Ceramic Matrix Composites For Hot Section Aero Turbine Applications

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMC Technology Background and Objectives

Ceramic Matrix Composites (CMCs) represent a revolutionary class of materials that have evolved significantly over the past four decades. Initially developed in the 1970s for space applications, CMCs have gradually transitioned into the aerospace sector, particularly for hot section components in gas turbine engines. These advanced materials combine ceramic fibers within a ceramic matrix, offering exceptional high-temperature capabilities while maintaining mechanical integrity under extreme conditions.

The evolution of CMC technology has been marked by several significant milestones. Early developments focused primarily on silicon carbide (SiC) and carbon fiber reinforced carbon (C/C) composites. By the 1990s, research expanded to include oxide-based CMCs, which offered improved oxidation resistance. The 2000s witnessed substantial advancements in manufacturing processes, enabling more complex geometries and improved reliability, critical factors for aerospace applications.

Current technological trends in CMC development are centered on enhancing temperature capabilities beyond 1300°C, improving damage tolerance mechanisms, and developing more cost-effective manufacturing processes. The integration of computational modeling with experimental validation has accelerated development cycles, allowing for more rapid iteration and optimization of material compositions and architectures.

The primary objective of CMC technology for hot section aero turbine applications is to replace traditional nickel-based superalloys, which have nearly reached their theoretical temperature limits. By implementing CMCs, engine designers aim to achieve operating temperatures 150-200°C higher than current metallic components permit, without requiring complex cooling systems that reduce overall engine efficiency.

Additional technical goals include weight reduction of 30-40% compared to metal components, which translates directly to fuel efficiency improvements; extending component lifespans by 2-3 times current standards through superior thermal fatigue resistance; and reducing cooling air requirements by up to 50%, allowing for more efficient combustion processes and lower emissions.

The long-term vision for CMC technology encompasses full integration into next-generation aircraft engines, enabling higher thrust-to-weight ratios, reduced fuel consumption, and lower maintenance costs. Research institutions and aerospace manufacturers are collaboratively working toward standardizing CMC design methodologies and testing protocols to facilitate broader industry adoption. As environmental regulations become increasingly stringent, the ability of CMCs to contribute to more efficient, cleaner-burning engines aligns perfectly with global sustainability initiatives in aviation.

The evolution of CMC technology has been marked by several significant milestones. Early developments focused primarily on silicon carbide (SiC) and carbon fiber reinforced carbon (C/C) composites. By the 1990s, research expanded to include oxide-based CMCs, which offered improved oxidation resistance. The 2000s witnessed substantial advancements in manufacturing processes, enabling more complex geometries and improved reliability, critical factors for aerospace applications.

Current technological trends in CMC development are centered on enhancing temperature capabilities beyond 1300°C, improving damage tolerance mechanisms, and developing more cost-effective manufacturing processes. The integration of computational modeling with experimental validation has accelerated development cycles, allowing for more rapid iteration and optimization of material compositions and architectures.

The primary objective of CMC technology for hot section aero turbine applications is to replace traditional nickel-based superalloys, which have nearly reached their theoretical temperature limits. By implementing CMCs, engine designers aim to achieve operating temperatures 150-200°C higher than current metallic components permit, without requiring complex cooling systems that reduce overall engine efficiency.

Additional technical goals include weight reduction of 30-40% compared to metal components, which translates directly to fuel efficiency improvements; extending component lifespans by 2-3 times current standards through superior thermal fatigue resistance; and reducing cooling air requirements by up to 50%, allowing for more efficient combustion processes and lower emissions.

The long-term vision for CMC technology encompasses full integration into next-generation aircraft engines, enabling higher thrust-to-weight ratios, reduced fuel consumption, and lower maintenance costs. Research institutions and aerospace manufacturers are collaboratively working toward standardizing CMC design methodologies and testing protocols to facilitate broader industry adoption. As environmental regulations become increasingly stringent, the ability of CMCs to contribute to more efficient, cleaner-burning engines aligns perfectly with global sustainability initiatives in aviation.

