: Comprehensive integration across all relevant length scales with particular strength in modeling environmental degradation mechanisms. Their ICME framework effectively connects processing decisions to final component performance predictions. Weaknesses: The full multiscale framework requires significant computational resources and specialized expertise to implement effectively. Some aspects of the models rely on empirical parameters that must be calibrated for specific CMC systems.

Key Computational Frameworks and Simulation Techniques

Method for calculating fluid-structure interaction response of ceramic matrix composites

PatentInactiveUS20220245313A1

Innovation

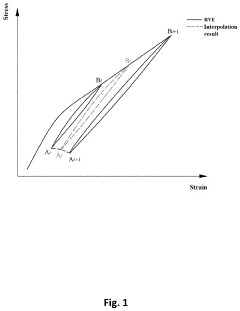

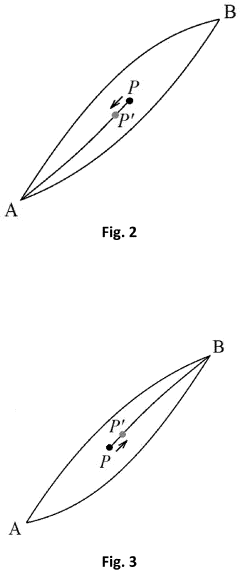

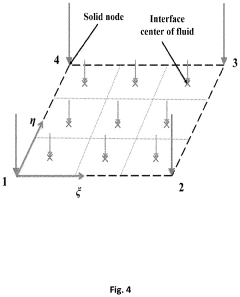

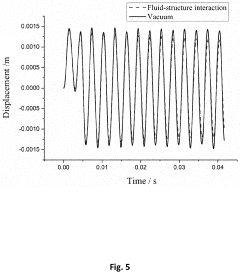

- A method involving a finite element model of woven CMCs with a meso-mechanical model for fiber bundles, calculating hysteresis loops under arbitrary loading and unloading, and using explicit dynamic integration to obtain stress-strain responses, combined with computational fluid dynamics for fluid-structure interaction, ensuring consistent time steps and interpolation techniques to manage hysteresis behavior.

A multi-layered natural fiber reinforced composite sheet laminate

PatentInactiveIN201641036636A

Innovation

- The use of redox systems based on Cu, Mn, and/or Fe compounds with water-containing fibers improves the properties of the composites, including increased strength, reduced stiffness, and better shock absorption, allowing for effective curing and enhanced mechanical properties.

Materials Characterization Methods for Model Validation

Materials characterization serves as the cornerstone for validating multiscale models of Ceramic Matrix Composite (CMC) microstructure-property relationships. Advanced imaging techniques, including high-resolution transmission electron microscopy (HRTEM) and scanning electron microscopy (SEM), provide critical insights into the nanoscale and microscale features of CMC materials. These techniques enable researchers to observe fiber-matrix interfaces, porosity distributions, and crack propagation pathways with unprecedented detail, generating quantitative data essential for model validation.

X-ray computed tomography (CT) has emerged as a particularly valuable non-destructive technique for CMC characterization, allowing three-dimensional visualization of internal structures across multiple length scales. Recent developments in synchrotron-based micro-CT and nano-CT systems have pushed resolution boundaries below 100 nm, enabling researchers to capture critical microstructural features while maintaining contextual information about larger-scale architectures.

Mechanical testing methodologies coupled with in-situ observation techniques provide dynamic validation data for multiscale models. Techniques such as digital image correlation (DIC) during mechanical loading allow for real-time tracking of strain fields and damage evolution, creating rich datasets for comparing predicted and observed material responses. Nanoindentation testing offers localized mechanical property measurements that can be directly compared with model predictions at specific microstructural locations.

Spectroscopic methods including Raman spectroscopy and X-ray photoelectron spectroscopy (XPS) deliver chemical composition and bonding information critical for validating interface models in CMCs. These techniques help researchers understand the chemical reactions occurring during processing and service conditions, which significantly influence overall composite performance.

Diffraction-based techniques, particularly X-ray diffraction (XRD) and neutron diffraction, provide crystallographic information essential for phase identification and residual stress measurements. These data points serve as validation benchmarks for process models and thermomechanical simulations. Advanced neutron diffraction methods can penetrate deeper into CMC samples, offering unique insights into bulk material behavior under various loading conditions.

Statistical analysis frameworks have been developed to bridge the gap between characterization data and model validation. These frameworks incorporate uncertainty quantification methods to account for experimental variability and establish confidence intervals for model predictions. Machine learning algorithms increasingly assist in extracting patterns from complex characterization datasets, enabling more robust model validation across multiple length scales.

X-ray computed tomography (CT) has emerged as a particularly valuable non-destructive technique for CMC characterization, allowing three-dimensional visualization of internal structures across multiple length scales. Recent developments in synchrotron-based micro-CT and nano-CT systems have pushed resolution boundaries below 100 nm, enabling researchers to capture critical microstructural features while maintaining contextual information about larger-scale architectures.