Market Demand Analysis for Aerospace Turbine Materials

The aerospace turbine materials market is experiencing significant growth driven by increasing demand for fuel-efficient aircraft engines with higher operating temperatures. The global market for high-temperature aerospace materials was valued at approximately $4.5 billion in 2022 and is projected to reach $7.2 billion by 2030, representing a compound annual growth rate of 6.1%. This growth is primarily fueled by the expanding commercial aviation sector and increasing defense budgets worldwide.

Ceramic Matrix Composites (CMCs) are emerging as a critical segment within this market, with their specific demand growing at nearly 8.5% annually. This accelerated adoption is driven by the superior performance of CMCs in hot section components of aero turbines, where traditional superalloys reach their operational limits. Industry analysts estimate that CMCs could replace up to 30% of nickel-based superalloy components in next-generation turbine engines.

The commercial aviation sector represents the largest market segment for CMCs in turbine applications, accounting for approximately 65% of the total demand. Major aircraft manufacturers have committed to reducing fuel consumption by 15-20% in their next-generation aircraft, creating strong market pull for advanced materials like CMCs that can withstand higher operating temperatures and reduce engine weight.

Defense applications constitute roughly 35% of the market, with military aircraft engines requiring materials capable of withstanding extreme thermal conditions and offering enhanced durability. The F135 engine program alone has created a market opportunity exceeding $300 million for CMC components over the next decade.

Regional analysis indicates North America leads the market with a 42% share, followed by Europe (31%) and Asia-Pacific (21%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate at 9.3% annually through 2030, driven by China's and India's expanding aerospace industries and increasing defense modernization programs.

Key market drivers include stringent environmental regulations mandating reduced emissions, which necessitate higher operating temperatures for improved thermodynamic efficiency. Additionally, the industry-wide focus on reducing the weight of aircraft components to improve fuel efficiency has created strong demand for lightweight materials like CMCs, which offer 30-40% weight reduction compared to metallic alternatives.

Market challenges include the high production costs of CMCs, currently 5-8 times more expensive than traditional superalloys, and complex manufacturing processes that limit mass production capabilities. However, ongoing advancements in manufacturing technologies are expected to reduce production costs by 40-50% over the next five years, potentially accelerating market adoption.

Ceramic Matrix Composites (CMCs) are emerging as a critical segment within this market, with their specific demand growing at nearly 8.5% annually. This accelerated adoption is driven by the superior performance of CMCs in hot section components of aero turbines, where traditional superalloys reach their operational limits. Industry analysts estimate that CMCs could replace up to 30% of nickel-based superalloy components in next-generation turbine engines.

The commercial aviation sector represents the largest market segment for CMCs in turbine applications, accounting for approximately 65% of the total demand. Major aircraft manufacturers have committed to reducing fuel consumption by 15-20% in their next-generation aircraft, creating strong market pull for advanced materials like CMCs that can withstand higher operating temperatures and reduce engine weight.

Defense applications constitute roughly 35% of the market, with military aircraft engines requiring materials capable of withstanding extreme thermal conditions and offering enhanced durability. The F135 engine program alone has created a market opportunity exceeding $300 million for CMC components over the next decade.

Regional analysis indicates North America leads the market with a 42% share, followed by Europe (31%) and Asia-Pacific (21%). However, the Asia-Pacific region is expected to demonstrate the highest growth rate at 9.3% annually through 2030, driven by China's and India's expanding aerospace industries and increasing defense modernization programs.

Key market drivers include stringent environmental regulations mandating reduced emissions, which necessitate higher operating temperatures for improved thermodynamic efficiency. Additionally, the industry-wide focus on reducing the weight of aircraft components to improve fuel efficiency has created strong demand for lightweight materials like CMCs, which offer 30-40% weight reduction compared to metallic alternatives.

Market challenges include the high production costs of CMCs, currently 5-8 times more expensive than traditional superalloys, and complex manufacturing processes that limit mass production capabilities. However, ongoing advancements in manufacturing technologies are expected to reduce production costs by 40-50% over the next five years, potentially accelerating market adoption.

Current State and Challenges of CMCs in Hot Section Applications

Ceramic Matrix Composites (CMCs) have emerged as revolutionary materials for hot section components in aero turbine applications, offering significant advantages over traditional superalloys. Currently, CMCs are being implemented in combustor liners, shrouds, and turbine blades in next-generation aircraft engines by major manufacturers including GE Aviation, Rolls-Royce, and Safran. The state-of-the-art CMCs typically utilize SiC fibers in SiC matrices (SiC/SiC), with advanced environmental barrier coatings (EBCs) to protect against oxidation and water vapor attack.

Despite promising advancements, CMCs face several critical challenges in hot section applications. Temperature capability remains a primary limitation, with current systems generally restricted to operating temperatures below 1400°C, whereas future engine designs demand performance at 1500°C and beyond. The degradation mechanisms in harsh engine environments, particularly the recession of silicon-based ceramics due to water vapor exposure, continue to pose significant reliability concerns for long-term operation.

Manufacturing complexity and cost present substantial barriers to widespread adoption. Current production methods, including chemical vapor infiltration (CVI) and polymer infiltration and pyrolysis (PIP), require multiple processing cycles and specialized equipment, resulting in high component costs and extended lead times. The industry has yet to achieve the economies of scale necessary to make CMCs cost-competitive with traditional materials for broader implementation.

Quality control and non-destructive evaluation (NDE) techniques for CMCs remain underdeveloped compared to metallic counterparts. The complex microstructure of these composites makes defect detection challenging, and standardized testing protocols are still evolving. This creates uncertainty in component qualification and certification processes, slowing industry adoption.

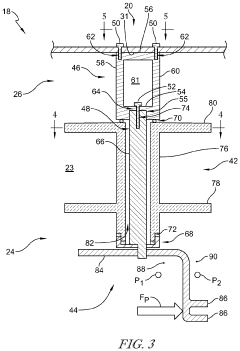

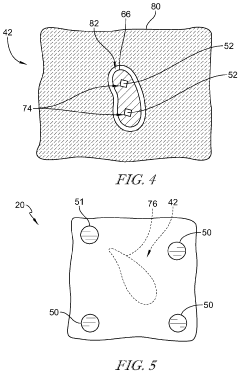

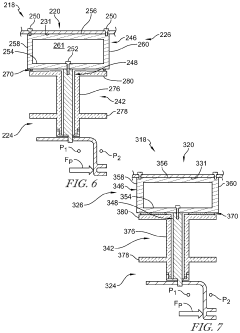

Joining and integration of CMC components with metallic engine structures present significant technical hurdles. Differences in thermal expansion coefficients and mechanical properties at interfaces create stress concentrations that can lead to premature failure. Current attachment methods often involve complex designs that add weight and cost, partially offsetting the benefits of CMCs.

Globally, the United States leads CMC development for aerospace applications, with significant research programs at NASA, AFRL, and major engine manufacturers. Japan maintains strong capabilities in fundamental CMC research, while European efforts are concentrated within aerospace consortia and research institutions. China has made substantial investments in recent years to close the technology gap, particularly in military applications.

The path to broader implementation requires addressing these interconnected challenges through coordinated efforts in materials science, manufacturing technology, and design methodology. Breakthrough innovations in fiber architecture, matrix compositions, and processing techniques will be essential to unlock the full potential of CMCs in next-generation turbine engines.

Despite promising advancements, CMCs face several critical challenges in hot section applications. Temperature capability remains a primary limitation, with current systems generally restricted to operating temperatures below 1400°C, whereas future engine designs demand performance at 1500°C and beyond. The degradation mechanisms in harsh engine environments, particularly the recession of silicon-based ceramics due to water vapor exposure, continue to pose significant reliability concerns for long-term operation.