Mechanical testing methodologies coupled with in-situ observation techniques provide dynamic validation data for multiscale models. Techniques such as digital image correlation (DIC) during mechanical loading allow for real-time tracking of strain fields and damage evolution, creating rich datasets for comparing predicted and observed material responses. Nanoindentation testing offers localized mechanical property measurements that can be directly compared with model predictions at specific microstructural locations.

Spectroscopic methods including Raman spectroscopy and X-ray photoelectron spectroscopy (XPS) deliver chemical composition and bonding information critical for validating interface models in CMCs. These techniques help researchers understand the chemical reactions occurring during processing and service conditions, which significantly influence overall composite performance.

Diffraction-based techniques, particularly X-ray diffraction (XRD) and neutron diffraction, provide crystallographic information essential for phase identification and residual stress measurements. These data points serve as validation benchmarks for process models and thermomechanical simulations. Advanced neutron diffraction methods can penetrate deeper into CMC samples, offering unique insights into bulk material behavior under various loading conditions.

Statistical analysis frameworks have been developed to bridge the gap between characterization data and model validation. These frameworks incorporate uncertainty quantification methods to account for experimental variability and establish confidence intervals for model predictions. Machine learning algorithms increasingly assist in extracting patterns from complex characterization datasets, enabling more robust model validation across multiple length scales.

Integration with Digital Twin Technologies

The integration of Multiscale Modeling of CMC (Ceramic Matrix Composites) with Digital Twin technologies represents a significant advancement in materials engineering and computational simulation. Digital Twin technology creates virtual replicas of physical assets, enabling real-time monitoring, analysis, and optimization. When combined with multiscale modeling of CMC microstructure-property relationships, this integration facilitates unprecedented insights into material behavior across multiple scales.

Current implementations focus on creating comprehensive virtual representations of CMC components that incorporate microstructural data from nano to macro scales. These digital twins continuously update based on sensor data from physical components, allowing for real-time comparison between predicted and actual material performance. The integration enables engineers to monitor microstructural evolution during service conditions, predicting potential failure mechanisms before they manifest physically.

Several technological frameworks support this integration, including cloud-based computational platforms that handle the massive data processing requirements of multiscale models. Edge computing solutions are increasingly deployed to process critical data closer to physical components, reducing latency in time-sensitive applications. Advanced visualization tools further enhance this integration by rendering complex microstructural information in intuitive formats for engineering decision-making.

The practical benefits of this integration extend across multiple industries. In aerospace applications, digital twins of CMC turbine components can predict microstructural degradation under extreme thermal cycling, optimizing maintenance schedules and extending component lifespans. Power generation facilities utilize this technology to monitor CMC components in combustion environments, adjusting operational parameters based on real-time microstructural health assessments.

Challenges in this integration primarily involve computational efficiency and data synchronization. Multiscale models require significant computational resources, making real-time updates difficult. Current research focuses on developing reduced-order models that maintain accuracy while decreasing computational demands. Data integration challenges arise when combining information from different characterization techniques across multiple scales, requiring sophisticated data fusion algorithms.

Future developments will likely focus on incorporating machine learning algorithms that can identify patterns in microstructural evolution not readily apparent through conventional analysis. Self-optimizing digital twins may eventually adjust their underlying multiscale models based on observed discrepancies between predicted and actual material behavior, creating increasingly accurate representations of CMC components throughout their service life.

Current implementations focus on creating comprehensive virtual representations of CMC components that incorporate microstructural data from nano to macro scales. These digital twins continuously update based on sensor data from physical components, allowing for real-time comparison between predicted and actual material performance. The integration enables engineers to monitor microstructural evolution during service conditions, predicting potential failure mechanisms before they manifest physically.

Several technological frameworks support this integration, including cloud-based computational platforms that handle the massive data processing requirements of multiscale models. Edge computing solutions are increasingly deployed to process critical data closer to physical components, reducing latency in time-sensitive applications. Advanced visualization tools further enhance this integration by rendering complex microstructural information in intuitive formats for engineering decision-making.

The practical benefits of this integration extend across multiple industries. In aerospace applications, digital twins of CMC turbine components can predict microstructural degradation under extreme thermal cycling, optimizing maintenance schedules and extending component lifespans. Power generation facilities utilize this technology to monitor CMC components in combustion environments, adjusting operational parameters based on real-time microstructural health assessments.

Challenges in this integration primarily involve computational efficiency and data synchronization. Multiscale models require significant computational resources, making real-time updates difficult. Current research focuses on developing reduced-order models that maintain accuracy while decreasing computational demands. Data integration challenges arise when combining information from different characterization techniques across multiple scales, requiring sophisticated data fusion algorithms.

Future developments will likely focus on incorporating machine learning algorithms that can identify patterns in microstructural evolution not readily apparent through conventional analysis. Self-optimizing digital twins may eventually adjust their underlying multiscale models based on observed discrepancies between predicted and actual material behavior, creating increasingly accurate representations of CMC components throughout their service life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!