Manufacturing complexity and cost present substantial barriers to widespread adoption. Current production methods, including chemical vapor infiltration (CVI) and polymer infiltration and pyrolysis (PIP), require multiple processing cycles and specialized equipment, resulting in high component costs and extended lead times. The industry has yet to achieve the economies of scale necessary to make CMCs cost-competitive with traditional materials for broader implementation.

Quality control and non-destructive evaluation (NDE) techniques for CMCs remain underdeveloped compared to metallic counterparts. The complex microstructure of these composites makes defect detection challenging, and standardized testing protocols are still evolving. This creates uncertainty in component qualification and certification processes, slowing industry adoption.

Joining and integration of CMC components with metallic engine structures present significant technical hurdles. Differences in thermal expansion coefficients and mechanical properties at interfaces create stress concentrations that can lead to premature failure. Current attachment methods often involve complex designs that add weight and cost, partially offsetting the benefits of CMCs.

Globally, the United States leads CMC development for aerospace applications, with significant research programs at NASA, AFRL, and major engine manufacturers. Japan maintains strong capabilities in fundamental CMC research, while European efforts are concentrated within aerospace consortia and research institutions. China has made substantial investments in recent years to close the technology gap, particularly in military applications.

The path to broader implementation requires addressing these interconnected challenges through coordinated efforts in materials science, manufacturing technology, and design methodology. Breakthrough innovations in fiber architecture, matrix compositions, and processing techniques will be essential to unlock the full potential of CMCs in next-generation turbine engines.

Current Technical Solutions for Hot Section CMC Implementation

01 Manufacturing processes for CMCs

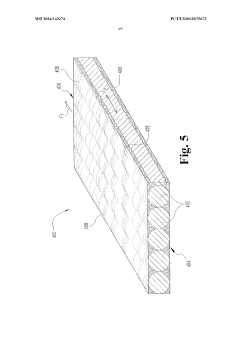

Various manufacturing processes are employed to produce Ceramic Matrix Composites, including chemical vapor infiltration, melt infiltration, and polymer infiltration and pyrolysis. These processes involve the infiltration of ceramic matrices with reinforcing fibers to create composites with enhanced mechanical properties. The manufacturing techniques aim to optimize the interface between the matrix and reinforcement while minimizing porosity and defects in the final composite structure.- Manufacturing methods for CMCs: Various manufacturing techniques are employed to produce Ceramic Matrix Composites, including chemical vapor infiltration, melt infiltration, and polymer infiltration and pyrolysis. These processes involve infiltrating ceramic fibers with matrix materials and subsequent heat treatments to create strong, lightweight composites with enhanced mechanical properties. The manufacturing methods focus on achieving optimal fiber-matrix interfaces and minimizing porosity to ensure structural integrity.

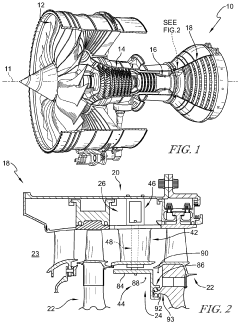

- CMC applications in gas turbine engines: Ceramic Matrix Composites are increasingly used in gas turbine engine components due to their high temperature resistance and lightweight properties. These materials are particularly valuable for combustor liners, turbine shrouds, nozzles, and blades where they can withstand extreme operating conditions. The implementation of CMCs in these applications allows for higher operating temperatures, improved fuel efficiency, and reduced cooling requirements compared to traditional metal alloys.

- Environmental barrier coatings for CMCs: Environmental barrier coatings (EBCs) are essential for protecting Ceramic Matrix Composites from oxidation, water vapor, and other environmental factors in high-temperature applications. These specialized coating systems typically consist of multiple layers designed to provide thermal protection, prevent oxygen penetration, and maintain adhesion during thermal cycling. Advanced EBC formulations incorporate rare earth silicates and other compounds to enhance durability and extend component lifespan.

- Testing and inspection methods for CMCs: Non-destructive testing and inspection techniques are critical for evaluating the quality and integrity of Ceramic Matrix Composites. Methods include ultrasonic testing, thermography, X-ray computed tomography, and acoustic emission monitoring. These techniques allow for the detection of defects, delaminations, and matrix cracks without damaging the components. Advanced monitoring systems can also be employed during service to track the health and remaining life of CMC components in critical applications.

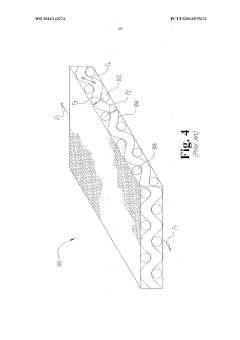

- Fiber reinforcement in CMCs: The selection and treatment of reinforcing fibers play a crucial role in determining the performance of Ceramic Matrix Composites. Common reinforcement materials include silicon carbide, carbon, alumina, and oxide fibers. Fiber architecture, including weave patterns, fiber orientation, and volume fraction, significantly impacts the mechanical properties of the final composite. Interface coatings between fibers and matrix materials are engineered to control crack propagation and enhance toughness while maintaining high-temperature stability.

02 CMCs for high-temperature applications in gas turbine engines

Ceramic Matrix Composites are specifically designed for high-temperature applications in gas turbine engines, offering superior heat resistance and durability compared to traditional materials. These composites can withstand extreme operating conditions while maintaining structural integrity, making them ideal for components such as combustor liners, turbine blades, and shrouds. The use of CMCs in these applications leads to improved engine efficiency, reduced cooling requirements, and extended component lifespans.Expand Specific Solutions03 Testing and inspection methods for CMCs

Various testing and inspection methods are developed for evaluating the quality and performance of Ceramic Matrix Composites. These include non-destructive testing techniques such as ultrasonic inspection, thermography, and X-ray computed tomography, which help identify defects, delaminations, and other structural anomalies without damaging the components. Additionally, mechanical testing methods assess properties such as strength, toughness, and fatigue resistance under simulated operating conditions to ensure reliability in service.Expand Specific Solutions04 Novel compositions and reinforcement materials for CMCs

Innovative compositions and reinforcement materials are being developed to enhance the performance of Ceramic Matrix Composites. These include advanced ceramic matrices such as silicon carbide, alumina, and zirconia, combined with various reinforcement fibers like carbon, silicon carbide, or oxide fibers. The development of novel interface coatings between the matrix and reinforcement improves load transfer and crack deflection mechanisms, resulting in composites with superior mechanical properties and damage tolerance.Expand Specific Solutions05 Environmental barrier coatings for CMCs

Environmental barrier coatings (EBCs) are applied to Ceramic Matrix Composites to protect them from oxidation, corrosion, and other environmental degradation mechanisms in harsh operating environments. These specialized coating systems typically consist of multiple layers designed to provide thermal protection, prevent oxygen penetration, and maintain compatibility with the underlying CMC substrate. Advanced EBCs incorporate rare earth silicates, hafnia, or zirconia-based materials to enhance durability and extend the service life of CMC components in high-temperature applications.Expand Specific Solutions

Key Industry Players in Aerospace CMC Development

The Ceramic Matrix Composites (CMCs) for hot section aero turbine applications market is in a growth phase, driven by increasing demand for lightweight, high-temperature resistant materials in aerospace. The global market is projected to expand significantly as major players like GE, Rolls-Royce, Safran Aircraft Engines, and RTX Corp invest heavily in CMC technology development. Technical maturity varies across competitors, with GE and Safran leading commercial implementation, while companies like AECC, Siemens Energy, and IHI are advancing their capabilities. Academic institutions including Northwestern Polytechnical University and Beihang University collaborate with industry to bridge research gaps. The technology is transitioning from specialized military applications to broader commercial adoption, with ongoing challenges in manufacturing scalability and cost reduction.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed advanced oxide-oxide ceramic matrix composites (Ox-Ox CMCs) for turbine applications, focusing on components like combustor tiles, shrouds, and vanes. Their approach utilizes alumina-based ceramic fibers in an alumina matrix, offering excellent oxidation resistance without requiring complex environmental barrier coatings [4]. Rolls-Royce's CMC technology employs a unique sol-gel infiltration process that achieves near-net shape manufacturing, reducing machining requirements and production costs. Their CMCs demonstrate temperature capabilities exceeding 1200°C while providing 30-40% weight reduction compared to metallic alternatives [5]. The company has established partnerships with academic institutions and specialized manufacturers to accelerate CMC development and implementation. Rolls-Royce has successfully tested CMC components in their Advance3 demonstrator engine, validating performance benefits including 1.5% improvement in specific fuel consumption and reduced cooling air requirements [6].

Strengths: Expertise in oxide-based CMCs requiring less complex protective coatings; established testing infrastructure; strong academic partnerships. Weaknesses: Less commercial flight experience compared to competitors; higher production costs than conventional materials; challenges in scaling manufacturing processes.

General Electric Company

Technical Solution: GE has pioneered silicon carbide (SiC) ceramic matrix composites for aero engine hot section components, particularly in their LEAP engine program. Their CMC technology reduces weight by approximately 30% compared to traditional nickel superalloys while enabling operating temperatures up to 2400°F (1315°C) - about 500°F higher than metal alternatives [1]. GE's proprietary manufacturing process involves chemical vapor infiltration (CVI) combined with melt infiltration (MI) techniques to create dense, high-strength CMC components. The company has invested over $1.5 billion in CMC research and production facilities, including their Asheville, North Carolina plant dedicated to mass production of CMC shrouds, combustor liners, and high-pressure turbine nozzles [2]. GE's CMCs have accumulated over 10 million flight hours since their commercial introduction in 2016, demonstrating exceptional durability with near-zero in-service issues related to these components [3].

Strengths: Industry-leading experience with CMCs in commercial service; vertically integrated supply chain; proven durability in operational environments. Weaknesses: High manufacturing costs; complex production processes requiring specialized facilities; proprietary technology limiting broader industry adoption.

Critical Patents and Innovations in Turbine CMC Technology

Ceramic matrix composite

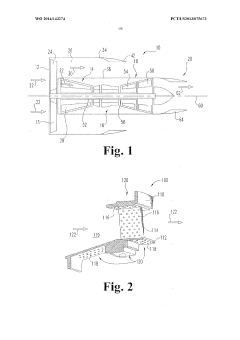

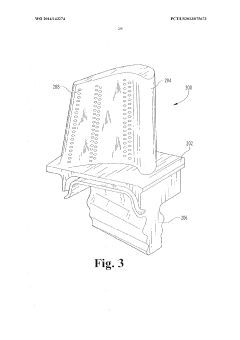

PatentWO2014143274A1

Innovation

- The use of non-crimped fiber patterns in ceramic matrix composites, where fibers are oriented substantially parallel to each other and stitched together with small elastic fibers, allows for a more uniform matrix infiltration and enhanced mechanical properties, reducing off-axis loading and improving thermal behavior.

Turbine section assembly with ceramic matrix composite vane

PatentActiveUS11149559B2

Innovation

- A vane-stage support system comprising a metallic torsion box and spar, which transfers loads from the ceramic matrix composite vane to the turbine case, utilizing threaded fasteners and a compliant seal to minimize stress and deflection, and allowing for cooling air distribution.

Environmental Impact and Sustainability of CMC Technologies

The adoption of Ceramic Matrix Composites (CMCs) in hot section aero turbine applications presents significant environmental and sustainability implications that warrant careful consideration. As these advanced materials replace traditional superalloys, they contribute to substantial reductions in aircraft weight, directly translating to improved fuel efficiency. Studies indicate that CMC implementation can reduce component weight by 30-40% compared to nickel-based superalloys, potentially decreasing fuel consumption by 5-10% in next-generation aircraft engines.

From a lifecycle perspective, CMC manufacturing processes currently demand considerable energy inputs, particularly during the high-temperature sintering and chemical vapor infiltration phases. The production of silicon carbide fibers, a key component in many aerospace CMCs, requires temperatures exceeding 1200°C maintained for extended periods, resulting in a significant carbon footprint. However, when considering the total environmental impact across the entire product lifecycle, the operational efficiency gains typically offset the initial manufacturing emissions within 2-3 years of service.

Material resource efficiency represents another critical sustainability dimension. CMCs demonstrate exceptional durability with service lifespans potentially 20-30% longer than conventional materials in high-temperature applications. This extended operational life reduces the frequency of component replacement, minimizing waste generation and resource consumption over the engine's service period.

Recycling and end-of-life management present ongoing challenges for CMC technologies. The complex multi-phase structure of these composites, often incorporating silicon carbide, carbon fibers, and various oxide matrices, complicates traditional recycling approaches. Current recovery methods typically achieve only partial material reclamation, with research indicating recovery rates of 40-60% for valuable constituents like silicon carbide.

Emissions reduction represents perhaps the most significant environmental benefit of CMC implementation. The higher operating temperatures enabled by CMCs improve thermodynamic efficiency in turbine engines, reducing NOx emissions by an estimated 15-25% and CO2 by 10-15% compared to conventional technology. These improvements align with increasingly stringent international aviation environmental standards, including ICAO's CORSIA framework and the industry's commitment to carbon-neutral growth.

Looking forward, sustainable manufacturing innovations are emerging to address current limitations. These include microwave-assisted processing techniques that can reduce energy consumption by up to 50%, water-based slurry systems replacing solvent-intensive processes, and bio-derived precursors for ceramic matrices that offer reduced environmental impact compared to traditional petrochemical-based alternatives.

From a lifecycle perspective, CMC manufacturing processes currently demand considerable energy inputs, particularly during the high-temperature sintering and chemical vapor infiltration phases. The production of silicon carbide fibers, a key component in many aerospace CMCs, requires temperatures exceeding 1200°C maintained for extended periods, resulting in a significant carbon footprint. However, when considering the total environmental impact across the entire product lifecycle, the operational efficiency gains typically offset the initial manufacturing emissions within 2-3 years of service.

Material resource efficiency represents another critical sustainability dimension. CMCs demonstrate exceptional durability with service lifespans potentially 20-30% longer than conventional materials in high-temperature applications. This extended operational life reduces the frequency of component replacement, minimizing waste generation and resource consumption over the engine's service period.

Recycling and end-of-life management present ongoing challenges for CMC technologies. The complex multi-phase structure of these composites, often incorporating silicon carbide, carbon fibers, and various oxide matrices, complicates traditional recycling approaches. Current recovery methods typically achieve only partial material reclamation, with research indicating recovery rates of 40-60% for valuable constituents like silicon carbide.

Emissions reduction represents perhaps the most significant environmental benefit of CMC implementation. The higher operating temperatures enabled by CMCs improve thermodynamic efficiency in turbine engines, reducing NOx emissions by an estimated 15-25% and CO2 by 10-15% compared to conventional technology. These improvements align with increasingly stringent international aviation environmental standards, including ICAO's CORSIA framework and the industry's commitment to carbon-neutral growth.

Looking forward, sustainable manufacturing innovations are emerging to address current limitations. These include microwave-assisted processing techniques that can reduce energy consumption by up to 50%, water-based slurry systems replacing solvent-intensive processes, and bio-derived precursors for ceramic matrices that offer reduced environmental impact compared to traditional petrochemical-based alternatives.

Certification and Qualification Standards for Aerospace CMCs

The certification and qualification of Ceramic Matrix Composites (CMCs) for aerospace applications represents one of the most significant challenges in their widespread adoption. Unlike traditional metallic materials with well-established standards, CMCs require specialized testing protocols and certification frameworks that account for their unique properties and failure mechanisms.

Current aerospace certification standards for CMCs are primarily governed by organizations such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and industry bodies like SAE International. These standards typically require extensive testing under simulated operating conditions, including high-temperature exposure, thermal cycling, and mechanical loading that replicate the harsh environment of turbine hot sections.

The qualification process for aerospace CMCs generally follows a building block approach, progressing from coupon-level testing to sub-component and full-component validation. This hierarchical methodology ensures that material behavior is thoroughly characterized at multiple scales before implementation in critical applications. Key qualification tests include tensile, compression, and shear strength evaluations at elevated temperatures, as well as creep, fatigue, and oxidation resistance assessments.

A significant challenge in CMC certification is the establishment of damage tolerance criteria. Unlike metals, which typically exhibit plastic deformation before failure, CMCs can develop microcracks during normal operation without catastrophic consequences. This necessitates the development of specialized non-destructive evaluation (NDE) techniques capable of detecting and monitoring damage progression in these complex microstructures.

Life prediction methodologies represent another critical aspect of CMC qualification. Current standards require manufacturers to demonstrate reliable service life estimation through accelerated testing protocols and sophisticated modeling approaches. These models must account for the progressive nature of damage in CMCs, including matrix cracking, fiber-matrix debonding, and environmental degradation mechanisms.

Recent advancements in certification frameworks include the development of probabilistic approaches that better address the inherent variability in CMC properties. These statistical methods provide more realistic assessments of component reliability compared to traditional deterministic approaches. Additionally, digital certification pathways are emerging, where computational models validated by targeted physical testing can reduce the extensive experimental campaigns traditionally required.

Industry-academia collaborations have been instrumental in developing standardized test methods specifically tailored for CMCs. Organizations such as ASTM International have published several standards addressing CMC testing, including C1275 for tensile strength and C1359 for high-temperature properties, which serve as foundational elements in aerospace qualification programs.

Current aerospace certification standards for CMCs are primarily governed by organizations such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and industry bodies like SAE International. These standards typically require extensive testing under simulated operating conditions, including high-temperature exposure, thermal cycling, and mechanical loading that replicate the harsh environment of turbine hot sections.

The qualification process for aerospace CMCs generally follows a building block approach, progressing from coupon-level testing to sub-component and full-component validation. This hierarchical methodology ensures that material behavior is thoroughly characterized at multiple scales before implementation in critical applications. Key qualification tests include tensile, compression, and shear strength evaluations at elevated temperatures, as well as creep, fatigue, and oxidation resistance assessments.

A significant challenge in CMC certification is the establishment of damage tolerance criteria. Unlike metals, which typically exhibit plastic deformation before failure, CMCs can develop microcracks during normal operation without catastrophic consequences. This necessitates the development of specialized non-destructive evaluation (NDE) techniques capable of detecting and monitoring damage progression in these complex microstructures.

Life prediction methodologies represent another critical aspect of CMC qualification. Current standards require manufacturers to demonstrate reliable service life estimation through accelerated testing protocols and sophisticated modeling approaches. These models must account for the progressive nature of damage in CMCs, including matrix cracking, fiber-matrix debonding, and environmental degradation mechanisms.

Recent advancements in certification frameworks include the development of probabilistic approaches that better address the inherent variability in CMC properties. These statistical methods provide more realistic assessments of component reliability compared to traditional deterministic approaches. Additionally, digital certification pathways are emerging, where computational models validated by targeted physical testing can reduce the extensive experimental campaigns traditionally required.

Industry-academia collaborations have been instrumental in developing standardized test methods specifically tailored for CMCs. Organizations such as ASTM International have published several standards addressing CMC testing, including C1275 for tensile strength and C1359 for high-temperature properties, which serve as foundational elements in aerospace qualification programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!